Overview

The best practices for using sawhorse barricades in construction projects include conducting thorough site assessments, ensuring high visibility, and performing regular inspections to enhance safety and prevent accidents. The article supports this by detailing how effective barricade placement and maintenance can significantly reduce workplace injuries and improve overall project workflow, demonstrating their critical role in managing hazards on construction sites.

Key Highlights:

- Sawhorse barricades are portable structures used on construction sites to mark restricted areas and enhance safety.

- They play a critical role in accident prevention by guiding individuals away from hazardous zones.

- Effective use of sawhorse barricades can reduce workplace injuries and associated costs by up to 40%.

- Barricades help manage traffic flow, establish storage zones, and control crowds during inspections or public visits.

- OSHA identifies caught-in and caught-between incidents as major dangers in construction, emphasizing the need for protective measures.

- Best practices for setting up barricades include conducting site assessments, ensuring visibility, and maintaining stability against environmental factors.

- Different types of sawhorse barricades (plastic and metal) serve specific purposes based on project needs and traffic levels.

- Regular inspection and maintenance of barricades are essential for ensuring safety and compliance with regulations.

- Training team members on barricade use promotes a culture of safety in the workplace.

Introduction

In the bustling environment of construction sites, safety is paramount, and sawhorse barricades emerge as indispensable tools in safeguarding both workers and the public. These portable barriers serve not only to delineate hazardous areas but also to manage traffic flow and enhance overall operational efficiency. With their lightweight design and versatility, sawhorse barricades are essential for establishing clear boundaries, preventing unauthorized access, and minimizing the risk of accidents.

As the construction industry grapples with the pressing need for effective safety measures, understanding the best practices, types, and maintenance of these barricades becomes crucial for project managers aiming to protect their teams and streamline workflows.

This article delves into the definition, practical applications, and best practices surrounding sawhorse barricades, illuminating their vital role in construction safety.

