Overview

This article presents a comprehensive overview of four essential steps for effective trench digging equipment rental.

- It emphasizes the importance of understanding the various types of equipment available, ensuring that users can select the most suitable tools for their projects.

- It details the evaluation of project requirements, guiding readers in assessing their specific needs and conditions.

- It discusses the necessity of considering budget constraints, providing insights into financial planning for equipment rental.

- It highlights the critical aspect of ensuring safety compliance, outlining necessary protocols to protect both workers and equipment.

Each step is backed by thorough explanations of equipment capabilities, project assessment criteria, financial considerations, and safety measures, creating a reliable guide for making informed rental decisions.

Key Highlights:

- Walk-Behind Trenchers are suitable for small to medium tasks, digging up to 24 inches deep, ideal for residential work, with rental costs ranging from $150 to $250 per day in Texas.

- Ride-On Trenchers are designed for larger tasks, capable of deeper and wider trenches, making them suitable for utility installations.

- Chain Trenchers excel in heavy-duty tasks and tough soil conditions, ensuring efficient excavation for commercial projects.

- Wheel Trenchers are best for softer soils, providing clean cuts for larger jobs in landscaping or construction.

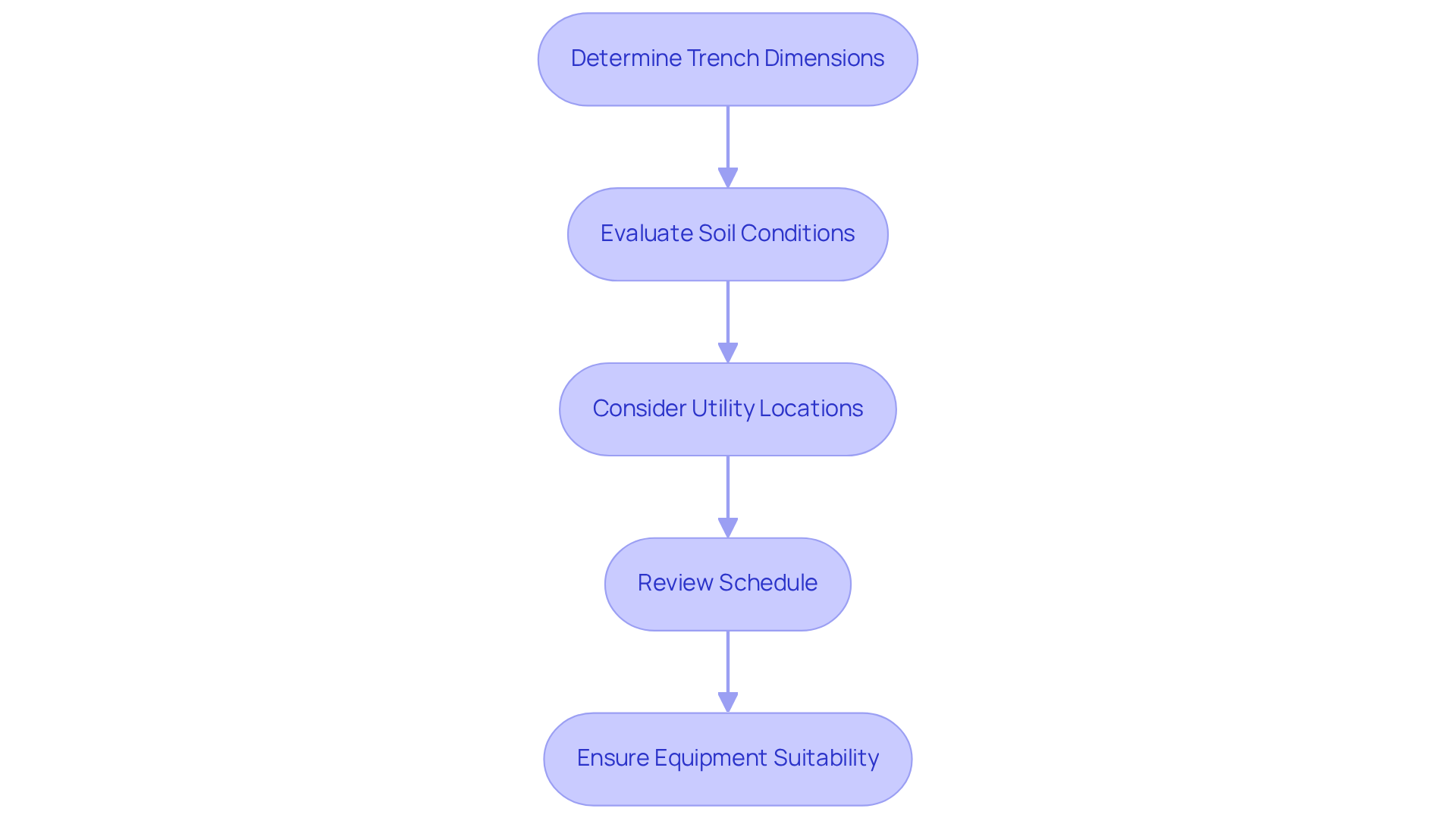

- Evaluating project requirements involves determining trench dimensions, assessing soil conditions, checking for existing utilities, and reviewing equipment availability.

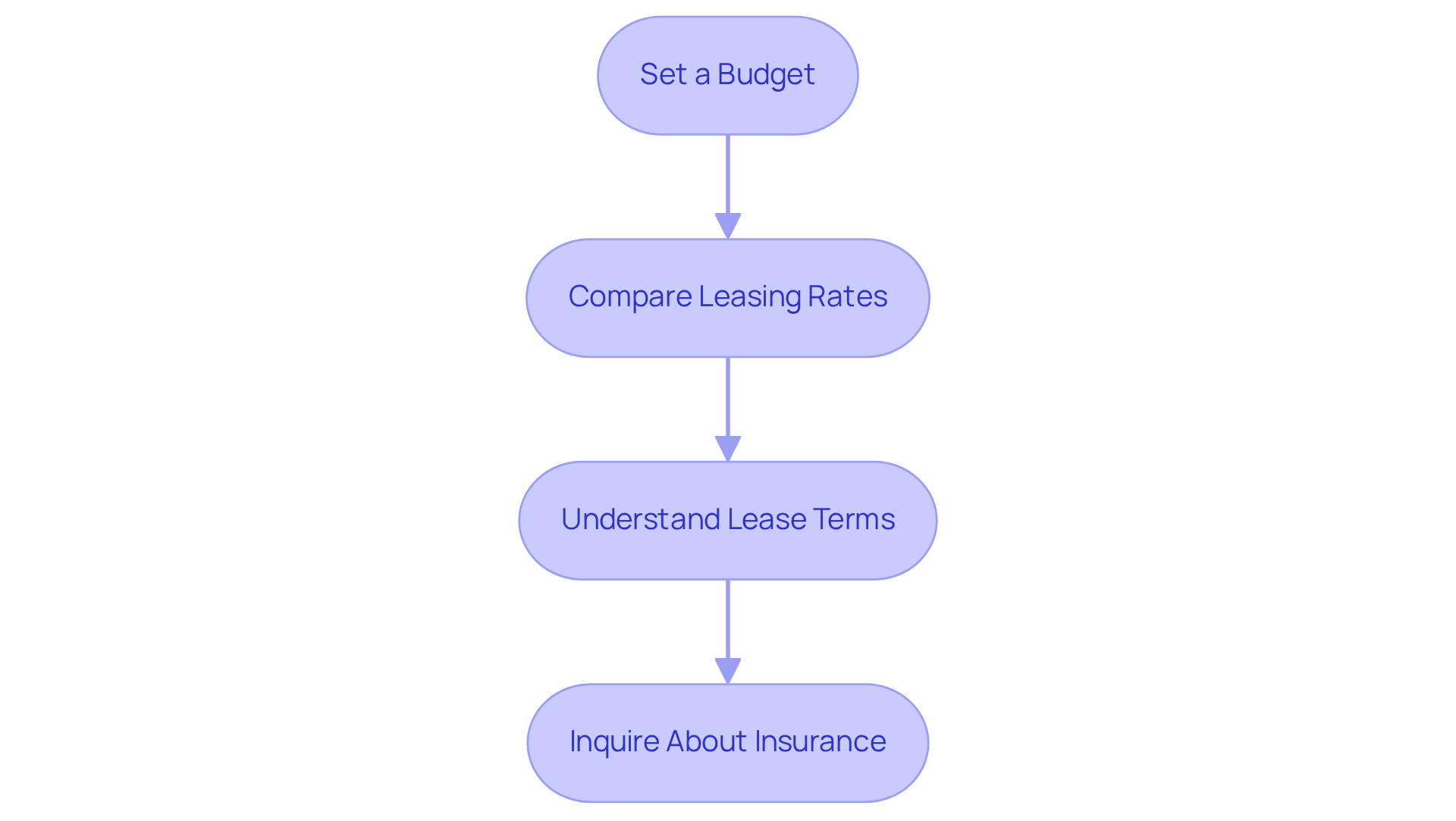

- Budget considerations include setting a clear budget, comparing leasing rates, understanding lease terms, and inquiring about insurance coverage.

