Overview

Leasing an air compressor for your construction project involves four key steps:

- Assessing your needs

- Researching rental firms

- Requesting quotes

- Inspecting the equipment upon delivery

This process not only ensures that you select the right equipment tailored to your project but also highlights the significant benefits of cost-effectiveness, flexibility, and access to maintenance services that leasing provides. Ultimately, these advantages enhance project efficiency and reduce operational challenges.

In addition, understanding your specific requirements is crucial. By thoroughly assessing your needs, you can identify the appropriate air compressor that meets the demands of your project. Researching rental firms allows you to compare options and select a reliable provider that aligns with your expectations for service and equipment quality. Furthermore, requesting quotes enables you to evaluate pricing and terms, ensuring you make an informed decision.

Finally, inspecting the equipment upon delivery is essential to guarantee its condition and functionality. This step not only ensures that you receive quality equipment but also reinforces the reliability of your chosen rental firm. By following these steps, you position yourself for success in your construction project, leveraging the advantages of leasing to overcome challenges effectively.

Key Highlights:

- Leasing air compressors is cost-effective, allowing for lower initial expenses and resource allocation to other needs.

- Flexible leasing agreements can be tailored to project timelines, avoiding long-term commitments.

- Leasing provides access to the latest technology, such as the GA FLX dual-speed screw device, enhancing energy efficiency.

- Many leasing contracts include maintenance services, reducing downtime and operational challenges.

- Key steps for leasing include assessing needs, researching rental firms, requesting quotes, and inspecting equipment upon delivery.

- Critical factors for leasing decisions include task duration, budget constraints, equipment specifications, rental firm reputation, maintenance support, and flexibility of terms.

- Common leasing challenges include unexpected costs, maintenance issues, miscommunication, insufficient equipment, and late returns, all of which can be mitigated through proactive measures.

Introduction

In the construction industry, where efficiency and cost-effectiveness reign supreme, the choice to lease an air compressor can profoundly influence project success. As projects become increasingly complex and lengthy, project managers must grasp the nuances of leasing. The advantages are compelling:

- Lower upfront costs

- Flexibility of customized leasing agreements

- Access to state-of-the-art technology

- Included maintenance services that boost productivity

- Minimized downtime

This article explores the critical elements of air compressor leasing, offering a thorough guide that equips decision-makers to navigate the leasing landscape with confidence and clarity.

Understand Air Compressor Leasing Basics

Renting an air device presents numerous advantages over purchasing, particularly for construction projects. Consider the following essential points:

- Cost-Effectiveness: Leasing typically incurs lower initial costs compared to buying, allowing you to allocate resources to other critical needs. In 2025, a cost analysis comparing leasing and purchasing air devices highlights substantial savings, especially with models like the GA 37+-45+, which feature a power range of 30-45 kW (40-75 hp). This makes leasing a financially sound choice.

- Flexibility: Leasing agreements can be tailored to fit your project timeline, offering the necessary equipment without the constraints of a long-term commitment. This flexibility is vital in the ever-changing landscape of construction.

- Access to Latest Technology: Leasing affords you the opportunity to utilize cutting-edge models, such as the GA FLX dual-speed screw device, known for its energy efficiency and operational effectiveness. As stated by Atlas Copco, "The GA FLX was developed and built to give you double-digit energy savings no fixed-speed compressor can, pressure setting flexibility, and optimal flow at any pressure." This ensures that you have reliable and efficient tools at your disposal without the responsibilities of ownership.

- Maintenance and Support: Many leasing agreements come with maintenance services, reducing operational challenges and minimizing downtime. This support ensures that your equipment remains in optimal condition, enhancing overall productivity. The inclusion of maintenance in lease contracts is a significant advantage, allowing you to focus on your work without the burden of equipment upkeep.

Understanding these key factors can empower you to make informed decisions regarding whether renting is the best choice for your construction endeavor. Furthermore, the case study titled 'GA FLX Air Solution: A New Approach' illustrates that businesses can realize substantial energy savings and improved performance by adopting the GA FLX device, further reinforcing the benefits of leasing.

Follow the Step-by-Step Leasing Process

To rent an air device, follow these steps:

- Assess Your Needs: Begin by determining the specifications required for your project. This includes identifying the type of compressor, power source, and airflow requirements. Understanding these elements is crucial for selecting the right equipment.

- Research Rental Firms: Next, look for reputable rental firms in your area. Companies like EZ Equipment Rental are known for their expert guidance and support in selecting the right gear, including towable and diesel models.

- Request Quotes: Reach out to multiple companies to obtain quotes tailored to your specific needs. It’s essential to understand the terms, including payment schedules and maintenance options. The knowledgeable staff at EZ Equipment Rental can assist with common inquiries, such as equipment compatibility and rental duration, including how to lease air compressor equipment, while you carefully review the lease agreement, paying close attention to the duration, costs, and any additional fees. Clarify any uncertainties with the leasing company. Once you are satisfied with the conditions, sign the lease air compressor contract and arrange for the delivery of the air compressor to your work location.