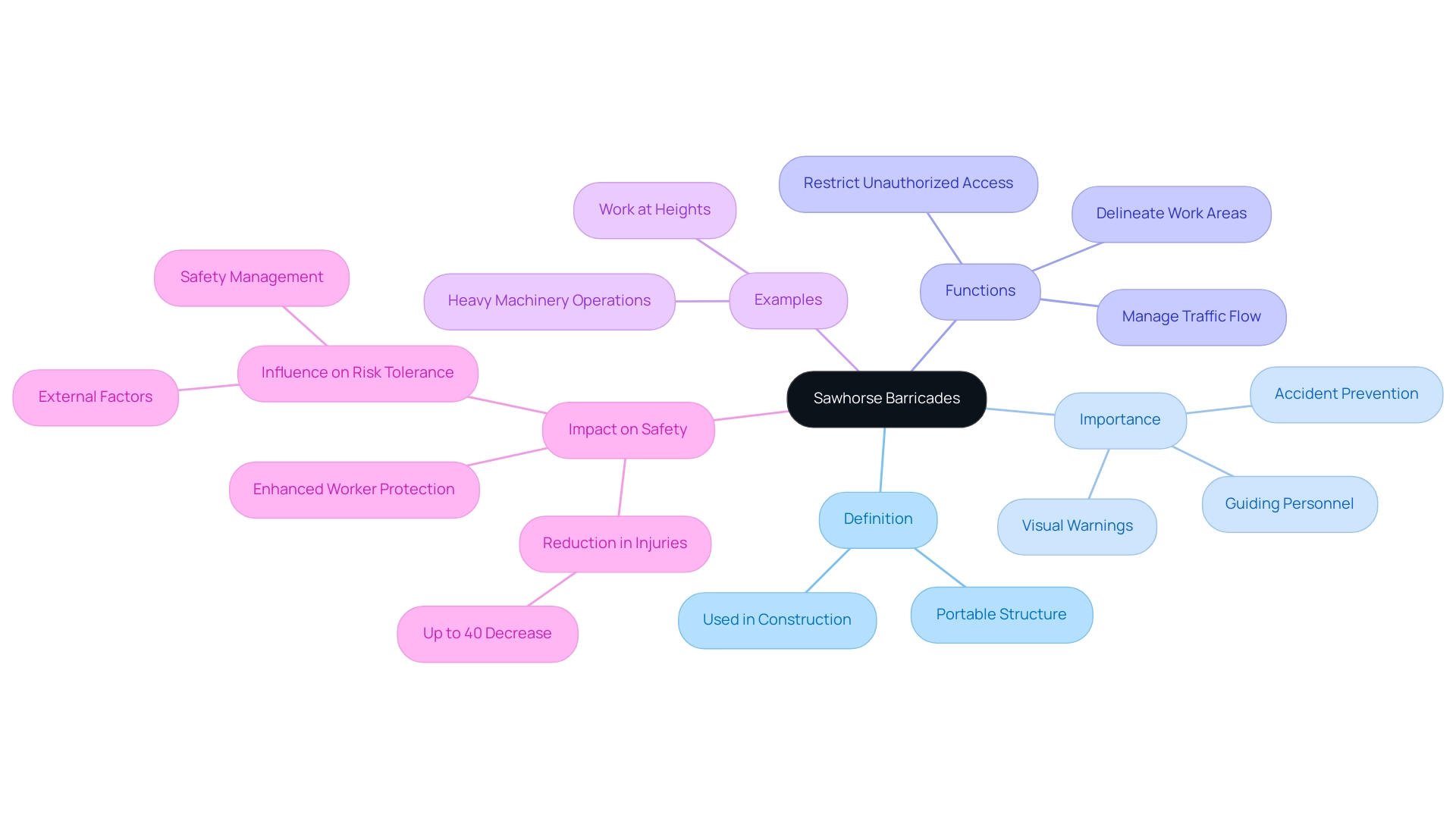

Understanding Sawhorse Barricades: Definition and Importance

A sawhorse barricade is an essential, portable structure commonly used on construction sites to delineate work areas, manage traffic flow, and enhance overall safety. These lightweight structures serve as critical visual warnings, signaling restricted zones or potential hazards to both workers and the public. The importance of utilizing a sawhorse barricade cannot be overstated; it plays a pivotal role in accident prevention by guiding individuals away from hazardous areas.

For example, when heavy machinery is in operation or work is being conducted at heights, sawhorse barricades effectively restrict unauthorized access, ensuring that only trained personnel are permitted near potential hazards. According to the Center for Construction Research and Training USA, developing effective protective standards is vital, as numerous obstacles hinder the comparability of injury and fatality data. This highlights the necessity for efficient protective measures such as sawhorse barricades.

Moreover, studies show that implementing a protection program can decrease injuries and associated expenses by as much as 40%, emphasizing the significance of such initiatives in improving workplace security. Furthermore, a case study named 'Critical Factors and Paths Influencing Workers' Risk Tolerances' demonstrates that risk management greatly affects employees' risk tolerance, further highlighting the importance of employing barriers to control risks on building locations. By efficiently employing a sawhorse barricade, project managers can improve location security and reduce hazards, demonstrating a strong dedication to worker protection.

This comprehension is a vital initial step toward executing these protective measures in project management.

Practical Applications of Sawhorse Barricades in Construction

Sawhorse barricades serve a crucial role in enhancing safety and project workflow on construction sites through various practical applications. By marking off areas designated for excavation, the sawhorse barricade effectively redirects foot traffic away from potential hazards, significantly reducing the risk of accidents. They can also establish clear zones for materials storage, using a sawhorse barricade to ensure that pathways remain unobstructed for both workers and machinery, which is vital for maintaining efficiency in task execution.

During critical events such as inspections or public visits, a sawhorse barricade facilitates effective crowd control by distinctly outlining safe viewing areas. This strategic use not only enhances protocols but also streamlines overall project workflow, minimizing confusion and mitigating the likelihood of incidents. As highlighted by various building supervisors, a sawhorse barricade is essential in keeping orderly locations, thus improving operational efficiency.

With construction-related accidents frequently associated with insufficient protective measures, it is essential to acknowledge that the Occupational Safety and Health Administration (OSHA) classifies caught-in and caught-between incidents as among the primary dangers in construction environments. Indeed, in 2022, 142 deaths were associated with such incidents, mainly involving heavy machinery, highlighting the necessity for improved protective measures like barriers. Furthermore, while OSHA certifications can range from $60 to $180, investing in appropriate protocols is crucial for maintaining high standards and ensuring the well-being of all staff present.

Best Practices for Setting Up Sawhorse Barricades

To set up sawhorse barriers effectively, it is crucial to conduct a thorough assessment of the area to identify where these structures are necessary. They should be strategically placed to ensure high visibility, clearly marking restricted zones to guide workers and visitors alike. Maintaining a safe distance from hazards is essential to prevent accidental access, thus enhancing site safety.

In outdoor environments, barriers must be secured against potential wind or movement to ensure stability. Regular inspections for damage or instability are essential; any barriers that show signs of wear should be promptly replaced to maintain a safe environment. Moreover, educating team members on the appropriate use and importance of these barriers not only encourages adherence but also strengthens a culture of safety in the workplace.

