Overview

This article outlines four essential tips for successful earth compactor rental:

- Assessing project needs

- Researching rental companies

- Understanding rental terms

- Inspecting equipment before use

Each of these recommendations is backed by detailed explanations, illustrating how proper evaluation and preparation can lead to more efficient equipment selection and safer operations. Ultimately, these practices enhance project outcomes in construction, ensuring that every aspect of the rental process is optimized for success.

Key Highlights:

- Earth compactors are essential tools in construction, categorized into plate compactors, rammers, rollers, and vibratory compactors, each designed for specific applications.

- Plate compactors are ideal for small to medium tasks, while rammers excel in confined areas; rollers are used for large projects like road construction.

- The earth compactor rental market is expected to grow by 2025 due to increased demand for soil consolidation and supportive government infrastructure policies.

- When renting compactors, assess project needs, research rental companies, check equipment availability, understand rental terms, inspect equipment, and request training if necessary.

- Selecting the right compactor involves considering ground type, project size, depth of compression, site conditions, and the weight and power of the machine.

- Best practices for compactor usage include pre-operation checks, proper operating techniques, compacting in layers, maintaining appropriate soil moisture, and regular maintenance to ensure safety and efficiency.

Introduction

In the realm of construction, the selection of equipment is pivotal to achieving project efficiency and success. Earth compactors, in particular, serve a vital function in preparing soil for building and infrastructure endeavors. With an array of compactors available—such as plate compactors, rammers, rollers, and vibratory compactors—each tailored for specific applications, a thorough understanding of their functionalities is essential for any project manager.

As the demand for soil compaction escalates, fueled by infrastructure development and agricultural requirements, the ability to select, rent, and maintain these machines becomes critical. This article explores the intricacies of earth compactors, providing insights into their various types, effective rental processes, selection criteria, and best practices for usage and maintenance, all aimed at optimizing construction outcomes.

Understand Earth Compactors: Types and Functions

Earth compactor rental provides essential tools in the construction industry, with each type meticulously designed for specific applications. The primary categories include:

- Plate Compactors: Ideal for small to medium-sized tasks, these machines effectively compact granular materials and asphalt. They operate by exerting downward pressure combined with vibration, ensuring a solid surface that withstands the test of time.

- Rammers: Perfectly suited for confined areas, rammers excel in compacting cohesive materials. Utilizing rapid impacts, they achieve the necessary density, making them indispensable for tight spaces.

- Rollers: Larger and more robust, rollers are utilized in extensive projects such as road construction. Available in both smooth and padded variants, they efficiently compact large areas, significantly accelerating the process.

- Vibratory Compactors: These machines leverage both weight and vibration to compress earth efficiently, adapting seamlessly to various ground types.

Looking ahead to 2025, the market for earth compactor rental is poised for substantial growth, driven by a rising demand for soil consolidation in agriculture and supportive government policies that promote infrastructure development. Notably, North America has experienced the fastest growth in terms of CAGR in recent years. Producers are innovating to enhance functionalities such as compression strength and engine varieties, aligning with the evolving demands of the construction sector. According to Fortune Business Insights, forward plate compactors are expected to exhibit remarkable CAGR during the forecast period. Understanding these varieties and their roles is crucial for selecting the appropriate equipment, ensuring optimal outcomes and efficiency in construction endeavors.

Follow Effective Steps for Renting Earth Compactors

To ensure a seamless rental experience for earth compactors, it is essential to follow these critical steps:

- Assess Your Undertaking Needs: Begin by evaluating the type of soil, the scale of your endeavor, and specific compaction requirements. Understanding these factors is crucial for selecting the right equipment.

- Research rental companies to identify reputable options, such as EZ Equipment Rental, that offer earth compactor rental along with a diverse range of compactors, boom lifts, forklifts, and mini excavators, all backed by positive customer feedback. This will assist you in finding reliable options that meet your needs across the DFW Metroplex.

- Check Equipment Availability: Contact the rental company to confirm the availability of your preferred machine. Inquire about rental terms, including duration and pricing, to ensure they align with your timeline.

- Understand Rental Terms: Carefully review the rental agreement, focusing on the rental duration, costs, and any potential additional fees. This understanding is vital to avoid unexpected expenses.

- Inspect the Equipment: Prior to finalizing the rental, conduct a thorough inspection of the device for any damages or operational issues. This step is crucial to prevent liability for pre-existing conditions.

- Ask for Training: If you are not familiar with operating the equipment, request a demonstration or training session from the rental company. Proper training can significantly enhance safety and efficiency on the job site.

By adhering to these steps, managers can effectively navigate the rental process, ensuring they select the appropriate machine for their specific needs while minimizing potential challenges.

