Overview

Selecting the right asphalt rental equipment requires a systematic approach. First, assess your project requirements to identify the specific equipment needed. Next, evaluate your budget alongside rental costs to ensure financial feasibility. It is crucial to locate reputable rental providers who can meet your needs. Understanding the various types of equipment available is essential to making an informed decision. Defining the project scope will further clarify which machinery aligns with your goals.

Conducting thorough research on rental options is paramount. Look for providers that offer reliable and high-quality equipment, as this can significantly impact your project's success. Testimonials from satisfied customers can provide insights into the reliability of the equipment and the service quality of the rental provider. By emphasizing these factors, you can ensure that your selection process is both effective and efficient.

In conclusion, choosing the right asphalt rental equipment is a critical step in achieving project success. By following these steps—assessing requirements, evaluating costs, and researching providers—you can confidently select machinery that fits your budget and project scope. Take action today by reaching out to reputable rental providers to discuss your equipment needs.

Key Highlights:

- Asphalt paving requires specialized equipment including paving machines, rollers, milling machines, compactors, and sealcoating equipment.

- Paving machines are crucial for spreading asphalt evenly; demand is increasing in the Asia-Pacific region due to road construction investments.

- Rollers compact the pavement and come in various types to meet specific density needs.

- Milling machines remove old pavement layers to prepare for new asphalt installation.

- Compactors ensure asphalt density, available in hand-held and machine-operated forms.

- Sealcoating equipment applies protective sealants to extend pavement lifespan.

