Overview

This article presents four essential steps for effectively renting an asphalt crack filler machine:

- Define your project requirements.

- Estimate the rental duration to ensure that you have the machine for the necessary timeframe.

- Establish a comprehensive budget to manage costs effectively.

- Confirm the worksite location to guarantee that the equipment will be delivered to the right place.

Supporting these steps are detailed considerations that enhance the rental process:

- Choosing the right machine type is fundamental to achieving optimal results in your asphalt repair projects.

- Understanding the rental process will streamline your experience, making it easier to navigate any complexities.

- Adhering to safety guidelines is imperative, ensuring that users operate equipment safely and efficiently.

By following these guidelines, users can confidently select appropriate equipment while managing costs effectively. The combination of careful planning and informed decision-making will lead to successful asphalt repair projects. Take action today to ensure your project runs smoothly and efficiently.

Key Highlights:

- Define project requirements, including the type and size of cracks, to select the appropriate machine.

- Estimate the rental duration to understand pricing models and budget effectively.

- Establish a comprehensive budget, including leasing fees, delivery, pickup, and insurance costs.

- Confirm the worksite location and ensure the rental company can deliver the equipment.

- Assess your experience level with heavy machinery to determine if training or assistance is needed.

- Choose the right type of machine, considering direct-fire vs. oil-jacketed units based on project needs.

- Evaluate the machine's capacity and heating method for efficiency and effectiveness.

- Ensure user-friendliness of the machine with features like adjustable flow rates and clear gauges.

- Research reputable brands for reliability and customer support when selecting equipment.

- Apply filler under optimal conditions (50°F to 85°F) and ensure proper surface preparation for effective results.

- Follow a step-by-step rental process: contact the provider, cheque availability, review the lease agreement, and inspect the equipment upon delivery.

- Adhere to operation and safety guidelines, including reading the manual, wearing protective gear, and conducting routine maintenance.

Introduction

Navigating the world of asphalt repair can be a formidable challenge, particularly when it comes to renting the appropriate equipment for the task at hand. As the demand for well-maintained surfaces continues to rise, it becomes increasingly vital for both contractors and DIY enthusiasts to understand how to effectively rent an asphalt crack filler machine.

This guide explores the essential steps and considerations for securing the right equipment, ensuring that projects are completed efficiently and cost-effectively.

- What pitfalls should be avoided to guarantee a seamless rental experience?

- Furthermore, how can one maximize the benefits of this investment?

