Overview

The key strategies for achieving success in machine rental involve:

- A clear definition of project scope

- A thorough assessment of soil conditions

- Meticulous planning for equipment availability

- The establishment of a comprehensive budget

These factors significantly influence rental choices and costs, underscoring the necessity of proactive planning and effective negotiation. By prioritizing these strategies, you can enhance cost efficiency and overall project effectiveness.

Key Highlights:

- Defining the project scope is crucial; larger projects require robust machinery, while smaller tasks can use compact models.

- Soil conditions impact machine selection; rocky or clay-heavy soils need more powerful equipment.

- Equipment availability is affected by seasonal demand, making early planning essential for access.

- Establishing a comprehensive budget should include leasing costs, delivery, insurance, and maintenance fees.

- Longer lease durations typically offer better rates compared to short-term agreements.

- Base rental rates for trenching machines range from $120 to $400 daily, averaging around $280.

- Delivery and pickup charges can add significant costs; understanding these fees is vital for budgeting.

- Insurance requirements vary; it's important to clarify these upfront to avoid unexpected costs.

- Maintenance fees may be included in the rental price or charged separately, affecting the overall budget.

- Fuel costs vary based on machine efficiency and local prices; always factor this into your budget.

- Late fees can accumulate if equipment is not returned on time; timely returns are crucial.

- Different types of ditching machines include walk-behind trenchers, ride-on trenchers, chain trenchers, mini excavators, and vibratory ploughs, each suited for specific tasks.

- Negotiating rental terms and reviewing lease agreements can lead to significant savings and prevent unexpected costs.

- Flexible rental options and rent-to-own choices can enhance cost efficiency for long-term projects.

- Planning for seasonal demand and utilising management software can optimise rental agreements.

Introduction

The construction machinery rental market is experiencing significant growth, projected to reach an impressive USD 179.21 billion by 2030. As project managers and contractors navigate this expanding landscape, it becomes essential to grasp the intricacies of ditching machine rentals. This article explores four key strategies designed to streamline the rental process, enhance cost efficiency, and improve project outcomes. However, with numerous factors at play—from equipment selection to budget constraints—how can one ensure that their rental choices align seamlessly with their project needs?