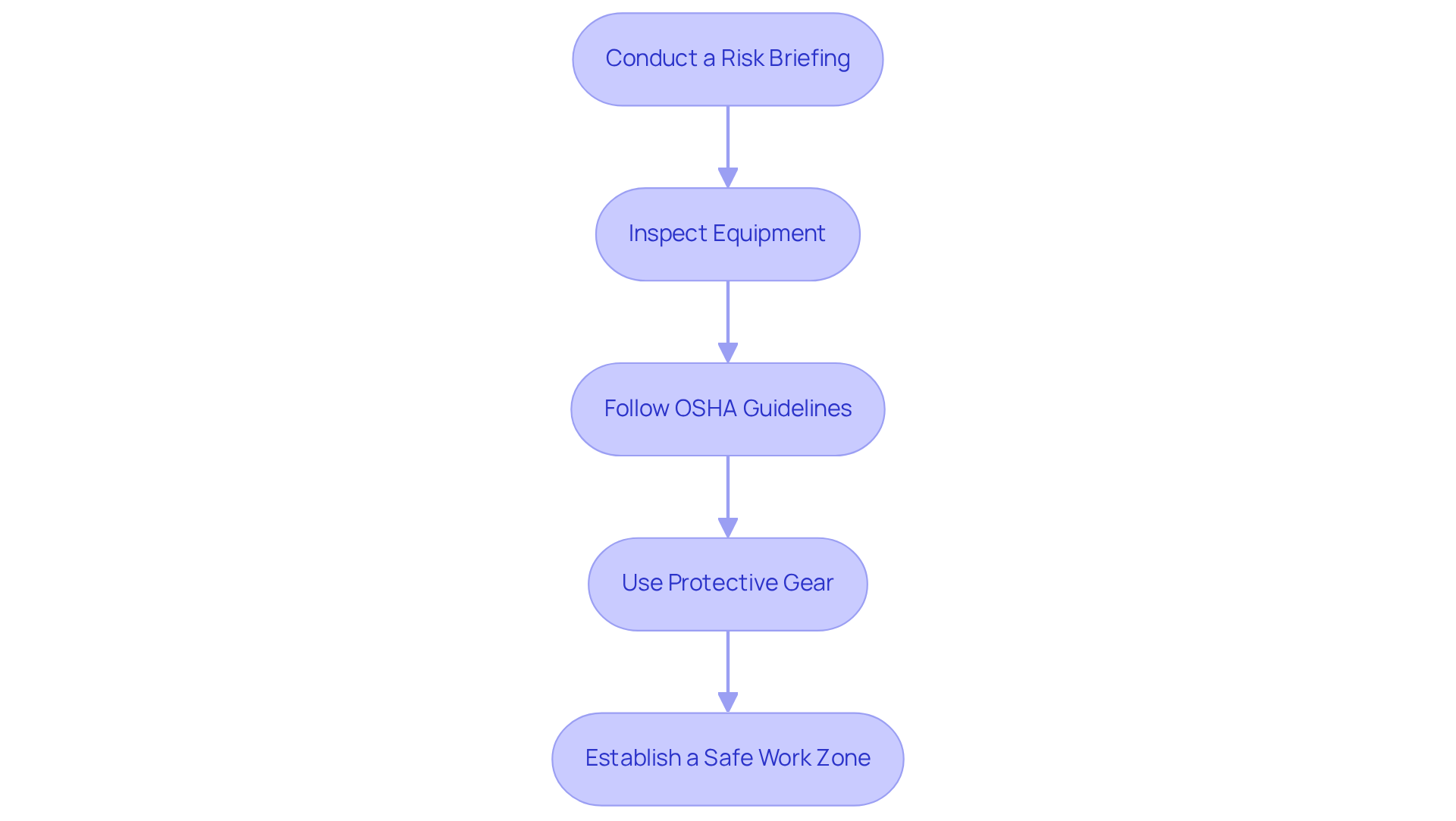

- Safety protocols involve conducting risk briefings, inspecting equipment, following OSHA guidelines, using personal protective equipment (PPE), and establishing safe work zones.

Introduction

Understanding the nuances of trench digging equipment rental is crucial for the success of any project. The right tools can mean the difference between a seamless execution and a costly setback. A diverse range of machines is available—from walk-behind trenchers that excel in tight spaces to robust chain trenchers designed for the most challenging soils. Project managers face the task of navigating this complex landscape to select the most suitable equipment.

