Key Highlights:

- Off-road forklifts are designed for rugged terrains, featuring high ground clearance, heavy-duty tyres, powerful diesel engines, and enhanced suspension systems.

- Key benefits include improved productivity, reduced manual effort, and increased safety on construction sites with challenging landscapes.

- When selecting an off-road forklift, consider terrain conditions, load capacity (typically between 5,500 lbs to 35,500 lbs), manoeuvrability, and fuel type (diesel or electric).

- Safety measures include proper operator training, pre-operation checks, load management, and safe driving techniques to minimise accident risks.

- Regular maintenance practises such as inspections, cleaning, lubrication, and adherence to manufacturer guidelines are crucial for ensuring forklift longevity and reliability.

Introduction

Off-road forklifts are transforming the construction landscape, specifically engineered to meet the demands of rugged terrains and uneven surfaces. These robust machines not only boost productivity but also significantly enhance safety on job sites, making them indispensable for any construction project in challenging environments.

However, with this power comes the responsibility of understanding their features, selecting the appropriate model, and following best practices for safe operation. Construction managers must consider how to maximize the benefits of off-road forklifts while minimizing risks and inefficiencies.

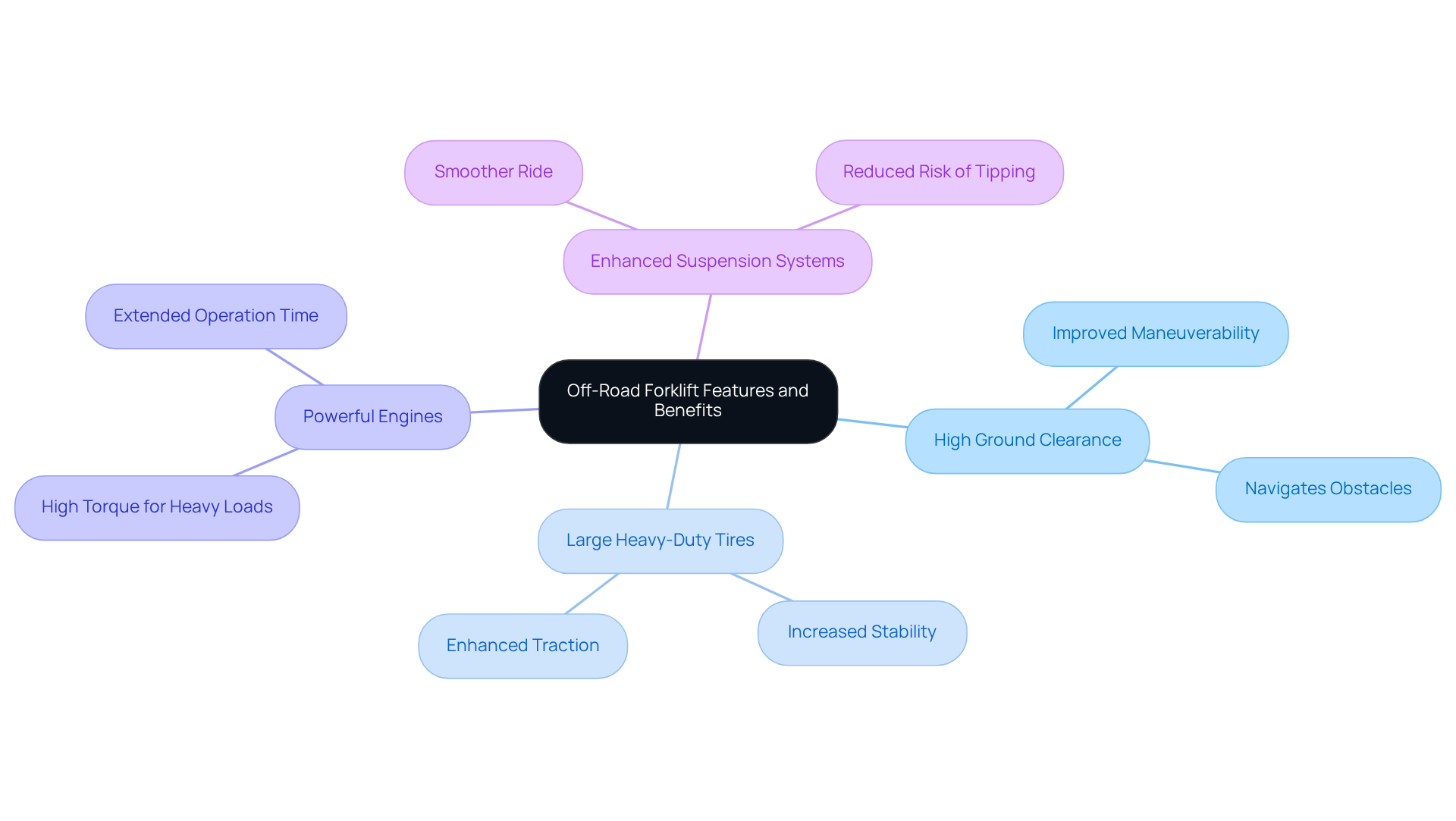

Understand Off-Road Forklift Features and Benefits

Off road forklifts are engineered to excel in uneven and rugged terrains, making them indispensable for construction projects. Their key features include:

- High Ground Clearance: This design enables forklifts to navigate obstacles without becoming stuck, providing a crucial advantage in challenging environments.

- Large, Heavy-Duty Tires: These tires improve traction and stability on loose or uneven surfaces, ensuring safe operation.

- Powerful Engines: Typically powered by diesel, these lifting machines deliver high torque, essential for raising heavy loads under demanding conditions.

- Enhanced Suspension Systems: These systems effectively absorb shocks, resulting in a smoother ride and reducing the risk of tipping over.

The advantages of utilizing an off road forklift are significant, resulting in increased productivity, reduced manual effort, and enhanced safety for both operators and team members. For example, a construction site situated in a hilly region can leverage the maneuverability and stability of an off road forklift, facilitating efficient material management and minimizing delays caused by terrain challenges. Industry leaders emphasize that high ground clearance is not just a feature but a vital element for maintaining operational efficiency in demanding settings, further highlighting the importance of investing in quality terrain vehicles for construction projects.

