Overview

Best practices for material lifts in construction begin with selecting the appropriate lift type tailored to specific project needs. This critical choice sets the foundation for operational success. Furthermore, ensuring comprehensive operator training is paramount; well-trained operators are essential for maximizing safety and efficiency on site. Regular maintenance is another cornerstone of effective lift management, as it not only enhances safety but also reduces the risk of equipment failure.

The article emphasizes that the right selection, coupled with thorough operator education and structured maintenance programs, significantly mitigates injury risks and minimizes operational downtime. These practices are not merely recommendations; they are proven strategies that lead to improved overall project outcomes. By investing in these areas, construction teams can enhance their productivity and ensure a safer working environment.

In addition, adopting these best practices fosters a culture of safety and reliability within the construction industry. The evidence is clear: projects that prioritize proper lift management tend to experience fewer accidents and delays. This not only protects workers but also contributes to the timely completion of projects, reinforcing the importance of reliability and quality in equipment rental.

To achieve these benefits, it is crucial to take action now. Evaluate your current practices and consider how implementing these best practices can transform your project outcomes. Engage with us to learn more about the right material lifts for your needs and how we can support your commitment to safety and efficiency.

Key Highlights:

- Material lifts are essential for transporting heavy materials vertically on construction sites, available in hydraulic, electric, and manual forms.

- Hydraulic lifts are preferred for large projects due to their speed and capacity, while electric lifts are favored for their eco-friendliness.

- The construction industry is increasingly adopting advanced hoisting technologies, driven by rising demand and significant investments, such as China's $4.2 trillion in infrastructure.

- Material lifts enhance operational efficiency and safety by reducing manual handling, which lowers injury risks and speeds up project timelines.

- Project managers must consider weight, height, and spatial limitations when selecting material lifts, and engage with rental specialists for optimal choices.

- Best practices for operating material lifts include comprehensive operator training, regular inspections, adherence to load limits, and maintaining a clear work area.

- Consistent maintenance of material lifts extends their lifespan and ensures safety, with structured programs reducing downtime and enhancing reliability.

- Continuous training programs for operators, including emergency simulations and skill refreshers, are vital for maintaining safety standards and reducing accident rates.

Introduction

In the dynamic world of construction, the efficient movement of materials is crucial to project success. Material lifts—ranging from hydraulic to electric models—serve as the backbone of this operation, enabling the vertical transport of heavy loads with ease and precision. As the industry evolves, the demand for these lifts is surging, driven by advancements in technology and a growing emphasis on safety and sustainability.

With significant investments in infrastructure and an increasing focus on operational efficiency, understanding the various types of material lifts and their applications has never been more important. This article delves into the essential role of material lifts in modern construction, exploring their advantages, best practices for safe operation, and the vital training needed to harness their full potential.

Understanding Material Lifts: An Overview

Material lifts for construction are indispensable equipment within the construction industry, specifically engineered to transport heavy materials vertically across job sites. These mechanisms manifest in various forms, including hydraulic systems, electric devices, and manual hoists, each tailored for specific tasks. Hydraulic platforms, for instance, are favored for their remarkable raising capacity and speed, rendering them particularly suitable for large-scale projects where time efficiency is critical.

Electric elevators are increasingly gaining traction due to their eco-friendly design, aligning seamlessly with the industry's shift towards sustainable practices. Meanwhile, manual hoists continue to serve as a reliable option for smaller tasks, ensuring versatility across various project sizes.

As we look toward 2025, is witnessing a significant rise in utilization, driven by the growing demand for effective and secure hosting solutions. This trend is underscored by construction sites increasingly adopting advanced hoisting technologies, such as forklifts and boom cranes, to enhance productivity and security. Forklifts play a pivotal role in this environment, enabling the lifting of heavy loads and ensuring that tasks are completed efficiently.

For example, full-body harnesses are mandated for boom equipment, ensuring worker safety during operation, while scissor devices can function without fall protection if guardrails are in place. The global construction landscape is further shaped by substantial investments, such as China's estimated 27 trillion yuan (US$ 4.2 trillion) investment in new infrastructure during the 14th Five-Year Plan Period. This investment is expected to boost demand for material lifts for construction and related equipment, further underscoring the vital function of boom apparatus in facilitating task completion.

