Overview

To secure a safety harness rental for your project, it is essential to follow four key steps:

- Evaluate your project needs

- Inspect the equipment for compliance and condition

- Compare rental options

- Ensure proper training for safe usage

This process is critical, as it emphasizes the importance of compliance with safety standards and the financial benefits of investing in safety training. By mitigating risks and enhancing workplace safety, you not only protect your team but also foster a culture of safety that can lead to greater productivity and morale.

In addition, evaluating your project needs allows you to select the most suitable equipment, ensuring that it meets the specific demands of your tasks. Inspecting the equipment for compliance and condition is vital; it guarantees that you are using reliable tools that adhere to industry standards. Furthermore, comparing rental options can help you identify the best deals, ensuring that you receive quality equipment at a competitive price.

Finally, ensuring proper training for safe usage cannot be overlooked. Investing in safety training not only protects your workforce but also enhances the overall efficiency of your operations. By prioritizing these steps, you are making a commitment to safety and excellence in your project execution. Take action now to secure your safety harness rental and elevate your project’s safety standards.

Key Highlights:

- Safety harnesses are essential for fall protection in construction, mandated by OSHA for workers at heights of six feet or more.

- Harnesses distribute fall forces, reducing injury risks and protecting employers from legal liabilities.

- Employee involvement in safety planning enhances responsibility and improves protective practices.

- Falls and machinery-related incidents are significant safety concerns, necessitating comprehensive protective strategies.

- Investing in safety training can yield financial benefits, with a 2.5% investment potentially increasing profits by 4 to 7% per project.

- Consider key criteria for safety harness rentals: type, fit, weight capacity, compliance with standards, and equipment condition.

- Inspect rented harnesses for damage and ensure they meet OSHA and ANSI compliance standards.

- Training on equipment use is crucial to mitigate risks associated with improper usage, especially in light of high injury statistics in construction.

Introduction

In the construction industry, safety is paramount—especially when it comes to preventing falls from heights. As regulations evolve, the requirement for safety harnesses becomes increasingly urgent, with OSHA mandating their use for workers operating at six feet or more. These essential tools not only protect workers but also shield employers from potential legal repercussions.

The significance of safety harnesses extends beyond mere compliance; they foster a culture of accountability and teamwork, ultimately enhancing overall safety practices on job sites. This article delves into the critical role of safety harnesses, offering insights on how to:

- Select the right rental

- Troubleshoot common issues

- Ensure compliance with industry standards

By prioritizing safety harnesses in project planning, construction firms can create a safer environment while also reaping financial benefits.

Understand the Importance of Safety Harnesses in Construction

Safety restraints are essential elements of fall protection systems in the construction industry, designed to prevent falls from heights—an issue that accounts for a significant number of injuries and fatalities. As of 2025, OSHA mandates that any employee working at a height of six feet or more must wear a protective device, underscoring the importance of compliance with safety regulations. These harnesses effectively distribute the force of a fall across the body, greatly diminishing the risk of injury. Moreover, they are vital in protecting both workers and employers from potential legal liabilities.

Involving employees in the planning of safety measures has been shown to foster a sense of ownership and responsibility, leading to improved protective practices and a collaborative work environment. Notably, falls are not the only concern; incidents where workers are trapped or struck by construction machinery accounted for 14% of worker fatalities on road construction sites, highlighting the urgent need for comprehensive protective strategies. As construction companies increasingly recognize the financial benefits of investing in safety measures—where a mere 2.5% investment in training can yield a profit increase of 4 to 7% per project—the importance of securing reliable options for safety harness rental and protective gear becomes clear.

Additionally, with women representing 10.9 percent of the U.S. construction workforce in 2022, it is crucial to incorporate diverse perspectives into training and engagement strategies. Understanding these factors is essential for creating a safe working environment and emphasizes the necessity of prioritizing protective gear in project planning.

Identify Key Criteria for Selecting a Safety Harness Rental

When choosing a safety harness rental, it is essential to consider the following key criteria:

- Type of Safety Gear: Identify the suitable type of safety gear for your project needs, such as full-body, positioning, or suspension options. Positioning devices (Class P) secure the wearer while permitting unrestricted hand usage, making them appropriate for various tasks.

- Size and Fit: A proper fit is crucial for both security and comfort. Refer to the manufacturer's sizing chart and choose adjustable straps to accommodate diverse body types. As industry specialist Hany Elmancy notes, 'The efficiency of a protective strap significantly relies on its fit and comfort.'

- Weight Capacity: Ensure that the device can safely support the user's weight along with any additional tools or equipment they may carry. This is vital to prevent accidents and ensure adherence to regulatory standards.

- Compliance with Standards: Confirm that the equipment adheres to OSHA and ANSI standards. Seek labels or documentation that confirm compliance, as this is essential for ensuring security on the job site.