Identify Key Factors Influencing Ditching Machine Rentals

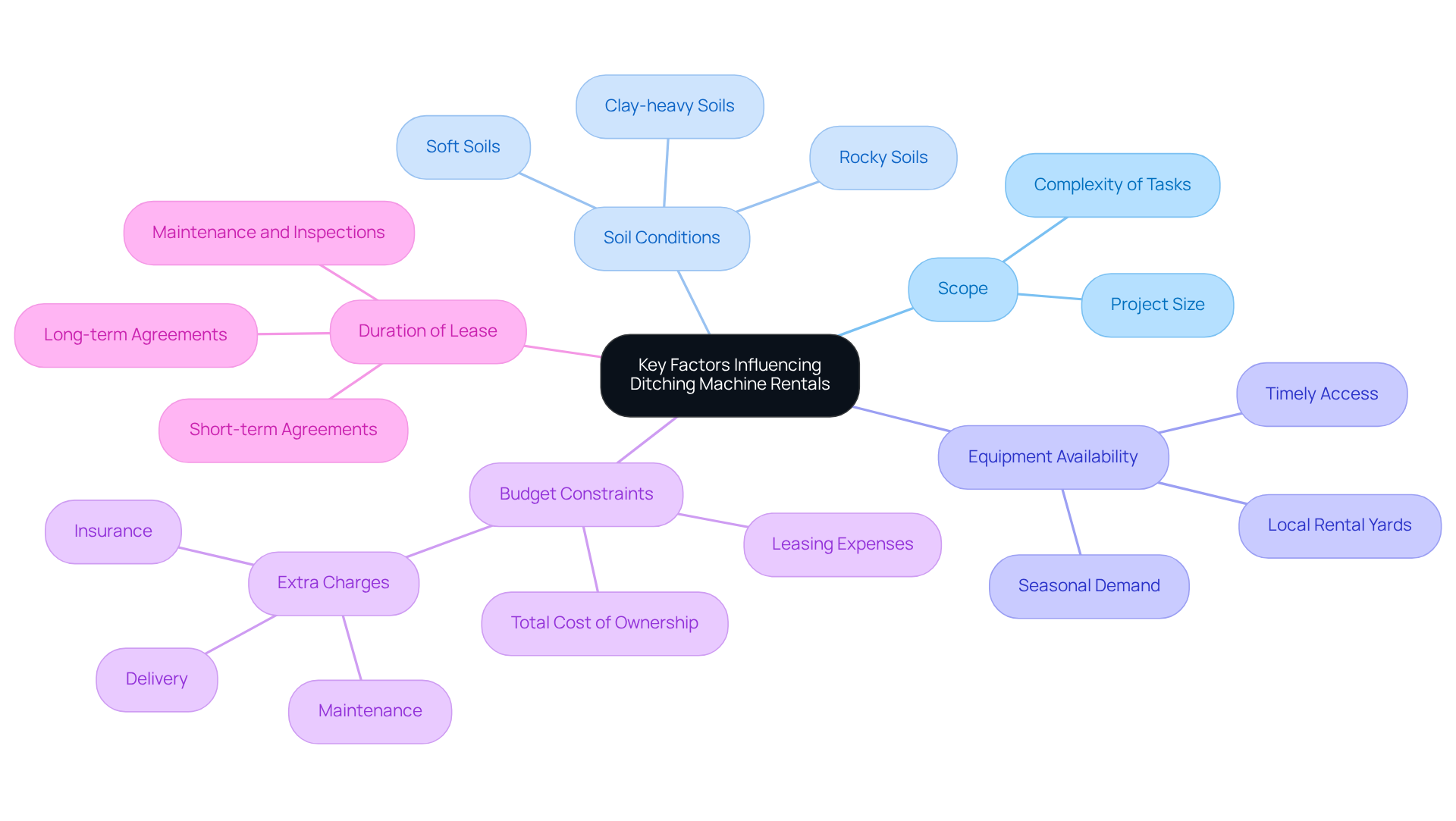

When evaluating ditching machine rentals, several key factors significantly influence your choices:

-

Scope: Clearly defining the size and complexity of your initiative is essential. Larger projects often necessitate more robust machinery, while smaller tasks can be efficiently managed with compact models. Notably, the construction machinery rental market is anticipated to attain USD 179.21 billion by 2030, underscoring the increasing demand for efficient solutions.

-

Soil Conditions: Assessing the type of soil is crucial. Rocky or clay-heavy soils typically require more powerful machines, whereas lighter equipment suffices for softer soils. Failing to adequately assess soil conditions can lead to inefficiencies and increased costs, impacting your project's success.

-

Equipment Availability: Checking the availability of required machines at local rental yards is vital. Seasonal demand can influence availability, making early planning crucial to ensure access to the necessary tools. A case study on utility installations highlights the importance of timely equipment access for project success.

-

Budget Constraints: Establishing a comprehensive budget is important. This should include not only leasing expenses but also possible extra charges for delivery, insurance, and maintenance. As emphasized by industry specialists, understanding the total cost of ownership compared to leasing can greatly influence your financial planning.

-

Duration of Lease: Determining the lease duration is essential. Longer lease durations often result in better rates, while short-term agreements can be more expensive on a daily basis. Regular maintenance and inspections are also critical to ensure operational efficiency and minimize downtime.

By thoroughly evaluating these factors, including the potential pitfalls of inadequate planning, you can make informed decisions about ditching machine rental that align with your project requirements and budget. This proactive approach ultimately leads to successful outcomes in ditching machine rental.

