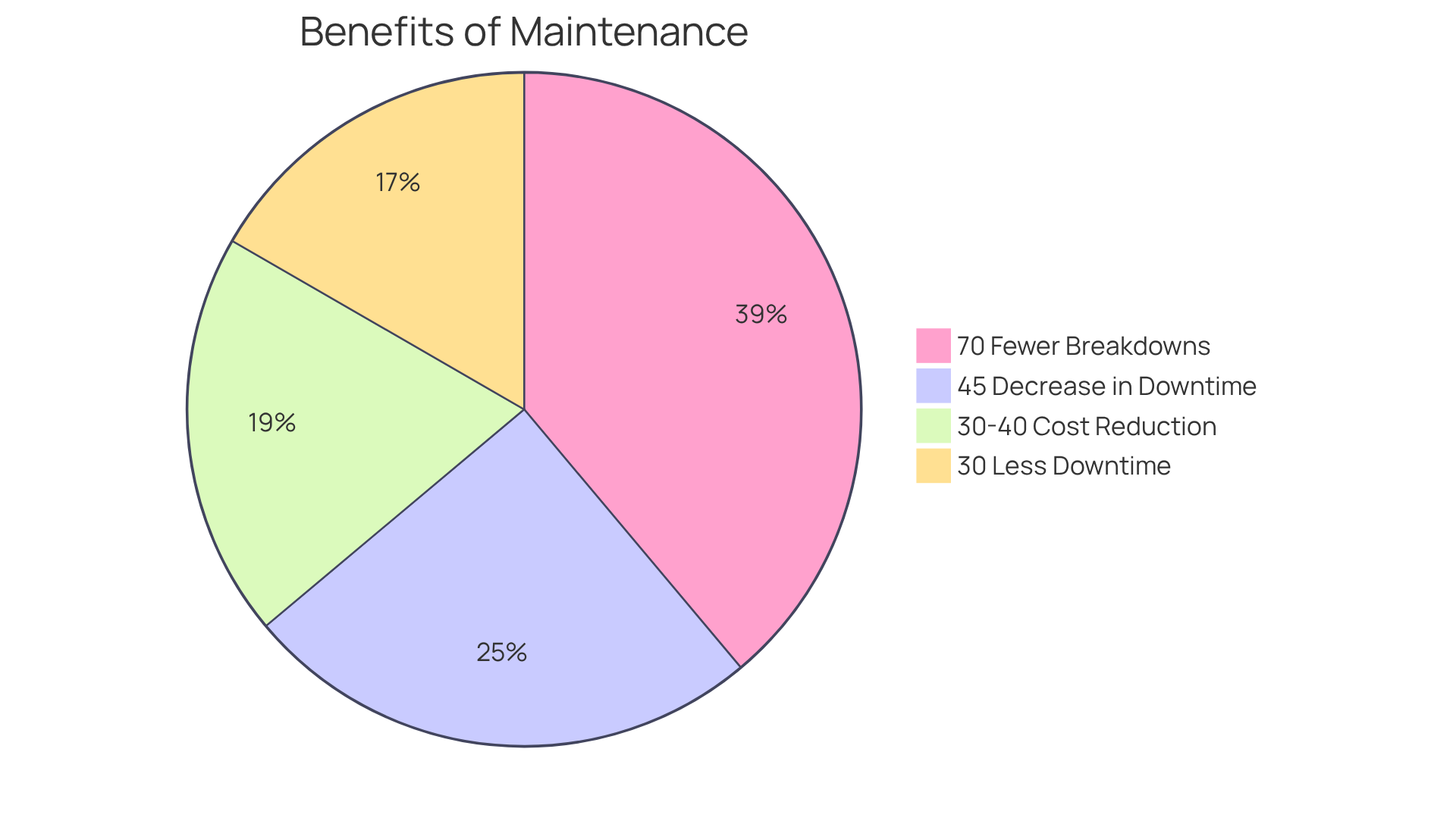

Key Highlights:

- Heavy equipment maintenance extends machinery lifespan and reliability, preventing unexpected breakdowns.

- Consistent maintenance schedules can lead to up to 30% less downtime for businesses.

