Overview

This article presents seven compelling advantages of renting welder equipment for construction projects:

- Renting offers significant cost savings, allowing businesses to allocate resources more effectively.

- The flexibility provided by rental options enables quick adaptations to project needs, ensuring that teams can respond promptly to changing circumstances.

- Access to advanced technology is another key benefit; renting allows companies to utilize the latest equipment without the burden of ownership.

- Predictable budgeting is achieved through rental agreements, eliminating unexpected costs associated with maintenance and repairs.

- These advantages are substantiated by data indicating lower initial expenses compared to purchasing.

- Renting enhances operational efficiency and financial control in a dynamic construction environment.

Key Highlights:

- Renting welding equipment significantly reduces initial expenses compared to purchasing, which can range from $1,500 to $4,000.

- Average lease costs for fabrication tools in Dallas-Fort Worth are $50 to $100 daily and $250 to $500 weekly, making it an economical choice.

- Rental agreements often include maintenance and support services, minimizing unexpected costs associated with ownership.

- Over 60% of construction projects require welder equipment rental to meet specialized needs, emphasizing its growing importance in the industry.

- Leasing provides access to cutting-edge technology without the financial strain of ownership, enhancing efficiency and safety.

- Short-term rentals allow project managers to swiftly adapt to changing task requirements, crucial in a dynamic construction environment.

- The ability to eliminate maintenance responsibilities enhances operational efficiency, allowing managers to focus on core tasks.

- Predictable rental costs aid in effective budget management, helping avoid unforeseen expenses from machinery breakdowns.

- The construction machinery leasing market is projected to grow at a CAGR of 5.2%, reflecting a shift towards rental solutions for better financial control.

- EZ Equipment Rental offers a diverse range of tools, enabling managers to scale equipment needs easily as projects evolve.

Introduction

In the dynamic landscape of construction, the choice between purchasing and renting welding equipment can significantly influence project success. With budgets tightening and project scopes evolving, renting emerges as a strategic solution that alleviates upfront costs and enhances flexibility while providing access to cutting-edge technology. As project managers navigate the complexities of modern construction, the advantages of rental agreements become increasingly apparent, eliminating maintenance burdens and ensuring cost predictability.

This article delves into the multifaceted benefits of renting welding equipment, highlighting how it empowers construction teams to remain agile, efficient, and financially savvy in a rapidly changing industry.

Cost-Effectiveness of Renting Welding Equipment

Renting welder equipment offers a strategic advantage by significantly lowering initial expenses compared to direct acquisitions, which typically range from $1,500 to $4,000. This approach is particularly beneficial for projects operating on tight budgets or those requiring specialized tools for short durations. By opting for leases, project managers can reallocate resources to other critical aspects of the project, thereby enhancing overall financial management.

In 2025, average lease costs for fabrication tools in the Dallas-Fort Worth area range from $50 to $100 daily and $250 to $500 weekly, presenting an economical choice for many construction projects. Furthermore, welder equipment rental agreements often encompass maintenance and support services, mitigating unexpected costs associated with ownership. At EZ Equipment Rental, we prioritize dependability and exceptional service, ensuring that our clients receive the necessary assistance for a seamless leasing experience.

Current data indicates that businesses can achieve substantial savings by choosing welder equipment rental over purchasing machinery. The machinery leasing market in North America is experiencing growth, fueled by advancements in infrastructure within the construction and oil and gas sectors, with an increasing emphasis on welder equipment rental. This trend underscores the financial benefits of renting, as managers can access advanced tools equipped with enhanced safety features without the financial burden of ownership.

The market is categorized by rental duration—Rent By Day, Rent By Week, and Rent By Month—and by application, including Home Use and Commercial Use, providing flexibility to meet diverse needs.

With EZ Equipment Rental's commitment to reliability and outstanding customer service, managers can navigate the evolving market with confidence. The cost-effectiveness of welder equipment rental emerges as a compelling option for optimizing resources while ensuring project success.

