Overview

Achieving success in hammer drill rental hinges on four key strategies:

- Selecting the appropriate tool

- Understanding rental terms

- Maintaining the equipment

- Planning rental schedules according to project timelines

Choosing the right drill for specific tasks is crucial, as it directly impacts project outcomes. Furthermore, clarifying rental agreements can prevent disputes and ensure a smooth rental experience. Implementing maintenance practices is essential to prolong the life of the tools, thus enhancing their reliability. Finally, coordinating rental schedules effectively can significantly enhance project efficiency and reduce overall costs.

Key Highlights:

- Selecting the right hammer drill is crucial for project success; rotary tools are preferred for heavy-duty tasks.

- Power ratings, including BPM and RPM, are important metrics for evaluating hammer drill performance.

- Ergonomics, adjustable speed settings, and SDS chucks enhance usability during extended use.

- Reviewing rental agreements is essential to understand lease duration, fees, and maintenance obligations.

- Ambiguity in lease terms can lead to disputes; clarity is vital for smooth operations.

- Regular maintenance, including cleaning and lubricating, prolongs the life of rented hammer drills.

- Predictive maintenance can save businesses 30-40% in costs, emphasising the importance of proper care.

- Creating a detailed rental schedule aligned with project timelines boosts efficiency and reduces costs.

- Effective communication with rental companies ensures availability of tools when needed.

Introduction

Selecting the right tools for construction projects is crucial, particularly when it comes to hammer drills. The increasing demand for efficient and reliable equipment makes it essential for both novice and experienced contractors to understand the nuances of hammer drill rentals.

What challenges might arise when navigating rental agreements, maintaining tools, and aligning schedules with project timelines?

By exploring these key strategies, users can empower themselves to maximize their rental experience and ensure project success.

