Overview

The article outlines four essential steps for successful hydraulic breaker rental. It emphasizes the importance of:

- Selecting the right type of breaker

- Ensuring compatibility with equipment

- Evaluating project requirements

- Navigating the rental process effectively

Each step is supported by practical considerations, such as:

- Matching tool specifications to project needs

- Understanding lease agreements

These elements collectively enhance the efficiency and success of construction and demolition projects.

Key Highlights:

- Hydraulic breakers are vital tools in construction and demolition, designed to break tough materials like concrete and rock.

- Types of hydraulic breakers include Side Type Breakers for confined spaces, Top Type Demolishers for heavy tasks, Silent Breakers for noise-sensitive areas, and Underwater Devices for marine construction.

- Selecting the right hydraulic breaker involves considering compatibility with carrier machines, application needs, and tool durability.

- Key factors for hydraulic breaker rental include size, weight, and power needs, ensuring tools align with project requirements for optimal performance.

- Proper compatibility between the breaker and excavator is crucial, with guidelines suggesting the breaker should not exceed 10% of the carrier's weight.

- Navigating the rental process requires understanding lease conditions, comparing costs, reviewing agreements, and inspecting tools for damage.

- Leasing options can be beneficial for small-scale construction firms due to the high upfront costs of hydraulic tools.

Introduction

In the construction and demolition industry, hydraulic breakers are indispensable tools that revolutionize the handling of challenging materials such as concrete and rock. With a range of types available, each tailored for specific applications, grasping the intricacies of these machines is essential for project success.

For instance, side-type breakers are particularly effective in confined urban environments, while silent models are perfect for noise-sensitive areas. The selection process, though complex, can yield significant rewards when approached thoughtfully.

As technology advances, construction managers face the challenge of navigating compatibility, project requirements, and rental agreements to ensure optimal performance and cost-effectiveness.

This article explores the fundamental aspects of hydraulic breakers, providing insights that empower professionals to make informed decisions in their construction projects.

Understand Hydraulic Breakers: Types and Functions

Hydraulic hammers, commonly referred to as hammers, are essential tools in the construction and demolition sectors, engineered to effectively break through tough materials such as concrete and rock. It is imperative to understand the different types of hydraulic breakers available to select the most suitable equipment for specific applications.

- Side Type Breakers are mounted on the side of excavators, making them particularly effective in confined spaces. Their design provides excellent visibility of the work area, which is especially advantageous in urban settings where space is at a premium.

- Conversely, Top Type Demolishers are positioned atop the excavator, designed for larger tasks that demand enhanced stability and strength. These are typically utilized in heavy demolition activities, where robust performance is crucial.

- In addition, Silent Breakers are engineered to operate quietly, making them ideal for use in residential areas or other noise-sensitive environments. Their reduced noise output significantly minimizes disruption during construction operations.

- Furthermore, Underwater Devices are tailored for marine construction, adeptly handling the unique challenges presented in submerged conditions.

Each type of impact tool possesses distinct characteristics that cater to various operational needs. Selecting the right tool requires consideration of compatibility with carrier machines, application demands, and durability. A case analysis on tool selection illustrates that informed decisions lead to optimal performance and prevent equipment damage, ultimately resulting in successful project outcomes. This case study highlights how a construction manager evaluated different options, ultimately choosing a pressure-driven tool that aligned with the project’s specific needs, thereby enhancing efficiency and reducing costs.

As we progress towards 2025, advancements in impactor technology are continuously evolving, further improving their efficiency and effectiveness across diverse construction scenarios. The market currently offers a wide array of impact tool types, with the inner valve type and outer valve type being the most prevalent. According to a Site Editor, "The device for breaking rock has two varieties namely inner valve type and outer valve type." Notably, brands like Soosan represent the inner valve type, while Furukawa is recognized for the outer valve type. Understanding these distinctions not only aids in effective planning but also ensures that construction managers can employ the appropriate tools for their specific tasks. Additionally, the substantial upfront costs associated with fluid-powered tools may limit their accessibility for small-scale construction firms, making leasing options an appealing alternative.

