Key Highlights:

- A thorough assessment of project requirements is crucial before starting roofing projects, including evaluating roof size, type, materials, site conditions, and labour needs.

- Accurate measurement of roof area and identification of its type are necessary to determine the right roofing equipment.

- Different roofing materials require specific tools; ensure all necessary tools for installation are available.

- Conduct comprehensive site assessments to identify hazards that may affect machinery usage.

- Implementing personal protective equipment (PPE) is essential for worker safety, including hard hats, harnesses, and non-slip footwear.

- Regular training sessions for workers on safety practises and equipment use are critical to prevent accidents.

- Frequent site safety inspections help identify and mitigate hazards, ensuring a safer working environment.

- Clear emergency procedures should be established and communicated to all workers to ensure effective responses to incidents.

- Selecting the right tools for specific roofing materials enhances project efficiency and quality.

- Regular maintenance practises, including cleaning, inspections, lubrication, and proper storage, extend the lifespan and reliability of roofing equipment.

Introduction

Effective management of roofing equipment is essential for the success of any construction project. However, many overlook the complexities involved in this critical task. By understanding the specific requirements of a roofing project - such as assessing the roof's dimensions and materials and implementing stringent safety protocols - professionals can streamline operations and enhance safety.

The challenge remains: how can one ensure that the right tools are selected and maintained while prioritizing worker safety? This article explores best practices for managing roofing equipment effectively, providing insights that can lead to improved project outcomes and reduced risks on the job site.