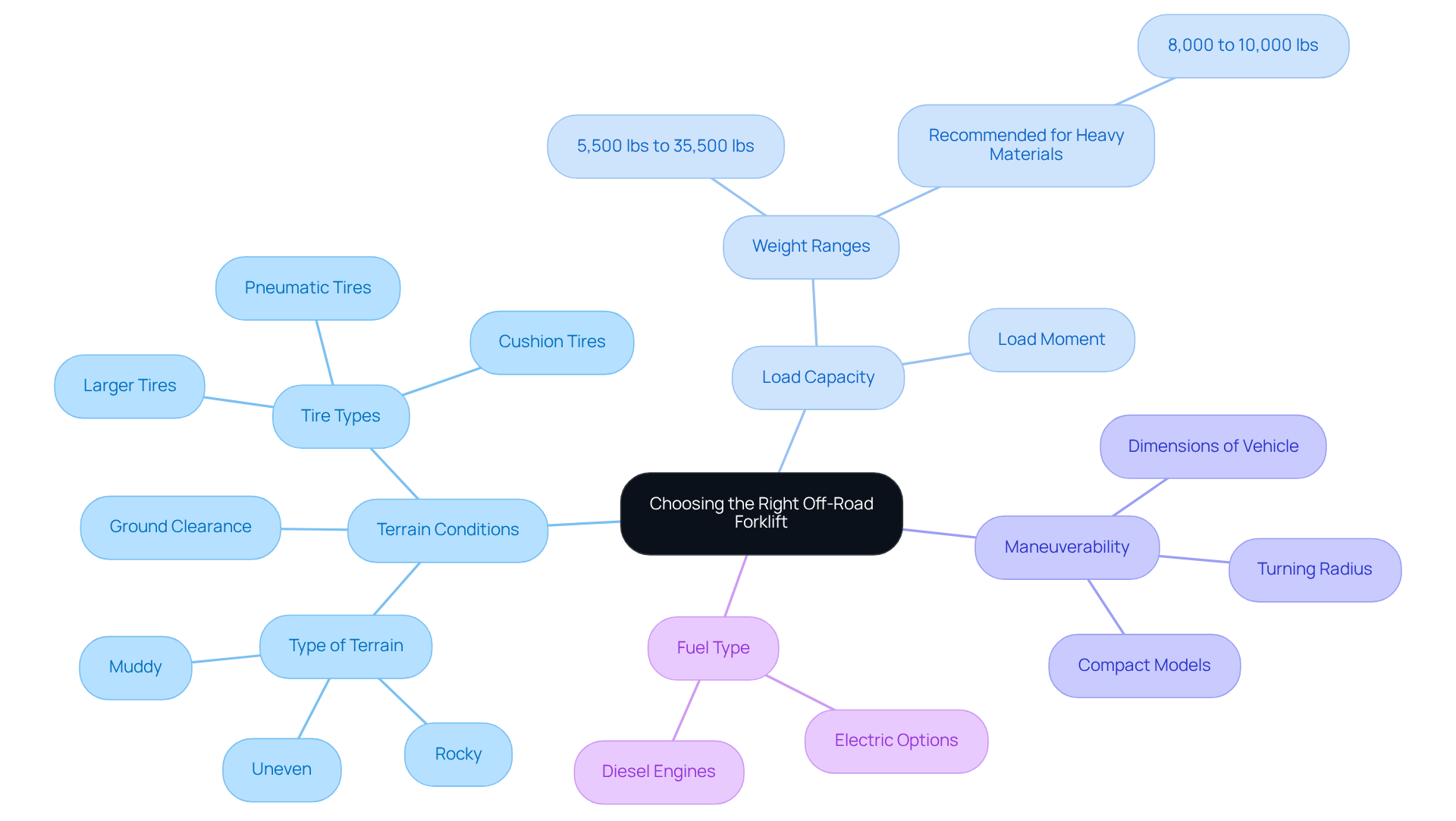

Choose the Right Off-Road Forklift for Your Project Needs

Careful consideration of several critical factors is required when selecting the right off road forklift for construction projects.

-

Assess Terrain Conditions: Analyze the terrain type-whether muddy, rocky, or uneven-to determine the necessary ground clearance and appropriate tire type. Rough terrain vehicles with larger tires and higher ground clearance are essential for navigating challenging surfaces.

-

Load Capacity: Understanding the maximum weight that needs to be lifted is vital. Off-road forklifts typically have load capacities that range from 5,500 lbs to 35,500 lbs. It is crucial to select a model that can comfortably handle the anticipated loads, especially for heavy materials like steel beams or concrete blocks. For substantial materials, consider a lift truck with a load rating of 8,000 to 10,000 lbs to ensure security and adherence.

-

Maneuverability: Assess the dimensions of the lifting vehicle and its turning radius, particularly in tight areas. Compact models may be necessary for projects with limited maneuverability, ensuring efficient operation without compromising safety. In areas with limited space, such as shipping containers or narrow aisles, a compact lifting device with a tight turning radius is essential.

-

Fuel Type: Diesel engines are common in off road forklifts due to their power and efficiency, especially in challenging environments. However, electric options can be suitable for less intensive tasks, providing quieter functionality and zero emissions.

Safety is crucial in lift truck operation, as statistics indicate that an estimated 35,000 to 62,000 injuries related to these vehicles occur annually in the U.S. Proper training is essential for operators to mitigate risks. For instance, a construction project on a steep slope may necessitate a lifting device with a higher load capacity and enhanced traction features to ensure both safety and operational efficiency. By thoroughly evaluating these factors, construction managers can choose the most suitable all-terrain lift to satisfy their project requirements.