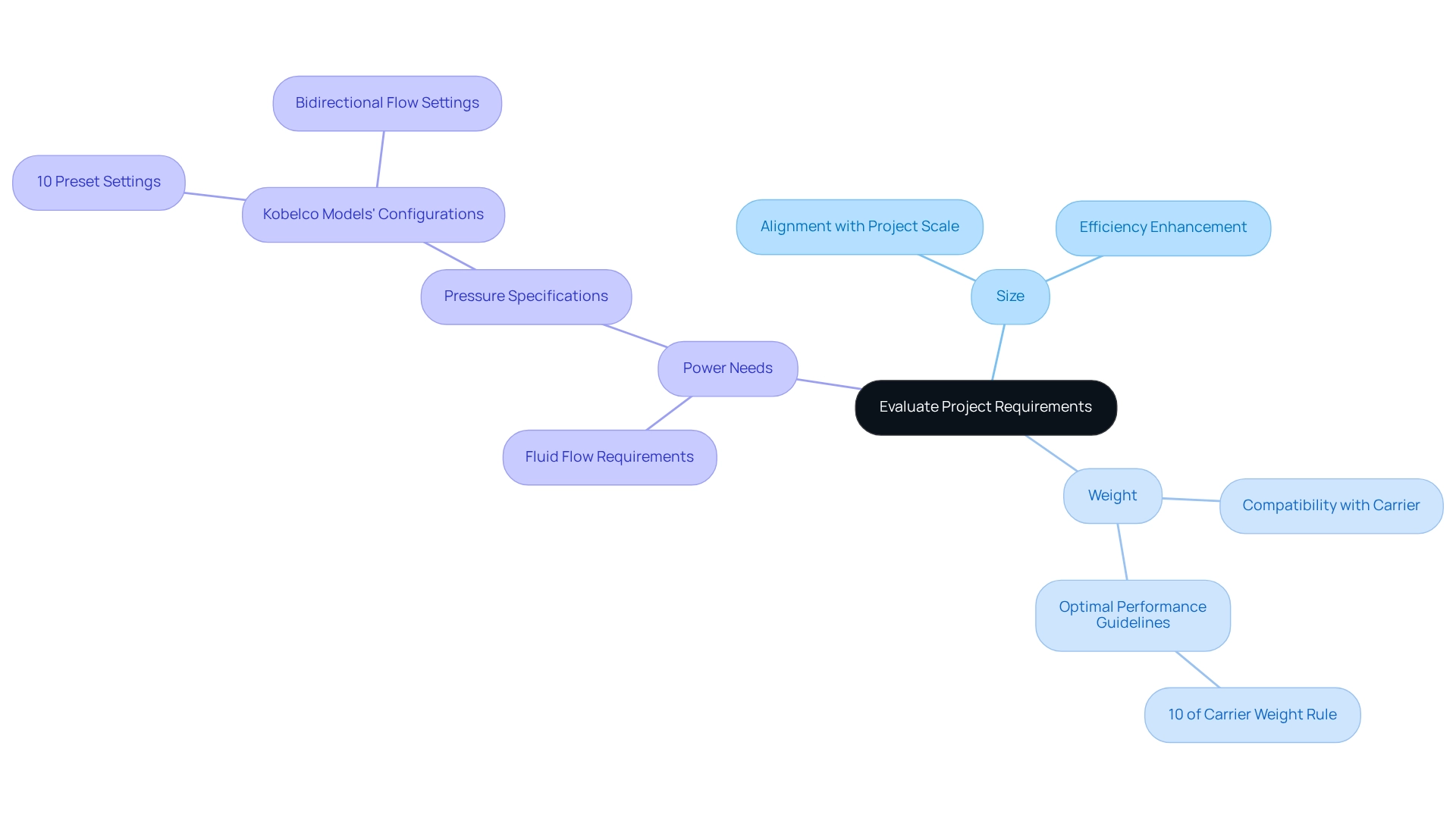

Evaluate Project Requirements: Size, Weight, and Power Needs

To ensure a successful hydraulic breaker rental, it is essential to thoroughly assess your needs. Key factors to consider include:

