Key Highlights:

- Understanding telehandler specifications, including maximum lift capacity and reach, is crucial for safe operation.

- Safety features such as load-sensing systems and stability controls enhance operational efficiency and safety.

- Boom lifts offer significant vertical and horizontal reach, essential for tasks like construction and repairs.

- Pre-operation checks should include fluid levels, tyre conditions, and functionality of protective features.

- Regular maintenance following manufacturer guidelines can extend equipment lifespan and reduce repair costs.

- Comprehensive training and certification for operators ensure compliance with OSHA standards and safe equipment use.

- Operators must follow safety protocols, including maintaining a clear line of sight and securing loads before lifting.

- Regular safety meetings reinforce operational guidelines and promote a culture of safety on job sites.

Introduction

Operating a 12k telehandler involves distinct challenges and opportunities that require a thorough understanding of its specifications and safety features. By mastering best practices, operators can improve efficiency while prioritizing safety across various work environments. However, with the risk of accidents and expensive repairs, how can operators ensure they are adequately prepared to handle the complexities of telehandler operation? This article explores essential strategies for safe and effective telehandler use, providing insights that can enhance operational practices on the job site.

Understand Telehandler Specifications and Safety Features

Before operating a material handler, it is crucial to understand its specifications, such as maximum lift capacity, reach, and height. For example, a 12k telehandler usually has a maximum lift capacity of 12,000 pounds and can achieve heights of up to 55 feet. Familiarity with these specifications enables personnel to make informed decisions regarding load management and ensures that they do not exceed the machine's limits.

Additionally, users should be aware of safety features like load-sensing systems, stability controls, and emergency stop functions. Understanding these features not only enhances safety but also improves operational efficiency, allowing users to maximize the telehandler's capabilities. Moreover, recognizing the relationship between boom extension and lifting capacity is vital for safe operation, as it directly affects the machine's stability.

Boom lifts, known for their impressive vertical and horizontal reach, offer similar advantages, enabling workers to access elevated areas and navigate around obstacles with ease. This capability is essential for tasks such as painting, repairs, or construction work. Increased ground clearance in telehandlers also improves mobility over challenging terrain, which is critical for maintaining safety on job sites.

Ergonomic factors, including cab size and seat quality, significantly impact driver comfort during extended shifts, reducing fatigue and enhancing overall safety. As highlighted by construction risk specialists, recognizing these functional boundaries is essential for preventing incidents and ensuring effective equipment use.

