Overview

This article presents best practices for effectively utilizing man lifts with jibs, underscoring critical safety measures and efficiency strategies essential for construction and maintenance operations. It highlights vital safety protocols, including:

- Thorough training

- Comprehensive pre-operation inspections

- Strict adherence to load limits

Additionally, it discusses efficiency strategies such as:

- Regular maintenance

- Fostering effective communication

All designed to enhance operational safety and productivity on job sites. By implementing these practices, organizations can significantly reduce risks and improve overall performance.

Key Highlights:

- Man lifts with jibs enhance reach and versatility, crucial for construction and maintenance tasks.

- Types include articulating man lifts for flexibility and telescopic man lifts for height, each serving specific job needs.

- Recent advancements include electric and hybrid models, promoting sustainability and efficiency in operations.

- Safety protocols emphasize training, pre-operation inspections, PPE usage, stability checks, and adherence to load limits.

- Best practices for efficiency involve planning, regular maintenance, effective communication, and continuous training.

- Daily inspections, fluid level checks, and scheduled servicing are essential for maintaining man lifts in optimal condition.

- Common issues include power failures, jib malfunctions, stability problems, and control malfunctions, with specific troubleshooting steps provided.

- The construction industry anticipates growth in man lift usage, highlighting the need for well-trained operators and efficient practices.

Introduction

In the realm of construction and maintenance, man lifts equipped with jibs have emerged as essential tools, offering unparalleled reach and versatility. These specialized aerial work platforms are meticulously designed to tackle challenging tasks, enabling operators to access hard-to-reach areas with precision and efficiency.

As the industry evolves, understanding the various types of man lifts, their operational advantages, and best practices for their use becomes increasingly important. Ensuring safety through rigorous training and maintenance is paramount, as is maximizing efficiency with strategic planning.

This comprehensive guide delves into the critical aspects of operating man lifts with jibs, highlighting their significance in modern construction projects. As demand for efficient solutions grows, so does the imperative for operators to stay informed and prepared to navigate the complexities of these vital machines.

Understanding Man Lifts with Jibs: An Overview

Man lifts with jibs are specialized aerial work platforms that provide extended reach and versatility, making them indispensable for various construction and maintenance tasks. The jib, an extension of the crane's boom, significantly enhances horizontal outreach and maneuverability, enabling operators to access hard-to-reach areas effortlessly. These devices are particularly valuable in applications such as electrical work, building maintenance, and construction projects where height and precision are essential.

Understanding the different types of man hoists is crucial for selecting the appropriate equipment for specific job requirements. Articulating man raises feature joints that allow the platform to bend, offering exceptional flexibility and the ability to navigate around obstacles. In contrast, telescopic man raises extend straight up and out, providing greater height and reach but with reduced maneuverability. Each type possesses unique advantages, and the choice between them should be guided by the specific demands of the task at hand.

Recent advancements in the industry have led to the introduction of electric and hybrid boom devices, which enhance operational efficiency while reducing emissions, aligning with the growing emphasis on sustainability in construction. The efficiency of boom devices streamlines tasks, enabling workers to complete their jobs swiftly and effectively, resulting in cost savings and timely project completion. As the rental segment continues to dominate the market, driven by cost-efficiency and flexibility, understanding the capabilities of man lifts with jibs becomes increasingly important for project managers, particularly when considering options from EZ Equipment Rental.

In 2025, the market share of man lifts with jibs in the construction industry is projected to grow, reflecting their rising popularity and effectiveness across various applications. Expert insights underscore the importance of understanding the operational boundaries and benefits of these devices to optimize safety and efficiency on work sites. Angela Patterson, a product management specialist lead at JLG, emphasizes that "the EC600AJ's articulating design provides the versatility and precise positioning capabilities that modern construction and maintenance operations demand, all while delivering the environmental benefits and lower total cost of ownership of an electric platform."

