Key Highlights:

- Walk behind forklifts, or walkie stackers, are pedestrian-controlled lifts designed for manoeuvring in confined spaces.

- These forklifts are typically electric-powered and can lift loads between 2,000 to 4,000 pounds to heights of about 15 feet.

- Their compact design enhances manoeuvrability in tight areas, making them ideal for warehouses and construction sites.

- They facilitate efficient transport of materials, reducing the need for manual labour and minimising lifting-related injuries.

- Electric operation reduces noise and emissions, suitable for indoor use and environmentally conscious projects.

- The evolution of walk behind forklifts began in the early 20th century, with significant advancements in hydraulics and battery technology over the decades.

- Modern walk behind forklifts feature ergonomic controls, advanced safety mechanisms, and improved manoeuvrability.

- Safety features include automatic braking systems and load stability mechanisms to ensure safe operation.

- Proper training for operators is essential for maximising efficiency and safety in material handling operations.

Introduction

Walk-behind forklifts have become essential tools in the construction industry, transforming material handling on job sites. Their compact design and electric operation enhance maneuverability in tight spaces, contributing to a safer and more efficient workflow. As construction managers strive to optimize productivity while adhering to safety standards, a pertinent question arises: how can these versatile machines be utilized to maximize operational efficiency and minimize workplace injuries? This article explores four key insights that underscore the functionality, benefits, and advancing technology of walk-behind forklifts, providing valuable guidance for those aiming to improve their material handling strategies.