Conduct Pre-Operation Checks and Regular Maintenance

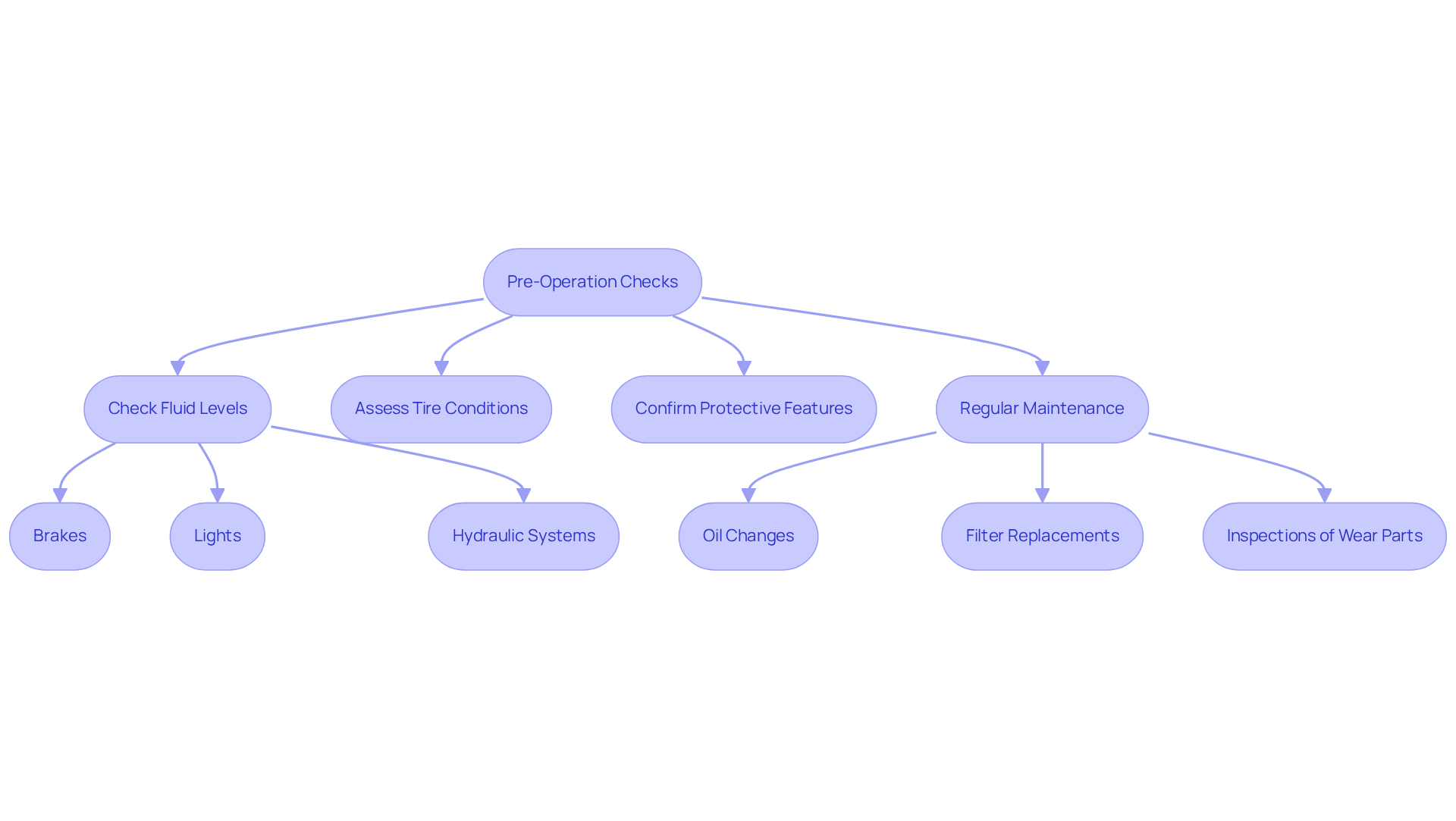

Before each use, operators must conduct a thorough pre-operation inspection of the 12k telehandler. This inspection should include:

- Checking fluid levels

- Assessing tire conditions

- Confirming that all protective features are operational

A detailed checklist can streamline this process, ensuring that critical components such as:

- Brakes

- Lights

- Hydraulic systems

are thoroughly examined. Regular maintenance must adhere to the manufacturer's guidelines, covering essential tasks like:

- Oil changes

- Filter replacements

- Inspections of wear parts

For example, routinely checking the integrity of boom hoses and the functionality of the hydraulic system can significantly reduce the risk of costly repairs and enhance safety on the job site. Additionally, quarterly maintenance should be scheduled to ensure all components of the machine are functioning optimally. Implementing a structured maintenance schedule not only extends the lifespan of the equipment but also promotes a safer working environment. As Joshua Taylor, Product Manager at Genie, emphasizes, "Pre-operation inspections and function tests should be conducted before the equipment is put in use for the day, every time." This proactive approach to maintenance is essential for preventing accidents and ensuring operational integrity.