Flexibility for Short-Term and Specialized Needs

Leasing fabrication tools offers remarkable adaptability, allowing managers to select the most appropriate instruments for particular jobs without the long-term obligation linked to ownership. This flexibility is especially advantageous for initiatives that require diverse kinds of tools at different phases. For example, a building endeavor may begin with MIG techniques and later shift to TIG methods, demonstrating how leases can efficiently adapt to these evolving needs.

The construction sector is progressively acknowledging the benefits of leased tools, particularly for specialized fabrication requirements. A considerable portion of construction endeavors—estimated at over 60%—necessitates welder equipment rental to meet distinct requirements. This trend underscores the importance of having access to a diverse range of welder equipment rental tools without the burden of ownership.

Furthermore, the incorporation of telematics in leased machinery is transforming how managers supervise their operations. By utilizing IoT technologies, leasing companies can monitor device usage and location, improving operational efficiency and safety. This technological advancement not only simplifies management tasks but also aids sustainability efforts by tracking performance and decreasing the carbon footprint.

As highlighted in the case study titled "Impact of IoT on Construction Equipment Rental," the incorporation of IoT is expected to enhance sustainability in construction by improving accuracy and safety.

In 2025, expert opinions emphasize that short-term rentals are becoming increasingly popular due to their cost-effectiveness and convenience. Project leaders can swiftly adjust to task demands, ensuring they possess the appropriate tools available when necessary. This flexibility is essential in a fast-paced construction environment where scopes can change rapidly.

The United Nations Conference on Trade and Development (UNCTAD) predicts that the worldwide urban population will grow by 1.5 times to 6 billion by 2045, further enhancing the demand for construction and rental tools.

Ultimately, the ability to use welder equipment rental for short-term tasks enables construction teams to stay flexible and responsive, ensuring that they can meet deadlines and quality standards without the financial burden of buying tools outright. Instances of specialized joining tools available for rent consist of portable MIG machines, TIG units, and multi-process devices, all of which address diverse task requirements.

Access to Cutting-Edge Technology

Leasing fabrication tools as part of a welder equipment rental provides a strategic edge, granting access to the latest technology without the considerable financial strain linked to purchasing. Rental companies, such as EZ Equipment Rental, frequently refresh their inventory to include state-of-the-art models that enhance efficiency, safety, and performance. This ensures that project leaders can utilize advanced tools that not only improve the quality of their work but also optimize operations, leading to superior project outcomes.

For example, ergonomic tools designed to minimize physical strain have been shown to boost worker efficiency. These tools, including adjustable torches and lightweight devices, significantly enhance worker safety and reduce fatigue, resulting in increased productivity and job satisfaction. In fact, studies indicate that utilizing contemporary equipment can yield efficiency enhancements of up to 25%, making leases an attractive option for those aiming to optimize their projects.

Moreover, the latest advancements in joining technology, such as advanced arc joining techniques, are now available for lease. These innovations are particularly beneficial in specialized applications, including the manufacturing of space vehicles and the sealing of nuclear fuel canisters, where welds must be highly resistant to cracking and corrosion. By utilizing welder equipment rental, managers can ensure they are equipped with the best technology to meet the demands of their assignments.

In a competitive market where 30% of the US rental sector is dominated by national players, independent rental companies like EZ Equipment Rental maintain their service advantages by providing access to the latest fabrication technology. This not only assists companies in enhancing their fabrication capabilities but also fosters a culture of innovation and efficiency in construction endeavors. As highlighted by YesWelder, with dedicated support, flexible wholesale options, and a commitment to customer satisfaction, welder equipment rental becomes an ideal choice for businesses looking to elevate their capabilities.

Adaptability for Unexpected Challenges

Construction endeavors frequently encounter unexpected challenges, such as design modifications and unforeseen site conditions. In these scenarios, welder equipment rental becomes essential for managers, enabling them to swiftly adjust their resources to meet evolving requirements. For instance, when a project experiences a surge in workload that demands additional welding capacity, utilizing welder equipment rental grants immediate access to the necessary resources, effectively circumventing the delays typically associated with purchasing new machinery.