- Implementing predictive maintenance can reduce machinery downtime by 45% and operational costs.

- Proactive maintenance programmes can result in 70% fewer breakdowns and a 30-40% reduction in maintenance costs.

- Establishing a regular maintenance schedule tailored to usage enhances machinery performance.

- Detailed service records help forecast future maintenance needs and improve machinery availability.

- Utilising maintenance management software can automate schedules and reduce maintenance-related downtime by 40%.

- Regular inspections and comprehensive checklists are crucial for safety and reliability, reducing accidents by up to 50%.

- Allocating 5-10% of annual budgets to maintenance reflects the financial importance of proactive strategies.

Introduction

Heavy equipment serves as the backbone of construction projects, with its reliability being crucial to meeting timelines and budgets. Effective maintenance practices not only extend the lifespan of this machinery but also significantly minimize unexpected downtime and safety risks on job sites. Given the stakes involved, project managers must implement the most effective maintenance strategies.

By exploring essential practices such as:

- Preventive maintenance

- The utilization of management software

- Conducting regular inspections

critical insights can be uncovered that lead to enhanced operational efficiency and project success.

Understand the Importance of Heavy Equipment Maintenance

Heavy equipment maintenance is essential for extending the lifespan and reliability of machinery used in construction projects. Regular heavy equipment maintenance not only prevents unexpected breakdowns but also reduces costly delays and safety hazards on job sites. By prioritizing heavy equipment maintenance, project managers can ensure smoother execution of projects.

For example, businesses that adhere to consistent maintenance schedules can experience up to 30% less downtime compared to those that neglect this practice. Furthermore, implementing predictive maintenance strategies in heavy equipment maintenance can decrease machinery downtime by as much as 45%, underscoring the benefits of proactive approaches. This approach not only lowers operational costs but also enhances safety by ensuring that equipment operates within safe parameters.

Additionally, proactive heavy equipment maintenance programs can lead to 70% fewer breakdowns, emphasizing the importance of a disciplined care strategy. According to the U.S. Department of Energy, such programs can result in a 30-40% reduction in maintenance costs.

At EZ Equipment Rental, our team of knowledgeable professionals offers expert guidance and support, ensuring smooth operations throughout the rental period. By implementing these practices, managers can significantly improve machinery reliability and overall task efficiency, while recognizing that over 80% of failures in heavy equipment maintenance are preventable.

