Key Highlights:

- Stand-up forklifts are designed for superior manoeuvrability and visibility, ideal for confined spaces.

- Key features include a compact design for improved space utilisation, enhanced visibility for safer operations, quick entry and exit for efficiency, and ergonomic controls to reduce operator fatigue.

- Implementing safety protocols such as pre-operation checks, thorough training, ergonomic practises, and clear communication is crucial to prevent accidents.

- Statistics indicate that 70% of forklift incidents could be avoided with better training, highlighting the importance of operator education.

- When selecting a stand-up forklift, consider factors like load capacity, lift height, operational environment, and frequency of use to ensure safety and efficiency.

- Routine maintenance practises, including daily inspections and adherence to service schedules, are essential for optimal forklift performance and safety.

- A Computerised Maintenance Management System (CMMS) can aid in tracking maintenance tasks and enhancing operational efficiency.

Introduction

Stand-up forklifts have transformed material handling on construction sites, providing exceptional maneuverability and visibility in confined areas. Their compact design and ergonomic features not only boost operational efficiency but also play a vital role in upholding safety standards. Yet, a challenge persists: how can construction teams effectively implement best practices to maximize the advantages of these machines while minimizing risks? By examining the essential features, safety protocols, and maintenance strategies for stand-up forklifts, we uncover key insights that can significantly enhance project execution.