Analyze Cost Components of Ditching Machine Rentals

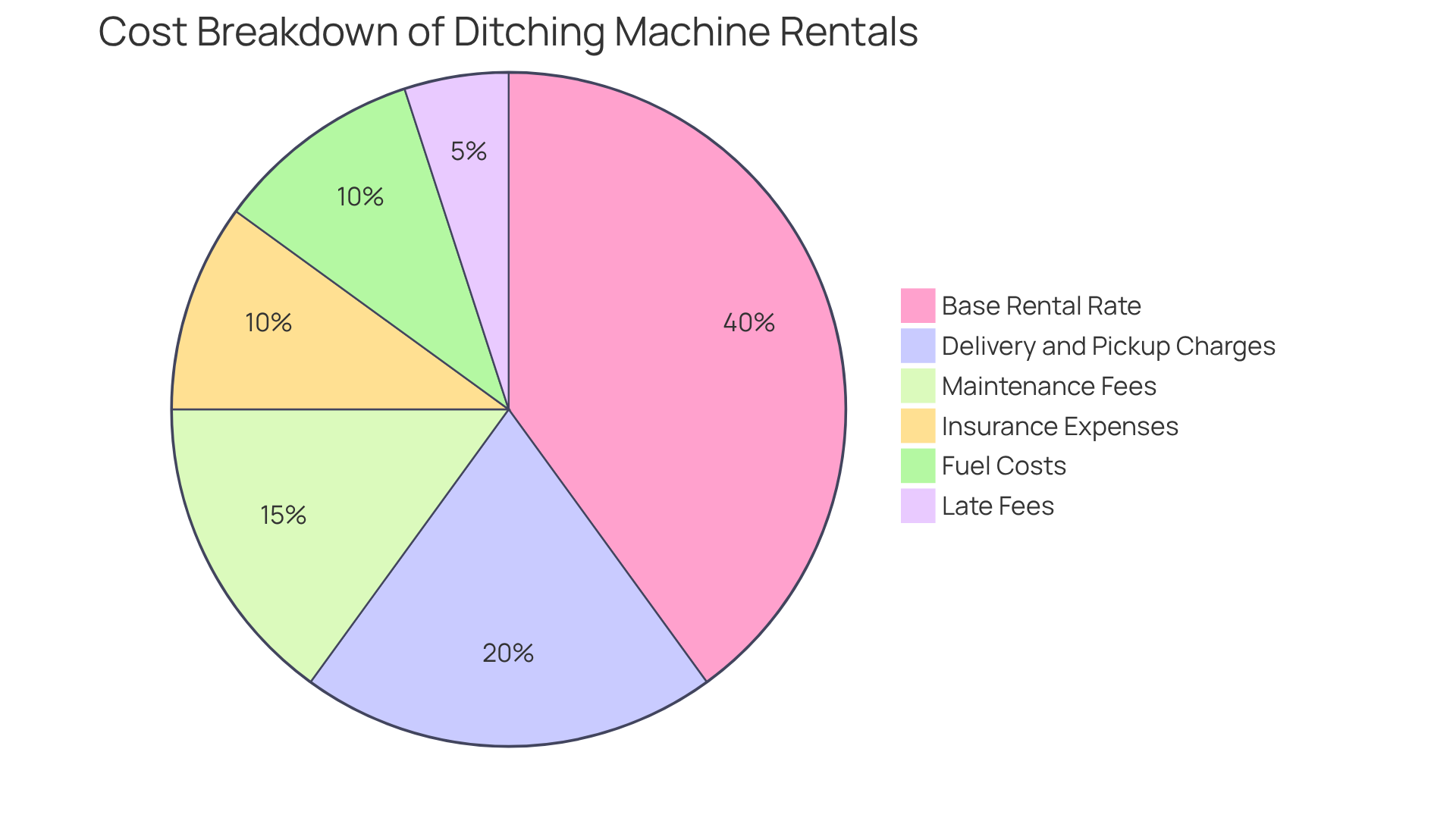

When considering ditching machine rental, it is crucial to analyze the various cost components to maintain budget control.