Statistics reveal that resource availability significantly influences project timelines, with 30% of construction projects facing setbacks due to inadequate tools. This underscores the importance of having flexible leasing options for welder equipment rental that can be mobilized quickly to address sudden changes. Furthermore, the American Rental Association anticipates a 5.2% expansion in leasing services by 2025, highlighting the growing importance of leasing solutions within the construction sector.

Moreover, the adaptability of welder equipment rental is crucial for managing the complexities of modern construction. As the industry embraces digital transformation, managers increasingly leverage welder equipment rental solutions to enhance efficiency and responsiveness. For example, predictive analytics and supply chain technologies, including Building Information Modeling (BIM), are employed to optimize designs and minimize material waste.

These advanced technologies facilitate accurate material assessments and early identification of design issues, ensuring that welder equipment rental can be utilized effectively when required. A case study examining rising construction material costs illustrates how predictive analytics can alleviate financial pressures by optimizing designs and reducing material waste.

Expert insights indicate that the ability to adapt swiftly with welder equipment rental not only mitigates risks associated with changes but also enhances overall project success. Organizations that have embraced this approach report improved timelines and reduced expenses, demonstrating the strategic advantages of utilizing leasing solutions like welder equipment rental in the face of unforeseen challenges. Wynne Systems Inc. highlights this trend, noting their collaboration with Foresight Intelligence to enhance telematics in the leasing industry, further illustrating the digital transformation underway in this sector.

In summary, the utilization of welder equipment rental not only facilitates prompt resource adjustments but also aligns with broader trends of efficiency and adaptability in the construction industry. By leveraging rental services, project managers can navigate project complexities with greater confidence and agility, particularly in response to challenges such as an aging workforce, where 23% of construction workers are over 55, necessitating flexible solutions to adapt to workforce changes.

Eliminate Maintenance and Repair Hassles

One of the most compelling benefits of renting tools and forklifts from EZ Equipment Rental is the total removal of maintenance and repair responsibilities. Renting from a reputable company guarantees that all machinery, including fabrication tools and forklifts, is maintained to the highest standards and is in optimal working condition. This proactive strategy not only reduces downtime but also enables managers to concentrate on their primary duties without the burden of handling maintenance, which can often be both time-consuming and costly.

In fact, statistics indicate that preventive maintenance compliance should ideally be 90% or higher to ensure machinery operates efficiently. This is particularly relevant in the context of welder equipment rental, where the responsibility for maintenance is transferred to EZ Equipment Rental, thereby enhancing operational efficiency. By outsourcing maintenance to a trusted rental company, project managers can significantly improve project timelines and efficiency, especially in the current competitive landscape where meeting deadlines is crucial in the construction industry.

Furthermore, a recent case study highlights the transformative impact of augmented and virtual reality (AR/VR) technologies in maintenance training and execution. These tools empower technicians to access manuals and expert support on-site, while immersive VR simulations provide essential training without disrupting ongoing operations. For example, technicians can utilize AR glasses to receive real-time guidance during maintenance tasks, ensuring that devices are serviced accurately and efficiently. As these technologies become integral to maintenance practices, the advantages of welder equipment rental—where maintenance is expertly managed by EZ Equipment Rental—become even more pronounced.

Additionally, over half of the revenue in the Machinery Maintenance & Heavy Tool Repair Services industry originates from maintenance and repair services, underscoring the significance of effective management. As noted by IBISWorld, this highlights the critical role that maintenance plays in the overall functioning of machinery. By opting for welder equipment rental from EZ Equipment Rental, managers can eliminate the inconveniences associated with repairs and maintenance, allowing them to allocate resources more effectively and enhance overall results.