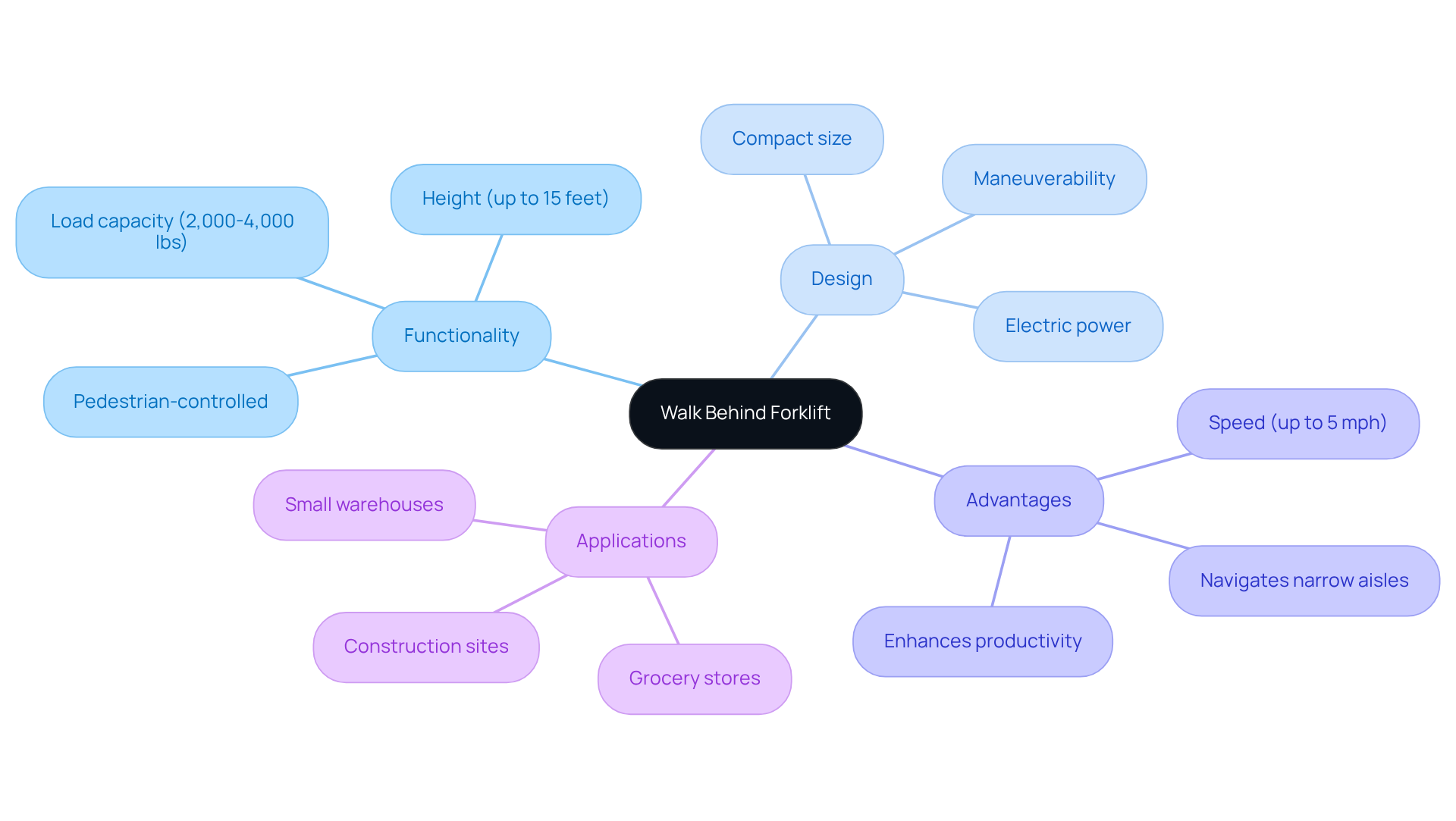

Define Walk Behind Forklift: Functionality and Design

A pedestrian-controlled lift, commonly referred to as a walkie stacker, serves as a compact material handling solution designed for elevating and moving loads in confined spaces. Unlike traditional lifting machines that are operated from a seated position, walk-behind forklift models require users to walk behind the device, controlling it via a handle. This design significantly enhances maneuverability in tight areas, making them particularly suitable for warehouses and construction sites where space is limited.

Typically powered by electricity, these material handling vehicles can lift loads ranging from 2,000 to 4,000 pounds, with some models capable of reaching heights of approximately 15 feet. Their versatility extends beyond lifting; they efficiently transport pallets and other materials, streamlining workflows across various operational settings. Industry leaders emphasize the advantages of ride-on lifting machines, noting their ability to navigate narrow aisles and tight corners, which is essential for optimizing storage efficiency and enhancing operational productivity.

Real-world applications illustrate their effectiveness in environments such as grocery stores and small warehouses, where they facilitate the swift movement of goods from loading docks to sales floors or storage areas. With a top speed of around 5 mph, walk behind forklifts strike a balance between speed and safety, making them invaluable assets in material handling operations.

Contextualize Walk Behind Forklifts: Importance in Construction Projects

Walk behind forklift trucks play a vital role in building projects, significantly enhancing the efficiency of material transport across work sites. Their compact design facilitates easy navigation through narrow aisles and tight corners, common challenges in construction environments. By enabling the swift and secure movement of heavy loads, these machines reduce reliance on manual labor and lower the risk of lifting-related injuries. Research indicates that using ride-on lifts can lead to a substantial decrease in workplace injuries, with some studies suggesting that proper training and equipment can prevent up to 70% of lift-related incidents.

Moreover, the electric operation of walk behind forklifts minimizes noise and emissions, making them particularly suitable for indoor use and environmentally conscious projects. This feature is especially beneficial in urban development sites where noise regulations are often in place. Construction managers can leverage these lift trucks to optimize logistics, ensuring that materials are delivered precisely where and when needed. This capability ultimately supports adherence to project timelines and budgets.

Incorporating lift trucks into operations allows construction teams to enhance productivity while prioritizing safety and efficiency. By investing in this equipment, companies can ensure a reliable and effective approach to material handling, reinforcing their commitment to quality and operational excellence.