- Inspect the Equipment: Upon delivery, take the time to examine the air compressor thoroughly. Ensure it meets your specifications and is in good working order before use. This step is vital to guarantee that the equipment performs reliably throughout your project.

Evaluate Key Factors for Leasing Decisions

When considering a lease air compressor, several critical factors must be evaluated to ensure optimal decision-making.

- Task Duration: Understanding the length of your endeavor is essential. Temporary projects often benefit more from renting, as it offers flexibility without the long-term commitment of purchasing equipment. Conversely, for long-term projects, consider the overall cost of renting compared to buying. The construction and demolition waste management sector plays a vital role in minimizing environmental impacts, and comprehending timeframes can aid in making informed rental decisions.

- Budget Constraints: Establish a clear budget for renting. Monthly payments should align with your financial plan, factoring in the potential for unexpected costs. It’s crucial to consider the average duration of the lease air compressor, which typically ranges from a few weeks to several months, depending on the scope of work. Notably, metal prices have risen by an average of 4.5% each year over the last decade, influencing overall expenses and budget considerations.

- Equipment Specifications: Ensure that the air compressor meets your project's specific requirements, including the necessary pressure and airflow. This is vital for maintaining efficiency and productivity on-site. Consider modern technologies such as Variable Speed Drive (VSD) technology, which automatically adjusts the compressor's motor speed to meet compressed air demand in real time, saving energy and costs.

- Reputation of the Rental Firm: Investigate the rental company's reliability and customer support. Look for reviews and testimonials from previous clients to assess their experiences. A reputable company can significantly impact your project's success. As Vincent Cerniglia from Noreast Capital Corporation states, "Trust Noreast Capital to be your ally in navigating the complexities of asset rental and achieving your business objectives."

- Maintenance and Support: Clarify what maintenance services are included in the lease air compressor agreement. Quick access to assistance in case of equipment failure can prevent costly downtime, making this a crucial consideration.

- Flexibility of Terms: Explore whether the rental company offers flexible terms. The ability to adjust lease length or change equipment types as needs evolve can provide substantial benefits, particularly in dynamic construction environments. North America's dominance in construction composites reflects strong demand and market activity, underscoring the importance of dependable equipment rental in supporting robust construction operations.

By thoughtfully assessing these elements, construction managers can make informed rental choices that align with their objectives and financial constraints.