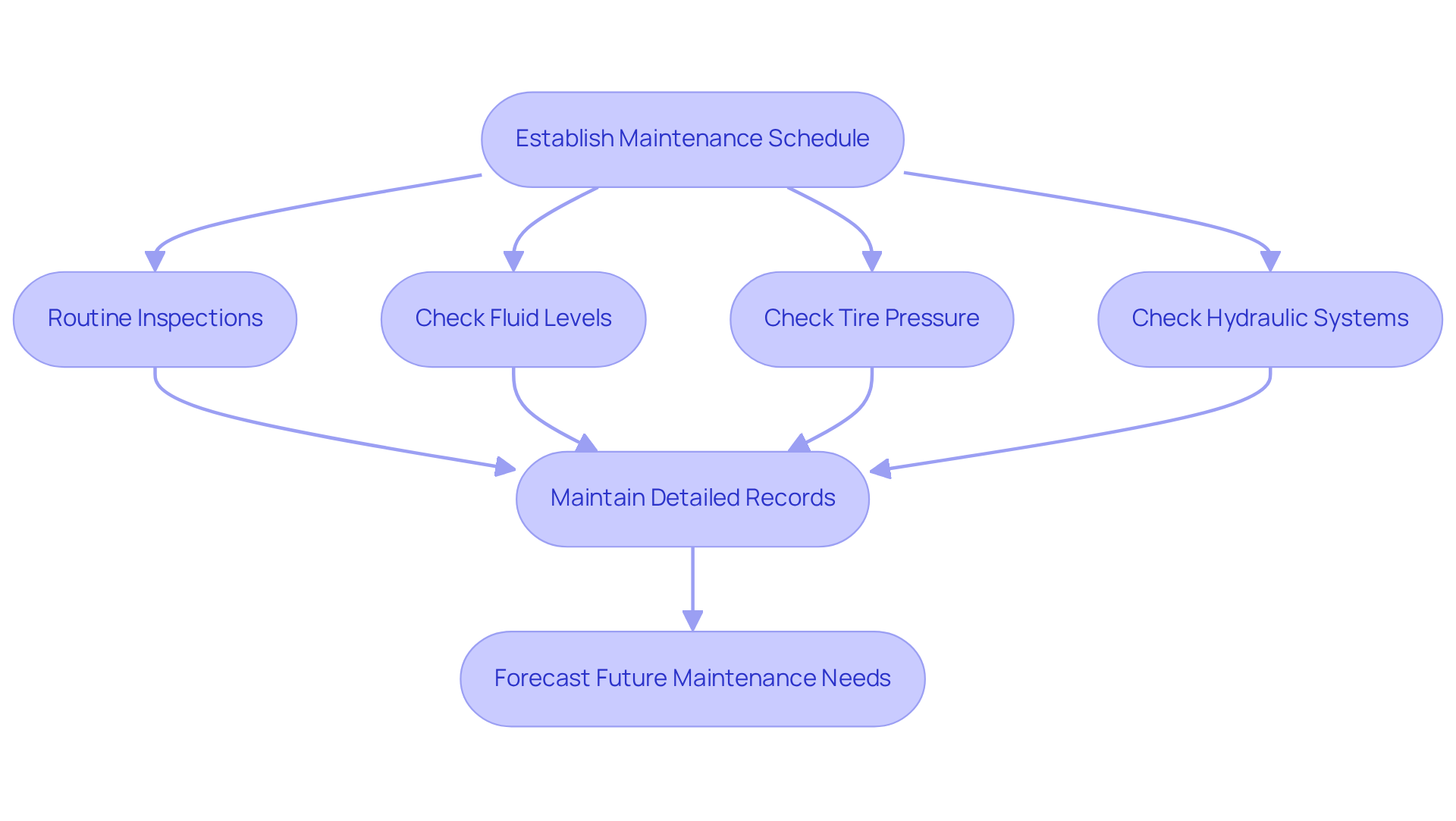

Implement Preventive Maintenance Strategies

To effectively implement preventive maintenance strategies, project managers should establish a regular schedule for heavy equipment maintenance tailored to usage and manufacturer recommendations. This schedule must include routine inspections essential for heavy equipment maintenance, such as:

- Checking fluid levels

- Tire pressure

- Hydraulic systems

For instance, a construction company that embraced a preventive maintenance program experienced a remarkable 25% reduction in emergency repairs and a 15% increase in machinery availability. Furthermore, maintaining detailed records to track service history can reveal trends and forecast future heavy equipment maintenance needs, ensuring that machinery operates at peak performance.