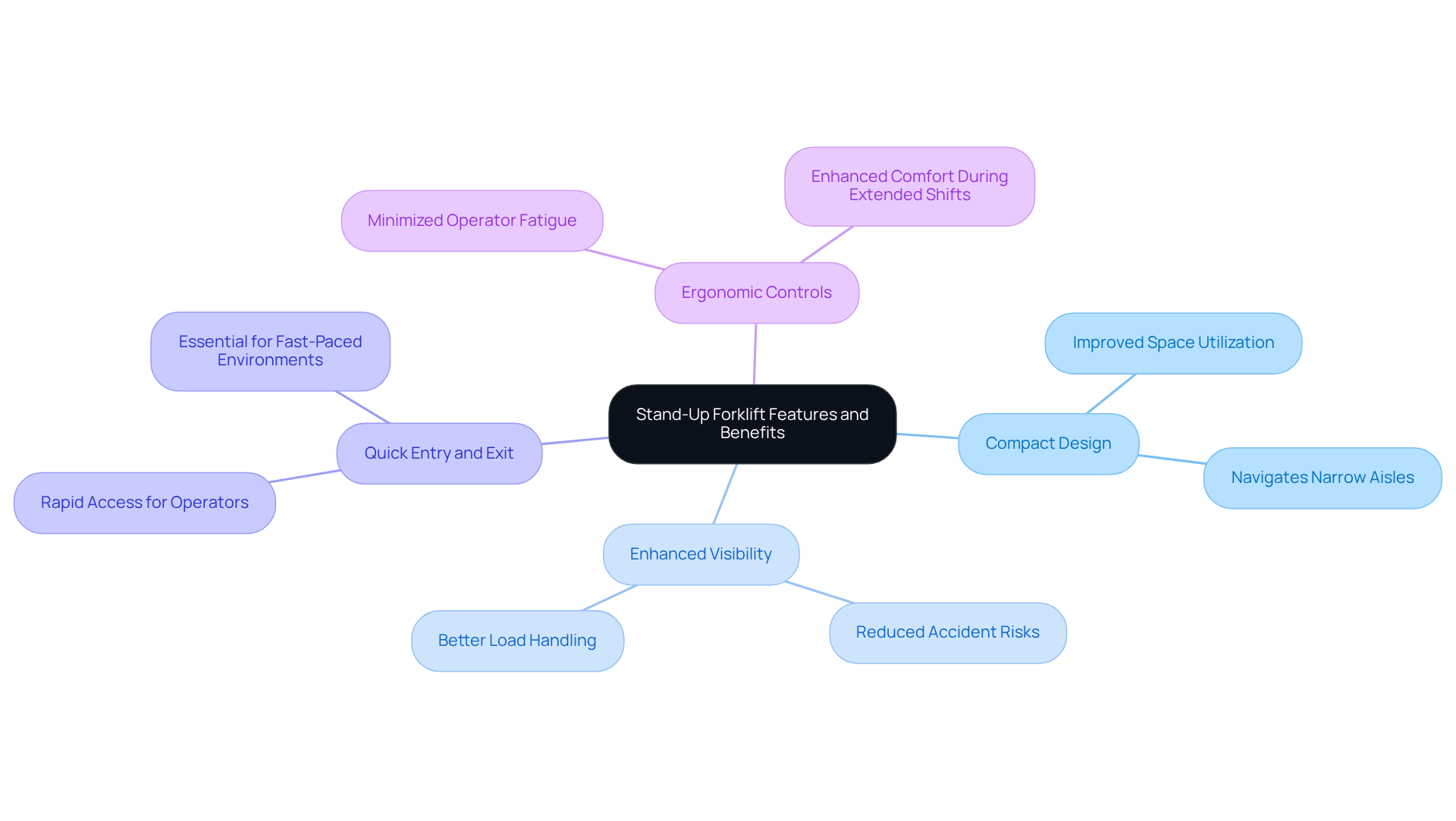

Understand Stand-Up Forklift Features and Benefits

Stand-up lifting machines are engineered for exceptional maneuverability and visibility, making them ideal for the confined spaces commonly found on construction sites. Their key features include:

- Compact Design: With a smaller footprint, stand-up forklifts can easily navigate narrow aisles and crowded areas, significantly improving space utilization.

- Enhanced Visibility: Operators enjoy an unobstructed line of sight, which reduces accident risks and facilitates better load handling.

- Quick Entry and Exit: The design allows for swift access, enabling operators to mount and dismount rapidly - an essential feature in fast-paced environments.

- Ergonomic Controls: Many models come equipped with adjustable controls that help minimize operator fatigue and enhance comfort during extended shifts.

Together, these features enhance efficiency and safety, positioning stand-up forklifts as the preferred choice for both construction and storage applications. Their ability to operate effectively in tight spaces not only optimizes workflow but also contributes to a safer working environment, aligning with industry standards.