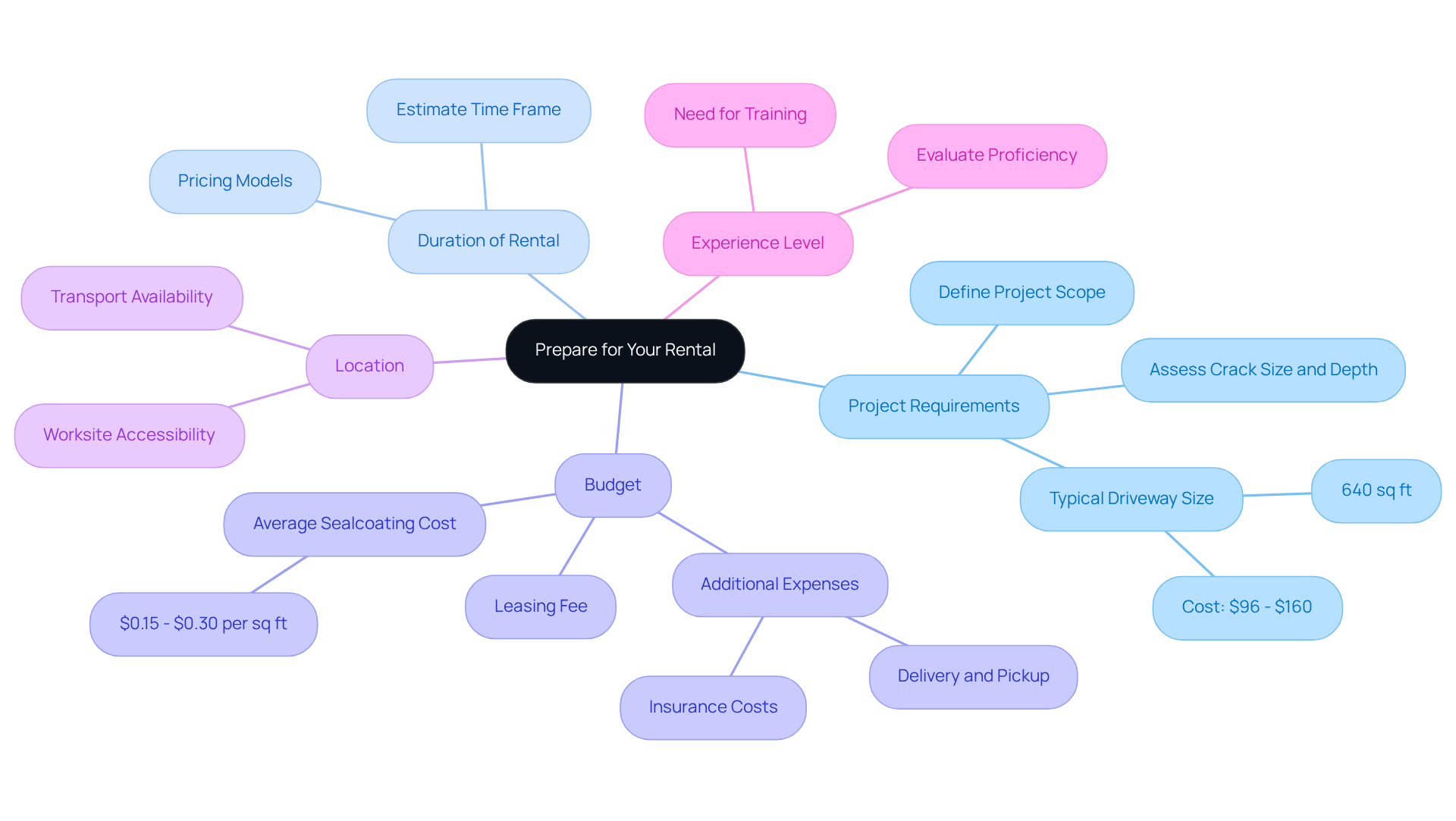

Prepare for Your Rental: Key Considerations

Before you rent an asphalt crack filler machine, it is essential to evaluate several key considerations to ensure a successful rental experience.

Project Requirements: Clearly define the scope of your project. Are you dealing with fissures in a driveway, parking area, or road? Understanding the size and depth of the cracks will guide you in selecting the appropriate equipment. For instance, a typical residential driveway averages 640 square feet, which can cost between $96 to $160 to sealcoat.

Duration of Rental: Estimate the time frame for which you will need the machine. Leasing firms generally provide different pricing models depending on the duration of the lease, so obtaining a clear estimate can assist in efficient budgeting.

Budget: Establish a comprehensive budget for your lease. Consider not only the leasing fee but also any extra expenses such as delivery, pickup, and insurance, which can greatly affect your total costs. The average cost of sealcoating ranges from $0.15 to $0.30 per square foot, making it crucial to understand these costs for financial planning.

Location: Determine the worksite location. Verify that the leasing firm can transport the device to your location and evaluate any possible access issues that might occur.

Experience Level: Evaluate your proficiency in operating heavy machinery. If you lack experience, consider whether you will require additional training or assistance to operate the equipment safely and effectively. As mentioned by the Ezequipment Content Team, investing in asphalt repair devices is an essential action for preserving the integrity of asphalt surfaces.

By addressing these considerations, you can streamline the rental process and ensure you can rent an asphalt crack filler machine that is tailored to your project's needs. Furthermore, proper planning can lead to significant financial benefits, as highlighted in case studies showing the profitability of sealcoating for contractors.

Select the Right Asphalt Crack Filler Machine

Selecting the right rent asphalt crack filler machine is crucial for achieving optimal results. Consider the following factors:

-

Machine Type: Various asphalt crack fillers are available, including direct-fire and oil-jacketed units. Direct-fire devices are generally more economical and simpler to operate, while oil-jacketed equipment offers superior temperature regulation, essential for optimal outcomes in diverse weather conditions.

-

Capacity: Assess the capability of the device. Larger equipment can handle more material, making it advantageous for larger projects, while smaller units provide portability and ease of maneuverability.

-

Heating Method: Look for devices with efficient heating methods. A machine that heats rapidly will save you time on the job site, significantly reducing downtime and facilitating a smoother workflow.

-

Ease of Use: User-friendliness is key. Features such as adjustable flow rates and easy-to-read gauges can enhance your experience and lead to better application results.

-

Brand Reputation: Research reputable brands known for reliability and customer support. Reading reviews and seeking recommendations can guide you toward making a better choice.

-

Optimal Application Conditions: Ensure the filler is applied when temperatures are between 50°F and 85°F for effective results. Applying in extreme temperatures or wet conditions can hinder proper curing.