-

Base Rental Rate: This is the primary expense associated with renting the machine, typically charged on a daily, weekly, or monthly basis. For instance, trenching machines generally range from $120 to $400 daily, with an average daily fee of approximately $280. Understanding this cost is essential for effective budgeting.

-

Delivery and Pickup Charges: Numerous leasing firms impose fees for transporting the tools to and from the work location. Delivery charges can vary significantly; some companies charge flat rates or fees based on distance. Comprehending these charges can assist you in budgeting more precisely, as they can add hundreds of dollars to your project expenses. For example, delivery fees might reach as high as $500 for transporting construction materials over 100 miles.

-

Insurance Expenses: Lease agreements frequently require insurance coverage for the equipment, which can be an additional expense that varies according to the leasing company and the equipment's value. It's essential to clarify these requirements upfront to avoid surprises, as variability in insurance costs can significantly impact your budget.

-

Maintenance Fees: Some leasing companies include maintenance in the rental price, while others may charge extra for repairs or servicing during the leasing period. Knowing whether maintenance is included can greatly influence your overall rental budget. Notably, 40.2% of surveyed fleet managers reported increasing maintenance budgets to extend the useful life of the equipment, underscoring the importance of considering maintenance in your financial planning.

-

Fuel Costs: Depending on the machine's fuel efficiency and duration of use, fuel can become a significant expense. Always factor this into your overall budget, as machines need to be returned with a full tank, and fuel costs can vary based on local prices. Some trenchers use gasoline, while others use diesel, adding another layer of complexity to fuel budgeting.

-

Late Fees: If you exceed the borrowing period, late fees can quickly accumulate. Ensure to return the equipment on time or communicate with the rental company if you need an extension to avoid these additional charges. Timely returns are crucial for maintaining your budget and avoiding unexpected expenses.

By thoroughly analyzing these cost elements related to ditching machine rental, you can avoid unexpected expenses and ensure that your endeavor remains within budget.