Real-world applications of these devices underscore their versatility. In a recent project, a major construction firm employed hydraulic devices to streamline the installation of heavy structural components, significantly reducing project timelines. Similarly, electric elevators have been utilized in urban settings to minimize noise and emissions, reflecting the industry's commitment to sustainability.

Experts underscore the importance of understanding the various types of equipment and their applications. As Kevin O’Shea aptly notes, "It’s a competitive world out there – and it seems more so than pre-pandemic," highlighting the necessity for managers to remain informed about the latest equipment trends and safety protocols. The equipment rental market features key players such as EZ Equipment Rental, who prioritize client satisfaction and innovative hoisting solutions.

By leveraging the appropriate equipment rentals, such as those offered by EZ Equipment Rental, managers can not only enhance operational efficiency but also ensure a safer working environment for their teams.

The Advantages of Utilizing Material Lifts in Construction Projects

Integrating material lifts for construction, especially forklifts from , presents numerous advantages that significantly enhance operational efficiency and safety. These elevators facilitate the swift transportation of goods, greatly reducing the time employees spend on manual handling. This increased efficiency not only accelerates project timelines but also leads to substantial cost savings, allowing projects to be completed more quickly and within budget constraints.

Moreover, equipment plays a crucial role in bolstering safety on construction sites. By reducing the need for manual lifting and carrying of heavy loads, they considerably diminish the risk of injuries, particularly back injuries, which are common in manual handling scenarios. The construction industry has faced significant safety challenges, with a staggering 112,000 large truck injury collisions recorded in 2018, highlighting the importance of safety protocols, including the use of material handling equipment, to mitigate such risks.

For instance, a construction site utilizing equipment for lifting materials can witness a marked decrease in injury occurrences, fostering a safer working environment. The strategic deployment of equipment from EZ Equipment Rental also streamlines workflows by ensuring that materials are delivered precisely where needed, thereby alleviating congestion on the site. This targeted delivery not only enhances productivity but also cultivates a more organized and efficient work atmosphere.

As the construction sector grapples with rising material costs—projected to increase by 3%-6% in 2025 due to factors such as natural disasters and ongoing supply chain disruptions—the adoption of material elevating equipment becomes increasingly vital. By optimizing labor and reducing the risk of costly injuries, these tools represent a smart investment for managers seeking to enhance both safety and productivity on their sites. The forklifts available at EZ Equipment Rental are equipped with advanced features that ensure reliability and efficiency, making them indispensable for any construction project.

Furthermore, the Material Lifts Market Report 2025 reveals that the demand for material lifts in construction is fueled by urbanization and technological advancements, underscoring their significance in contemporary construction practices.