-

Surface Preparation: Proper surface preparation is essential. Neglecting this step can result in early repair failures, so thoroughly cleaning the fissure before application is critical.

-

Application Techniques: Be mindful of the consequences of improper application methods, such as overfilling or underfilling gaps, which can lead to ineffective repairs.

Asphalt Sealcoating Supply Inc. offers a range of high-quality crack fillers tailored to various crack types, ensuring optimal results. By carefully evaluating these factors, you can decide to rent asphalt crack filler machine that meets your project needs and enhances efficiency. Additionally, consider the adaptable leasing conditions and competitive pricing provided by EZ Equipment Rental to acquire the essential equipment affordably.

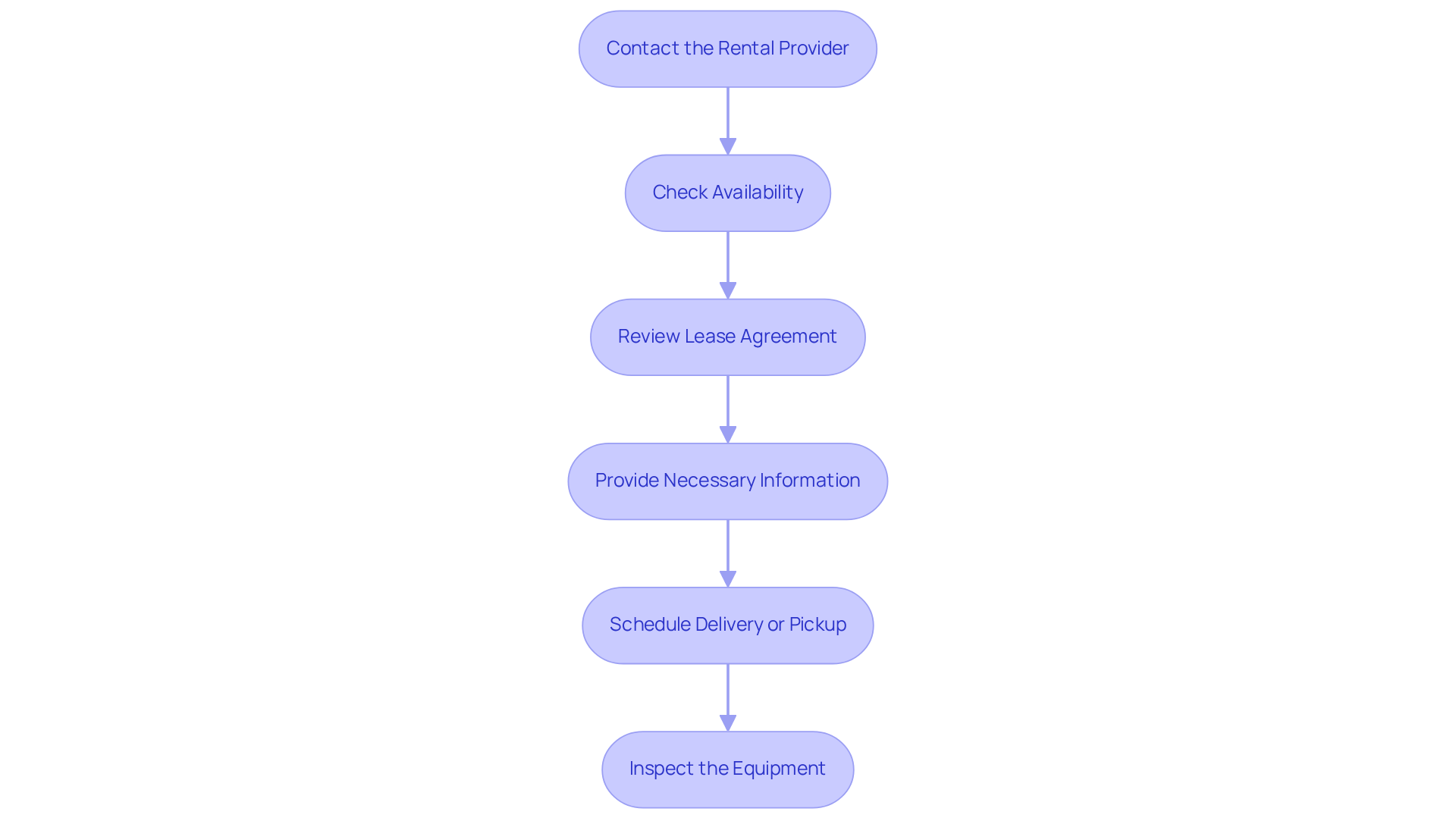

Complete the Rental Process: Step-by-Step Instructions

To successfully complete the rental process for an asphalt crack filler machine, follow these essential steps:

-

Contact the Rental Provider: Reach out to EZ Equipment Rental at (214) 951-7800 or your preferred leasing service. Clearly convey your project requirements and specify the type of equipment you need.