As OSHA highlights, effective channelizing devices can assist in alerting road users to conditions caused by work activities, emphasizing the significance of proper setup. It's also essential to keep in mind that common OSHA violations at building sites include:

- Fall protection

- Hazard communication

These are directly related to barrier usage. Additionally, when positioning barriers, ensure that the gap does not exceed 2 inches between the bottom rail and the ground surface to facilitate drainage.

By following these best practices, project managers can significantly decrease the risk of incidents related to improper barrier placement.

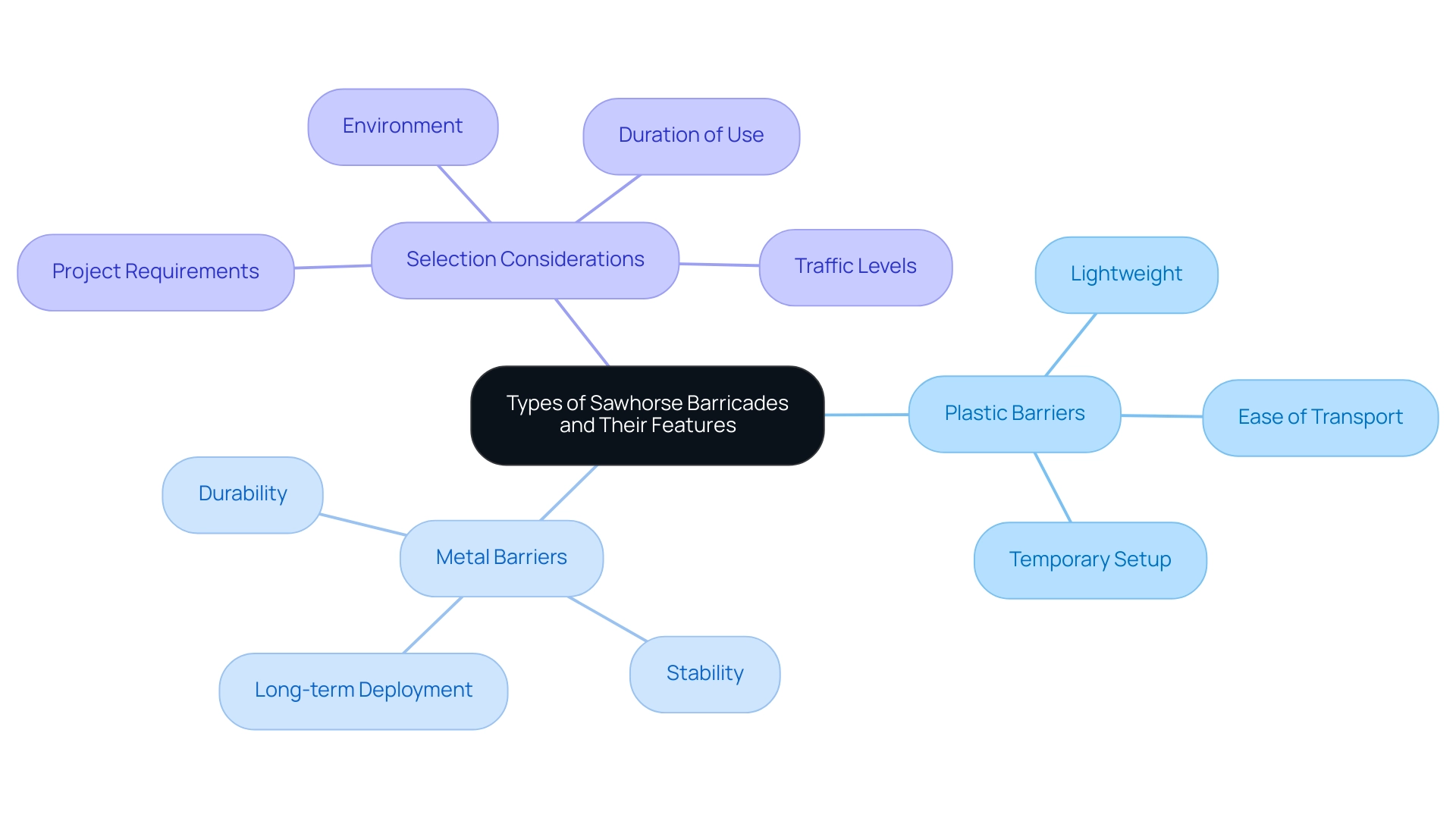

Types of Sawhorse Barricades: Features and Benefits

Sawhorse barricades come in various types, each tailored for distinct applications within the construction landscape. Plastic barriers, known for their lightweight design, are particularly advantageous for temporary setups where mobility is crucial. Their ease of transport makes them a preferred option for short-term projects.