Choose the Right Compactor for Your Project Requirements

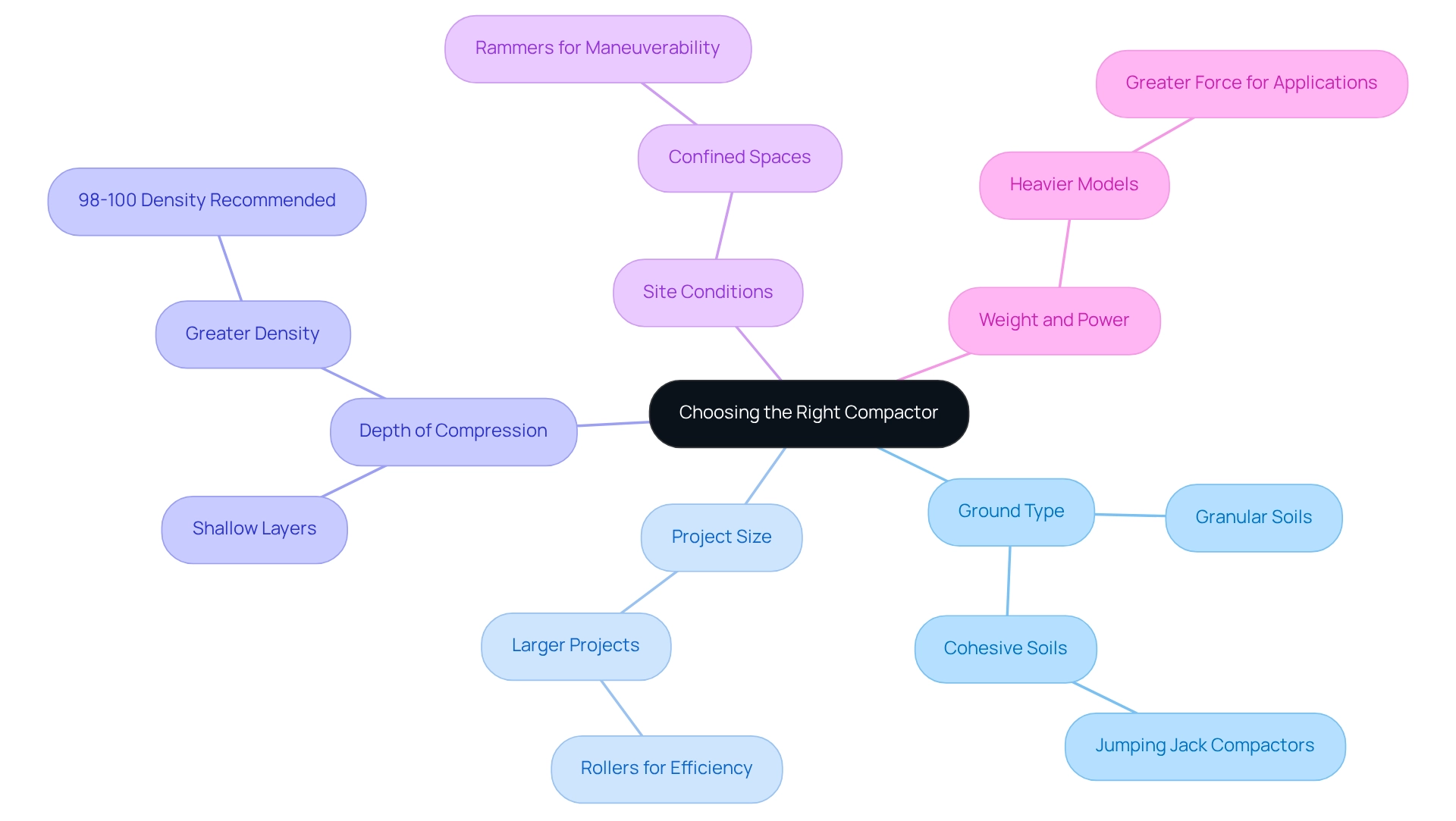

Selecting the appropriate compactor for your project demands careful consideration of several key factors.

- Ground Type is crucial; the effectiveness of compactors varies based on ground composition. For instance, plate compactors excel on granular soils, while jumping jack compactors are specifically designed to handle cohesive soils, making them versatile for various conditions.

- Project Size plays a significant role as well. Larger projects benefit from the efficiency of rollers, which can cover extensive areas quickly, thereby reducing overall project time.

- Depth of Compression must also be determined. It is essential to ascertain the necessary depth for densification. While some compactors are designed for shallow layers, others can achieve greater density, which is vital for stability. It is advisable to aim for 98-100% density for the base layer, with sub-layers possibly requiring slightly less to ensure proper drainage.