Choosing the Right Material Lift for Your Construction Needs

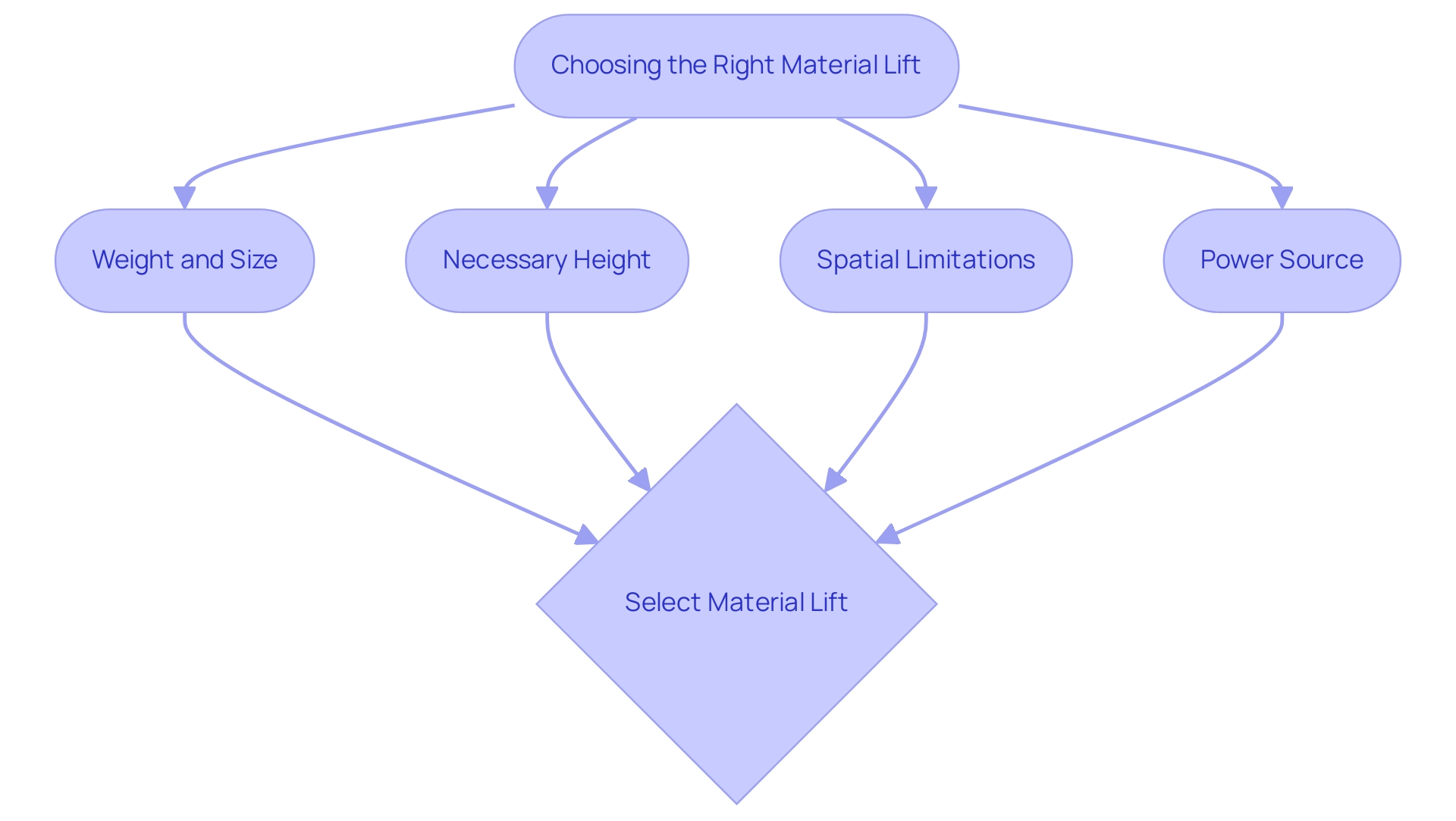

Selecting the appropriate material lifts for construction projects requires a thorough evaluation of several critical factors. Key considerations include:

- The weight and size of the items to be lifted

- The necessary height

- The spatial limitations of the job site

Project managers must also evaluate the hoist's power source—whether hydraulic or electric—since this decision significantly influences operational efficiency and maintenance needs.

For example, hydraulic systems are often preferred for handling heavier loads, while electric systems excel in maneuvering lighter materials in confined spaces.

Understanding the specific tasks that material lifts will perform is essential. Whether the lift is intended for transporting items to elevated levels or moving equipment across the site, this knowledge will inform the selection of the most appropriate material lifts. Notably, statistics indicate that a furniture company in New York improved its operational capacity by 50% through the use of an equipment hoist, underscoring the potential benefits of choosing the right tools.

Engaging with equipment rental specialists can offer invaluable insights into the best material lift options available. As Justin Ennis, a winemaker, remarked, "The PFlow VRC is a very important piece of equipment in the Freestone winery, the ideal operational complement for ." This statement emphasizes the significance of selecting specialized equipment tailored to specific operational requirements.

Moreover, the case study of the PFlow VRC at JPV Freestone Winery illustrates how adopting such equipment can enhance operational workflow, providing practical insights for managers when selecting handling systems.