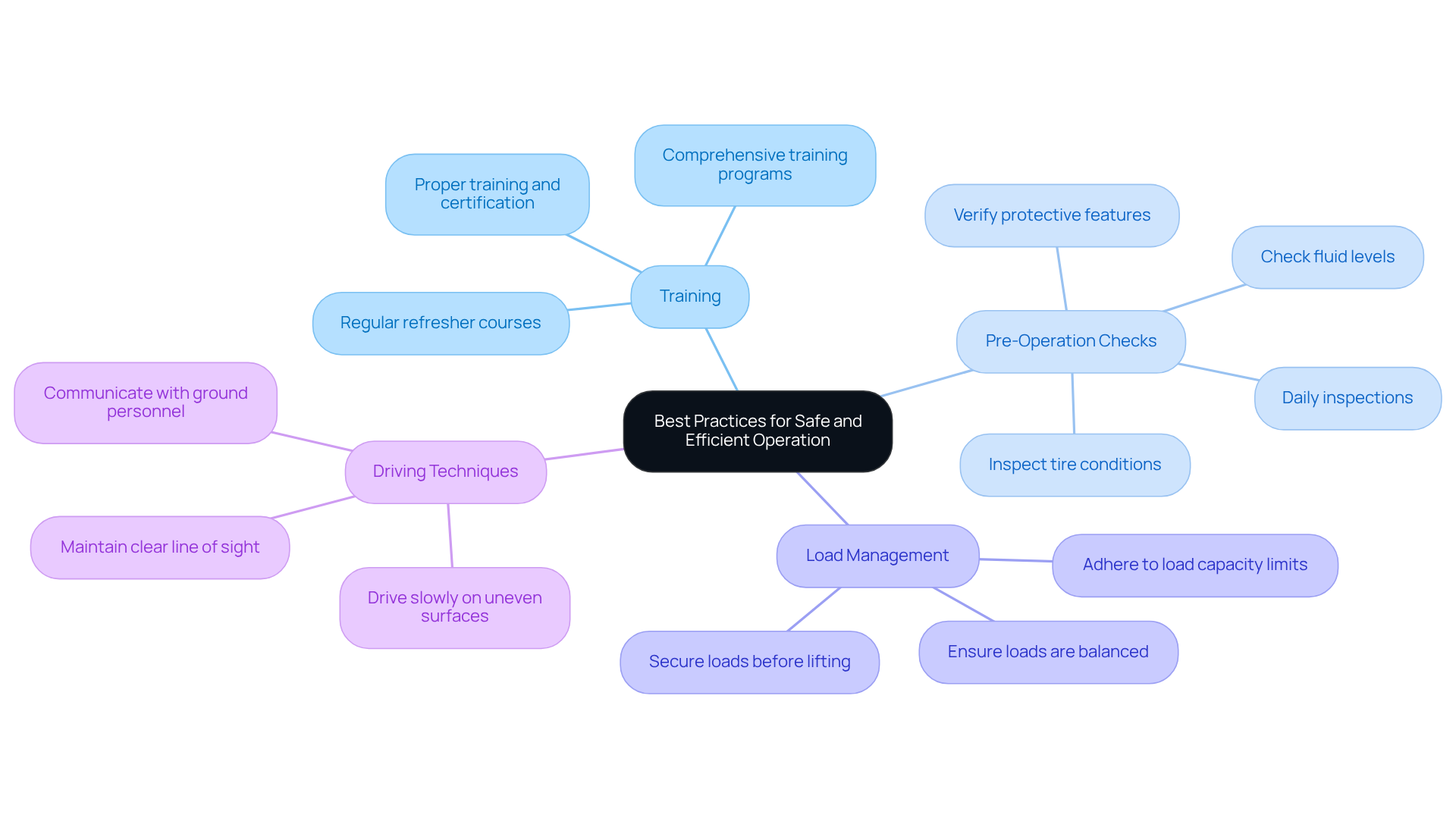

Implement Best Practices for Safe and Efficient Operation

To ensure the safe and efficient operation of the off-road forklift, implementing best practices is essential.