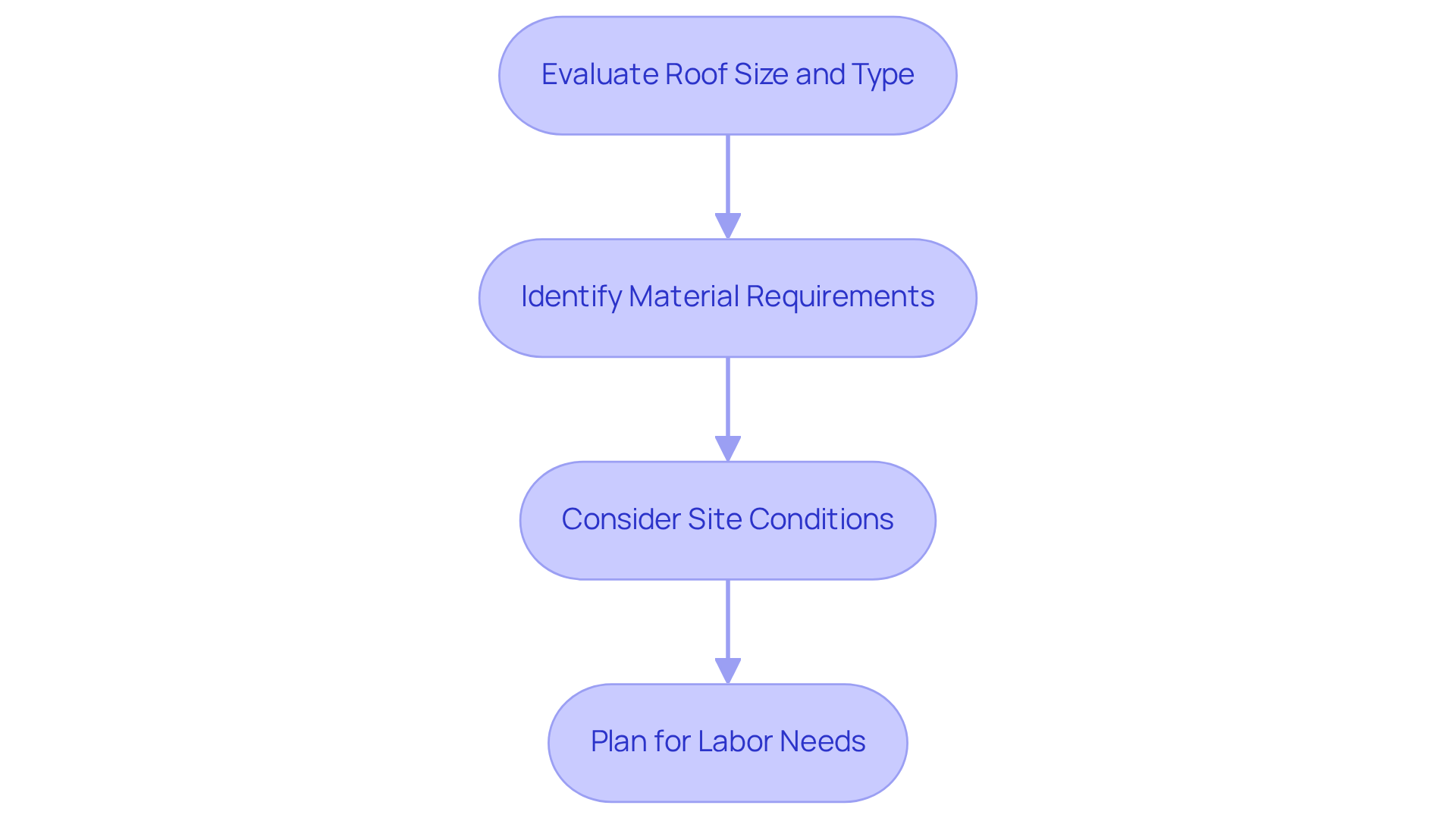

Assess Project Requirements for Roofing Equipment

Before embarking on any construction project, a thorough assessment of project requirements is essential. This includes evaluating the roof's size and complexity, the materials needed, and the specific tasks to be completed.

- Evaluate Roof Size and Type: Begin by accurately measuring the total area of the roof and identifying its type-whether flat, pitched, or another configuration. This assessment is crucial for determining the appropriate roofing equipment required, including ladders, scaffolding, or lifts.

- Identify Material Requirements: Different roofing materials, including asphalt shingles, metal, and tiles, necessitate specific roofing equipment for their installation. Ensure that all necessary tools for handling and installing these materials are readily available.

- Consider Site Conditions: Conduct a comprehensive site assessment to identify any obstacles or hazards that may impact machinery usage, such as overhead power lines or limited access points. This information will inform decisions regarding the size and type of tools needed.

- Plan for Labor Needs: Evaluate the number of workers involved and identify tools that will enhance their efficiency. This assessment should also consider safety gear and tools that promote productivity.

By meticulously evaluating these factors, project managers can ensure the availability of the right roofing equipment for roofing projects, leading to smoother operations and minimizing the risk of delays. Integrating these best practices not only enhances project efficiency but also safeguards investments in construction. Furthermore, EZ Equipment Rental offers innovative climbing solutions, such as Little Giant Ladders, which feature unique protective mechanisms and versatility, ensuring that both professionals and DIY enthusiasts have access to top-quality tools for their construction tasks.