Moreover, with over 1.3 million homes missing in Colombia's housing stock, the demand for efficient construction solutions is more urgent than ever, further highlighting the significance of personnel platforms with jibs in addressing these requirements.

Case studies illustrate the successful use of man lifts with jibs in construction projects, showcasing their contribution to improving productivity and safety. For example, a recent project utilized a man lift with jib to facilitate complex electrical installations in high-rise buildings, demonstrating their effectiveness in challenging environments. As the industry evolves, staying informed about the latest advancements and best practices concerning man lifts with jibs will empower construction project managers to make well-informed choices that enhance both performance and safety.

Safety First: Key Precautions for Operating Man Lifts

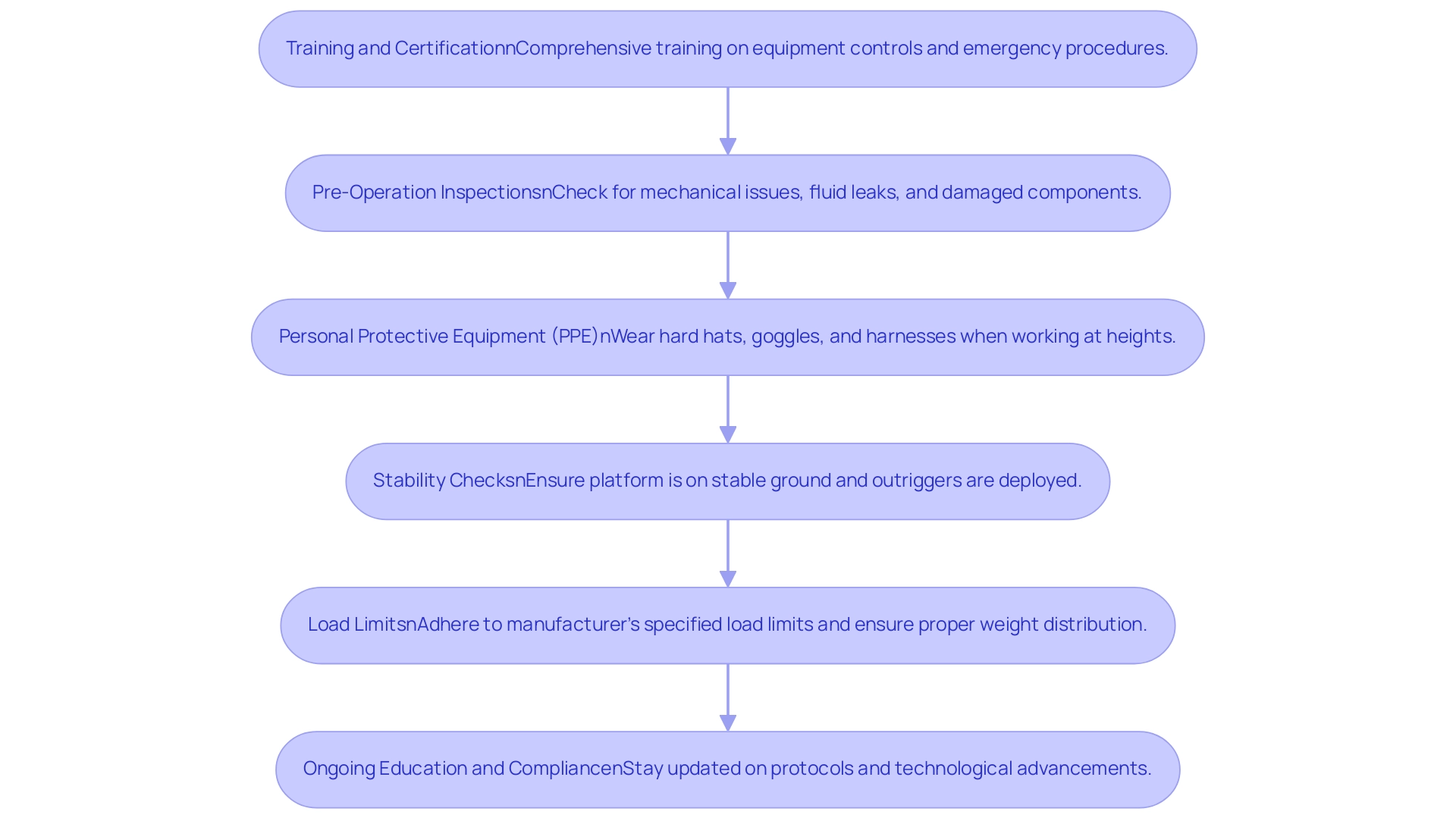

Operating a man lift with jib demands strict adherence to protocols to mitigate risks and enhance operational efficiency. Essential precautions include:

- Training and Certification: It is imperative that all personnel undergo comprehensive training and certification. This training should encompass a thorough understanding of the equipment's controls, protective features, and emergency procedures. Adequate training not only equips operators for the safe use of a man lift with jib but also significantly decreases accident rates linked to personnel platforms, a vital issue in the construction sector. According to statistics, 25% of aerial machinery fatalities result from scissor equipment mishaps, underscoring the necessity for thorough training and compliance with protocols.

- Pre-Operation Inspections: Conducting meticulous pre-operation inspections is vital. Operators should check for mechanical issues, fluid leaks, and any damaged components before each use. This proactive approach can prevent equipment failures that may lead to accidents, ensuring that the man lift with jib remains in optimal working condition.

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including hard hats, goggles, and harnesses when working at heights. The use of PPE is a fundamental aspect of workplace safety, protecting operators from potential hazards associated with aerial work.

- Stability Checks: Ensuring that the platform is positioned on stable ground is crucial. Operators should verify that outriggers are deployed when necessary to enhance stability. This precaution helps prevent tip-overs, which are a leading cause of accidents in aerial operation.