Ensure Proper Training and Certification for Operators

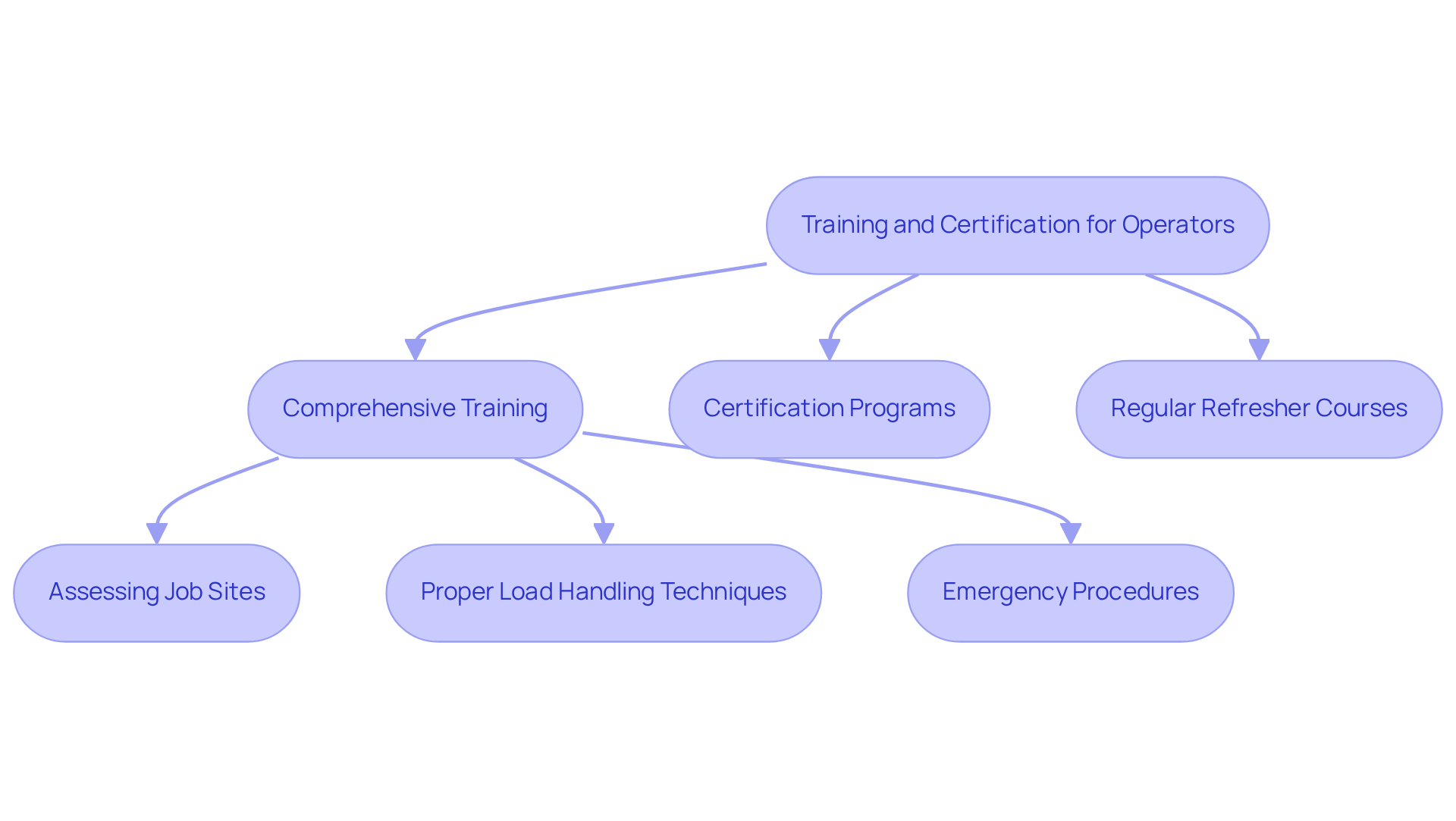

All handlers of equipment must undergo comprehensive training that includes both theoretical knowledge and practical skills. This training covers the operation of lifting machines, understanding load charts, and recognizing potential hazards. Certification programs compliant with OSHA standards ensure that personnel possess the necessary skills to operate equipment safely. For example, training should encompass:

- Assessing job sites for hazards

- Proper load handling techniques

- Emergency procedures

Most forklift training programs can be completed in just a few hours to one day, making them efficient and accessible. Regular refresher courses further uphold high-quality standards and keep personnel informed about best practices. According to OSHA, "OSHA requires that all equipment operators must be trained and certified before using this machinery." Non-compliance with OSHA regulations can lead to fines and penalties for employers, while improper operation may result in costly repairs or replacements.