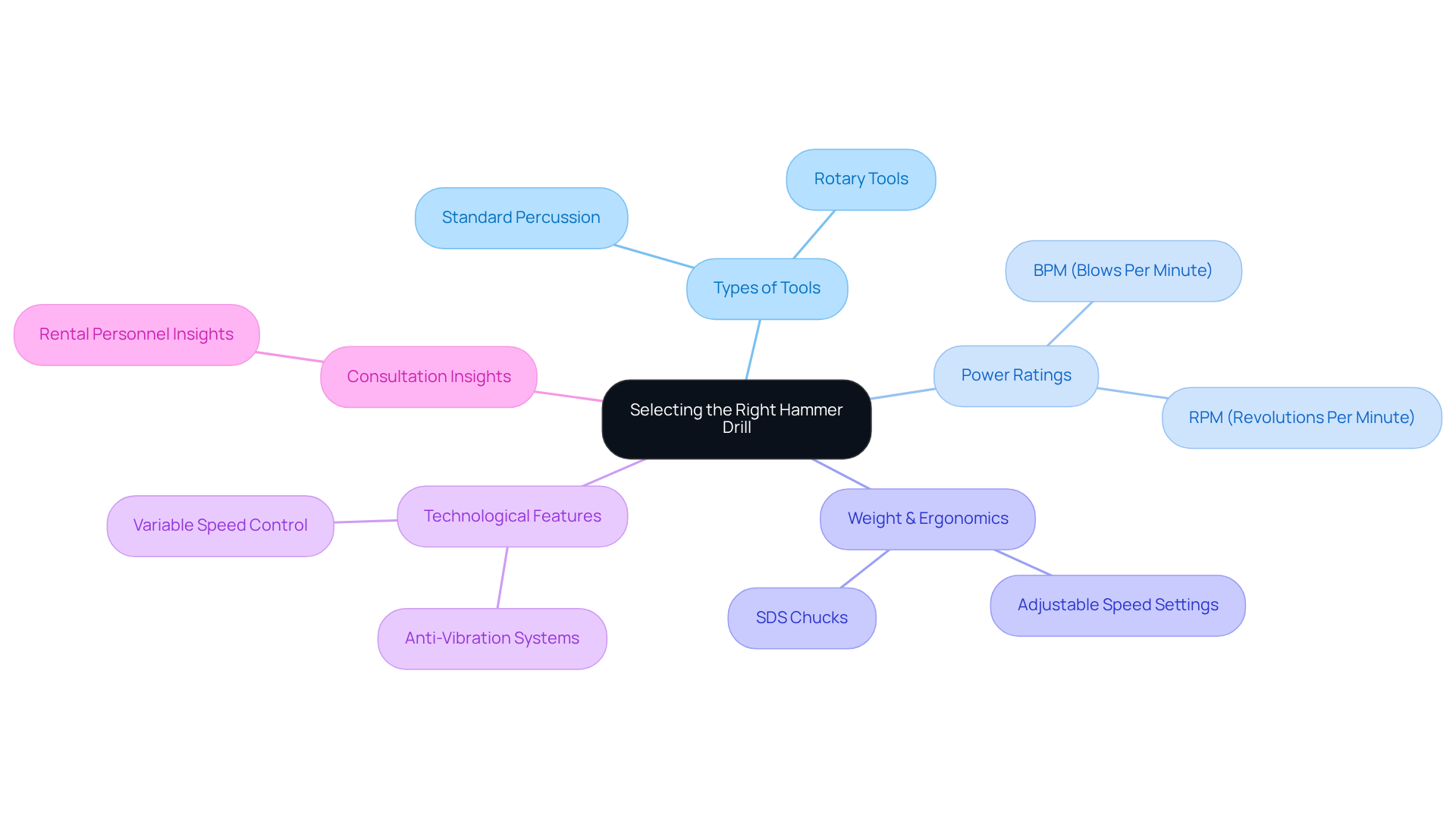

Select the Right Hammer Drill for Your Project

Selecting the appropriate tool is essential for the success of your concrete tasks. For light masonry tasks, a standard percussion tool may suffice; however, for heavy-duty applications like boring into concrete, a rotary tool is essential. As indicated by Grand View Research, "Rotary percussion tools are essential implements for these projects, as they can manage tough materials." When evaluating options, consider the tool's power ratings, typically measured in BPM (blows per minute) and RPM (revolutions per minute), as these metrics significantly impact performance. For example, rotary tools often feature higher RPMs, making them more effective for tough materials.

Weight and ergonomics also play a vital role in usability, especially during extended use. Look for features such as adjustable speed settings and the type of chuck—SDS chucks are preferred for their ease of bit changes and secure fit in demanding applications. Furthermore, advancements in technology, such as variable speed control and anti-vibration systems, improve the functionality of contemporary hammer tools.

Consulting with rental personnel can offer invaluable insights customized to your specific requirements, such as details about hammer drill rent. Their expertise can assist you in choosing the most appropriate hammer drill rent from their inventory, ensuring you have the right tool for the job. This collaborative approach not only enhances efficiency but also contributes to the overall success of your construction endeavors. With the rotary percussion tool market expected to attain USD 1.62 billion by 2025, the significance of selecting the appropriate equipment for construction projects cannot be emphasized enough. Furthermore, as urbanization continues to drive demand for effective construction tools, referencing case studies like the "Impact of Urbanization on Rotary Hammer Demand" illustrates the growing need for reliable equipment in the industry.