- Condition of Equipment: Before renting, thoroughly inspect the straps for any signs of wear or damage. A properly cared-for harness is crucial for reducing fall hazards and ensuring worker protection during high-risk tasks, as emphasized in case studies on personal fall protection systems. Proper placement of the attachment point is essential for security, emphasizing the need for thorough inspections and safety harness rental documentation. Ensure that training and inspections are documented, as this is important for compliance and enhancing practices on the job site.

By adhering to these standards, you can obtain a safety harness rental that not only fulfills regulatory requirements but also improves the security and comfort of your team on construction projects. For inquiries and reservations, contact EZ Equipment Rental at (214) 951-7800.

Explore Options and Compare Safety Harness Rentals

To investigate alternatives for harness leases, follow these steps:

-

Investigate Equipment Providers: Begin by locating nearby businesses that specialize in safety harness rental. Seek out companies with a solid reputation for quality and customer service, such as EZ Equipment Rental, recognized for its commitment to excellence in the Dallas-Fort Worth region. They offer a diverse range of machinery, including boom lifts, forklifts, and mini excavators.

Compare Pricing: Gather estimates from various leasing firms. Compare not only the rental prices but also the terms of service, including deposit requirements and rental duration, to fully understand the total cost involved.

-

Evaluate Equipment Quality: Check reviews or seek recommendations regarding the quality of the protective gear provided by each firm. Ensure that the equipment is well-maintained and compliant with health regulations. Remember, one primary cause of racking system failure is a damaged frame due to forklift impact, underscoring the critical need for high-quality equipment in maintaining workplace safety.

-

Inquire About Support Services: Some rental businesses offer additional services, such as training on how to properly utilize the equipment. Consider these services, as they can significantly enhance security and compliance at the job site.

Check Availability: Ensure that the straps you require are accessible for your project schedule. Booking in advance for a safety harness rental can assist in securing the appropriate gear and prevent last-minute complications.

By adhering to these guidelines, you can ensure that you select the best safety harness rental options for protective equipment that meet your project requirements while emphasizing security and dependability. Furthermore, fostering a culture of accountability and vigilance among employees promotes a more secure workplace.