Follow Operational Guidelines and Safety Protocols

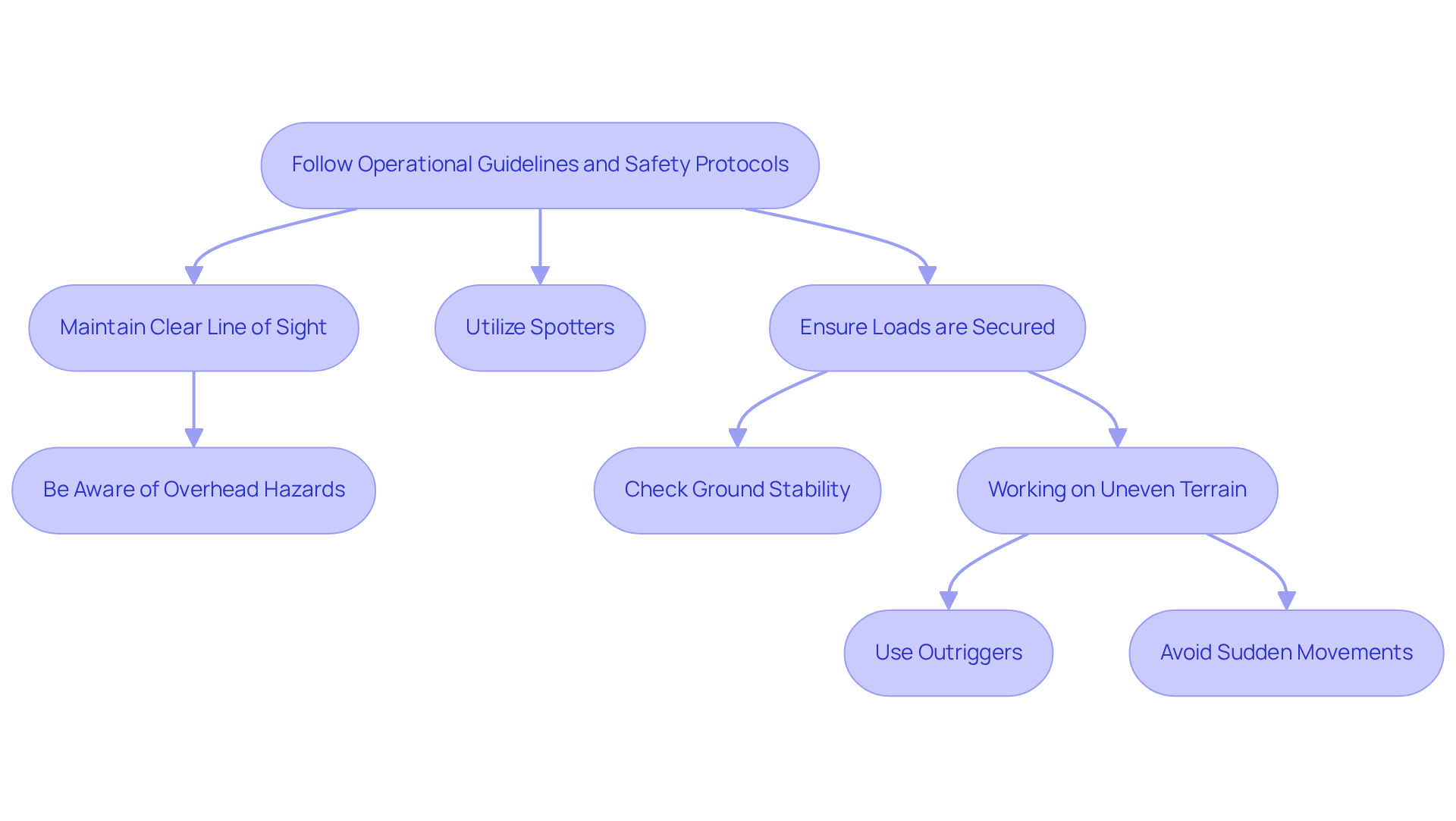

Operators must consistently follow the manufacturer's operational guidelines and safety protocols. This includes:

- Maintaining a clear line of sight while operating the lifting machine

- Utilizing spotters when necessary

- Ensuring that loads are secured before lifting

Furthermore, operators should remain vigilant about their surroundings, particularly regarding:

- Overhead hazards

- The stability of the ground beneath the 12k telehandler

For instance, when working on uneven terrain, it is essential to:

- Use outriggers if available

- Avoid sudden movements that could result in tipping

Regular safety meetings can reinforce these protocols, ensuring that safety remains a priority in daily operations. By adhering to these guidelines, operators contribute to a safer work environment and enhance the reliability of equipment usage.

Conclusion

Operating a 12k telehandler safely and efficiently requires a thorough understanding of its specifications, safety features, and operational protocols. Preparation, training, and strict adherence to safety measures are crucial for operators to maximize the telehandler's capabilities while minimizing risks. By fostering a culture of safety and efficiency, organizations can significantly enhance their operational effectiveness.