- Size: The dimensions of the hydraulic tool must align with the scale of your project. Larger construction tasks typically require more powerful tools, whereas smaller jobs can be effectively managed with lighter models. Project managers often emphasize the importance of selecting the correct size, noting that a suitably sized circuit interrupter enhances efficiency and reduces operational strain.

- Weight: Compatibility between the demolition tool and the excavator or carrier is critical. A general guideline is that the circuit interrupter should not exceed 10% of the carrier's weight, ensuring optimal performance and safety during operation. For instance, if your excavator weighs 10,000 pounds, the attachment should ideally weigh no more than 1,000 pounds. Statistics indicate that as project sizes increase, the demand for appropriately weighted tools also rises, making this factor vital.

- Power Needs: Assessing the fluid flow and pressure requirements of the breaker is crucial. Ensure that your excavator can deliver the necessary fluid power for effective operation. Most equipment specifications or user manuals provide this information. For example, all Kobelco models come equipped with 10 preset fluid flow and pressure configurations, allowing for customized performance based on specific requirements.

Given the growing reliance on mechanical tools in the construction and mining industries, as highlighted by recent market research, making informed leasing decisions, particularly regarding hydraulic breaker rental, is more important than ever. As Southeastern Equipment asserts, "Don’t leave your productivity to chance — partner with Southeastern Equipment to ensure you’re always equipped with the best tools for the job."

By carefully evaluating these elements, you can select a mechanical tool that not only meets your task requirements but also enhances efficiency and safety on site. Expert guidance suggests that understanding the specific needs of your project is essential for making an informed decision regarding hydraulic breaker rental, ultimately leading to successful outcomes.

Ensure Compatibility: Matching Breakers with Equipment

To ensure the successful functioning of fluid-powered tools in your projects, confirming compatibility with your equipment is essential. Begin by reviewing the specifications of both the demolition hammer and the excavator. Pay close attention to fluid flow rates, pressure requirements, and weight limits, as these factors are critical for optimal performance. Typical flow rates for excavators in the DFW region generally vary from 15 to 30 gallons per minute, corresponding with numerous attachment specifications.

Always refer to the manufacturer's instructions for both the circuit interrupter and the excavator. These documents typically include recommendations for compatible equipment combinations, which can save time and prevent costly errors. Furthermore, if possible, perform a trial operation with the power tool connected to the excavator. This practical step allows you to observe their interaction and identify any potential issues before commencing actual work, ensuring a smoother operation.

By following these guidelines, you can improve the effectiveness and safety of your hydraulic tool operations, ultimately aiding the success of your construction endeavors. Successful combinations, such as pairing a 3,000-pound breaker with a 20,000-pound excavator, have proven effective in various projects. The recent MYCON development in Mesquite illustrates this, as the compatibility of equipment played a crucial role in the initiative's success. As Michael Swick, Senior Vice President of H. J. Russell & Company, emphasizes, "Ensuring the right equipment match is vital for maximizing productivity and minimizing downtime in construction projects.

Navigate the Rental Process: Terms, Costs, and Agreements

To effectively hire a powerful hydraulic breaker rental, navigating the leasing process is essential.

- Understand Lease Conditions: Begin by familiarizing yourself with the lease terms, which include the duration of the agreement, maintenance responsibilities, and any penalties for late returns. It is crucial to clarify these terms with the leasing company, such as EZ Equipment Rental, which is known for providing a variety of equipment including hydraulic breaker rental, trailers, and forklifts that can significantly enhance your project efficiency.