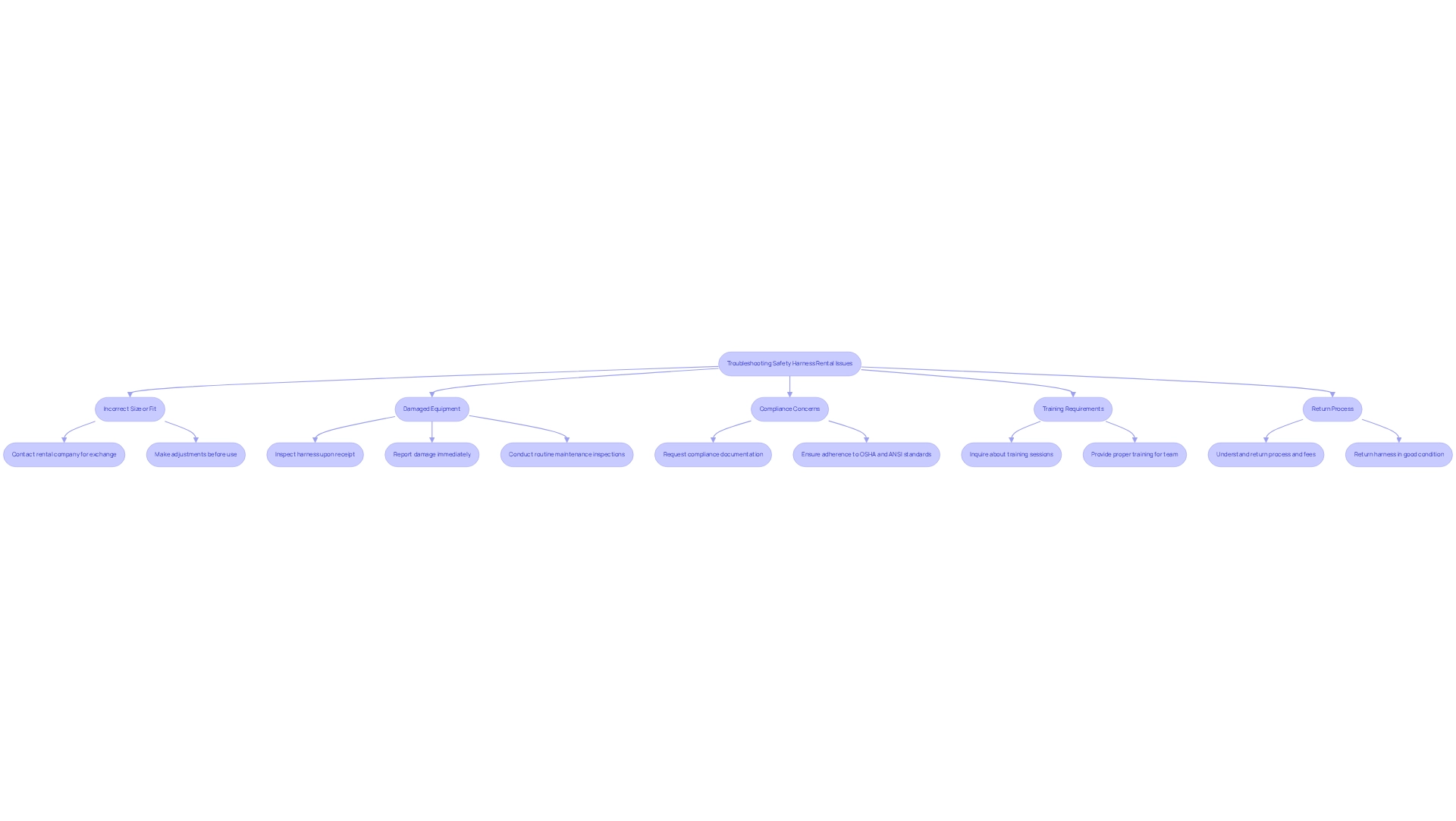

Troubleshoot Common Rental Issues and Ensure Compliance

When dealing with a safety harness rental, several typical problems may arise. Here’s how to effectively troubleshoot them:

- Incorrect Size or Fit: A proper fit is crucial for security. If the safety harness rental does not fit correctly, promptly contact the rental company to exchange it for the appropriate size. Ensure that adjustments are made before use to guarantee optimal safety.

- Damaged Equipment: Upon receiving the harness, conduct a thorough inspection. Report any visible damage to the safety harness rental company immediately to avoid liability for pre-existing issues. Routine maintenance inspections can avert equipment malfunctions that jeopardize security.

- Compliance Concerns: Confirm that the harness adheres to all security standards. Request documentation from the leasing firm regarding safety harness rental to ensure compliance with OSHA and ANSI regulations. This is critical, as non-compliance can lead to serious hazards on the job site.

- Training Requirements: If your team lacks experience with safety equipment, inquire whether the safety harness rental service offers training sessions. Proper training is vital; statistics indicate that in 2022, the construction industry recorded 169,600 non-fatal injuries, with 42% resulting in days away from work. This highlights the importance of addressing training requirements to mitigate risks linked to improper equipment use. As Lance Roux states, "Not only should a company have the appropriate equipment available, but employees should be fully trained on their correct usage."

- Return Process: Understand the return process and any associated fees. Ensure that the safety harness rental is returned in good condition to avoid additional charges. Familiarizing yourself with these details can save time and costs at the end of your rental period.

Conclusion

Prioritizing safety harnesses in the construction industry transcends mere regulatory compliance; it is an essential practice that safeguards the well-being of workers and fortifies the financial health of companies. The significance of safety harnesses is paramount, as they offer critical protection against falls—one of the leading causes of injuries and fatalities on job sites. By grasping the key criteria for selecting a suitable rental, such as type, fit, weight capacity, and adherence to safety standards, construction firms can make informed decisions that bolster workplace safety.

Furthermore, exploring various rental options and comparing equipment quality are vital steps in securing reliable safety harnesses. Addressing common issues like sizing, equipment damage, and compliance concerns ensures that safety remains a top priority throughout the rental process. Additionally, training employees on the proper use of safety harnesses fosters a culture of accountability and vigilance, ultimately leading to a safer work environment.

In conclusion, investing in safety harnesses not only protects workers but also contributes significantly to the overall success of construction projects. By nurturing a commitment to safety and compliance, construction firms can cultivate a more secure atmosphere that benefits everyone involved. Embracing these practices is crucial for establishing a robust safety culture that safeguards lives and enhances productivity on the job site.

Frequently Asked Questions

What are safety restraints in the construction industry?

Safety restraints are essential elements of fall protection systems designed to prevent falls from heights, which are a significant cause of injuries and fatalities in the construction industry.

What does OSHA mandate regarding safety restraints?

As of 2025, OSHA mandates that any employee working at a height of six feet or more must wear a protective device, highlighting the importance of compliance with safety regulations.

How do safety harnesses protect workers?

Safety harnesses effectively distribute the force of a fall across the body, greatly diminishing the risk of injury and protecting both workers and employers from potential legal liabilities.

How can involving employees in safety planning benefit construction sites?

Involving employees in the planning of safety measures fosters a sense of ownership and responsibility, leading to improved protective practices and a collaborative work environment.

What other safety concerns exist in construction besides falls?

Incidents where workers are trapped or struck by construction machinery account for 14% of worker fatalities on road construction sites, highlighting the need for comprehensive protective strategies.

What financial benefits can come from investing in safety measures?

Construction companies can see a profit increase of 4 to 7% per project with a mere 2.5% investment in training, demonstrating the financial benefits of investing in safety measures.

Why is it important to consider diversity in the construction workforce?

With women representing 10.9 percent of the U.S. construction workforce in 2022, incorporating diverse perspectives into training and engagement strategies is crucial for creating a safe working environment.

What is the overall importance of prioritizing protective gear in construction project planning?

Prioritizing protective gear is essential for ensuring a safe working environment and addressing the various factors that contribute to workplace safety in the construction industry.