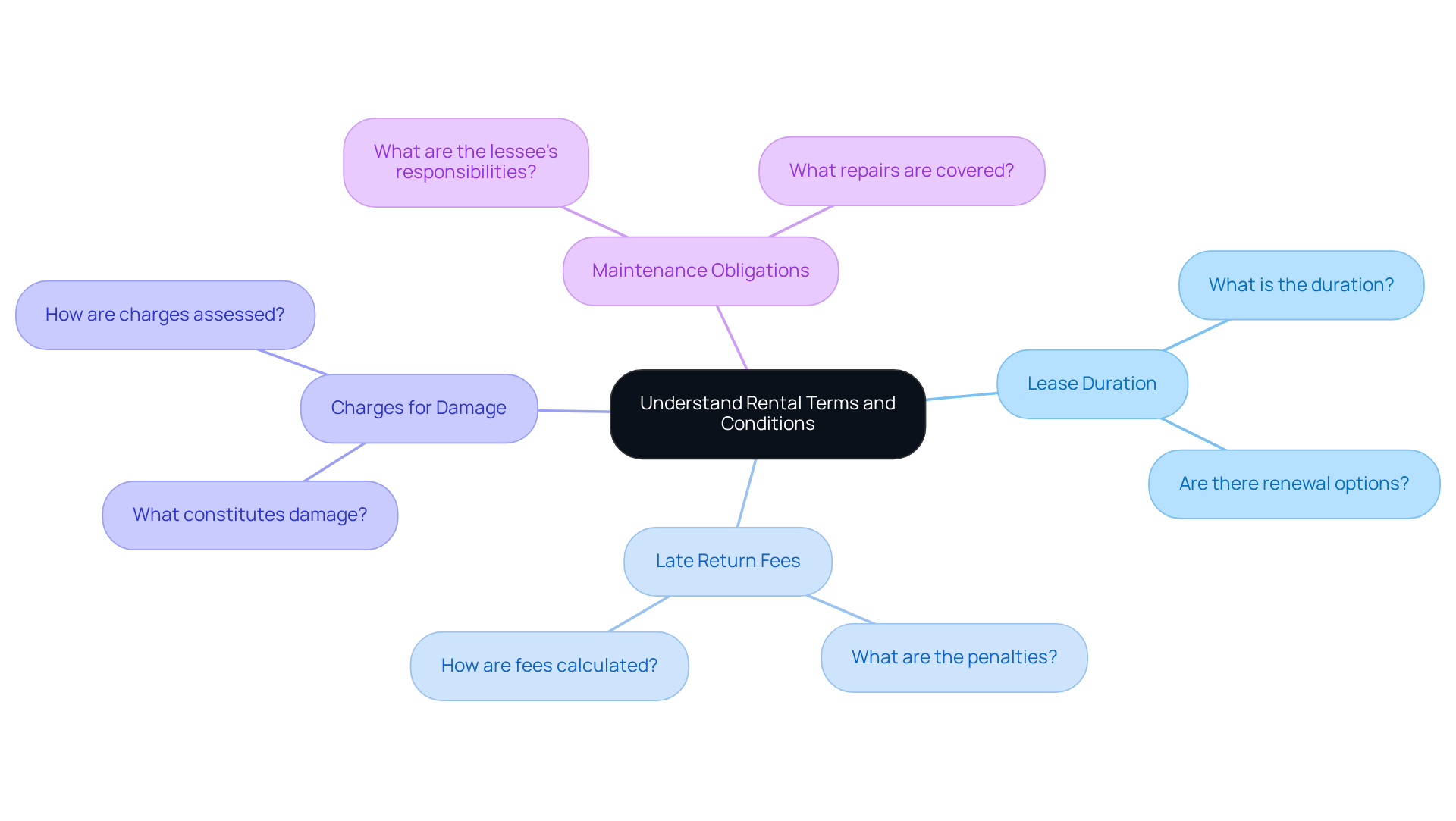

Understand Rental Terms and Conditions

Before hammer drill rent, it is essential to thoroughly review the lease agreement. Focus on key components such as the lease duration, late return fees, and any charges for damage or loss. Understanding your obligations regarding the maintenance and care of the equipment during the hammer drill rent period is vital. As B. Heath Witzen from the Consumer Financial Protection Bureau states, "Transparency in the terms and conditions of equipment leasing agreements is crucial for fostering trust between parties." If anything is unclear, do not hesitate to ask the leasing company for clarification.

Statistics indicate that 10.4% of leases that began in July 2022 faced disputes due to ambiguous terms, underscoring the importance of clarity. Being well-informed about these terms can save you from unexpected expenses and ensure compliance with leasing policies. Ultimately, clear rental agreements can significantly enhance project execution, leading to smoother operations and greater satisfaction.