Training: Proper training and certification for all operators are crucial when it comes to using an off-road forklift. Emphasis should be placed on protocols and equipment handling, as undertrained operators significantly contribute to accident rates. According to OSHA, a substantial number of accidents arise from inadequate training, underscoring the critical need for comprehensive training programs tailored to the operation of off-road forklifts. As OSHA states, "Successful accident prevention starts with consistent daily practices."

Pre-Operation Checks: Conducting thorough inspections before use is vital, focusing on fluid levels, tire conditions, and protective features. Daily inspections are mandatory to ensure that all equipment is in optimal working condition, which can prevent accidents and enhance operational efficiency.

Load Management: Always adhere to load capacity limits and ensure that loads are balanced and secured before lifting. Inadequate load management frequently leads to lift truck accidents, with tip-overs accounting for 42% of all documented injuries associated with these vehicles. Operators should be trained to recognize and manage these risks effectively.

Driving Techniques: Operators must drive slowly, especially on uneven surfaces, and maintain a clear line of sight to avoid obstacles. Effective communication with ground personnel is essential to ensure pedestrian safety, as 36% of forklift-related fatalities involve pedestrians. OSHA estimates that approximately 70% of forklift incidents could be avoided with improved protection strategies.

For example, a construction site manager could establish a daily checklist for operators to follow, ensuring that all precautionary measures are observed before starting work. This proactive approach not only enhances safety but also fosters a culture of accountability and awareness among all team members.