- Load Limits: Adhering to the manufacturer's specified load limits is essential. Overloading can lead to equipment failure and catastrophic accidents. Operators should be vigilant about weight distribution and ensure that the load does not exceed safe limits.

By implementing these safety measures, including the use of a man lift with jib, personnel can significantly reduce the risk of accidents and foster a safer working environment. The significance of training and certification cannot be overstated, as it equips operators with the knowledge and skills necessary to navigate the complexities of personnel hoist operations safely. As mentioned by ALC, "In a single afternoon, workers can be trained and certified to operate aerial equipment and be prepared to prevent these aerial equipment accidents."

Furthermore, ongoing education and compliance with protocols are essential considering the evolving technological advancements in construction, such as wearables and sensors, which continue to improve security and efficiency on job sites. Additionally, planning for challenges, such as operating heavy machinery in cold weather, can further ensure safety and productivity during personnel elevation operations.

Maximizing Efficiency: Best Practices for Using Man Lifts

To maximize efficiency when utilizing man hoists with jibs, adopting best practices is essential:

- Planning and Preparation: Before commencing any job, meticulous planning of movements and specific tasks is crucial. This strategic approach minimizes unnecessary repositioning, maximizing productivity and ensuring that every movement is purposeful.

- Regular Maintenance: Consistent upkeep and servicing of the man platform are vital. Renting from a reputable company like EZ Equipment Rental guarantees well-maintained machinery. Their equipment undergoes regular maintenance, including thorough inspections and necessary repairs, significantly reducing downtime and allowing for smoother project execution.

- Effective Communication: Clear communication among team members is essential, especially when multiple users are utilizing equipment in close proximity. This coordination streamlines movements and minimizes the risk of accidents, fostering a safer work environment.

- Utilizing the Job Effectively: Understanding how to leverage the job can greatly enhance operational efficiency. By using the job to access hard-to-reach areas without repositioning the entire equipment, teams can save valuable time and boost overall productivity.

- Continuous Training: Ongoing education for personnel is essential to keep them informed about new techniques and best practices. Regular training sessions ensure that all team members are equipped with the latest operational strategies, leading to improved performance on the job site.