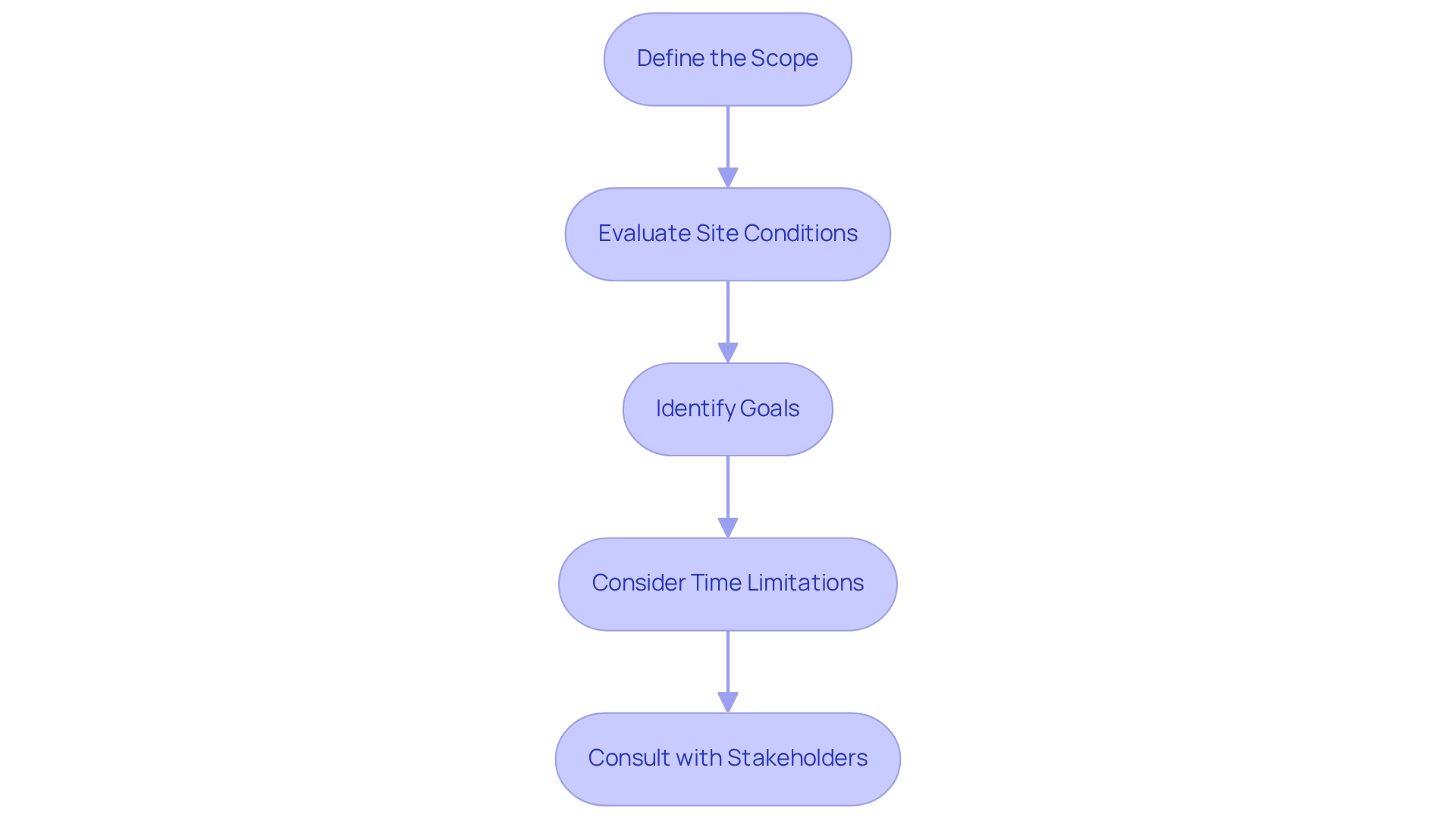

- Project assessment involves defining the scope, evaluating site conditions, identifying goals, considering timelines, and consulting stakeholders.

- Budgeting for equipment rentals includes determining overall costs, researching leasing options, considering rental duration, accounting for maintenance, and evaluating cost versus benefit.