Moreover, with 48% of manufacturing firms identifying hiring and retaining personnel as the largest challenge in maintenance, delegating these responsibilities to rental services such as EZ Equipment Rental becomes an even more strategic choice. Ultimately, the decision to rent fabrication tools and forklifts not only streamlines logistics but also boosts operational efficiency, making it a tactical decision for construction projects.

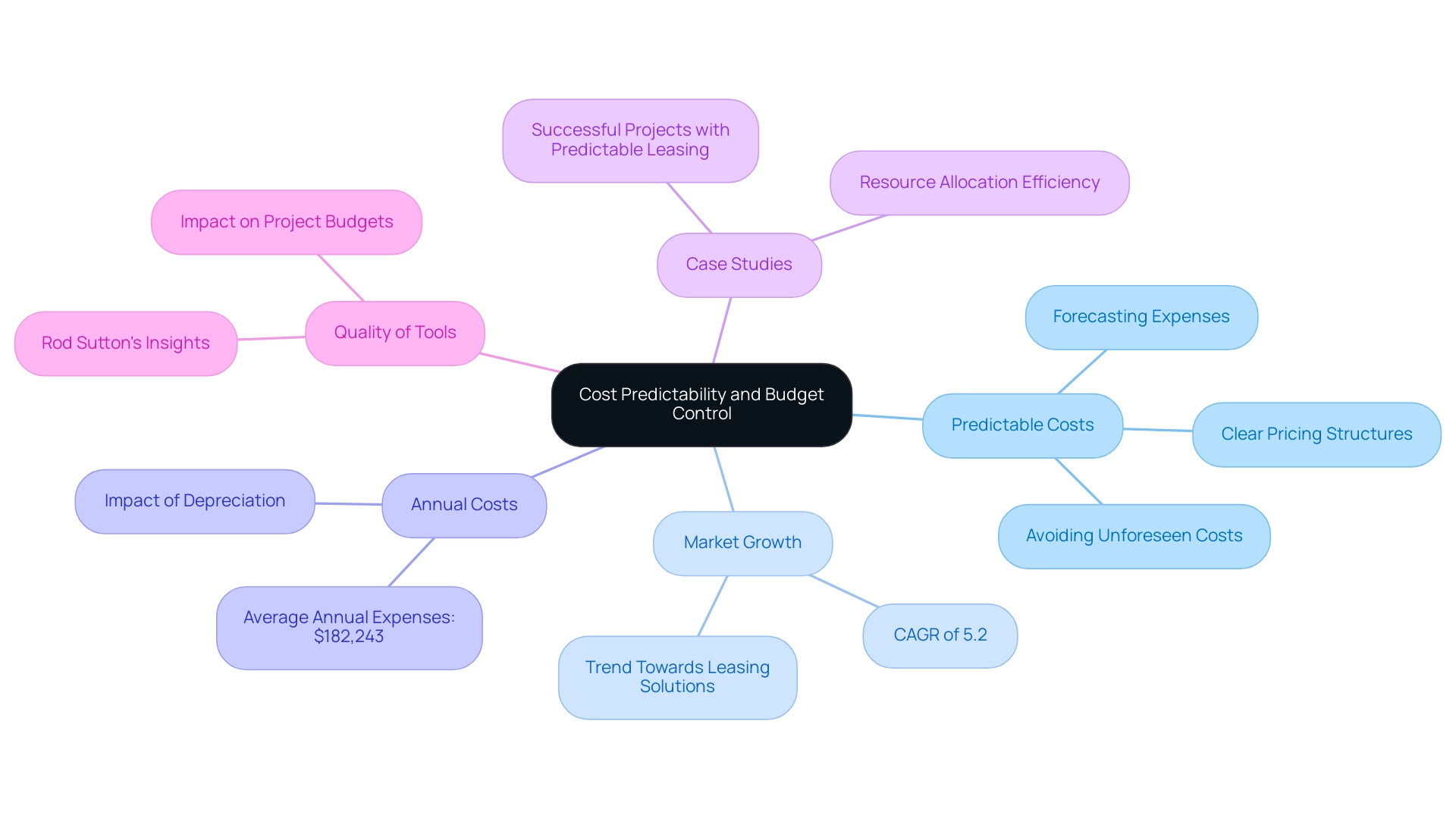

Cost Predictability and Budget Control

Renting welding tools provides a substantial advantage in budget management, particularly through predictable costs. Rental agreements feature clear pricing structures, enabling managers to forecast expenses with accuracy. This predictability is crucial in averting unforeseen costs that may arise from machinery breakdowns or maintenance issues, which can disrupt budget plans.

In 2025, the construction machinery leasing market is projected to grow at a compound annual growth rate (CAGR) of 5.2%. This growth reflects a broader trend towards leasing solutions that enhance financial control, making it increasingly vital for construction managers to view lease agreements as a strategic option for effective budget management.

Moreover, understanding the typical annual costs for machinery leasing companies in the U.S., which total $182,243 and often exceed their average annual income, can aid managers in budget oversight. This underscores the importance of cost predictability in leasing contracts, as it allows businesses to mitigate the financial risks associated with asset depreciation and maintenance.

Effective budget management through welder equipment rental is exemplified by case studies showcasing successful projects that utilized predictable leasing expenses. These examples demonstrate how managers can leverage lease contracts to maintain financial discipline, ensuring that resources are allocated efficiently and projects are completed on time and within budget.

Additionally, as noted by Rod Sutton, editorial lead of Construction Equipment magazine, "Our exclusive Field Tests take earthmoving machinery and trucks into the field for professional evaluations." This statement emphasizes the importance of quality in leased tools, which directly impacts project budgets. Furthermore, with North America being the largest region in the welder equipment rental and construction machinery rental market in 2024, managers have access to a robust array of rental options that can support their financial and operational goals.

Freedom to Scale Equipment as Needed