- Compare Costs: Next, obtain quotes from various leasing firms to evaluate costs comprehensively. Consider not only the leasing price but also any additional fees, such as delivery charges or insurance costs. Renting equipment like trailers can save you both time and money, making it a cost-effective choice for your projects.

- Review the Rental Agreement: Before signing, it is imperative to carefully review the rental agreement. Ensure that it encompasses all agreed-upon terms and conditions. If anything is unclear, do not hesitate to ask questions. Understanding the advantages of leasing equipment can empower you to make informed choices that enhance the success of your endeavor.

- Examine the Tools: Prior to acquiring the equipment, inspect it for any damage or deterioration. Document any existing issues to prevent disputes upon returning the equipment. Ensuring that the equipment is in good condition is vital for maintaining efficiency on your job site, and by following these steps, you can navigate the rental process with ease to secure a successful hydraulic breaker rental experience, ultimately maximizing both efficiency and cost-effectiveness in your construction projects.

Conclusion

Selecting the right hydraulic breaker is a pivotal decision in the construction and demolition industry. Understanding the various types of breakers—such as side-type, top-type, silent, and underwater models—enables professionals to choose equipment that aligns with specific project needs. The case study highlighted within the article illustrates how thoughtful selection can enhance efficiency and reduce costs, underscoring the importance of matching the right tool to the task at hand.

Moreover, evaluating project requirements, including size, weight, and power needs, is crucial for ensuring optimal performance. As the article emphasizes, compatibility between the hydraulic breaker and the excavator is essential for safe and effective operation. By adhering to manufacturer guidelines and conducting compatibility tests, project managers can avoid costly errors and maximize productivity on site.

Navigating the rental process effectively can further enhance project success. By understanding rental terms, comparing costs, reviewing agreements, and inspecting equipment, construction professionals can ensure that they are well-equipped for the challenges ahead. With the continued evolution of hydraulic breaker technology, staying informed about the latest advancements and rental options can lead to improved outcomes and greater efficiency in construction projects.

In conclusion, the strategic selection and management of hydraulic breakers not only contribute to the success of individual projects but also play a significant role in optimizing overall operational efficiency in the construction industry. Embracing these insights will empower professionals to make informed decisions that drive project success and deliver exceptional results.

Frequently Asked Questions

What are hydraulic hammers used for?

Hydraulic hammers, commonly referred to as hammers, are essential tools in the construction and demolition sectors, engineered to effectively break through tough materials such as concrete and rock.

What are the different types of hydraulic breakers available?

The main types of hydraulic breakers include:\n- Side Type Breakers: Mounted on the side of excavators, effective in confined spaces with excellent visibility.\n- Top Type Demolishers: Positioned atop the excavator for larger tasks requiring enhanced stability and strength.\n- Silent Breakers: Operate quietly, ideal for residential areas or noise-sensitive environments.\n- Underwater Devices: Tailored for marine construction, handling challenges in submerged conditions.

How should one select the appropriate hydraulic breaker?

Selecting the right hydraulic breaker requires consideration of compatibility with carrier machines, application demands, and durability. Informed decisions lead to optimal performance and prevent equipment damage.

Can you provide an example of effective tool selection?

A case study illustrated how a construction manager evaluated different hydraulic breaker options, ultimately choosing a pressure-driven tool that aligned with the project’s specific needs, enhancing efficiency and reducing costs.

What advancements are expected in hydraulic breaker technology by 2025?

Advancements in impactor technology are continuously evolving, improving efficiency and effectiveness across diverse construction scenarios.

What are the most prevalent types of impact tools in the market?

The most prevalent types of impact tools are the inner valve type and outer valve type. Brands like Soosan represent the inner valve type, while Furukawa is recognized for the outer valve type.

What are the considerations regarding the costs of hydraulic tools?

The substantial upfront costs associated with fluid-powered tools may limit accessibility for small-scale construction firms, making leasing options an appealing alternative.