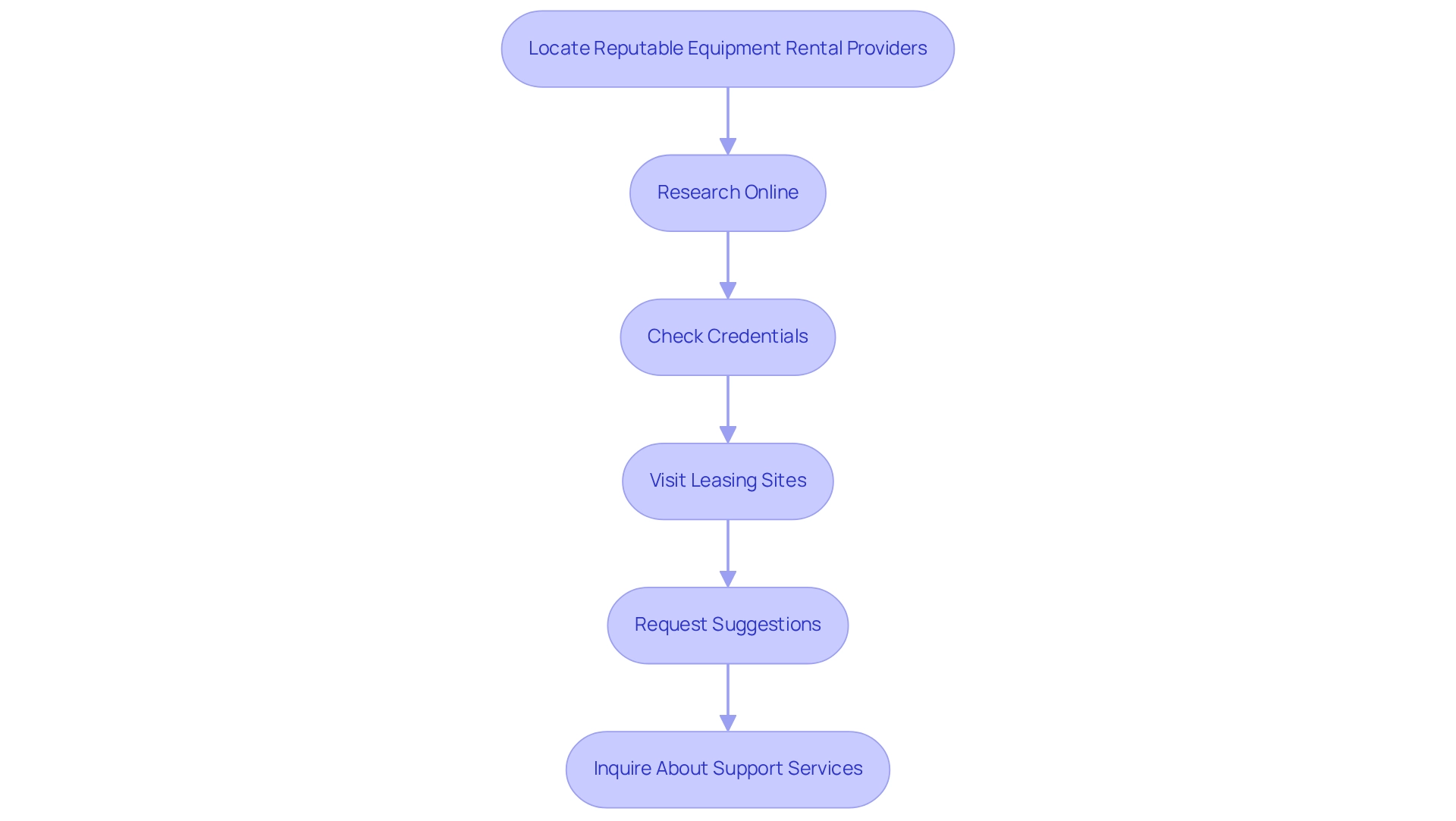

- Finding reputable rental providers involves researching online, checking credentials, visiting sites, seeking referrals, and inquiring about support services.

Introduction

Navigating the world of asphalt paving can be a daunting task, particularly given the multitude of equipment options available. Each piece of machinery plays a crucial role in ensuring projects are completed efficiently and to the highest standards. From asphalt pavers that lay the groundwork to rollers that compact the surface, understanding the different types of equipment is essential for any paving endeavor.

Furthermore, assessing project requirements, evaluating budgets, and locating reputable rental providers are pivotal steps that significantly influence the success of a project. This article delves into these critical aspects, providing insights that empower readers to make informed decisions in their asphalt paving ventures.

Understand Different Types of Asphalt Equipment

Asphalt paving encompasses a range of specialized equipment, each tailored for distinct tasks. Understanding these categories is crucial for selecting the right tools for your needs.

Paving Machines are essential for spreading the asphalt mixture evenly across the surface, ensuring a smooth finish. Available in various sizes and configurations—both tracked and wheeled—these machines are vital in the paving process. Notably, the Asia-Pacific region is expected to witness substantial growth in the demand for paving machines, driven by increased public and private investments in road construction.

Rollers play a critical role in compacting the pavement after it has been laid. They come in different types, including static, vibratory, and pneumatic, each designed to meet specific compaction requirements. This versatility ensures that the pavement achieves the necessary density for durability.

Milling Machines are indispensable for removing old pavement layers before new material is applied. This process prepares the surface effectively, facilitating a seamless installation of fresh asphalt. Additionally, Compactors are crucial for achieving the required density in the pavement. Available in both hand-held and machine-operated forms, they ensure that the asphalt is compacted to meet industry standards.

Sealcoating Equipment is utilized to apply a protective sealant over paved surfaces, significantly extending their lifespan and enhancing their appearance. A case study highlights the important distinction between resurfacing and sealcoating: resurfacing involves adding a new layer of pavement over an existing surface, while sealcoating serves as a maintenance layer to protect and preserve, which can be achieved using asphalt rental equipment. By familiarizing yourself with these equipment categories, you can make informed decisions that cater to your specific paving needs. Furthermore, a report by Fact.MR underscores the importance of understanding price points from key producers of paving machines, crucial for navigating the competitive landscape of paving equipment. Engage with us today to explore the best options for your project.