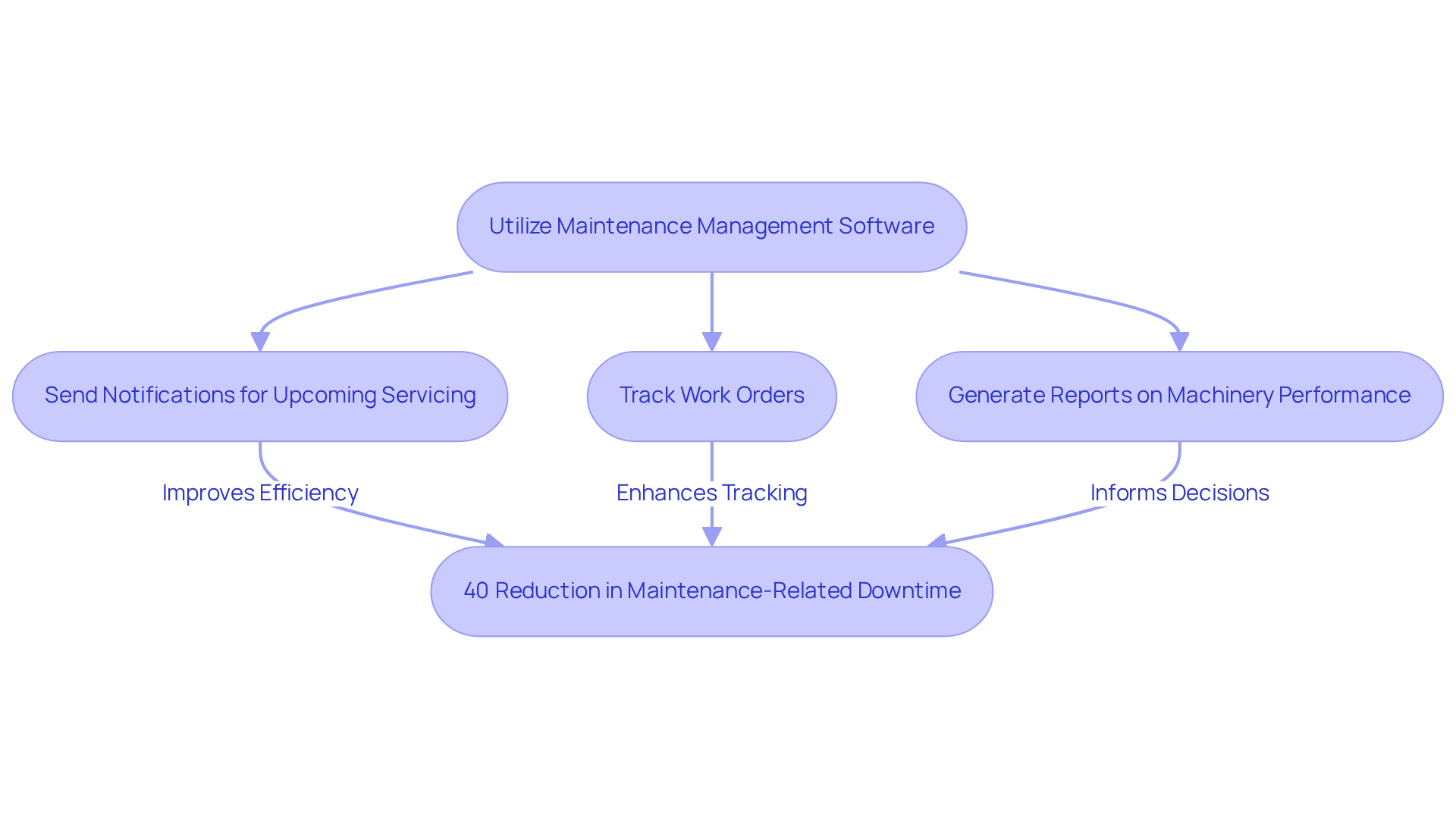

Utilize Maintenance Management Software for Efficiency

This software revolutionizes how project managers oversee heavy equipment maintenance. By automating heavy equipment maintenance schedules and tracking service history, these tools ensure that no tasks are overlooked. For instance, Computerized Maintenance Management Systems (CMMS) can:

- Send notifications for upcoming servicing

- Track work orders

- Generate reports on machinery performance

A construction firm that adopted such software reported a 40% reduction in maintenance-related downtime, underscoring the role of technology in improving operational efficiency.