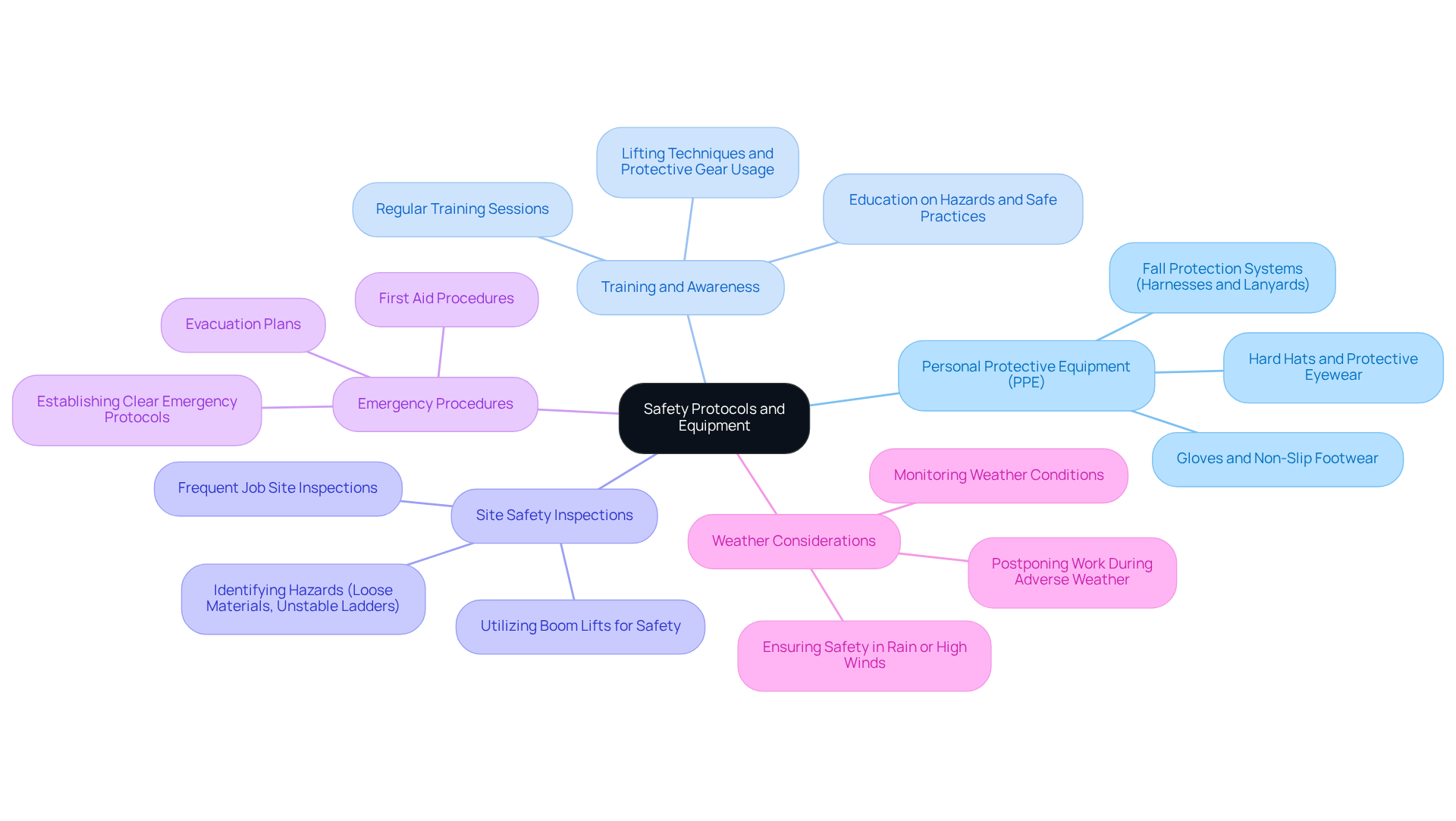

Implement Safety Protocols and Equipment

Protection is essential for any roofing project, and implementing robust safety protocols can significantly reduce the likelihood of incidents and injuries. Here are key practices to consider:

-

Personal Protective Equipment (PPE): Ensure all workers are equipped with necessary PPE, including hard hats, protective eyewear, gloves, and non-slip footwear. When working at heights, harnesses and lanyards are vital for fall protection. The construction industry has a fatality rate of nearly 60 per 100,000 full-time equivalent workers, underscoring the importance of effective PPE usage.

-

Training and Awareness: Regular training sessions are crucial for educating workers about potential hazards and safe practices. This training should cover appropriate lifting techniques and the correct use of protective gear, ensuring that all team members are well-prepared to handle risks associated with roofing tasks.

-

Site Safety Inspections: Conduct frequent inspections of the job site to identify hazards such as loose materials, unstable ladders, or inadequate scaffolding. Promptly addressing these issues is essential for maintaining a safe working environment and preventing accidents. Utilizing boom lifts from EZ Equipment Rental significantly mitigates the risks of working at heights. The stable platform and safety features of boom lifts provide a secure working environment for operators, reducing the likelihood of accidents and injuries.

-

Emergency Procedures: Establish clear emergency protocols for accidents or injuries, including first aid procedures and evacuation plans. All workers should be familiar with these protocols to ensure a swift and effective response in case of an emergency.

-

Weather Considerations: Be mindful of adverse weather conditions that can introduce additional risks, such as rain or high winds, which can lead to slips and falls. While postponing roofing work by a day or two may seem inconvenient, it is crucial for ensuring safety and long-term durability.