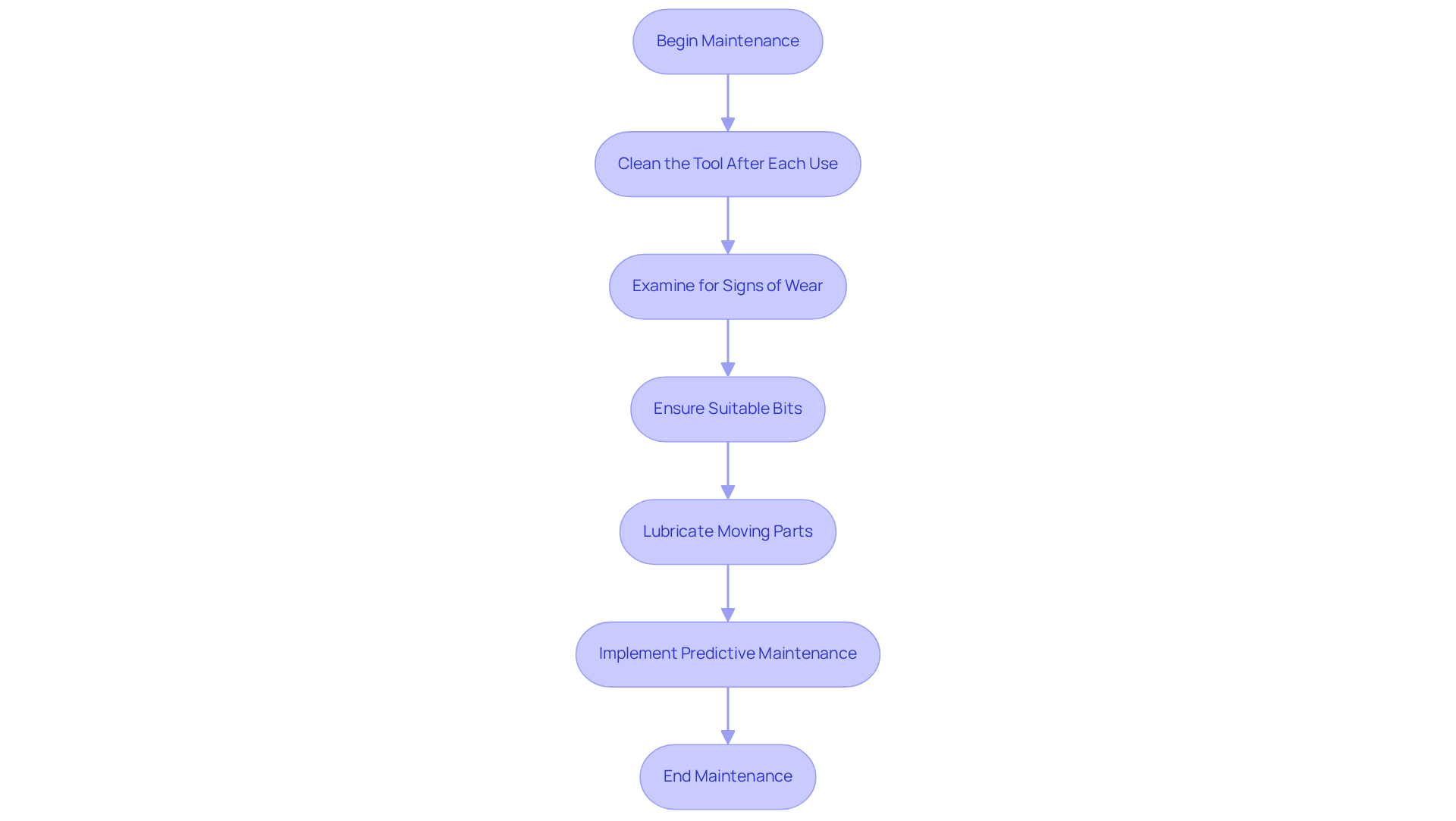

Maintain and Care for Rented Hammer Drills

To ensure optimal performance and longevity of your hammer drill rent, it is crucial to adhere to the manufacturer's guidelines for usage and maintenance. Begin by thoroughly cleaning the tool after each use to eliminate dust and debris that could impact its functionality. Consistently examine the tool for any signs of wear or damage; aging equipment is almost three times more likely to result in unplanned downtime. This underscores the importance of proper maintenance practices to mitigate risks associated with older equipment.