Leasing welding tools provides unmatched adaptability, allowing managers to adjust resources in accordance with changing task requirements. As building initiatives advance, the needs for different kinds or amounts of tools can change considerably. This adaptability is essential for maintaining momentum and meeting tight deadlines.

In 2025, the construction industry is experiencing a notable trend where roughly 1.5 million new homes were approved by building permits, emphasizing the growing need for effective management. With this surge, the capacity to modify inventory becomes paramount. Rental services, such as welder equipment rental provided by EZ Equipment Rental in Irving, TX, enable managers to effortlessly adjust their tool requirements, guaranteeing they possess the appropriate resources without the weight of long-term obligations.

EZ Equipment Rental offers a range of machinery, including forklifts, boom lifts, and mini excavators, to satisfy various task needs.

Furthermore, the adaptability of lease contracts enables swift reactions to evolving work scopes. For example, if a task necessitates extra welding tools because of unexpected situations, welder equipment rental offers prompt access to essential instruments, thus avoiding holdups. This adaptability is further supported by insights from industry experts, who emphasize that "everything is in place - it just needs that impetus for the uptick to begin."

As E&C companies maneuver through the changing economic and regulatory environment in 2025, the significance of adaptable machinery leasing alternatives, such as welder equipment rental, becomes even more evident. The ongoing government investment, particularly since the enactment of the Infrastructure Investment and Jobs Act (IIJA) in 2021, has led to a doubling of manufacturing construction spending. This demonstrates how strategic leasing collaborations, including access to essential machinery like forklifts, boom lifts, and welder equipment rental, can improve outcomes and take advantage of growth opportunities in the sector.

Additionally, as the market for Building Information Modeling (BIM) expands—projected to grow from $8.06 billion in 2023 to $9.43 billion in 2024—construction professionals are increasingly adopting innovative solutions to optimize their operations. Notably, 70% of construction professionals have adopted BIM, underscoring the industry's shift towards technology-driven approaches. This trend emphasizes the importance of having adaptable resource leasing choices that can expand based on task requirements, ensuring that construction companies stay competitive and agile in a changing environment.