Assess Your Project Requirements

To effectively evaluate your project needs for paving, it is essential to follow these crucial steps:

- Define the Scope: Begin by clearly outlining the size of the area to be paved. Specify the type of asphalt work required—whether it’s new paving, resurfacing, or repairs. This foundational step sets the stage for a successful project.

- Evaluate Site Conditions: Conduct a thorough analysis of the terrain, soil type, and existing pavement conditions. These factors significantly influence the selection of appropriate asphalt rental equipment. Understanding site conditions is crucial for operational efficiency. EZ Equipment Rental offers a diverse range of machinery, including boom lifts, excavators, and forklifts, tailored to meet various requirements in the DFW Metroplex.

- Identify Goals: Establish your objectives for the initiative, focusing on critical aspects such as durability, aesthetics, and the required traffic load capacities. Clearly defined goals will guide your decision-making process.

- Consider Time Limitations: Evaluate the schedule for task completion, as this will directly influence the type and amount of resources required to meet deadlines. A realistic timeline is vital for project success.

- Consult with Stakeholders: Engage with team members and clients to gather insights on expectations and requirements. This collaborative approach ensures that all perspectives are taken into account, fostering a comprehensive understanding of project needs, which includes the selection of asphalt rental equipment. By meticulously evaluating these factors, you can determine the most suitable asphalt rental equipment for your paving project, ultimately enhancing both efficiency and effectiveness.

Evaluate Budget and Rental Costs

When evaluating your budget and rental costs for asphalt equipment, it is essential to follow these guidelines:

- Determine Your Budget: Establish a comprehensive budget that encompasses all associated costs, including transportation, insurance, and potential damages. This thorough approach ensures you consider every aspect of the leasing process.

- Research Leasing Costs: Conduct thorough comparisons of leasing rates from various providers to identify competitive pricing. Be vigilant about additional fees that may not be immediately apparent, as these can significantly impact your overall costs. As noted by The Cat Rental Store, "By selecting a provider with a broad selection across various locations, you’ll be much more likely to find the specialized tools you require when you require them without having to pay elevated rates."

- Consider Rental Duration: Assess the duration for which you will need the equipment. Extended lease durations frequently include discounts, whereas short-term agreements might incur elevated daily charges. Understanding your project timeline can enhance your leasing strategy.

- Account for Maintenance Costs: Factor in any maintenance or operational costs that may arise during the rental period, such as fuel, wear and tear, and routine maintenance. These expenses can accumulate and should be included in your budget evaluation.

- Evaluate Cost vs. Benefit: Consider the costs of renting compared to the advantages of using high-quality tools. Investing slightly more in reliable machinery can lead to significant savings in the long run by minimizing downtime and enhancing project efficiency.

Current trends indicate that typical expenses for asphalt rental equipment leasing in Texas are influenced by seasonal demand, with usage rates reaching around 50% during peak times. Furthermore, public leasing companies remain cautiously optimistic about the remainder of 2025, citing steady demand in infrastructure and non-residential construction. By thoroughly assessing these factors, you can ensure that your machinery leasing aligns with your budget and project objectives, ultimately resulting in successful paving endeavors.

For additional details and to book gear, reach out to EZ Equipment Rental at (214) 951-7800.

Locate Reputable Equipment Rental Providers

To find trustworthy equipment leasing providers, consider the following steps:

- Research Online: Utilize online platforms to identify leasing companies in your area. Pay close attention to customer feedback and ratings; these insights can reveal the reliability and quality of service offered by different providers.

- Check Credentials: Verify that the leasing company is properly licensed and insured. This step is essential for safeguarding yourself from liability in the event of accidents or device malfunctions.