-

Check the availability to rent the asphalt crack filler machine for your desired booking dates. Inquire about any promotions or discounts that may apply, as EZ Equipment Rental offers flexible terms and competitive pricing to enhance customer convenience and maximize cost-effectiveness.

-

Review Lease Agreement: Thoroughly examine the lease agreement. Pay close attention to the terms, fees, and any insurance requirements to avoid surprises later. EZ Equipment Rental is committed to transparency, ensuring you understand all aspects of your lease.

-

Provide Necessary Information: Be prepared to supply identification, payment details, and any other required documentation to facilitate the leasing process.

-

Schedule Delivery or Pickup: Organize the delivery of the equipment to your project site or arrange to collect it from the leasing location at your convenience. EZ Equipment Rental's flexible options allow you to choose what works best for your project timeline.

-

Inspect the Equipment: Upon receiving the machine, conduct a thorough inspection for any damage or operational issues. Promptly notify the leasing company of any issues to guarantee a smooth leasing experience. Their customer-centric service ensures that any concerns are addressed swiftly.

By following these steps, you can streamline your leasing process and commence your project without unnecessary delays. With the equipment rental market projected to reach $164.6 billion by 2029, utilizing rental services like those offered by EZ Equipment Rental is a strategic decision for construction project managers.

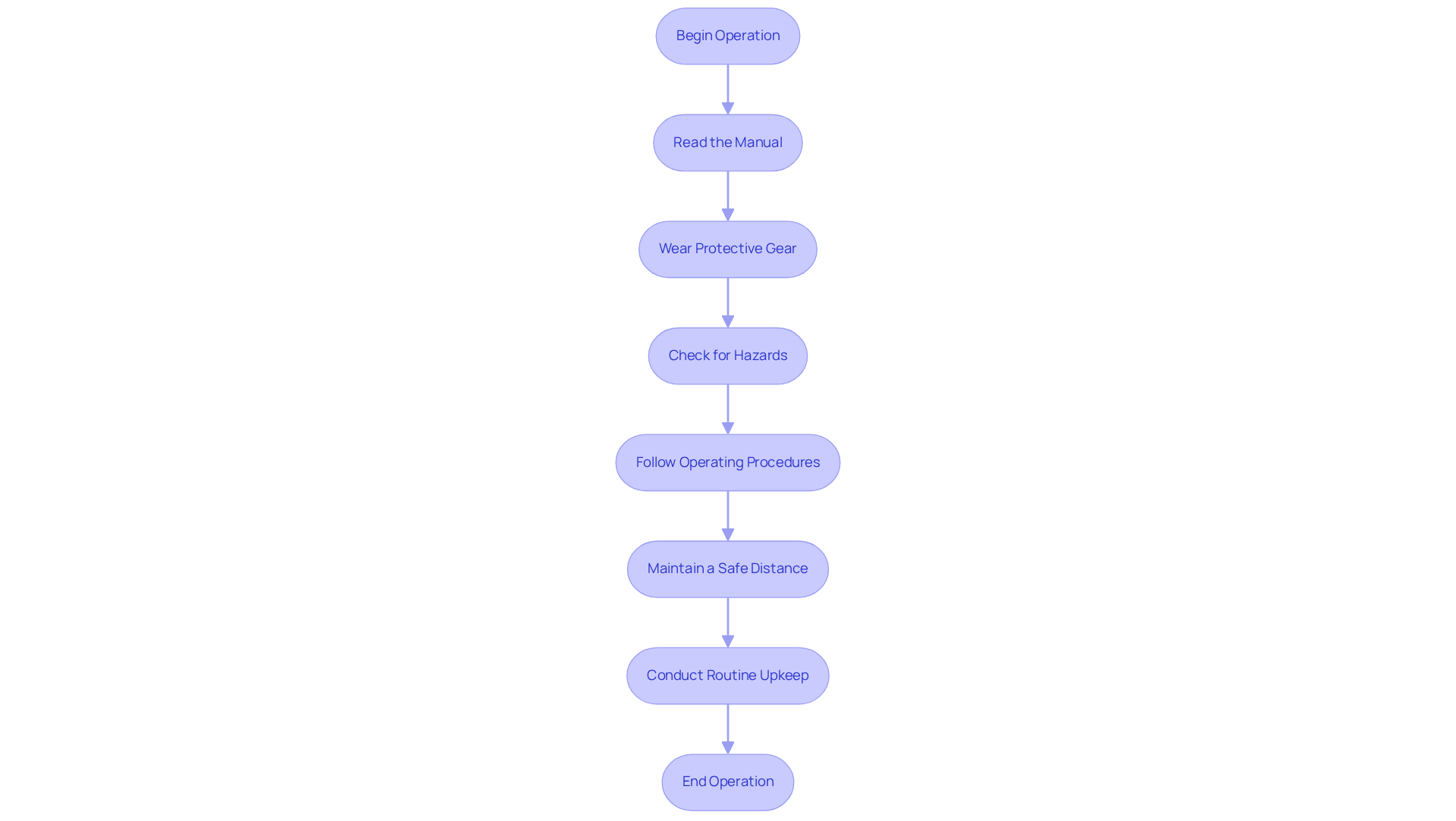

Understand Operation and Safety Guidelines

To operate the asphalt crack filler machine safely and effectively, it is crucial to adhere to the following guidelines:

- Read the Manual: Before using the equipment, thoroughly read the manufacturer's manual to understand its features and functions. This foundational step ensures that you are well-informed about the machine's operation.

- Wear Protective Gear: Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and a mask, to protect yourself from harmful fumes and debris. Your safety is paramount when operating machinery.

- Check for Hazards: Prior to starting, inspect the work area for any hazards, such as uneven surfaces or overhead obstructions. Identifying potential risks helps in creating a safer working environment.

- Follow Operating Procedures: Adhere to the operating procedures outlined in the manual. This includes starting, stopping, and adjusting the equipment correctly, which is essential for safe operation.

- Maintain a Safe Distance: Keep bystanders at a safe distance while using the equipment to prevent accidents. Ensuring that others are out of harm's way is a critical aspect of safe operation.

- Conduct Routine Upkeep: After usage, clean the equipment and perform any required maintenance as advised by the manufacturer. Regular upkeep not only prolongs the equipment's life but also ensures its optimal performance.