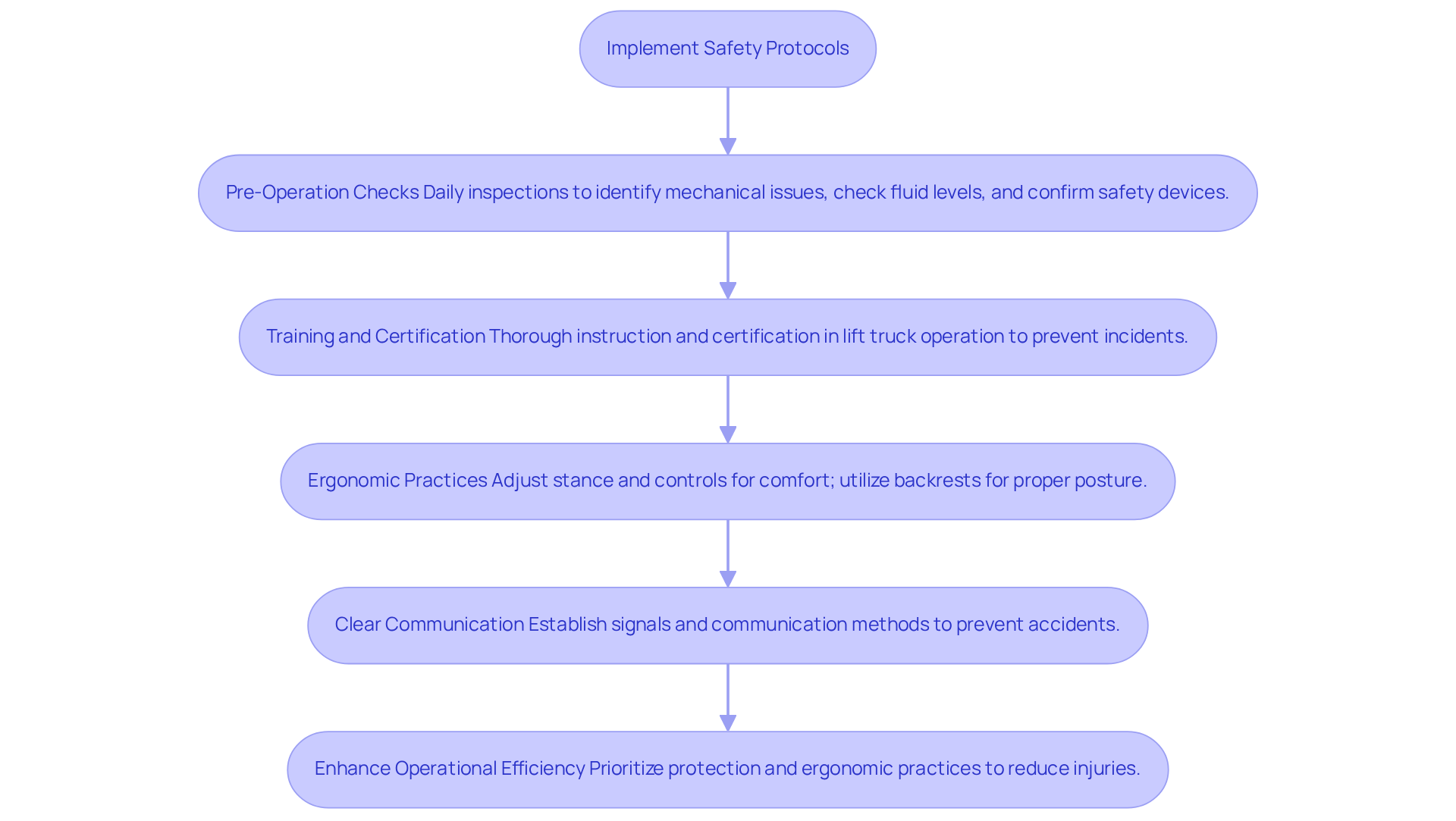

Implement Safety Protocols and Ergonomic Practices

Implementing comprehensive safety protocols is essential to ensure the safe operation of stand up forklifts.

Pre-Operation Checks: Operators should conduct daily inspections to identify mechanical issues, check fluid levels, and confirm that all safety devices are functional. This proactive approach can prevent accidents before they occur.

Training and Certification: All operators must complete thorough instruction and certification in lift truck operation, focusing on protective protocols specific to stand up forklifts. Statistics indicate that 70% of forklift incidents could have been prevented with better training, underscoring the critical need for comprehensive operator education, as insufficient training is a key factor in the rise of incidents.

Ergonomic Practices: Operators should be encouraged to adjust their stance and controls for comfort and reduced strain. Utilizing backrests promotes proper posture, which is crucial for long-term health and efficiency.

Clear Communication: Establishing clear signals and communication methods among team members is vital to prevent accidents, particularly in busy environments where visibility may be limited.

By prioritizing protection and ergonomic practices, construction teams can significantly enhance operational efficiency while reducing the likelihood of injuries. With service-providing industries accounting for over 50% of forklift-related casualties, including 36 fatalities recorded in two years, implementing these protocols is not just beneficial but necessary for a safer workplace. As occupational safety expert Dan Peterson states, "paper doesn't save people - people save people," emphasizing the importance of human involvement in safety measures.