Conversely, metal barriers are recognized for their superior durability and stability, making them ideal for high-traffic zones or situations requiring long-term deployment. A case study titled 'Simulation of Impact Phenomena' has demonstrated that the design and material characteristics of barriers significantly influence their capacity to absorb impact energy and prevent projectiles from escaping. This study emphasizes the significance of choosing the appropriate type of obstruction based on the specific conditions of the project.

Numerous contemporary obstacles are also created with improved visibility elements, such as reflective tape or built-in lights, which are crucial for protection in dimly lit settings. As stated by Hideki Kayaba, 'The identification of cutting tool malfunction can guide the design of barriers to improve their protective attributes.' When choosing the suitable sawhorse barricade, considerations should include:

- The specific project requirements

- The environment in which the sawhorse barricade will be used

- The anticipated duration of use

- The traffic levels expected in the area

This tactical method guarantees that the selected barrier effectively addresses protection and operational requirements.

Maintaining Safety: Inspection and Care for Sawhorse Barricades

Guaranteeing security on building sites relies on the routine examination of sawhorse barricades. With women making up 10.9% of the U.S. building workforce in 2022, it is essential to introduce protective measures that safeguard all employees, especially those from underrepresented groups. Project managers should meticulously check for signs of wear, damage, or instability, addressing any issues without delay to prevent potential hazards.

As mentioned by Zippia, there are around 7,500,000 construction workers in the U.S., and disregarding protocols could result in tragic consequences, including the yearly fatalities of 1,000 workers from construction accidents and an extra 4,000-5,000 suicides among construction workers. Regular cleaning of the sawhorse barricade is essential, as it maintains its visibility and effectiveness, which is crucial for guiding workers and visitors safely. Moreover, it is essential that all team members undergo training to identify when barriers need maintenance or substitution, promoting a proactive culture of security.

This is particularly relevant in light of the mental health crisis in construction, where a supportive environment can significantly impact worker well-being. Keeping a record of the sawhorse barricade and systematically monitoring its condition not only aids in adhering to regulatory requirements but also improves overall project security throughout its lifecycle. This disciplined approach to barricade management can significantly mitigate risks and ensure that safety protocols remain a top priority.

Conclusion

Sawhorse barricades are integral to maintaining safety and efficiency on construction sites. Their primary function as portable barriers is to delineate hazardous areas, manage traffic flow, and provide critical visual warnings to both workers and the public. By effectively guiding individuals away from danger zones, these barricades play a vital role in accident prevention, reflecting a commitment to worker protection within the construction industry.

The practical applications of sawhorse barricades extend beyond mere delineation. They are essential for:

- Redirecting foot traffic

- Establishing organized zones for material storage

- Controlling crowd movements during inspections or public visits

By minimizing confusion and enhancing operational workflows, these barricades contribute significantly to overall site efficiency while addressing the serious risks associated with construction-related accidents.

Implementing best practices in the setup and maintenance of sawhorse barricades is crucial for maximizing their effectiveness. This includes:

- Strategic placement for visibility

- Regular inspections for damage

- Training team members on their proper use

By adhering to these guidelines, project managers can ensure that barricades serve their intended purpose and foster a culture of safety on site.

In conclusion, the importance of sawhorse barricades in construction cannot be overstated. They not only enhance safety measures but also streamline project workflows, ultimately protecting workers and the public from potential hazards. As the construction industry continues to evolve, prioritizing the effective use and maintenance of these barricades will remain essential in safeguarding lives and ensuring operational success.

Frequently Asked Questions

What is a sawhorse barricade and its primary purpose?

A sawhorse barricade is a portable structure used on construction sites to delineate work areas, manage traffic flow, and enhance overall safety by signaling restricted zones or potential hazards to workers and the public.

How do sawhorse barricades contribute to accident prevention?

Sawhorse barricades restrict unauthorized access to hazardous areas, ensuring only trained personnel are near potential dangers, which plays a crucial role in accident prevention.

What impact do sawhorse barricades have on workplace safety?

Implementing sawhorse barricades can decrease injuries and associated costs by up to 40%, highlighting their significance in improving workplace security.

What role do sawhorse barricades play during inspections or public visits?

They facilitate effective crowd control by outlining safe viewing areas, which enhances protocols, streamlines project workflow, and minimizes confusion.

What are the risks associated with construction environments that sawhorse barricades help mitigate?

Sawhorse barricades help mitigate risks associated with caught-in and caught-between incidents, which are among the primary dangers in construction environments, particularly involving heavy machinery.

Why is it important to invest in protective measures like sawhorse barricades?

Investing in protective measures is crucial for maintaining high safety standards and ensuring the well-being of all staff on construction sites, especially given the significant number of accidents related to insufficient protective measures.