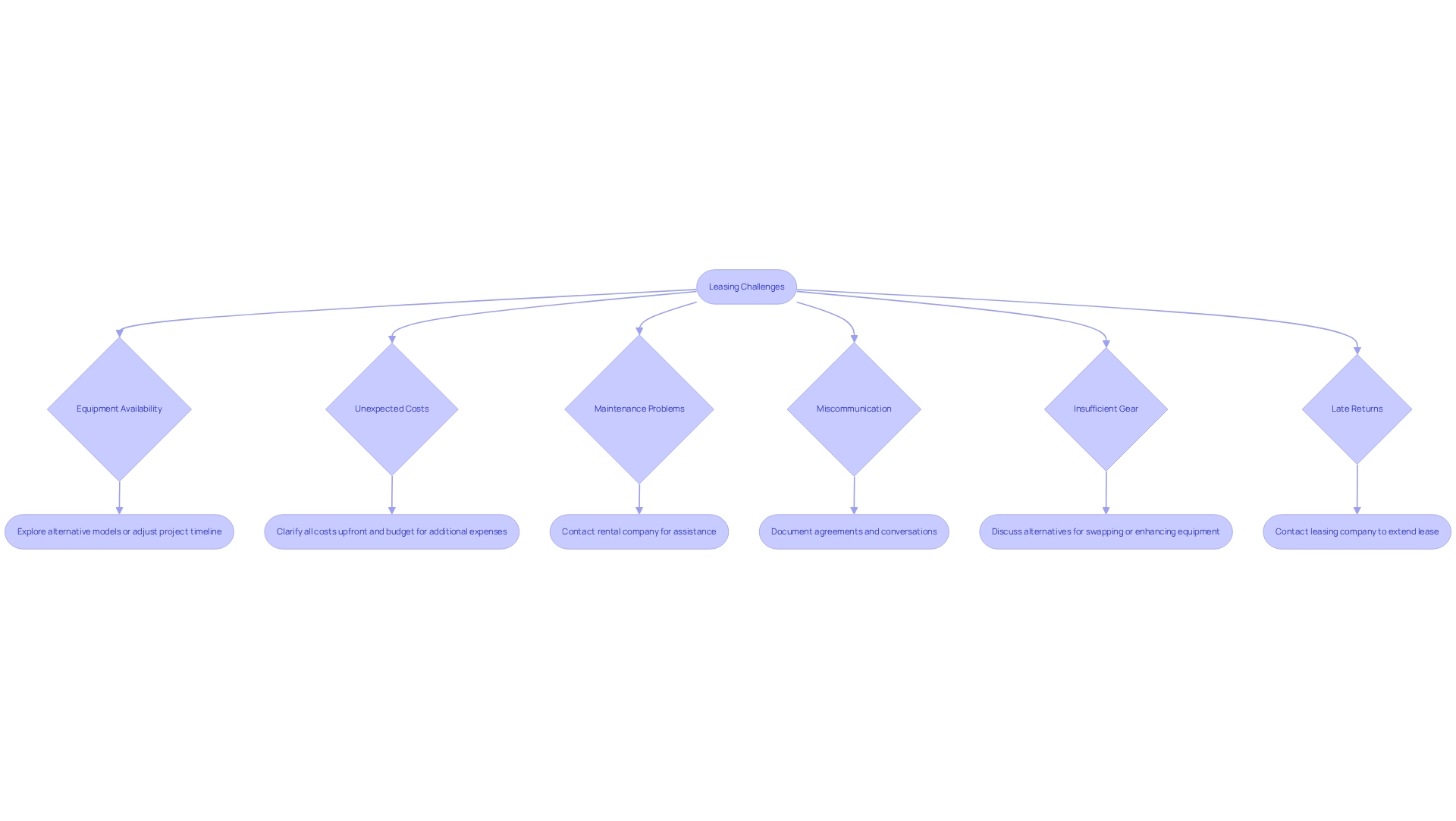

Troubleshoot Common Leasing Challenges

Leasing an air compressor can present several challenges, but understanding how to troubleshoot them can ensure a smooth lease air compressor experience. Equipment availability is crucial; when the desired machine is unavailable, consider exploring alternative models or adjusting your project timeline to better align with availability. This proactive approach can mitigate delays and keep your project on track.

- Unexpected Costs: Hidden fees in lease agreements can catch you off guard. It is essential to clarify all costs upfront and budget for any potential additional expenses to avoid surprises later on.

- Maintenance Problems: Should the unit encounter difficulties during the rental period, promptly reach out to the rental company for assistance. Familiarize yourself with the process for reporting and resolving maintenance issues to minimize downtime.

- Miscommunication with the Rental Company: Clear communication with the rental company is crucial throughout the leasing process. Document all agreements and conversations to prevent misunderstandings and ensure a smooth transaction.

- Insufficient Gear for Project Demands: If the machine fails to meet your project specifications, engage with the rental company to discuss alternatives for swapping or enhancing the equipment. This dialogue can help you secure the right tools for your needs.

- Late Returns: If you foresee needing the compressor longer than initially planned, contact the leasing company as soon as possible to discuss extending the lease. This proactive measure to lease air compressor can help you avoid incurring late fees and ensure uninterrupted project progress.

Conclusion

Leasing an air compressor stands out as a strategic choice for construction projects, presenting substantial advantages that enhance efficiency and lower costs. The key benefits—including reduced upfront expenses, flexible agreements, and access to cutting-edge technology—make leasing an appealing option for project managers navigating intricate job sites. Furthermore, included maintenance services not only relieve operational burdens but also guarantee that equipment remains in optimal condition, directly influencing productivity.

The leasing process is straightforward, involving a meticulous assessment of project needs, thorough research on leasing companies, and a comprehensive review of agreements. By adhering to this structured approach, decision-makers can secure the right equipment tailored to their specific requirements. Evaluating crucial factors such as project duration, budget constraints, and the reputation of leasing companies empowers managers to make informed choices that align with their project goals.

While challenges such as equipment availability and unexpected costs may arise, proactive communication and meticulous planning can effectively mitigate these issues. Ultimately, leasing air compressors offers a compelling solution for construction firms, merging financial prudence with operational flexibility. By embracing this approach, businesses not only streamline project execution but also position themselves to adapt to the ever-evolving demands of the construction landscape, ensuring long-term success and sustainability.

Frequently Asked Questions

What are the main advantages of renting an air device for construction projects?

The main advantages include cost-effectiveness, flexibility, access to the latest technology, and maintenance support.

How does renting compare to purchasing in terms of cost?

Renting typically incurs lower initial costs compared to purchasing, allowing for better allocation of resources. A cost analysis in 2025 shows substantial savings when leasing air devices, particularly models like the GA 37+-45+.

What flexibility does leasing offer for construction projects?

Leasing agreements can be customized to fit project timelines, providing necessary equipment without the long-term commitment associated with purchasing.

What benefits come from accessing the latest technology through leasing?

Leasing allows you to use advanced models like the GA FLX dual-speed screw device, which offers energy efficiency and operational effectiveness, ensuring reliable tools without ownership responsibilities.

How does leasing provide maintenance and support?

Many leasing agreements include maintenance services, reducing operational challenges and minimizing downtime, allowing you to focus on your work without worrying about equipment upkeep.

What does the case study 'GA FLX Air Solution: A New Approach' illustrate?

The case study demonstrates that businesses can achieve substantial energy savings and improved performance by adopting the GA FLX device, highlighting the benefits of leasing.