Best Practices for Safe Operation of Material Lifts

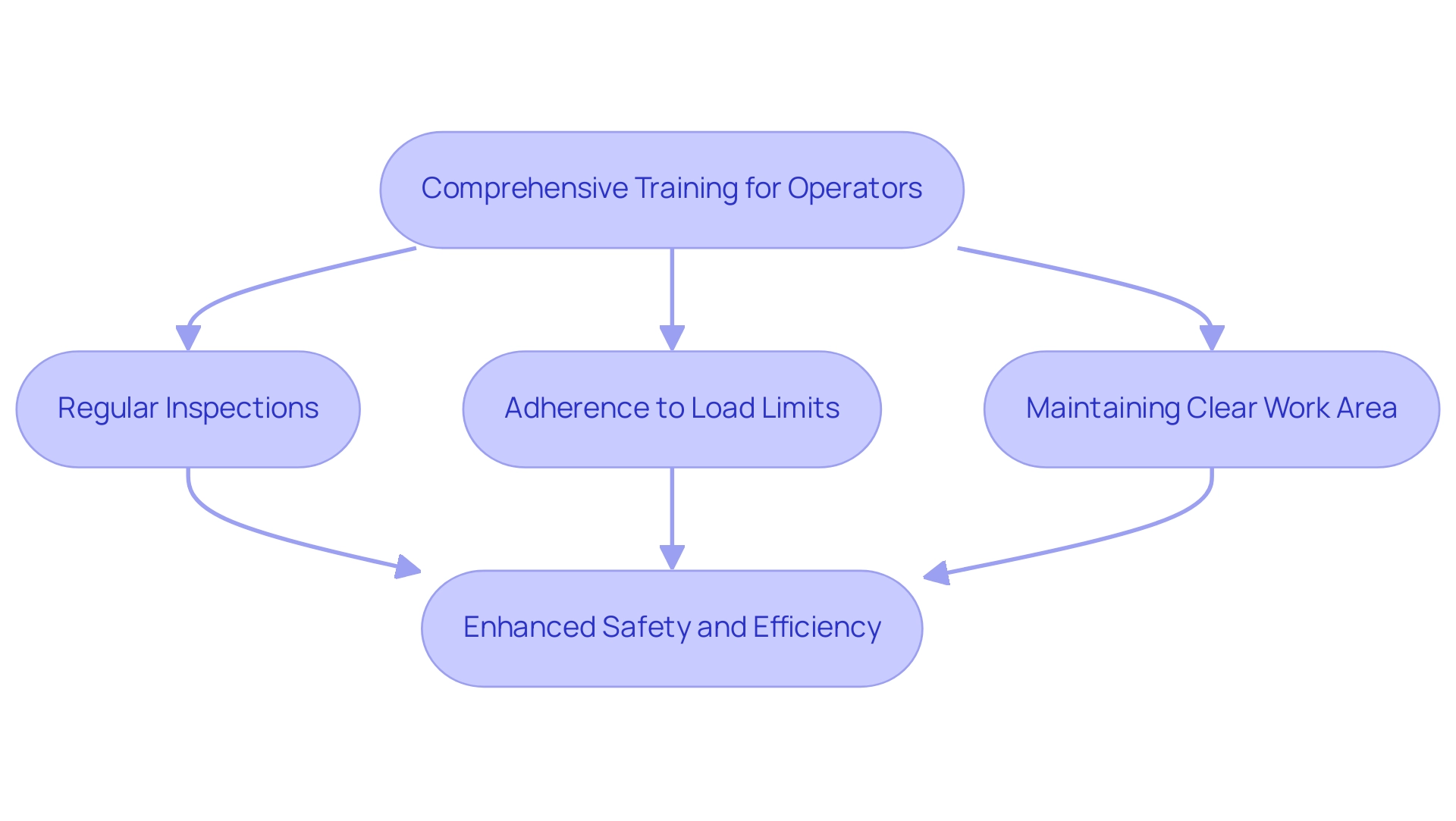

To ensure the secure functioning of material lifts for construction, project managers must adopt a series of best practices that prioritize both security and efficiency. Comprehensive training for operators is paramount, covering the equipment's controls, protective features, and operational protocols. This training is essential; improper use of material lifts can lead to significant accident rates, including injuries from being struck by or caught between objects, as well as falls from the lifts themselves.