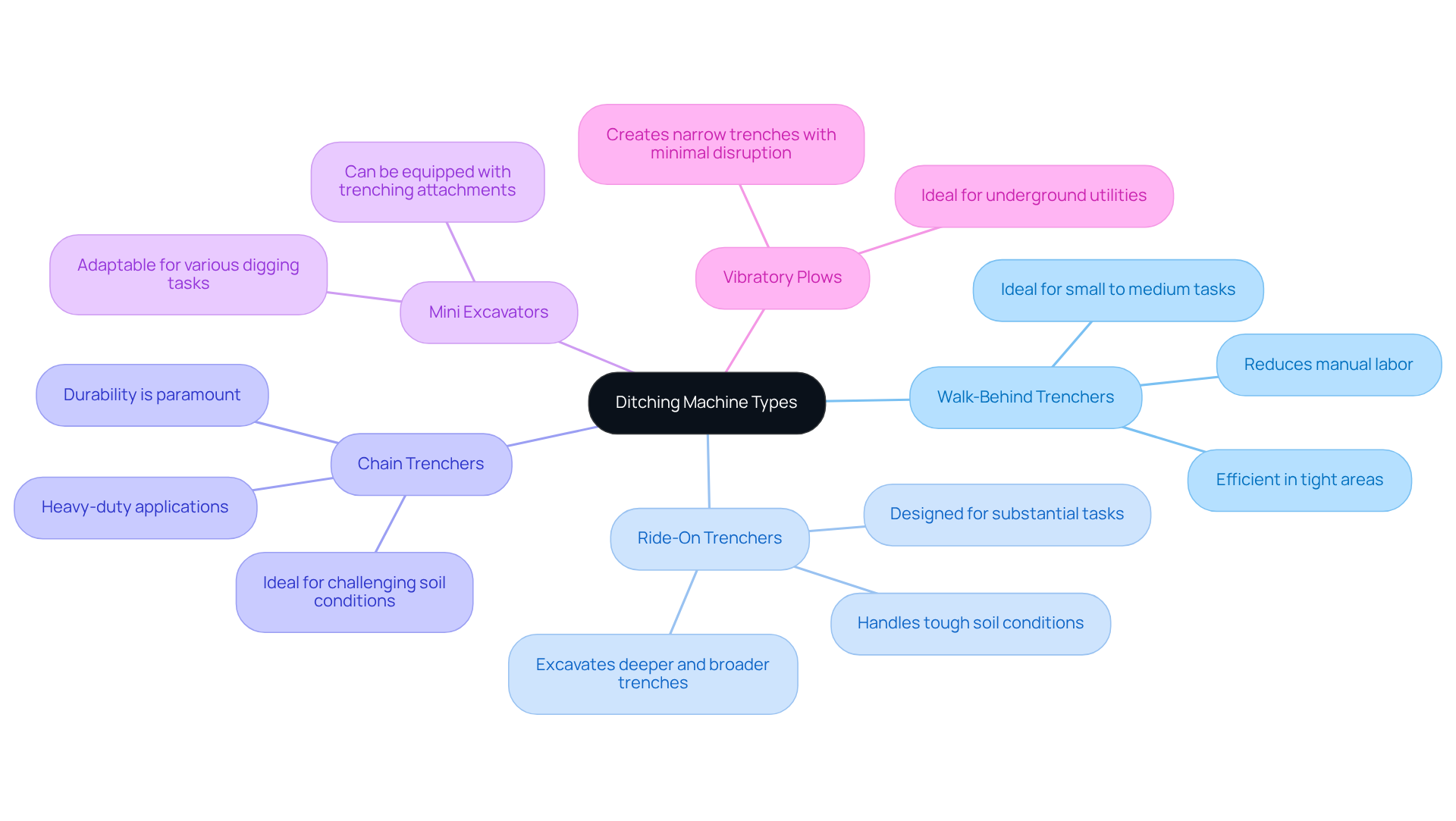

Select Appropriate Ditching Machine Types for Your Project

Selecting the appropriate kind of ditching machine rental is crucial for the success of your endeavor. Understanding the various types and their ideal applications can significantly enhance your project outcomes:

- Walk-Behind Trenchers: These machines are perfect for small to medium-sized tasks, excelling in creating narrow trenches while efficiently maneuvering through tight areas. They greatly reduce manual labor on smaller tasks, making them a practical choice for utility installations.

- Ride-On Trenchers: Designed for more substantial tasks, ride-on trenchers offer enhanced power and efficiency for excavating deeper and broader trenches, which is vital for extensive utility installations. Their robust design is adept at handling tough soil conditions.

- Chain Trenchers: Built for heavy-duty applications, these machines can tackle challenging soil conditions, making them ideal for utility installations where durability is paramount. As noted, "A trench can collapse or cave-in at any moment," underscoring the necessity for reliable equipment.

- Mini Excavators: While not traditional trenchers, mini excavators can be equipped with trenching attachments, proving adaptable for a variety of digging tasks across different scopes.

- Vibratory Plows: Ideal for installing underground utilities without extensive trenching, vibratory plows create narrow trenches with minimal surface disruption, making them an efficient option for less invasive methods.

When choosing a machine, consider the depth and width of the trench required, the type of soil, and the overall scope of your undertaking. Consulting with leasing specialists can provide valuable insights into the best equipment for your specific needs, such as ditching machine rental. For example, the RT60 walk-behind trencher is particularly effective for general utility trenching, while the CAT D10 bulldozer can push up to 20 tons of dirt, showcasing the range of options available for different project demands. Remember, "Workers should never work in an unprotected trench," highlighting the importance of safety in trenching operations.