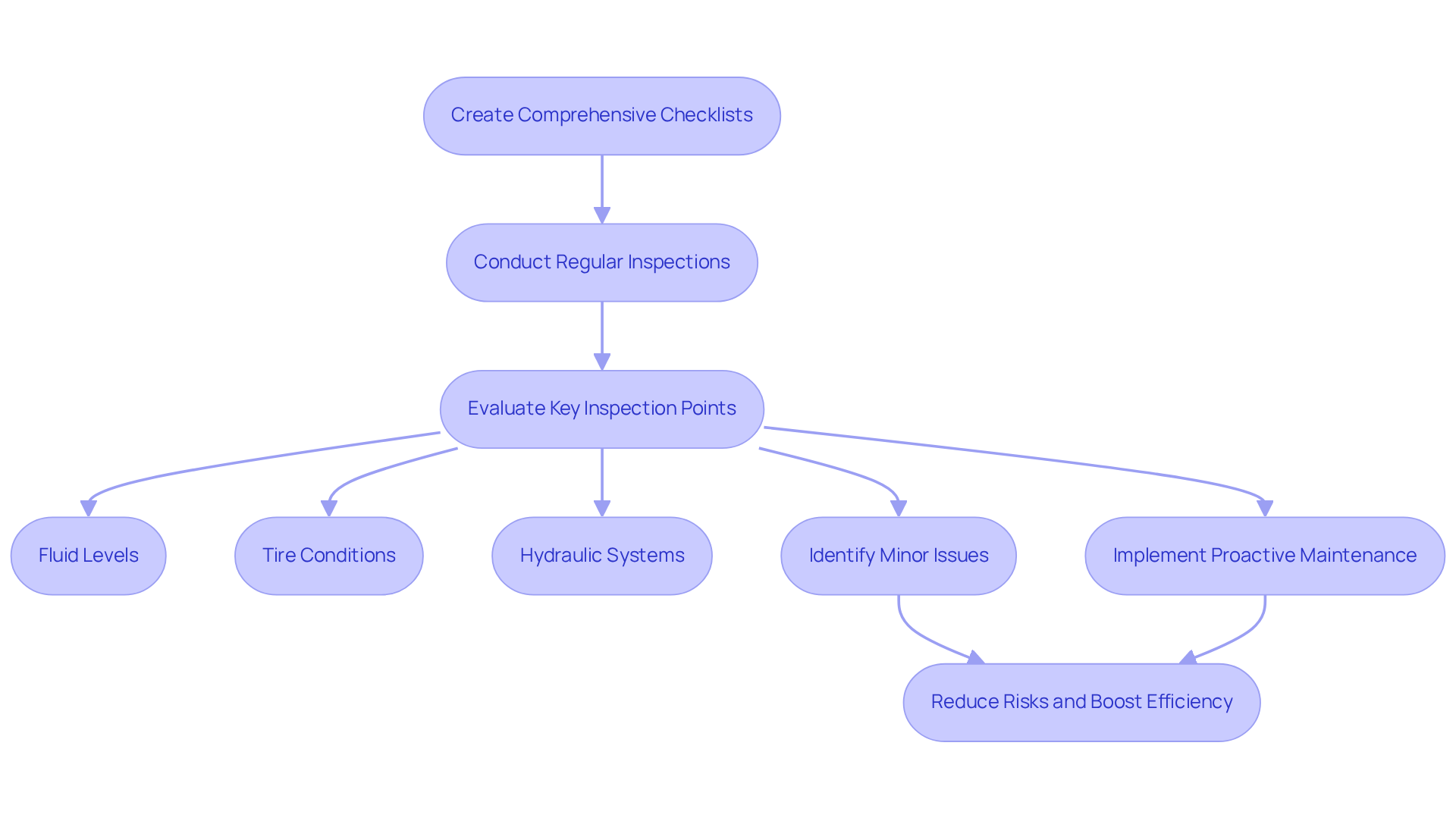

Conduct Regular Inspections and Use Maintenance Checklists

Incorporating regular inspections into maintenance programs is crucial for ensuring equipment safety and reliability. Project managers should create comprehensive checklists that address key inspection points, such as:

- Fluid levels

- Tire conditions

- Hydraulic systems

For example, a construction firm that implemented a rigorous inspection protocol saw a significant 50% reduction in equipment-related accidents.

Routine inspections not only help identify minor issues before they escalate into major problems but also align with effective maintenance strategies that can substantially lower overall repair needs and downtime. Given that falls are the leading cause of fatalities among construction workers, the importance of robust maintenance practices cannot be overstated. Many organizations allocate 5-10% of their annual budgets to maintenance, underscoring the financial implications of a proactive care strategy.

By utilizing inspection checklists, managers can systematically evaluate all critical components, fostering a culture of safety and extending the lifespan of their equipment. Adhering to warranty conditions and OEM maintenance recommendations is vital to avoid costly repairs. This proactive approach not only reduces risks but also boosts operational efficiency, ultimately contributing to successful project outcomes.

Conclusion

Prioritizing heavy equipment maintenance is not merely a best practice; it is an essential strategy for project managers who seek to enhance the reliability and efficiency of their construction operations. By understanding and implementing key maintenance practices, managers can significantly reduce downtime, lower operational costs, and ensure a safer working environment on job sites.