- Visit Leasing Sites: Whenever feasible, visit leasing sites to examine the tools directly. This enables you to evaluate the professionalism of the company and the state of the tools, as well as to measure the quality of customer service offered.

- Request Suggestions: Contact colleagues or industry connections who have experience with gear leasing. Personal referrals can lead you to trustworthy providers who have a proven track record.

- Inquire About Support Services: Choose a leasing provider that offers comprehensive support services, including maintenance and emergency assistance. Leasing from a reputable business like EZ Equipment Rental guarantees you obtain well-maintained forklifts, boom lifts, and mini excavators. Their machinery undergoes regular upkeep, which decreases the likelihood of failures during essential operations. Furthermore, their team provides prompt support to address any issues related to asphalt rental equipment, minimizing downtime and ensuring you have access to help should any problems arise during your rental period.

By following these steps, you can effectively identify a reputable asphalt rental equipment provider that aligns with your project requirements, facilitating a seamless rental experience.

Conclusion

Understanding the various types of asphalt equipment is essential for successful paving projects. Each machine, from asphalt pavers to rollers, plays a specific role that impacts efficiency and quality. Familiarity with these tools enables project managers to make informed decisions, ensuring that every aspect of the project is optimized for success.

Assessing project requirements is crucial in selecting the right equipment. By defining the project scope, evaluating site conditions, and consulting with stakeholders, one can ensure that the chosen machinery aligns with project goals and timelines. This strategic alignment streamlines the process, leading to better results and enhanced productivity.

Budget considerations are vital when renting equipment. Establishing a comprehensive budget, researching rental rates, and understanding all associated costs can significantly influence financial success. Balancing cost against the benefits of high-quality machinery leads to strategic decisions that enhance efficiency and save money in the long run, ultimately maximizing the return on investment.

Finally, locating reputable rental providers is key to securing reliable equipment. Conducting thorough research, checking credentials, and seeking recommendations helps identify trustworthy sources that offer well-maintained machinery and excellent customer support. This diligence ensures a smooth rental experience, allowing projects to proceed without unnecessary delays.

In summary, navigating the asphalt paving landscape involves understanding equipment types, assessing project needs, strategically budgeting, and finding reputable rental providers. By focusing on these critical areas, individuals can enhance their paving projects and achieve high-quality results that stand the test of time.

Frequently Asked Questions

What is asphalt paving equipment used for?

Asphalt paving equipment encompasses specialized tools designed for various tasks involved in the paving process, ensuring the proper application, compaction, and maintenance of asphalt surfaces.

What are paving machines and why are they important?

Paving machines are essential for spreading asphalt mixture evenly across surfaces to ensure a smooth finish. They come in various sizes and types, including tracked and wheeled configurations, and are crucial for the paving process.

What role do rollers play in asphalt paving?

Rollers are critical for compacting the pavement after it has been laid. They come in different types—static, vibratory, and pneumatic—each suited to meet specific compaction requirements, ensuring the pavement achieves necessary density for durability.

How do milling machines contribute to the paving process?

Milling machines are used to remove old pavement layers before new material is applied, effectively preparing the surface for a seamless installation of fresh asphalt.

What are compactors and what is their purpose?

Compactors are essential for achieving the required density in asphalt pavement. They come in hand-held and machine-operated forms to ensure the asphalt is compacted to meet industry standards.

What is the function of sealcoating equipment?

Sealcoating equipment applies a protective sealant over paved surfaces to extend their lifespan and enhance their appearance. It serves as a maintenance layer to protect and preserve the pavement.

What is the difference between resurfacing and sealcoating?

Resurfacing involves adding a new layer of pavement over an existing surface, while sealcoating serves as a maintenance layer to protect and preserve the pavement.

Why is it important to understand the price points of paving machines?

Understanding price points from key producers of paving machines is crucial for navigating the competitive landscape of paving equipment and making informed purchasing decisions.