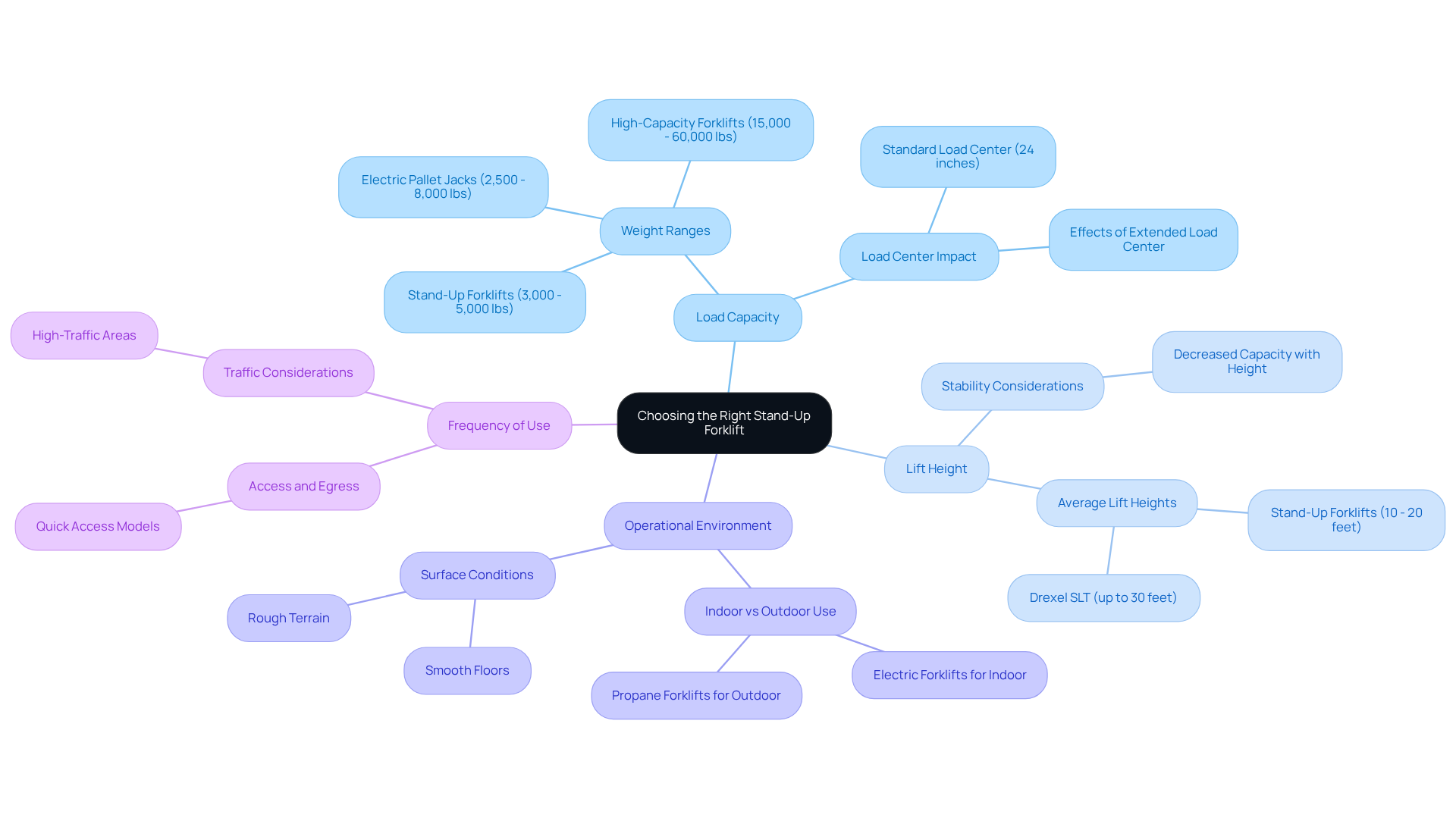

Choose the Right Stand-Up Forklift for Your Project Needs

Selecting the right stand-up forklift requires careful consideration of several critical factors:

- Load Capacity: Evaluate the maximum weight the forklift must lift. Stand-up pallet jacks typically support weights ranging from 2,000 to 5,500 lbs. It is essential to align capacity with project needs, as a lifting device rated at 5,000 lbs at a standard 24-inch center may only handle 4,000 lbs if the center shifts to 30 inches. This highlights the importance of center in determining lifting capacity.

- Lift Height: Identify the necessary lift height for your specific project. Ensure the lifting machine can safely reach the required elevations, as average lift heights for stand up forklifts in construction typically range from 10 to 20 feet. Be aware that as the lifting height increases, the load capacity may decrease due to stability challenges.

- Operational Environment: Evaluate the working conditions, including whether the lifting equipment will be utilized indoors or outdoors, and its capability to maneuver across different surfaces, from smooth floors to rough terrain. Operators should consider how the environment may affect the vehicle's performance and stability.

- Frequency of Use: Consider how often operators will enter and exit the vehicle. Opt for models designed for quick access to enhance productivity, especially in high-traffic areas. Operators should always keep the weight close to the ground when traveling to avoid instability.

By thoroughly assessing these factors, project managers can choose stand up forklifts that effectively meet their operational requirements, ensuring safety and efficiency on the job site. Integrating insights from case studies, such as the significance of load center calculations, can further strengthen best practices in equipment selection.

Maintain Stand-Up Forklifts for Optimal Performance

To ensure stand-up forklifts operate at peak performance, it is essential to implement rigorous maintenance practices:

- Daily Inspections: Conduct thorough checks before each shift, focusing on critical components such as brakes, steering, forks, and fluid levels. Daily inspections are essential, as data shows that avoidable vehicle accidents result in more than 20,000 severe injuries each year in the U.S., underscoring the importance of these evaluations as a precautionary step. Regular checks can significantly mitigate these risks.

- Scheduled Maintenance: Adhere to the manufacturer's recommended service schedule for routine maintenance tasks, including oil changes and brake inspections. This proactive approach helps prevent unexpected breakdowns and costly repairs.

- Cleanliness: Maintain the forklift's cleanliness to prevent dirt and debris from impairing its operation. Regularly check for hydraulic leaks and ensure the battery remains clean, as neglecting these aspects can lead to performance issues.

- Operator Training: Equip operators with the necessary training to recognize signs of wear or malfunction. Enabling them to report issues quickly can improve security and operational efficiency. Adhering to OSHA standards is vital, as it strengthens the importance of regular inspections and training as part of a compliant culture of protection.

By following these maintenance practices, construction teams can significantly improve the reliability and efficiency of their stand-up forklifts, resulting in smoother project execution and enhanced workplace safety. Additionally, implementing a Computerized Maintenance Management System (CMMS) can help track maintenance tasks and analyze performance, further enhancing operational efficiency.