By following these operation and safety guidelines, you can ensure a safe working environment and maximize the effectiveness of your rent asphalt crack filler machine.

Conclusion

Renting an asphalt crack filler machine can be a straightforward process when approached with the right knowledge and preparation. Understanding the nuances of project requirements, budget considerations, and equipment specifications is crucial for ensuring that the right machine is selected, leading to a smooth and efficient rental experience.

Key points are vital in this process, such as:

- Defining project needs

- Assessing machine types

- Following a structured rental process

- Emphasizing safety guidelines

- Adhering to operational best practices

These insights not only aid in making informed decisions but also contribute significantly to the overall success of asphalt maintenance projects.

In conclusion, being well-prepared for renting an asphalt crack filler machine is essential for achieving optimal results. By carefully considering the outlined steps and insights, individuals can enhance their project efficiency and reduce potential costs. Embracing these practices not only leads to successful repairs but also underscores the significance of proper asphalt maintenance in prolonging the life of surfaces. Taking action now to implement these strategies will pave the way for smoother, safer, and more effective asphalt repair projects in the future.

Frequently Asked Questions

What should I consider before renting an asphalt crack filler machine?

Before renting, consider your project requirements, the duration of rental, budget, location, and your experience level with operating heavy machinery.

How do I define my project requirements for asphalt crack filling?

Clearly define the scope of your project by identifying whether you are dealing with fissures in a driveway, parking area, or road, and understand the size and depth of the cracks.

Why is it important to estimate the duration of rental?

Estimating the rental duration helps you obtain a clear estimate for budgeting, as leasing firms often have different pricing models based on how long you need the equipment.

What costs should I include in my budget for renting an asphalt crack filler machine?

Your budget should include the leasing fee as well as additional expenses such as delivery, pickup, and insurance, which can significantly affect your total costs.

How does the location impact the rental of an asphalt crack filler machine?

You need to determine if the leasing firm can transport the machine to your worksite and assess any potential access issues that might arise.

What should I consider regarding my experience level with heavy machinery?

Evaluate your proficiency in operating heavy machinery; if you lack experience, consider whether you will need additional training or assistance to operate the equipment safely.

What are the financial benefits of proper planning when renting asphalt repair equipment?

Proper planning can lead to significant financial benefits, as demonstrated by case studies showing the profitability of sealcoating for contractors.