- Site Conditions should not be overlooked. Assessing the working environment is critical; in confined spaces, a rammer may be more suitable than a larger roller, allowing for effective compaction without compromising maneuverability.

- Weight and Power are additional considerations. The mass of the machine directly influences its performance. Heavier models deliver greater force, which is essential for certain applications. Ensure that the chosen compactor meets the power requirements of your specific task demands.

Understanding these elements not only enhances density efficiency but also mitigates potential expenses related to insufficient ground consolidation, which can average EUR 12,714 per hectare in certain areas. By making informed choices based on ground type and project size, construction project managers can optimize their equipment selection for successful outcomes. Furthermore, implementing improved practices, such as minimum tillage and precise farming techniques, can further mitigate soil compaction risks and enhance soil health.

Implement Best Practices for Compactor Usage and Maintenance

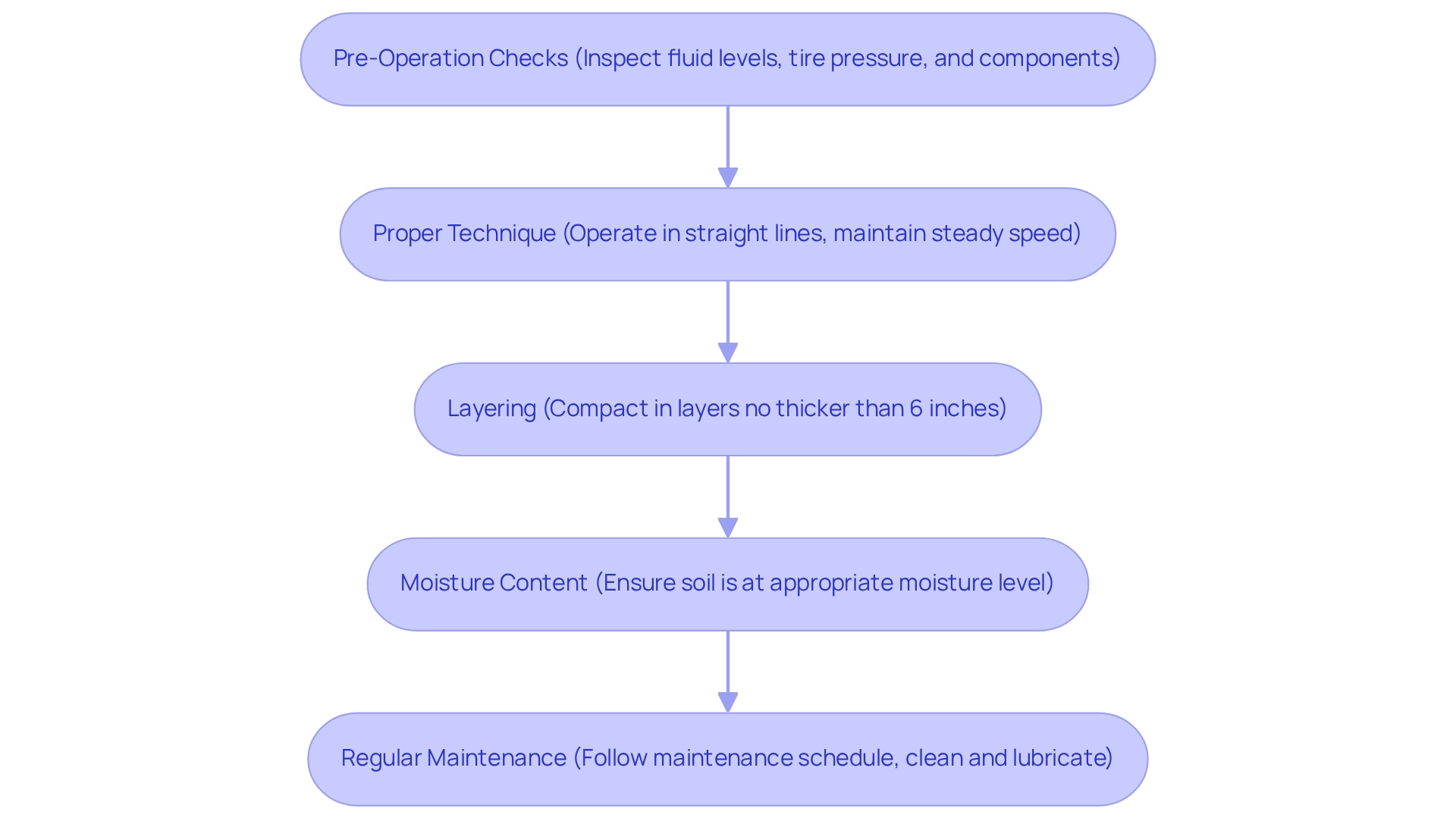

To ensure effective compactor usage and maintenance, it is essential to adhere to the following best practices:

- Pre-Operation Checks: Conduct thorough inspections before operating the machine. This includes checking fluid levels, tire pressure, and ensuring all components are functioning properly. Statistics indicate that machine operators frequently troubleshoot equipment issues, with studies showing that up to 30% of operators encounter problems that could be avoided with proper pre-operation checks.