By implementing these best practices, construction teams can significantly enhance their efficiency and effectiveness when utilizing a man lift with jib. The anticipated rise in jobs for construction machinery personnel, from 468,000 to 487,600 by 2033, fueled by heightened infrastructure investment, underscores the importance of enhancing man handling procedures. With approximately 45,700 job openings expected annually due to workforce turnover and retirements, ensuring that current operators are well-trained and efficient is more critical than ever.

For those seeking to improve operations, EZ Equipment Rental provides a broad selection of machinery, including boom raises and jib boom devices, along with extensive support services to assist in implementing these best practices effectively. Contact EZ Equipment Rental today at (214) 951-7800 to learn more about their offerings.

Maintenance Matters: Keeping Your Man Lift in Top Condition

Maintaining a man lift with jib is crucial for ensuring both safety and operational efficiency on construction sites. Essential maintenance practices must be followed to achieve this goal.

Daily Inspections: Conduct thorough walk-around inspections each day to identify any visible signs of wear, damage, or leaks. It is imperative to ensure that all protective features, such as emergency stop buttons and harness attachments, are functioning correctly to prevent accidents.

Fluid Levels: Regularly check and maintain hydraulic fluid levels, as insufficient fluid can significantly impair performance and compromise safety. Keeping fluid levels within the recommended range is essential for optimal operation.

Battery Maintenance: For electric hoists, ensure that batteries are fully charged and terminals are free from corrosion. Following the manufacturer's guidelines for battery care is critical to prolonging battery life and ensuring reliable performance.

Scheduled Servicing: Adhere to the manufacturer's recommended maintenance schedule, which typically includes more comprehensive inspections and servicing every few months. This proactive approach helps identify potential issues before they escalate, ensuring the elevator remains in peak condition.

Documentation: Maintain detailed records of all maintenance activities and inspections. This documentation is essential for monitoring the elevator's condition over time and ensuring adherence to regulatory standards.

In fact, a survey revealed that 48% of manufacturing companies face challenges in hiring skilled personnel, leading many to outsource maintenance. Maintaining detailed records can alleviate some of these challenges by offering clear insights into the equipment's maintenance history.

By emphasizing these maintenance practices, operators can improve the dependability and safety of their man lift with jib, ensuring it is always prepared for use on job sites. Compliance with daily inspection protocols is particularly important, as statistics indicate that preventive maintenance compliance should be 90% or higher to effectively reduce downtime and enhance safety. Furthermore, as the single man lifts market continues to grow due to technological advancements and infrastructure development, maintaining these lifts becomes increasingly relevant.

Manufacturers are also concentrating on product innovation and sustainability initiatives, making it essential for personnel to stay updated on best practices. Proper training and management support are critical, as highlighted by the statistic that 60-80% of CMMS implementations fail due to poor user engagement and unclear goals. By addressing these factors, personnel can ensure their maintenance practices are not only effective but also aligned with industry standards.

Troubleshooting Common Issues with Man Lifts

When utilizing a man lift with jib, operators may face a range of challenges. Here are common issues encountered along with effective solutions:

- Elevator Won't Move: If the elevator becomes unresponsive, first verify the power supply and ensure that all security switches are engaged. Additionally, inspect for hydraulic fluid leaks, as these can significantly impact operation.

- Jib Malfunction: Should the jib fail to extend or retract properly, examine the hydraulic lines for any leaks and confirm that all connections are secure. Regular maintenance checks on the man lift with jib can prevent these issues from arising.

- Stability Issues: If the lift exhibits instability, assess the ground conditions and ensure that outriggers are deployed correctly. Operating on uneven or soft ground can jeopardize security, so it’s crucial to establish a stable base before use.

- Overloading Alerts: In the event of an overload warning, promptly reduce the load to within the specified limits. It’s also important to review load distribution to ensure it is balanced, as improper loading can lead to dangerous situations.