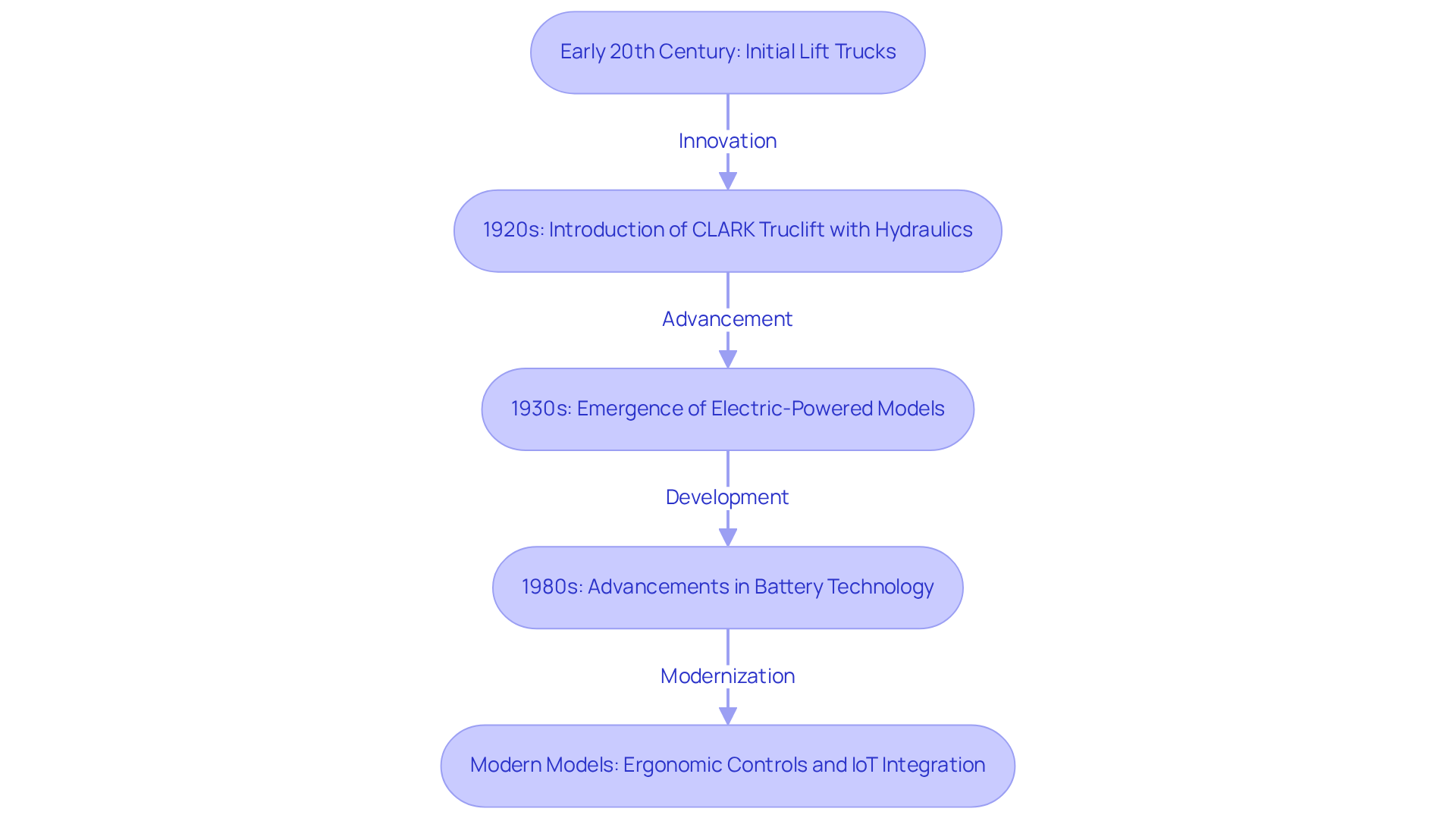

Trace the Evolution: History and Development of Walk Behind Forklifts

The development of pedestrian lifting devices began in the early 20th century, marked by the introduction of initial lift trucks aimed at enhancing material handling efficiency. These early machines were relatively basic, primarily designed for heavy lifting without the advanced features we recognize today. A significant milestone occurred in the 1920s with the launch of the CLARK Truclift, which incorporated hydraulics for lifting, paving the way for future innovations. By the 1930s, electric-powered models emerged, greatly improving usability and efficiency, particularly during WWII when labor shortages heightened the demand for lifting equipment.

The 1980s witnessed substantial advancements in battery technology, which extended operational durations and reduced charging times, transforming the functionality of walk behind forklifts. Modern models now feature ergonomic controls, advanced safety mechanisms, and improved maneuverability, making them indispensable in contemporary construction and warehousing operations. Notably, a larger, more sophisticated automated material handler can exceed $100,000, reflecting the significant investment in modern lifting technology.

Case studies illustrate the impact of these advancements; for example, the integration of IoT and telematics has enabled real-time data collection, optimizing fleet management and operational efficiency. Industry historians assert that the evolution of walk behind forklifts mirrors broader trends in industrial technology, emphasizing the necessity for continuous innovation to meet the demands of modern logistics and material handling. Today, these lifting machines are not merely tools but essential components of effective supply chain management, showcasing the remarkable evolution from their basic origins to their current advanced iterations.

Identify Key Features: Characteristics of Walk Behind Forklifts

Walk behind forklifts are essential in both warehouse and building environments due to their compact design, electric power sources, and user-friendly controls. Their compactness allows for seamless navigation in tight spaces, which is crucial for operations where maneuverability is limited. The electric power source minimizes emissions and ensures quieter operation, making these trucks suitable for indoor environments where noise reduction is a priority. Ergonomic features, such as comfortable handles and intuitive controls, significantly enhance operator comfort, reducing fatigue during extended use.

Safety is paramount in the operation of walk behind forklifts. Many models are equipped with automatic braking systems and load stability mechanisms, ensuring safe operation in busy work environments. Understanding these characteristics is vital for construction managers aiming to select the most effective equipment tailored to their operational needs.