By prioritizing safety through these practices, including the use of roofing equipment like boom lifts from EZ Equipment Rental, construction projects can proceed with significantly reduced risks, fostering a culture of safety that benefits everyone involved.

Select Appropriate Tools for Roofing Materials

Selecting the right roofing equipment for covering materials is crucial for achieving optimal results. Here are some best practices for tool selection:

- Understand Material Needs: Different covering materials require specific tools. For example, asphalt shingles may need a nailer, while metal coverings could require a metal shear or a standing seam device.

- Invest in Quality Equipment: High-quality equipment may come with a higher initial cost, but it often leads to better performance and durability. It is advisable to invest in roofing equipment that is designed for specific tasks.

- Consistently Care for Equipment: It is essential to maintain all tools in good working condition. Regular cleaning, lubrication, and inspections can prevent breakdowns and ensure safety.

- Train Workers on Equipment Use: Providing training on the proper use of equipment ensures that workers are familiar with their operation and safety features. This practice can help prevent accidents and enhance efficiency.

By selecting the appropriate roofing equipment and ensuring proper maintenance, construction projects can be completed more effectively, resulting in higher quality outcomes.

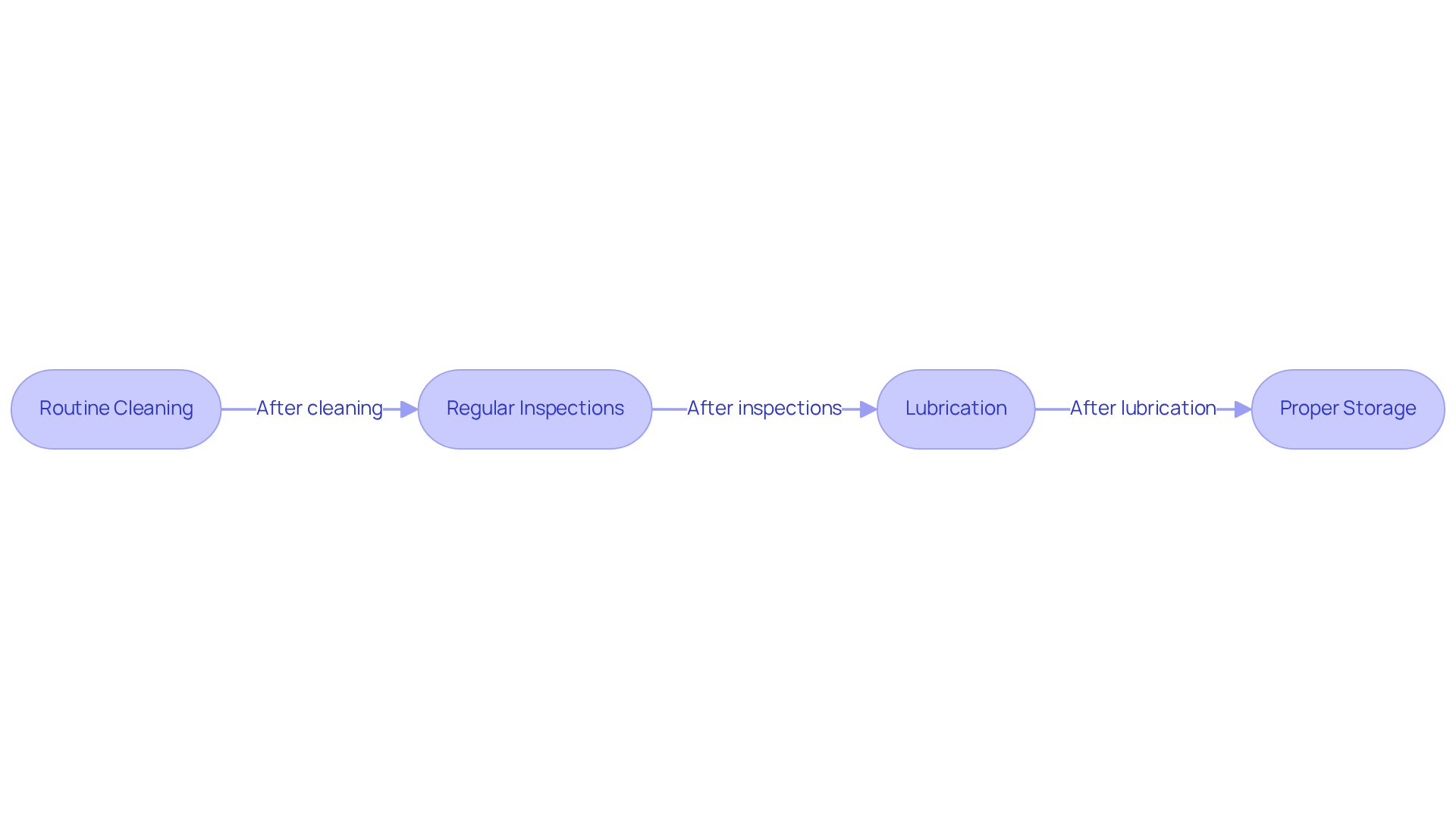

Maintain and Care for Roofing Equipment

To keep roofing equipment in peak condition, regular maintenance and care are crucial. Here are some best practices:

-

Routine Cleaning: After each use, thoroughly clean instruments and equipment to eliminate dust, debris, and materials that could lead to wear or damage. For instance, dust and asphalt can clog power tools and dull blades, impacting their performance. As noted by Enterprise Roofing, "Regular roof cleaning is an investment in the longevity, appearance, and safety of your home."

-

Regular Inspections: Schedule routine evaluations of all machinery to detect signs of wear or damage early. According to industry experts, "Regular inspections can help identify these problems and address them before they escalate." Addressing issues swiftly can prevent further deterioration and expensive repairs, as regular inspections can significantly extend the lifespan of machinery. Statistics indicate that device longevity can increase by up to 30% with consistent inspection practices.

-

Lubrication: Ensure that moving components of instruments are lubricated regularly to facilitate smooth operation and prevent rust. This is particularly crucial for power devices and machinery with mechanical parts, as overlooking lubrication can result in early failure. Cara Stout emphasizes, "Maintenance also helps extend the lifespan of your roof."