Ensure that the bits are suitable for the material being worked on, replacing them as necessary to maintain efficiency. Additionally, lubricate moving parts according to the manufacturer's recommendations to prevent premature wear and extend the tool's lifespan. According to the US Department of Energy, implementing predictive maintenance can save businesses between 30 to 40% in costs, highlighting the financial benefits of adhering to maintenance guidelines.

Implementing these best practices not only preserves the equipment but also enhances your productivity on the job site. This ultimately benefits both you and the rental company, reinforcing the value of maintaining your tools effectively.

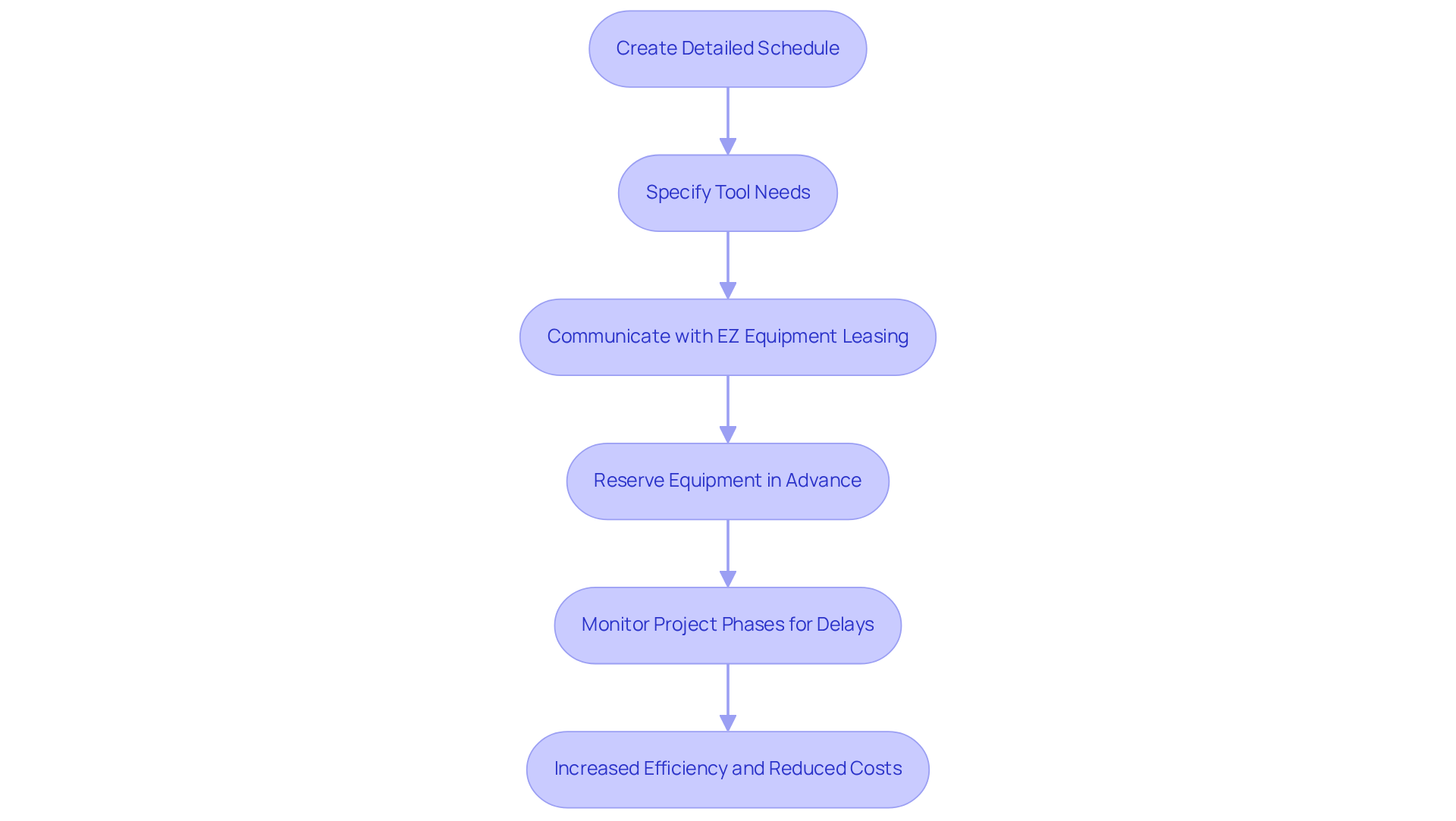

Plan Rental Schedules to Align with Project Timelines

To enhance task efficiency, creating a detailed schedule that specifies when the power tool will be necessary is essential. This timeline should encompass various project phases, potential delays, and the required time for setup and operation. Effective communication with EZ Equipment Leasing, the local leasing company in Irving, TX, is vital; sharing your schedule ensures that the equipment, including impact tools and other essential machinery like boom lifts and excavators, will be available when needed. Reserving the hammer drill rent in advance can mitigate last-minute complications. This is particularly important given that 40% of engineering and construction firms experienced schedule delays or cost impacts exceeding 20% in 2023 due to ineffective planning. By aligning your leasing schedule with your assignment timeline, you not only boost efficiency but also reduce the likelihood of incurring additional leasing costs. As one project manager noted, "Aligning rental schedules with project timelines is key to maintaining workflow and avoiding unnecessary costs.

Conclusion

Selecting the right hammer drill for a project is crucial, as it can significantly impact the success of construction tasks. Understanding the nuances of equipment rental—from choosing the appropriate tool to comprehending rental agreements and maintaining rented equipment—plays a pivotal role in achieving efficient and effective project outcomes.

Key strategies include:

- The importance of selecting a hammer drill that aligns with the specific needs of the project.

- Reviewing rental terms for clarity to prevent disputes.

- Implementing proper maintenance practices to ensure the tool's longevity and efficiency.

- Planning rental schedules in alignment with project timelines to enhance productivity and minimize unexpected costs.