EZ Equipment Rental offers a diverse fleet of walk behind forklifts, providing flexible rental options that cater to various project requirements. Investing in walk behind forklifts can yield a favorable return on investment by enhancing productivity. Proper training for operating these forklifts is essential to ensure safety and efficiency in operations.

Conclusion

Walk behind forklifts represent a significant advancement in material handling, especially in the construction sector. Their design emphasizes maneuverability and efficiency, making them essential for navigating tight spaces while safely lifting and transporting heavy loads. As construction managers increasingly recognize the value of these compact machines, they become vital tools that enhance operational productivity and safety.

Key insights throughout the article highlight the functionality, importance, and evolution of walk behind forklifts. Their ability to streamline logistics on construction sites, coupled with a notable reduction in workplace injuries associated with their use, underscores their efficiency and contribution to a safer working environment. The historical context illustrates how technological advancements have transformed modern walk behind forklifts into sophisticated machines equipped with ergonomic features and safety mechanisms.

The significance of walk behind forklifts goes beyond immediate operational benefits; they embody a commitment to innovation and efficiency in construction practices. As the industry evolves, embracing these tools can lead to improved project outcomes and a stronger focus on safety and sustainability. Construction managers are encouraged to integrate walk behind forklifts into their operations, ensuring they remain ahead of current trends and maximize project efficiency.

Frequently Asked Questions

What is a walk behind forklift?

A walk behind forklift, also known as a walkie stacker, is a pedestrian-controlled lift designed for elevating and moving loads in confined spaces. Users operate it by walking behind the device and controlling it via a handle.

What are the key features of walk behind forklifts?

Walk behind forklifts are compact, electrically powered, and can lift loads ranging from 2,000 to 4,000 pounds, reaching heights of approximately 15 feet. They are designed for enhanced maneuverability in tight areas.

Where are walk behind forklifts commonly used?

They are commonly used in environments such as warehouses, construction sites, grocery stores, and small warehouses, facilitating the movement of goods from loading docks to sales floors or storage areas.

What are the advantages of using a walk behind forklift?

The advantages include improved maneuverability in narrow aisles and tight corners, which optimizes storage efficiency and enhances operational productivity.

What is the top speed of a walk behind forklift?

The top speed of a walk behind forklift is around 5 mph, balancing speed and safety in material handling operations.

List of Sources

- Define Walk Behind Forklift: Functionality and Design

- Walk Behind Forklifts - The Pros and Cons (https://buyerzone.com/industrial/forklifts/ar-ac-walk-behind-forklifts)

- Guide to Walkie Stacker Forklifts - FleetNow (https://buyfleetnow.com/news/guide-to-walkie-stacker-forklifts?srsltid=AfmBOorAfY6dFeqOPgPAeQkpOe73PTBDNDYGyBWLPlISdSoTsII5Z75a)

- Forklift Types, Applications & Decision Tips | Hyworth Forklifts (https://hyworthforklifts.com.au/forklift-types-and-how-to-choose)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Forklift Weight Capacity - How Much Do You Need? (https://totalwarehouse.com/blogs/forklift-capacities-selection-guide)

- Contextualize Walk Behind Forklifts: Importance in Construction Projects

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Trace the Evolution: History and Development of Walk Behind Forklifts

- The Evolution of Forklift Technology From Inception to Today (https://intellaparts.com/blog/the-evolution-of-forklift-technology-from-inception-to-today?srsltid=AfmBOoqVkjj-mjP0DkSV7HofNXaT7Rk3cQLKlGKQIMF81QHQwBBALssw)

- The Evolution of Forklifts - 1920 to Today (https://nationalforkliftfoundation.com/forklift-evolution)

- Forklift History (https://atlanticforkliftservices.com/forklift-history)

- The History of The First Forklift (https://leavittmachinery.com/blog/information/the-first-forklift)

- The Evolution of Forklift Technology: A Journey Through Time (https://atlanticforkliftservices.com/the-evolution-of-forklift-technology)

- Identify Key Features: Characteristics of Walk Behind Forklifts

- 5 Best Walk Behind Fork Lifts That Will Transform Your Warehouse Operations (https://beaconhandlingrobot.com/blog/best-walk-behind-fork-lifts-for-warehouse-operations)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- What Is a Walk Behind Forklift? 7 Ways to Boost Operations (https://hyworthforklifts.com.au/what-is-a-walk-behind-forklift)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- 18 Important Forklift Statistics | BigRentz (https://bigrentz.com/blog/forklift-statistics?srsltid=AfmBOorH-jJEGeFz2LOSz_27F_UgJDRDanrReVFfyxnXni8pAUrvMcR7)