How can one ensure that the chosen equipment meets specific project requirements while also adhering to budget constraints and safety regulations? This guide provides essential steps for effectively renting trench digging equipment. By following these guidelines, you can ensure that every excavation task is completed efficiently and safely, paving the way for project success.

In addition to selecting the right equipment, understanding the benefits of each type is vital. Walk-behind trenchers offer maneuverability in confined areas, while heavy-duty chain trenchers provide the power needed for tougher jobs. Each machine has its unique advantages, and recognizing these can enhance project efficiency. Furthermore, adhering to safety regulations not only protects your team but also ensures compliance with industry standards.

Ultimately, the goal is to equip your project with reliable tools that deliver quality results. Engaging with trusted rental services can facilitate this process, providing access to well-maintained equipment that meets your needs. Let this guide be your resource for navigating the trench digging equipment rental landscape, ensuring that your projects are executed with precision and care.

Understand Trench Digging Equipment Types

When considering trench digging equipment rental, understanding the various types available is crucial for project success.

Walk-Behind Trenchers are ideal for small to medium-sized tasks, providing excellent maneuverability. These machines can dig trenches up to 24 inches deep, making them perfect for residential landscaping or utility work in tight spaces. Furthermore, the trench digging equipment rental for walk-behind trenchers is often more cost-effective, with average rates in Texas typically ranging from $150 to $250 per day.

Ride-On Trenchers are designed for more extensive tasks, capable of excavating deeper and wider trenches. This makes them especially suitable for utility installations, where larger trench dimensions are often required. Their enhanced digging capabilities ensure efficient excavation in commercial settings. Real-world examples demonstrate that these machines are frequently utilized in utility installations, providing the necessary depth and width for pipelines and cables.

Chain Trenchers, built for heavy-duty tasks, excel in cutting through tough soil conditions. They are perfect for commercial endeavors that demand strong performance and dependability, ensuring that even the most challenging excavation tasks can be accomplished efficiently. As OSHA Regional Administrator Bill Donovan emphasizes, "With proper training and use of required safety procedures, incidents like these can be prevented," highlighting the importance of safety when utilizing such tools.

Wheel Trenchers are best suited for softer soils, providing a clean cut and efficiency for larger trenching jobs. Their design enables rapid and effective excavation, making them a favored option for extensive landscaping or construction endeavors.

By comprehending trench digging equipment rental tools, managers can make informed choices that align with their specific requirements, ensuring optimal performance and efficiency. Moreover, comparing walk-behind and ride-on trenchers can assist in selecting the appropriate equipment based on scale and budget considerations.

Evaluate Project Requirements and Equipment Compatibility

To effectively evaluate your project requirements, it is essential to follow these steps:

-

Determine Trench Dimensions: Begin by accurately measuring the length, width, and depth of the trench required for your project. This information is crucial for determining the suitable size and type of trench digging equipment rental required.

-

Evaluate Soil Conditions: Recognize that various soil categories, including clay, sand, or rocky terrain, significantly impact machinery selection. For instance, rocky soil may necessitate a chain trencher, while softer soils might be effectively managed with a standard trencher. Understanding these conditions is vital for ensuring that the trench digging equipment rental can effectively handle the specific challenges of your site.

-

Consider Utility Locations: Prior to excavation, it is imperative to check for existing underground utilities. This precaution helps prevent damage to essential services and avoids costly delays.

-

Review Schedule: Confirm that the leased tools are accessible for the entire duration of your undertaking. Timely access to the right trench digging equipment rental is essential for maintaining your schedule and avoiding interruptions.

By thoroughly assessing these factors, you can ensure that the trench digging equipment rental you select will be suitable for your project needs, ultimately leading to a more efficient and successful trenching operation.

Consider Budget Constraints and Rental Terms

When navigating budget constraints and rental terms for trench digging equipment, consider the following steps:

-

Set a Budget: Establishing a clear budget for gear hire is essential. Factor in potential extra costs such as delivery fees and fuel expenses. According to industry insights, a well-prepared justification for your budget request can significantly enhance approval chances.

-

Compare Leasing Rates: Conduct thorough research across various leasing companies to identify competitive pricing. Be mindful that rates may vary depending on the type of apparatus and the length of the lease. For example, traditional wet extractors can use between 17 to 167 gallons of water per 1,000 sq. ft., leading to high energy costs for drying, which should be considered when budgeting.