Optimize Rental Agreements for Cost Efficiency and Flexibility

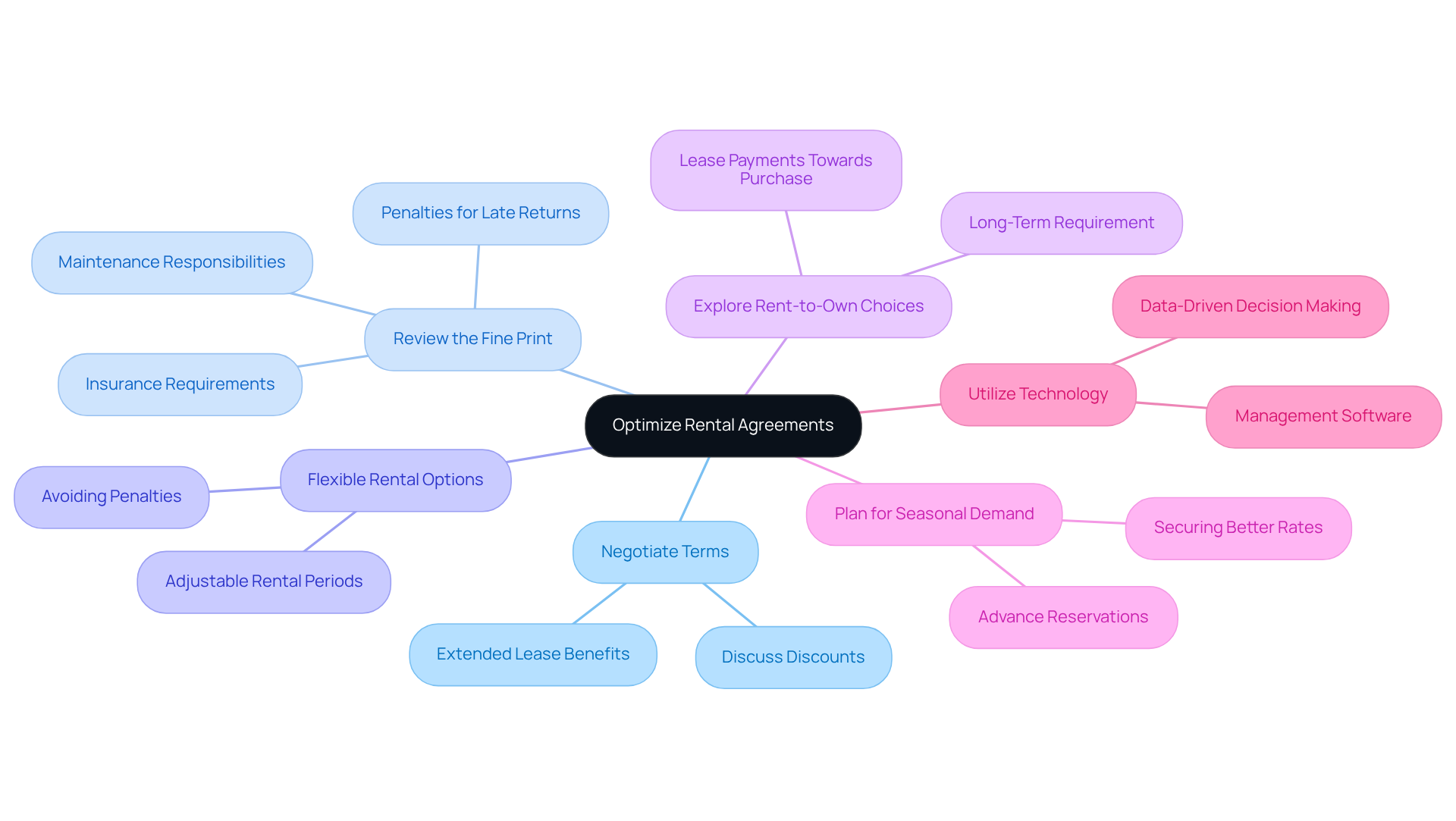

To optimize your rental agreements for cost efficiency and flexibility, consider the following strategies:

-

Negotiate Terms: Engage in discussions with your provider about potential discounts for extended lease periods or bundled services. Numerous businesses are willing to negotiate, particularly if you can agree to prolonged leases. This proactive approach can lead to significant savings.