Ultimately, the significance of these strategies cannot be overstated. By prioritizing informed decisions in selecting, renting, and maintaining hammer drills, project managers and construction professionals can enhance their operational efficiency and contribute to the overall success of their endeavors. Embracing these best practices will pave the way for smoother project execution and foster a more reliable and effective construction environment.

Frequently Asked Questions

What type of hammer drill should I select for light masonry tasks?

For light masonry tasks, a standard percussion tool may suffice.

What is the best hammer drill for heavy-duty applications like boring into concrete?

A rotary tool is essential for heavy-duty applications such as boring into concrete.

Why are rotary percussion tools important for concrete projects?

Rotary percussion tools are essential because they can manage tough materials effectively.

What power ratings should I consider when evaluating hammer drills?

Consider the tool's power ratings, typically measured in BPM (blows per minute) and RPM (revolutions per minute), as these metrics significantly impact performance.

What is the advantage of higher RPMs in rotary tools?

Higher RPMs in rotary tools make them more effective for working with tough materials.

How do weight and ergonomics affect the usability of hammer drills?

Weight and ergonomics are vital for usability, especially during extended use, as they influence comfort and control.

What features should I look for in a hammer drill?

Look for features such as adjustable speed settings and the type of chuck, with SDS chucks being preferred for their ease of bit changes and secure fit.

What technological advancements improve the functionality of contemporary hammer tools?

Advancements such as variable speed control and anti-vibration systems enhance the functionality of modern hammer tools.

How can consulting with rental personnel help in choosing a hammer drill?

Consulting with rental personnel can provide valuable insights tailored to your specific requirements, helping you select the most appropriate hammer drill from their inventory.

What is the expected market value for rotary percussion tools by 2025?

The rotary percussion tool market is expected to reach USD 1.62 billion by 2025.

Why is selecting the appropriate equipment important for construction projects?

Selecting the appropriate equipment is crucial for the success of construction projects, especially as urbanization drives the demand for effective construction tools.