-

Proper Storage: Keep instruments and equipment in a dry, secure place to safeguard them from weather-related harm and theft. Using toolboxes or racks not only maintains organization but also allows equipment to be easily reachable for upcoming projects. Neglecting proper storage can lead to significant damage, as tools exposed to the elements may require costly repairs or replacements.

By adopting these maintenance practices, roofing contractors can enhance the reliability and effectiveness of their tools, ultimately leading to more successful project outcomes. Incorporating insights from case studies, such as those highlighting successful equipment care strategies, can further illustrate the effectiveness of these recommended practices.

Conclusion

Effective management of roofing equipment is vital for project success, safety, and efficiency. By concentrating on thorough assessments, safety protocols, appropriate tool selection, and diligent maintenance, roofing professionals can significantly boost their operational effectiveness.

Key strategies include:

- Assessing project requirements to determine the right equipment.

- Implementing rigorous safety measures to protect workers.

- Choosing tools that align with specific materials.

- Maintaining equipment to extend its lifespan.

Each of these elements plays a crucial role in minimizing risks, preventing delays, and delivering high-quality results in roofing projects. Prioritizing these best practices not only safeguards investments but also fosters a culture of safety and efficiency within the roofing industry.

By adopting a proactive approach to equipment management, roofing contractors can ensure they are well-equipped to tackle any project challenges. This ultimately leads to successful outcomes and satisfied clients.

Frequently Asked Questions

Why is it important to assess project requirements before starting a roofing project?

Assessing project requirements is essential to ensure the availability of the right roofing equipment, leading to smoother operations and minimizing the risk of delays.

What factors should be evaluated when assessing the roof for a project?

Key factors include the roof's size and type, the materials needed, specific tasks to be completed, and site conditions.

How do you evaluate the size and type of a roof?

Start by accurately measuring the total area of the roof and identifying its type, whether it is flat, pitched, or another configuration. This assessment helps determine the appropriate roofing equipment required.

Why is it necessary to identify material requirements for roofing?

Different roofing materials, such as asphalt shingles, metal, and tiles, require specific roofing equipment for their installation. Ensuring all necessary tools are available is crucial for a successful project.

What should be considered regarding site conditions during the assessment?