-

Review the Fine Print: Thoroughly examine the lease agreement to grasp all terms, including maintenance responsibilities, insurance requirements, and penalties for late returns. Understanding these details is crucial as it can prevent unexpected costs that may arise later.

-

Flexible Rental Options: Seek out rental companies like EZ Equipment Rental that provide flexible terms, allowing you to adjust the rental period without incurring hefty penalties. This adaptability can be crucial for projects with changing timelines, ensuring you have ditching machine rental available when you need it.

-

Explore Rent-to-Own Choices: If you anticipate a long-term requirement for the tools, ask about rent-to-own contracts. These arrangements allow you to apply lease payments toward the purchase price, making it a financially wise choice for long-term projects.

-

Plan for Seasonal Demand: Anticipate peak leasing seasons and reserve your tools in advance. This proactive approach can secure better rates and ensure availability during high-demand periods, allowing you to stay ahead of the competition.

-

Utilize Technology: Leverage management software to track equipment usage, expenses, and leasing durations. This data-driven method can improve decision-making and refine your leasing strategy, leading to more efficient operations.

By implementing these strategies, you can tailor your agreements for ditching machine rental to meet project needs while maximizing cost efficiency and flexibility. For more information on how EZ Equipment Rental can assist you with your equipment needs, contact us today!

Conclusion

The success of ditching machine rental is fundamentally rooted in a strategic approach that includes:

- Understanding key factors

- Analyzing costs

- Selecting the right equipment

- Optimizing rental agreements

By recognizing these essential elements, stakeholders can significantly enhance project efficiency and ensure adherence to budget constraints, ultimately leading to successful outcomes.

Critical considerations such as:

- Defining project scope

- Assessing soil conditions

- Grasping the intricacies of rental agreements

are explored in depth. It is crucial to evaluate cost components, including:

- Base rental rates

- Delivery charges

- Maintenance fees

to maintain stringent budget control. Furthermore, selecting the appropriate type of ditching machine tailored to specific project needs is vital for achieving operational effectiveness.

As the construction machinery rental market continues to expand, the adoption of these best practices becomes increasingly significant. By implementing these strategies, stakeholders can adeptly navigate the complexities of ditching machine rentals, maximizing cost efficiency and flexibility while ensuring project success. Embracing a proactive and informed approach not only leads to improved financial outcomes but also enhances overall project delivery, paving the way for future opportunities in the industry.

Frequently Asked Questions

What are the key factors to consider when renting ditching machines?

The key factors include the scope of the project, soil conditions, equipment availability, budget constraints, and the duration of the lease.

How does the scope of the project influence machine rental choices?

Clearly defining the size and complexity of the project is essential; larger projects may require more robust machinery, while smaller tasks can be managed with compact models.

Why are soil conditions important when renting ditching machines?

The type of soil affects the choice of machinery; rocky or clay-heavy soils typically require more powerful machines, while lighter equipment suffices for softer soils.

How does equipment availability impact the rental process?

Checking the availability of required machines at local rental yards is vital, as seasonal demand can influence availability. Early planning is crucial to ensure access to necessary tools.

What should be included in the budget for ditching machine rentals?

The budget should encompass leasing expenses, potential extra charges for delivery, insurance, and maintenance, as well as a comparison of the total cost of ownership versus leasing.

How does the duration of the lease affect rental costs?

Longer lease durations often result in better rates, while short-term agreements can be more expensive on a daily basis. Regular maintenance and inspections are also critical to minimize downtime.

What is the benefit of thoroughly evaluating these factors before renting?

By evaluating these factors and avoiding inadequate planning, you can make informed decisions that align with your project requirements and budget, leading to successful outcomes in ditching machine rental.