This article highlights four critical maintenance practices:

- Recognizing the importance of maintenance

- Implementing preventive strategies

- Utilizing maintenance management software

- Conducting regular inspections

Each of these practices plays a vital role in minimizing unexpected breakdowns and maximizing equipment performance. For example, adopting a preventive maintenance schedule can lead to substantial reductions in emergency repairs and machinery downtime. Additionally, leveraging technology through maintenance management software can streamline operations and enhance productivity.

Given these insights, it is clear that effective heavy equipment maintenance is crucial for successful project management. By committing to these practices, project managers can not only extend the lifespan of their machinery but also foster a culture of safety and efficiency within their teams. Embracing these strategies is not just an operational choice; it is a pathway to achieving project success and safeguarding the well-being of all personnel involved.

Frequently Asked Questions

Why is heavy equipment maintenance important?

Heavy equipment maintenance is essential for extending the lifespan and reliability of machinery used in construction projects, preventing unexpected breakdowns, reducing costly delays, and minimizing safety hazards on job sites.

How does regular maintenance affect equipment downtime?

Businesses that adhere to consistent maintenance schedules can experience up to 30% less downtime compared to those that neglect maintenance practices.

What are the benefits of predictive maintenance strategies?

Implementing predictive maintenance strategies can decrease machinery downtime by as much as 45%, lowering operational costs and enhancing safety by ensuring equipment operates within safe parameters.

How does proactive maintenance impact breakdowns?

Proactive heavy equipment maintenance programs can lead to 70% fewer breakdowns, highlighting the importance of a disciplined care strategy.

What cost reductions can be achieved through effective maintenance programs?

According to the U.S. Department of Energy, effective maintenance programs can result in a 30-40% reduction in maintenance costs.

How can EZ Equipment Rental assist with heavy equipment maintenance?

EZ Equipment Rental offers expert guidance and support to ensure smooth operations throughout the rental period, helping managers improve machinery reliability and overall task efficiency.

What percentage of failures in heavy equipment maintenance are preventable?

Over 80% of failures in heavy equipment maintenance are preventable, emphasizing the need for regular maintenance practices.

List of Sources

- Understand the Importance of Heavy Equipment Maintenance

- The Transformative Impact of Preventive Maintenance in Construction (https://maintworld.com/Asset-Management/The-Transformative-Impact-of-Preventive-Maintenance-in-Construction)

- 7 Maintenance Mistakes That Are Killing Your Construction Equipment (https://zenduit.com/7-maintenance-mistakes-that-are-killing-your-construction-equipment)

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- Implement Preventive Maintenance Strategies

- 8 Examples of Preventive Maintenance That Transform Operations (https://worktrek.com/blog/preventive-maintenance-examples)

- The Transformative Impact of Preventive Maintenance in Construction (https://maintworld.com/Asset-Management/The-Transformative-Impact-of-Preventive-Maintenance-in-Construction)

- Optimizing Equipment Performance: Building an Effective Preventive Maintenance Plan – TTCA (https://ttca.com/optimizing-equipment-performance-building-an-effective-preventive-maintenance-plan)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- Utilize Maintenance Management Software for Efficiency

- CMMS: 9 Statistics and Insights You Need to Know (https://worktrek.com/blog/cmms-statistics)

- Maintenance Management Guide: Overview, Trends & Key Statistics | Accruent (https://accruent.com/resources/blog-posts/maintenance-management-guide-overview-trends-key-statistics)

- How CMMS Software Helps Reduce Downtime Improve Efficiency (https://coherentmarketinsights.com/blog/how-cmms-software-reduce-downtime-improve-efficiency-2097)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- Conduct Regular Inspections and Use Maintenance Checklists

- Construction Safety: 5 Statistics Everyone in the Industry Should Know (https://autodesk.com/blogs/construction/construction-safety-statistics)

- 6 Reasons to Regularly Perform Equipment Maintenance (https://worktrek.com/blog/perform-regular-equipment-maintenance-reasons)

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- The Transformative Impact of Preventive Maintenance in Construction (https://maintworld.com/Asset-Management/The-Transformative-Impact-of-Preventive-Maintenance-in-Construction)