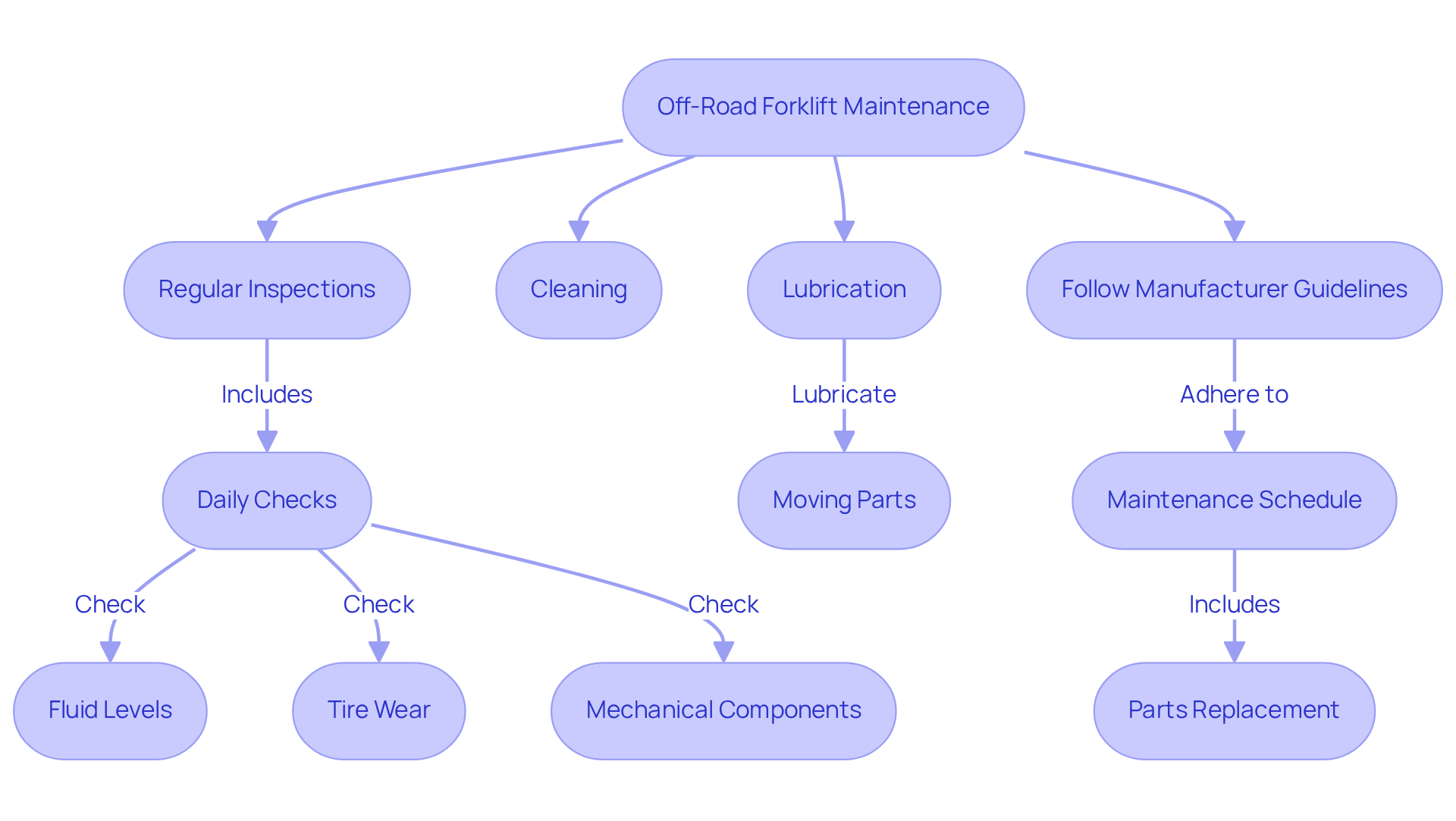

Maintain Off-Road Forklifts for Longevity and Reliability

To ensure the effective maintenance of off-road forklifts, implementing best practices is essential:

- Regular Inspections: Conduct routine checks on fluid levels, tire wear, and mechanical components to identify potential issues before they escalate. Daily inspections should encompass brakes, steering, controls, and warning devices, as these are vital for safe functioning. Forklifts exposed to harsh conditions should be inspected at least every 90 days to maintain safety and functionality.

- Cleaning: Maintain cleanliness to prevent dirt and debris from impairing performance, particularly in the engine and hydraulic systems. Regular cleaning helps uncover hidden issues like leaks or worn components, ensuring better performance and longevity.

- Lubrication: Consistently lubricate moving parts to minimize friction and wear, promoting smooth functionality. This practice is vital for components such as the mast, chains, and pivot points, which are subject to significant stress during operation.

- Follow Manufacturer Guidelines: Adhere strictly to the manufacturer's maintenance schedule for servicing and parts replacement. This includes timely oil changes and inspections, which are critical for maintaining optimal performance.

For instance, a construction firm that implements a weekly maintenance routine-monitoring hydraulic fluid levels and examining tires for damage-can significantly enhance the reliability of their lifting equipment. Regular inspections not only extend the lifespan of off-road forklifts, which can exceed 10,000 hours with proper maintenance, but also enhance safety and operational efficiency. Industry professionals emphasize that proactive maintenance is key to preventing costly breakdowns and ensuring smooth operations. As one expert noted, "Regular servicing and timely repairs can prevent accidents, reduce downtime, and extend the lifespan of your equipment." Furthermore, neglecting the manufacturer's maintenance schedule can lead to premature wear and costly repairs, underscoring the importance of diligent maintenance practices.

Conclusion

Off-road forklifts are essential for enhancing efficiency and safety on construction sites, especially in challenging terrains. Their distinctive features - such as high ground clearance, robust tires, and powerful engines - make them vital for navigating uneven surfaces and managing heavy loads. By understanding the specific capabilities of these machines, construction managers can make informed decisions that lead to improved productivity and reduced risks.

Key considerations for effectively utilizing off-road forklifts include:

- Selecting the appropriate model based on terrain conditions

- Load capacity

- Maneuverability

Proper training and adherence to safety protocols are crucial for preventing accidents, as statistics surrounding forklift-related injuries highlight the need for vigilance and preparation. Furthermore, regular maintenance practices, including inspections, cleaning, and lubrication, are essential for ensuring long-term reliability and performance.