Key practices include:

- Conducting thorough pre-operation checks

- Maintaining a regular maintenance schedule to ensure optimal machine performance

- Well-trained and certified operators possess the necessary skills to address potential hazards and manage loads correctly

- A solid grasp of the telehandler's specifications and safety features empowers operators to make informed decisions, ultimately leading to safer job sites

In conclusion, prioritizing safety through training, regular maintenance, and adherence to operational guidelines is essential for successful telehandler operation. Implementing these best practices not only protects personnel but also enhances productivity and equipment longevity. Embracing these principles contributes to a safer, more efficient work environment, where every operator can perform their duties with confidence and competence.

Frequently Asked Questions

What are the key specifications to understand before operating a telehandler?

Key specifications include maximum lift capacity, reach, and height. For instance, a 12k telehandler has a maximum lift capacity of 12,000 pounds and can reach heights of up to 55 feet.

Why is it important to know the specifications of a telehandler?

Understanding the specifications helps personnel make informed decisions regarding load management and ensures that they do not exceed the machine's limits, promoting safety and efficiency.

What safety features should users be aware of when operating a telehandler?

Users should be aware of safety features such as load-sensing systems, stability controls, and emergency stop functions, which enhance safety and improve operational efficiency.

How does boom extension affect the lifting capacity of a telehandler?

The relationship between boom extension and lifting capacity is crucial for safe operation, as it directly impacts the machine's stability.

What advantages do boom lifts offer?

Boom lifts provide impressive vertical and horizontal reach, allowing workers to access elevated areas and navigate around obstacles, making them essential for tasks like painting, repairs, or construction work.

How does increased ground clearance in telehandlers benefit operation?

Increased ground clearance improves mobility over challenging terrain, which is critical for maintaining safety on job sites.

What ergonomic factors impact driver comfort when using a telehandler?

Ergonomic factors such as cab size and seat quality significantly affect driver comfort during extended shifts, reducing fatigue and enhancing overall safety.

Why is it important to recognize functional boundaries in telehandler operation?

Recognizing functional boundaries is essential for preventing incidents and ensuring effective equipment use, as highlighted by construction risk specialists.

List of Sources

- Understand Telehandler Specifications and Safety Features

- JLG® 1255 Telehandler | Boost Operator Comfort & Confidence | JLG (https://jlg.com/en/equipment/telehandlers/jlg/1255)

- 12,000 lb. Telehandler, 53-69 ft., Variable for Rent - United Rentals (https://unitedrentals.com/marketplace/equipment/forklifts/telehandlers/12000-lb-telehandler-53-69-ft-variable)

- Telehandler Safety Tips Every Operator Must Know (https://yashequipments.com/post/telehandler-safety-tips)

- Telehandler Specifications: What Buyers Must Know | Expert (https://telescro.com/telehandler-specifications-what-to-know)

- Telehandler 12k 55’ | LTCRENTALS.COM | Rentals Power on Demand (https://ltcrentals.com/product/telehandler-12k-55)

- Conduct Pre-Operation Checks and Regular Maintenance

- The Simple Things: Keep Your Telehandler Productive with Regular Maintenance (https://masonrymagazine.com/blog/2022/08/10/the-simple-things-keep-your-telehandler-productive-with-regular-maintenance)

- Get a lift from telehandler telematics (https://equipmentjournal.com/tech-news/get-a-lift-from-telehandler-telematics)

- Why you Should Perform Daily To Do’s on Your Telehandler (https://forconstructionpros.com/rental/lifting-equipment/telescopic-handler/article/21283172/genie-terex-awp-why-you-should-perform-daily-to-dos-on-your-telehandler)

- Telehandler Forklift Maintenance Tips (https://wollongongforklift.com.au/blog/essential-maintenance-tips-for-equipment-when-hiring-a-telehandler-forklift)

- Ensure Proper Training and Certification for Operators

- Why Telehandler Training Is Essential For Operators (https://getdriversed.com/blog-details/why-telehandler-training-is-essential-for-operators)

- Training requirements for Telehandler users and what constitutes a 'Suitable and Sufficient' risk assessment? - Hastam (https://hastam.co.uk/training-requirements-for-telehandler)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- OSHA Forklift Trainer Requirements: The Ultimate Guide (https://conger.com/osha-forklift-trainer-requirements)

- Tips for Telehandler Operation & Training | JLG (https://jlg.com/en/directaccess/tips-for-telehandler-operation-training)

- Follow Operational Guidelines and Safety Protocols

- Most common risks when working with a telehandler | TVH (https://tvh.com/learning-hub/most-common-risks-when-working-with-a-telehandler)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)