Injury statistics reveal that these incidents are among the most frequent in forklift operations, underscoring the critical need for thorough training and precautionary measures. Regular inspections of material lifts are vital before each use to identify any mechanical issues or signs of wear and tear. These proactive measures mitigate risks associated with equipment failure. Operators must strictly adhere to the manufacturer's load limits, as overloading can result in dangerous tipping incidents.

For example, a case study on highlights the importance of cautious operation, particularly regarding speed, turning, and loading practices. The findings suggest that operators should remain particularly mindful of these factors to reduce the likelihood of accidents. Maintaining a clear and stable work area around the material lifts is equally important. Ensuring that the ground is even and free of debris significantly reduces the likelihood of accidents during operation. Operating on compromised surfaces, such as uneven or slippery areas, increases the risk of tip-overs, as noted in recent news reports.

Therefore, it is essential to thoroughly assess the work environment before operating material lifts for construction. Incorporating these best practices not only enhances security but also prolongs the lifespan of the equipment. As stated by Optimum Safety Management, "a culture of security through effective training and adherence to operational protocols can lead to improved engagement, productivity, and profitability." By nurturing such a culture, project managers can significantly enhance outcomes and operational efficiency on construction sites.

Maintaining Material Lifts: Ensuring Reliability and Safety

Consistent upkeep of equipment, including forklifts and boom hoists from EZ Equipment Rental, is essential for guaranteeing their dependability and security on construction sites. Project managers must implement that encompasses:

- Routine inspections

- Lubrication of moving parts

- Timely replacement of worn components

Keeping meticulous records of maintenance activities is crucial, as it helps identify patterns that may signal potential issues.

For example, if an elevator frequently requires maintenance, it may indicate that replacement is necessary to prevent risks and operational delays.

Adhering to the manufacturer's maintenance guidelines is vital, as it not only prevents costly breakdowns but also significantly extends the equipment's lifespan. Research indicates that well-maintained lifts can last significantly longer, with average lifespans extending beyond 10 years when proper care is taken. Furthermore, regular maintenance enhances the safety of operators, reducing the risk of accidents and injuries on site.

The economic implications of maintenance are significant, as equipment moving machine operators earn a median pay of $44,750, highlighting the value of skilled operators who are well-trained in maintenance practices.

To illustrate effective maintenance practices, consider the case study of a construction company that implemented a structured maintenance program for their material lifts, including forklifts from EZ Equipment Rental. By organizing:

- Weekly inspections

- Monthly thorough evaluations

They decreased equipment downtime by 30% and enhanced overall ratings. This proactive strategy not only ensured the reliability of their elevators but also contributed to a more efficient schedule, showcasing the essential role of these machines in enhancing construction efficiency.

Incorporating maintenance best practices, such as using template forms for temporary works to assist with compliance and safety, can further streamline the process. Additionally, the integration of augmented and virtual reality (AR/VR) tools is transforming maintenance training and execution, enabling technicians to access manuals and receive expert support on-site. By prioritizing maintenance and utilizing modern technology, including the innovative services provided by EZ Equipment Rental, project managers can ensure that equipment operates smoothly and safely throughout the project lifecycle, ultimately leading to successful project outcomes.

Furthermore, referencing the case study titled "Training Pathways for Construction Equipment Operators" emphasizes the importance of proper training and maintenance knowledge for operators, reinforcing the need for structured maintenance programs.

Training Your Team: Essential Skills for Operating Material Lifts

Training stands as a crucial pillar in ensuring the safe and effective operation of material lifts in construction settings. Project managers must prioritize the development of comprehensive training programs that encompass not only equipment operation but also essential protocols and emergency procedures. A combination of hands-on training sessions and theoretical knowledge significantly enhances operators' confidence and competence, preparing them to navigate various scenarios they may face on the job site.

Continuous training and refresher courses are vital for maintaining skill levels and ensuring compliance with the latest regulations. For instance, integrating simulations of emergency scenarios into training can equip operators to respond effectively in real-life situations, thereby bolstering workplace safety. Statistics reveal that regular training can lead to a significant reduction in accident rates, highlighting the necessity of investing in operator education.