- Control Malfunctions: If the controls become unresponsive, check for any error codes and refer to the user's manual for troubleshooting guidance. Regular inspections of control systems are essential to prevent malfunctions and ensure smooth operation.

By actively addressing these frequent problems, workers can enhance both productivity and safety on job sites employing a man lift with jib. The access industry is evolving, with updated ANSI standards emphasizing the importance of careful equipment selection and maintenance practices. As Brent Miller, Vice President of Sales Administration, Marketing & Latin America, states, "By embracing these trends, the access industry is poised for a more connected, productive, and safety-conscious future."

Furthermore, the integration of digital tools, such as JLG's Augmented Reality app, is becoming invaluable for planning and managing equipment effectively, further supporting operators in maintaining safe and efficient work environments. Given that approximately 2,000 deaths occur annually in accidents on stairs compared to 30 elevator accident deaths per year, it is essential to prioritize safety measures in the operation of man lifts.

Conclusion

Man lifts with jibs are indispensable in modern construction and maintenance, providing exceptional reach and versatility for accessing challenging areas. Understanding the various types of man lifts and their benefits is crucial for enhancing productivity and ensuring safety on job sites.

Safety remains the utmost priority when operating these lifts. Comprehensive training, diligent pre-operation inspections, and strict adherence to load limits are essential for minimizing accident risks. Furthermore, fostering a safety culture through ongoing education and the use of personal protective equipment significantly protects operators and enhances workplace safety.

In addition, employing best practices—such as careful planning and regular maintenance—can further elevate the efficiency of man lifts. As the demand for skilled operators continues to rise, staying informed about industry advancements and techniques becomes vital. This knowledge empowers teams to optimize their operations and contribute effectively to project success.

In conclusion, integrating man lifts with jibs transcends merely improving operational capabilities; it also encompasses ensuring safety and efficiency. As the industry evolves, operators must prioritize best practices and safety protocols. By embracing these strategies, construction teams can achieve safer, more productive outcomes on job sites.

Frequently Asked Questions

What are man lifts with jibs and their primary use?

Man lifts with jibs are specialized aerial work platforms that provide extended reach and versatility, making them essential for various construction and maintenance tasks, particularly in applications requiring height and precision.

What is the function of the jib on a man lift?

The jib is an extension of the crane's boom that enhances horizontal outreach and maneuverability, allowing operators to access hard-to-reach areas effortlessly.

What are the different types of man lifts available?

The two main types of man lifts are articulating man lifts, which feature joints for exceptional flexibility and navigation around obstacles, and telescopic man lifts, which extend straight up and out for greater height and reach but with reduced maneuverability.

What advancements have been made in man lift technology?

Recent advancements include the introduction of electric and hybrid boom devices, which enhance operational efficiency while reducing emissions, aligning with sustainability goals in construction.

How does the rental market influence the use of man lifts with jibs?

The rental segment is growing due to cost-efficiency and flexibility, making it increasingly important for project managers to understand the capabilities of man lifts with jibs.

What is the projected market trend for man lifts with jibs in the construction industry?

The market share of man lifts with jibs is expected to grow by 2025, reflecting their rising popularity and effectiveness across various applications.

What safety precautions should be taken when operating a man lift with jib?

Essential precautions include thorough training and certification, pre-operation inspections, wearing personal protective equipment (PPE), conducting stability checks, and adhering to load limits.

Why is training and certification important for operators of man lifts with jibs?

Comprehensive training and certification equip operators with the knowledge and skills necessary for safe operation, significantly decreasing accident rates associated with personnel platforms.

What role do pre-operation inspections play in the safe use of man lifts?

Pre-operation inspections help identify mechanical issues, fluid leaks, and damaged components before use, preventing equipment failures that could lead to accidents.

How can ongoing education and compliance with protocols enhance safety in man lift operations?

Ongoing education and adherence to safety protocols are essential to keep up with technological advancements and ensure operators are prepared to handle evolving challenges in construction environments.