A comprehensive site assessment should identify any obstacles or hazards, such as overhead power lines or limited access points, which may impact the usage of machinery and inform decisions about the size and type of tools needed.

How can labor needs be planned for in a roofing project?

Evaluate the number of workers involved and identify tools that will enhance their efficiency, including safety gear and tools that promote productivity.

What benefits do best practices in project assessment provide?

Integrating best practices enhances project efficiency and safeguards investments in construction by ensuring that the right equipment and tools are available for the tasks at hand.

What innovative solutions does EZ Equipment Rental offer for roofing projects?

EZ Equipment Rental provides innovative climbing solutions, such as Little Giant Ladders, which feature unique protective mechanisms and versatility, catering to both professionals and DIY enthusiasts.

List of Sources

- Assess Project Requirements for Roofing Equipment

- How to Evaluate Residential Roofing Quotes: A Homeowner's Guide (https://jobsonroofing.com/how-to-evaluate-residential-roofing-quotes)

- 7 tips for comparing industrial roofing quotes (https://eliteroofing.com/comparing-industrial-roofing-quotes)

- Evaluating Commercial Roofing Quotes: Smart Tips (https://southwestcommercialroofing.com/blog/evaluating-commercial-roofing-quotes-guide)

- 7 Tips for a Successful Roofing Project (https://johnstonroofing.com/roofing/7-tips-for-a-successful-roofing-project)

- 30 Roofing Industry Statistics Every Sales Pro Needs to Know (https://rooflink.com/insights/roofing-industry-statistics)

- Implement Safety Protocols and Equipment

- Roofing Safety (Multiple-Unit Roof Coverings) Stats and Facts (https://bhhcsafetycenter.com/roofing-safety-multiple-unit-roof-coverings-stats-and-facts?print=pdf)

- Best Safety Practices in Roofing Projects - DDP Roofing (https://ddproofing.com/blog/best-practices-for-safety-in-roofing)

- How Roofing Service Experts Ensure Safety During Roof Repairs (https://rainierroofingcompany.com/how-roofing-service-experts-ensure-safety-during-roof-repairs)

- The Importance of Personal Protective Equipment in Roofing Safety - Roofing (https://roofingmagazine.com/the-importance-of-personal-protective-equipment-in-roofing-safety)

- The Importance of Safety in Commercial Roofing - DDP Roofing (https://ddproofing.com/blog/importance-of-safety-in-commercial-roofing)

- Select Appropriate Tools for Roofing Materials

- Roofing Tools and Equipment Everything You Need to Know About (https://brothersexteriorcorp.com/roofing-tools-and-equipment)

- How to Choose the Right Roofing Tools for Your Projects | Preferred (https://preferredroofingsupply.com/how-to-choose-the-right-roofing-tools-for-your-projects)

- Atto: Timesheet & Time Tracking Software (https://attotime.com/blog/roofing-industry-statistics)

- Roofing Facts and Statistics (2025) (https://thisoldhouse.com/roofing/roofing-facts-and-statistics)

- TOP 25 ROOF QUOTES (of 662) | A-Z Quotes (https://azquotes.com/quotes/topics/roof.html)

- Maintain and Care for Roofing Equipment

- The Importance of Regular Roof Cleaning for Your Home - Enterprise Roofing (https://enterpriserfg.com/the-dayton-roofing-guide/the-importance-of-regular-roof-cleaning-for-your-home)

- The Importance of Regular Roof Inspections and Maintenance (https://commonwealthroofingpros.com/professional-roof-maintenance-frequency-of-roof-inspections-and-maintenance)

- Building a Preventive Maintenance Schedule for Commercial Roofs (https://cloudroofing.com/blog/building-preventative-maintenance-schedule-for-commercial-roofs)

- The Complete 2026 Roof Maintenance Checklist (https://roofgiant.com/blog/news/the-complete-2026-roof-maintenance-checklist?srsltid=AfmBOorQkQC4A-UDqC5_Z74OS5cDYg9Vn1Cp1Up5iXjg7qGTq3kL-9Uj)

- Roofing and Maintenance: 7 Vital & Essential Tasks (https://aastroroofing.com/roofing-and-maintenance)