In conclusion, leveraging the advantages of off-road forklifts while implementing best practices not only enhances operational efficiency but also fosters a safer working environment. Construction professionals should prioritize training, adhere to safety guidelines, and diligently maintain their equipment. By doing so, they can maximize the benefits of these powerful machines and ensure successful project outcomes, even in the most challenging conditions.

Frequently Asked Questions

What are off-road forklifts designed for?

Off-road forklifts are engineered to excel in uneven and rugged terrains, making them essential for construction projects.

What is a key feature of off-road forklifts that aids in navigating obstacles?

High ground clearance is a key feature that enables off-road forklifts to navigate obstacles without becoming stuck.

How do large, heavy-duty tires benefit off-road forklifts?

Large, heavy-duty tires improve traction and stability on loose or uneven surfaces, ensuring safe operation.

What type of engines do off-road forklifts typically use?

Off-road forklifts are typically powered by diesel engines, which deliver high torque essential for raising heavy loads in demanding conditions.

What role do enhanced suspension systems play in off-road forklifts?

Enhanced suspension systems absorb shocks effectively, resulting in a smoother ride and reducing the risk of tipping over.

What are the advantages of using off-road forklifts in construction?

The advantages include increased productivity, reduced manual effort, and enhanced safety for both operators and team members.

How can off-road forklifts improve operations on hilly construction sites?

Off-road forklifts provide maneuverability and stability, facilitating efficient material management and minimizing delays caused by terrain challenges.

Why is high ground clearance considered vital for operational efficiency in demanding settings?

High ground clearance is crucial for maintaining operational efficiency as it allows forklifts to navigate challenging terrains effectively.

List of Sources

- Understand Off-Road Forklift Features and Benefits

- 7 Benefits of Choosing an All-Terrain Forklift (https://intellaparts.com/blog/7-benefits-of-choosing-an-all-terrain-forklift?srsltid=AfmBOoqJcNV2Bty-fDGNWw0ErnyTc3RYyQqzcbpni9eDGORv90az0lse)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Rough Terrain Forklifts: Key Benefits, Features, and Why You Need One (https://forklifttire.com/articles/rough-terrain-forklifts-key-benefits-features-and-why-you-need-one?srsltid=AfmBOorFh29U952TyckKSjHajLuw7-apBTFqATMShYZ5tuku5wtsDvmh)

- Why rough terrain forklifts are essential for outdoor material handling - ROYAL (https://ryforklift.com/blog/why-rough-terrain-forklifts-are-essential-for-outdoor-material-handling.html)

- Rough Terrain Forklift Industry Growth Trends and Analysis (https://marketreportanalytics.com/reports/rough-terrain-forklift-127924)

- Choose the Right Off-Road Forklift for Your Project Needs

- Case Study On Accidents Involving Forklifts | PDF | Forklift | Risk Management (https://scribd.com/document/274573162/Case-Study-on-Accidents-Involving-Forklifts)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Choosing the Right Forklift for the Job: A Guide for Contractors (https://kmcequipment.com/blog/choosing-the-right-forklift-for-the-job-a-guide-for-contractors--98142)

- Forklift Weight Capacity: Everything You Need to Know (https://conger.com/forklift-weight-capacity)

- Implement Best Practices for Safe and Efficient Operation

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- Maintain Off-Road Forklifts for Longevity and Reliability

- Forklift Useful Life: Everything You Need to Know (https://conger.com/forklift-useful-life)

- The Ultimate Guide to Forklift Maintenance & Servicing | Service Geeni (https://servicegeeni.com/blog/the-ultimate-guide-to-forklift-maintenance)

- 10 Forklift Maintenance Tips for Safety & Efficiency (https://activeforklift.com.au/10-essential-forklift-maintenance-tips-to-maximise-safety-and-efficiency)

- Off-road Forklift Introduction : Everything You Need to Know About Off-road Forklift (https://lugongma.com/off-road-forklift-introduction-everything-you-need-to-know-about-off-road-forklift)

- 1 new message (https://my-forklift.com/pt/How-do-I-maintain-an-off-road-forklift-for-longevity-n.html)