As Tom Wilkerson, CEO of CertifyMe.net, aptly states, "Yet despite , training gaps continue to plague companies all across the United States."

Moreover, effective training programs must be tailored to meet the specific needs of equipment operators, focusing on critical skills such as:

- Load management

- Pre-shift inspections

- Proper maneuvering techniques

Regular maintenance of forklifts should also align with the manufacturer's guidelines, underscoring the importance of thorough training. By referencing case studies like 'How to Avoid Forklift Tip-Overs: 9 Simple Tips,' managers can incorporate practical training elements that prevent accidents, including:

- Operator training

- Pre-shift inspections

- Proper loading techniques

By cultivating a culture of continuous learning and safety, project managers can significantly mitigate risks associated with material lifts in construction operations, ultimately fostering a more efficient and secure work environment.

Conclusion

The critical role of material lifts in the construction industry is paramount. From hydraulic to electric models, these lifts are essential for the efficient vertical transport of heavy materials, significantly enhancing operational productivity and safety. By understanding the various types of lifts and their specific applications, project managers can make informed choices that align with the demands of modern construction projects.

Incorporating material lifts streamlines workflows and mitigates the risks associated with manual handling of heavy loads, thereby fostering a safer work environment. As the industry confronts rising material costs and the need for enhanced efficiency, the strategic utilization of these lifts becomes increasingly vital. Regular maintenance and comprehensive operator training further ensure that these machines operate reliably and safely, ultimately contributing to successful project outcomes.

As the construction landscape evolves, staying informed about the latest advancements in material lift technology and best practices is essential. By prioritizing safety, efficiency, and sustainability, project managers can harness the full potential of material lifts, paving the way for more successful and timely project completions. Investing in the right equipment and training is not merely a matter of compliance; it is a strategic decision that enhances overall project performance and safety on construction sites.

Frequently Asked Questions

What are material lifts used for in construction?

Material lifts are essential equipment in the construction industry designed to transport heavy materials vertically across job sites.

What types of material lifts are available?

Material lifts come in various forms, including hydraulic systems, electric devices, and manual hoists, each suited for specific tasks.

Why are hydraulic platforms preferred for large projects?

Hydraulic platforms are favored for their high raising capacity and speed, making them particularly suitable for large-scale projects where time efficiency is critical.

What advantages do electric elevators offer?

Electric elevators are gaining popularity due to their eco-friendly design, aligning with the construction industry's shift towards sustainable practices.

How do manual hoists fit into the material lift options?

Manual hoists are a reliable option for smaller tasks, ensuring versatility across various project sizes.

What is driving the increase in material lift utilization by 2025?

The growth in demand for effective and secure hosting solutions, along with substantial investments in infrastructure, is driving the rise in material lift utilization.

How do forklifts contribute to construction efficiency?

Forklifts enable the lifting of heavy loads, enhancing productivity and ensuring tasks are completed efficiently on construction sites.

What safety measures are necessary when using boom equipment?

Full-body harnesses are required for boom equipment operation to ensure worker safety, while scissor devices can operate without fall protection if guardrails are in place.

How is the global construction landscape evolving?

Significant investments, such as China's estimated 27 trillion yuan investment in new infrastructure, are expected to boost demand for material lifts and related equipment.

Can you provide an example of how material lifts have been applied in real-world projects?

A major construction firm used hydraulic devices to streamline the installation of heavy structural components, significantly reducing project timelines.

What are the benefits of using material lifts for safety on construction sites?

Material lifts reduce the need for manual lifting, which decreases the risk of injuries, particularly back injuries common in manual handling scenarios.

How do material lifts help in managing construction site workflows?

Material lifts ensure that materials are delivered precisely where needed, alleviating congestion on the site and fostering a more organized work atmosphere.

What challenges does the construction industry face regarding material costs?

Material costs are projected to increase by 3%-6% in 2025 due to factors like natural disasters and supply chain disruptions, making the adoption of material elevating equipment vital.

What does the Material Lifts Market Report 2025 indicate about the demand for material lifts?

The report indicates that demand for material lifts in construction is fueled by urbanization and technological advancements, highlighting their significance in modern construction practices.