For managers in the DFW Metroplex seeking to enhance their operations, EZ Equipment Rental in Irving, TX, offers comprehensive welder equipment rental services to assist with all your equipment rental needs. Contact us today to learn more about our extensive inventory and how we can support your projects.

Conclusion

Renting welding equipment offers a multitude of advantages that align perfectly with the evolving demands of the construction industry. By significantly reducing upfront costs and providing predictable expenses, renting stands out as a cost-effective solution that empowers project managers to allocate their budgets more efficiently. This financial flexibility is essential, especially in a landscape where project scopes can shift unexpectedly and specialized equipment may be needed for limited periods.

Additionally, the adaptability of rental agreements allows construction teams to respond swiftly to changing project requirements. With access to a diverse range of cutting-edge technology, project managers can utilize the latest tools without the burdens associated with ownership, such as maintenance and repair responsibilities. This not only enhances operational efficiency but also minimizes downtime, enabling teams to focus on what truly matters—delivering quality results on time.

The integration of modern technologies, including telematics and predictive analytics, further emphasizes the strategic advantage of renting equipment. These innovations improve resource management and operational safety, ensuring construction projects run smoothly even in the face of unforeseen challenges. As the construction industry continues to embrace these advancements, the ability to scale equipment needs quickly becomes essential for maintaining momentum and meeting tight deadlines.

Ultimately, the trend towards renting welding equipment transcends mere practicality; it represents a strategic approach that empowers construction teams to navigate the complexities of modern projects with agility and confidence. By leveraging rental solutions, project managers can enhance their operational capabilities while effectively managing costs, positioning themselves for success in an increasingly competitive market.

Frequently Asked Questions

What are the advantages of renting welder equipment instead of purchasing it?

Renting welder equipment significantly lowers initial expenses, which typically range from $1,500 to $4,000 for direct acquisitions. It is particularly beneficial for projects with tight budgets or those requiring specialized tools for short durations. This approach allows project managers to reallocate resources to other critical aspects of the project.

How much does it cost to lease fabrication tools in the Dallas-Fort Worth area in 2025?

In 2025, average lease costs for fabrication tools in the Dallas-Fort Worth area range from $50 to $100 daily and $250 to $500 weekly.

What additional services are often included in welder equipment rental agreements?

Welder equipment rental agreements often include maintenance and support services, which help mitigate unexpected costs associated with ownership.

How is the welder equipment rental market trending in North America?

The welder equipment rental market in North America is experiencing growth, driven by advancements in infrastructure within the construction and oil and gas sectors, with an increasing emphasis on financial benefits and access to advanced tools equipped with enhanced safety features.

What rental duration options are available for welder equipment?

The market is categorized by rental duration options including Rent By Day, Rent By Week, and Rent By Month, as well as by application such as Home Use and Commercial Use.

Why is flexibility in leasing fabrication tools important for construction projects?

Flexibility in leasing allows managers to select the most appropriate instruments for specific jobs without the long-term obligation of ownership. This is particularly advantageous for projects that require different types of tools at various phases.

What percentage of construction endeavors necessitates welder equipment rental?

Over 60% of construction endeavors require welder equipment rental to meet distinct requirements.

How is IoT technology impacting the management of leased machinery?

The incorporation of IoT technologies in leased machinery allows companies to monitor device usage and location, improving operational efficiency and safety. This technology aids in sustainability efforts by tracking performance and reducing carbon footprints.

What is the expected future demand for construction and rental tools according to UNCTAD?

The UNCTAD predicts that the worldwide urban population will grow by 1.5 times to 6 billion by 2045, which will enhance the demand for construction and rental tools.

What types of specialized joining tools are available for rent?

Specialized joining tools available for rent include portable MIG machines, TIG units, and multi-process devices, all tailored to meet diverse task requirements.