-

Understand Lease Terms: Carefully review the lease agreement. Pay attention to the specifics of daily, weekly, and monthly rates, as well as any penalties associated with late returns or equipment damage. As noted by industry experts, understanding these terms can prevent unexpected costs that may impact your budget.

-

Inquire About Insurance: Evaluate the insurance options provided by rental companies to cover potential damages. Determine if this coverage is necessary based on the scope and risks of your undertaking. As Ryan Griessmeyer, Founder and CEO of Race Day Events, emphasizes, ensuring you have the right protections in place is crucial for successful management of the endeavor.

By thoughtfully addressing these factors, you can ensure that your equipment rental decisions are both budget-conscious and aligned with your project requirements.

Ensure Safety and Compliance in Equipment Use

To ensure safety and compliance when using trench digging equipment, it is essential to follow these critical steps:

-

Conduct a Risk Briefing: Before commencing work, hold a meeting to discuss potential hazards and protection protocols. This initial step is vital for establishing a safety-first mindset among all team members.

-

Inspect Equipment: Prior to use, thoroughly check the equipment for any signs of wear or damage. Confirm that all protective features are functional to guarantee optimal safety during operations.

-

Follow OSHA Guidelines: Acquaint yourself with OSHA regulations regarding trenching and excavation. It is imperative that all workers receive training in these protection standards to ensure compliance and safety.

-

Use Protective Gear: All personnel must wear appropriate personal protective equipment (PPE), including hard hats, gloves, and steel-toed boots. This gear is not just a recommendation; it is a necessity for safeguarding against potential injuries.

-

Establish a Safe Work Zone: Set up barriers and signage to keep unauthorized personnel away from the work area. This proactive measure is crucial for maintaining a secure environment for all workers.

By prioritizing safety and compliance in trench digging equipment rental, you create a secure working environment and significantly minimize the risk of accidents. Take action now to implement these protocols and protect your team.

Conclusion

Understanding the nuances of trench digging equipment rental is essential for achieving project success. Selecting the right type of equipment—whether walk-behind, ride-on, chain, or wheel trenchers—can significantly impact the efficiency and effectiveness of excavation tasks. Each type serves specific needs based on trench dimensions, soil conditions, and project scale, making informed choices crucial for smooth operations.

Key considerations for effective trench digging equipment rental include:

- Evaluating project requirements

- Understanding budget constraints

- Ensuring safety compliance

By measuring trench dimensions, assessing soil types, and reviewing rental terms, project managers can optimize their equipment selection. Furthermore, prioritizing safety through risk briefings, equipment inspections, and adherence to OSHA guidelines safeguards the workforce and enhances overall project integrity.

Ultimately, making informed decisions about trench digging equipment rental not only streamlines operations but also contributes to successful project outcomes. By implementing the strategies discussed, individuals can navigate the complexities of equipment rental, ensuring that their projects are executed efficiently, safely, and within budget. Emphasizing these practices will lead to more effective trench digging operations and set a standard for future projects.

Frequently Asked Questions

What are the different types of trench digging equipment available for rental?

The main types of trench digging equipment available for rental include Walk-Behind Trenchers, Ride-On Trenchers, Chain Trenchers, and Wheel Trenchers.

What are Walk-Behind Trenchers used for?

Walk-Behind Trenchers are ideal for small to medium-sized tasks, providing excellent maneuverability and can dig trenches up to 24 inches deep, making them suitable for residential landscaping or utility work in tight spaces.

How much does it typically cost to rent a Walk-Behind Trencher in Texas?

The rental rates for Walk-Behind Trenchers in Texas typically range from $150 to $250 per day.

When should I use a Ride-On Trencher?

Ride-On Trenchers are designed for more extensive tasks and are capable of excavating deeper and wider trenches, making them especially suitable for utility installations that require larger trench dimensions.

What are Chain Trenchers best suited for?

Chain Trenchers are built for heavy-duty tasks and excel in cutting through tough soil conditions, making them perfect for commercial endeavors that demand strong performance and dependability.

What type of soil is best for Wheel Trenchers?

Wheel Trenchers are best suited for softer soils, providing a clean cut and efficiency for larger trenching jobs.

How can understanding trench digging equipment help project managers?

By comprehending trench digging equipment rental tools, managers can make informed choices that align with their specific requirements, ensuring optimal performance and efficiency.

What should be considered when comparing Walk-Behind and Ride-On Trenchers?

When comparing Walk-Behind and Ride-On Trenchers, managers should consider the scale of the job and budget considerations to select the appropriate equipment.