Conclusion

Stand-up forklifts mark a significant advancement in material handling, especially in the construction industry. Their unique design and features greatly enhance safety and operational efficiency. With their compact size, improved visibility, and ergonomic controls, construction teams can effectively navigate tight spaces and streamline workflows, leading to more productive job sites.

Key insights from this article emphasize the necessity of:

- Understanding stand-up forklift features

- Implementing strict safety protocols

- Selecting the right machine for specific project needs

- Adhering to rigorous maintenance practices

Daily inspections, operator training, and clear communication are vital components that contribute to a safer working environment. Moreover, choosing the appropriate forklift based on load capacity, lift height, and operational conditions ensures that equipment meets project demands.

Incorporating these best practices transcends mere compliance; it reflects a commitment to fostering a culture of safety and efficiency on construction sites. As the industry evolves, embracing the latest technologies and adhering to established safety standards will be essential in minimizing risks and maximizing the benefits of stand-up forklifts. Prioritizing these strategies not only enhances project execution but also protects the well-being of all team members involved.

Frequently Asked Questions

What are stand-up forklifts designed for?

Stand-up forklifts are engineered for exceptional maneuverability and visibility, making them ideal for confined spaces commonly found on construction sites.

What are the key features of stand-up forklifts?

Key features include a compact design for navigating narrow aisles, enhanced visibility for better load handling, quick entry and exit for rapid access, and ergonomic controls to minimize operator fatigue.

How does the compact design of stand-up forklifts benefit their operation?

The compact design allows stand-up forklifts to easily navigate narrow aisles and crowded areas, significantly improving space utilization.

Why is enhanced visibility important for stand-up forklift operators?

Enhanced visibility provides operators with an unobstructed line of sight, which reduces accident risks and facilitates better load handling.

What advantage does quick entry and exit provide for operators?

Quick entry and exit allow operators to mount and dismount rapidly, which is essential in fast-paced environments.

How do ergonomic controls benefit forklift operators?

Ergonomic controls help minimize operator fatigue and enhance comfort during extended shifts.

In what applications are stand-up forklifts preferred?

Stand-up forklifts are preferred for both construction and storage applications due to their efficiency and safety in tight spaces.

How do stand-up forklifts contribute to workplace safety?

Their ability to operate effectively in tight spaces optimizes workflow and contributes to a safer working environment, aligning with industry standards.

List of Sources

- Understand Stand-Up Forklift Features and Benefits

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Why Stand-Up Forklifts Are Best for Warehouses (https://andersenmaterialhandling.com/material-handling-resources/why-stand-up-forklifts-are-ideal-for-warehouse-operations)

- Advantages of Stand Up Forklifts: #1 Standing Forklift Guide (https://phsinc.com/guides/advantages-of-stand-up-forklifts?srsltid=AfmBOormUzwr98OCY5YDGILUreCM1hvQeNHYoRmvOuMXaOqrEu_SLtHH)

- Industrial Forklift Comparison: Sit-Down vs. Stand-Up Models (https://totalwarehouse.com/blogs/sit-down-stand-up-forklifts)

- Top Reasons to Choose a Stand Up Forklift for Your Warehouse (https://clarkmhc.com/top-reasons-to-choose-a-stand-up-forklift-for-your-warehouse)

- Implement Safety Protocols and Ergonomic Practices

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Safety Quotes: Motivation to Improve Work Safety Culture (https://osha.com/blog/work-safety-quotes)

- Forklift-related incidents: A growing concern on construction sites - Presight Solutions AS (https://presight.com/forklift-related-incidents-a-growing-concern-on-construction-sites)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Choose the Right Stand-Up Forklift for Your Project Needs

- Forklift Weight Capacity - How Much Do You Need? (https://totalwarehouse.com/blogs/forklift-capacities-selection-guide)

- How High Can Your Forklift Go? (https://zonemfc.com/forklift-lifting-height)

- Forklift Weight Capacity: Everything You Need to Know (https://conger.com/forklift-weight-capacity)

- Maintain Stand-Up Forklifts for Optimal Performance

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Forklift Maintenance: The 2025 Guide to Safety & Uptime (https://f7i.ai/blog/the-ultimate-guide-to-forklift-maintenance-from-daily-checks-to-ai-powered-reliability)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- 8 Essential Tips for a Forklift Maintenance Checklist - Top Osha Forklift Certification (https://forkliftacademy.com/forklift-maintenance-checklist-8-essential-tips?srsltid=AfmBOopuC5M9eevOoqbW9JFVxDW5L0Tglm-U5LAwm-6xHwTUVYud73b6)