- Proper Technique: Operate the compactor in straight lines and avoid turning on slopes to minimize the risk of tipping. Maintaining a steady speed is vital for attaining uniform density, which is essential for project integrity. As Witt observes, Weber MT’s intelligent density technology can enhance time efficiencies by as much as 25%, which also reduces expenses.

- Layering: Compact in layers, ideally no thicker than 6 inches, to achieve optimal density. This practice prevents excessive packing and ensures thorough coverage, aligning with manufacturer recommendations for effective packing.

- Moisture Content: Ensure the soil is at the appropriate moisture level. Soil that is too dry or too wet can significantly hinder effective compaction, leading to subpar results.

- Regular Maintenance: Adhere to the manufacturer's maintenance schedule, which includes cleaning, lubricating moving parts, and checking for wear and tear. Regular maintenance not only prolongs the life of the equipment but also enhances safety, as improper maintenance can lead to accidents. For instance, machine safeguarding assessments can help organizations identify potential risks and improve safety protocols in operations, contributing to a safer workplace.

By implementing these best practices, project managers can enhance the efficiency and safety of their compactor operations, ultimately contributing to successful project outcomes.

Conclusion

The effective use of earth compactors is crucial for the success of construction projects. Understanding the various types of compactors—such as plate compactors, rammers, rollers, and vibratory compactors—equips project managers with the knowledge to select the right equipment tailored to their specific needs. Each compactor serves distinct purposes, making it vital to assess factors like soil type, project size, and site conditions when making a selection.

Navigating the rental process effectively can further optimize project efficiency. By following essential steps, including:

- Assessing project requirements

- Researching rental companies

- Understanding rental terms

Project managers can secure the right compactor while minimizing potential challenges. Furthermore, thorough inspections and training can enhance safety and operational effectiveness, ensuring that all team members are prepared to utilize the equipment efficiently.

Implementing best practices for compactor usage and maintenance is equally important. Conducting pre-operation checks, adhering to proper techniques, and ensuring appropriate soil moisture levels can significantly improve compaction outcomes. Regular maintenance not only prolongs equipment life but also enhances safety on the job site, reducing the risk of accidents and ensuring a smooth workflow.

In summary, a comprehensive understanding of earth compactors, coupled with effective rental strategies and best practices for usage and maintenance, is essential for optimizing construction outcomes. By prioritizing these elements, project managers can ensure that their projects are executed with efficiency and precision, ultimately leading to successful infrastructure development. Take action today to elevate your project’s success by leveraging the right equipment and practices.

Frequently Asked Questions

What are the main types of earth compactors?

The main types of earth compactors include Plate Compactors, Rammers, Rollers, and Vibratory Compactors. Each type is designed for specific applications in construction.

What is the purpose of Plate Compactors?

Plate Compactors are ideal for small to medium-sized tasks and are effective in compacting granular materials and asphalt by exerting downward pressure combined with vibration.

When should Rammers be used?

Rammers are perfectly suited for confined areas and excel in compacting cohesive materials using rapid impacts to achieve the necessary density.

What are Rollers used for in construction?

Rollers are larger and more robust machines used in extensive projects like road construction. They efficiently compact large areas and are available in both smooth and padded variants.

How do Vibratory Compactors work?

Vibratory Compactors use both weight and vibration to compress earth efficiently, adapting to various ground types.

What is the outlook for the earth compactor rental market by 2025?

The earth compactor rental market is expected to experience substantial growth by 2025, driven by rising demand for soil consolidation in agriculture and supportive government policies for infrastructure development.

Which region has seen the fastest growth in the earth compactor rental market?

North America has experienced the fastest growth in terms of compound annual growth rate (CAGR) in recent years.

What innovations are being made in the earth compactor industry?

Producers are innovating to enhance functionalities such as compression strength and engine varieties to meet the evolving demands of the construction sector.

What is expected to show remarkable CAGR during the forecast period?

Forward plate compactors are expected to exhibit remarkable CAGR during the forecast period according to Fortune Business Insights.