Overview

This article outlines best practices for the safe and efficient use of walk-behind saws. It emphasizes the critical importance of proper training, maintenance, and adherence to safety protocols. By detailing essential safety measures—such as the use of personal protective equipment (PPE) and conducting thorough inspections before use—it builds a strong foundation of knowledge for operators. Furthermore, it highlights the benefits of renting these tools, allowing access to the latest technology while minimizing costs and maintenance responsibilities.

Engaging with walk-behind saws not only enhances operational efficiency but also ensures safety on the job site. Proper training equips users with the necessary skills to handle these powerful tools effectively. Additionally, regular maintenance is crucial for optimal performance and longevity, reinforcing the value of investing time in equipment care. By prioritizing safety protocols and utilizing PPE, operators can significantly reduce the risk of accidents and injuries, fostering a safer work environment.

Renting walk-behind saws offers a strategic advantage. It provides access to high-quality equipment without the burden of ownership costs, allowing businesses to allocate resources more effectively. Moreover, the flexibility of rental agreements means that companies can choose the latest models, ensuring they remain competitive and efficient. This approach not only enhances reliability but also supports a commitment to quality in every project.

In conclusion, implementing these best practices is essential for anyone utilizing walk-behind saws. By focusing on proper training, maintenance, and safety measures, operators can maximize their effectiveness while minimizing risks. Consider renting these tools to leverage the latest technology and maintain cost efficiency. Take action today to ensure a safer and more productive work environment.

Key Highlights:

- Walk-behind saws are essential tools for construction and masonry, capable of cutting concrete and asphalt with features like adjustable blade depth and water attachments for dust control.

- The market is shifting towards electric and battery-powered walk-behind saws, driven by sustainability and efficiency demands.

- Applications include creating expansion joints, cutting trenches, and road repairs, making them valuable for contractors and DIY enthusiasts.

- Renting walk-behind saws eliminates upfront costs, provides maintenance support, and allows access to the latest technology, with over 70% of contractors preferring rental options.

- Safety is critical; operators should wear PPE, conduct thorough inspections, and incorporate water during cutting to reduce dust and keep blades cool.

- Comprehensive training on equipment use and safety protocols is essential for operators to minimize risks and enhance productivity.

- Regular maintenance, including cleaning and inspecting the saw, is vital for optimal performance and longevity, with effective practices linked to reduced downtime.

- Common pitfalls include using incorrect blades, skipping pre-use inspections, rushing cuts, and neglecting safety protocols, which can compromise efficiency and safety.

Introduction

In the construction and masonry sectors, walk-behind saws are indispensable tools specifically engineered for heavy-duty cutting tasks. These robust machines excel in cutting through tough materials such as concrete and asphalt, establishing their necessity on job sites where precision and efficiency are crucial. Furthermore, as the industry advances, the rising popularity of electric and battery-powered models highlights a commitment to sustainability and operational convenience.

This article explores the multifaceted aspects of walk-behind saws, detailing their features, applications, and the advantages of renting these powerful tools. It also underscores the critical importance of safety, training, and maintenance, ensuring that operators can maximize performance while minimizing risks. For contractors and DIY enthusiasts alike, a thorough understanding of these elements is vital for achieving success in today’s dynamic construction landscape.

Understanding Walk-Behind Saws: Features and Applications

Walk behind saw rental options are robust tools meticulously engineered for demanding tasks in construction and masonry. These machines, available through walk behind saw rental services, boast a rotating blade adept at cutting through concrete, asphalt, and other resilient materials, rendering them essential on job sites. Key features include adjustable blade depth, water attachments for effective dust control, and ergonomic handles designed for user comfort during prolonged use.

In 2025, the market is experiencing a significant shift towards electric and battery-powered walk-behind tools, driven by an increasing focus on sustainability and efficiency. This transition not only minimizes emissions but also enhances operational convenience, aligning with the rising demand for specialized and tailored solutions in the construction sector.

Machines available for walk behind saw rental excel in a variety of applications, such as creating expansion joints, cutting trenches, and executing repairs on roads and sidewalks. Their ability to handle substantial workloads efficiently makes them the preferred choice for contractors and DIY enthusiasts alike, particularly when it comes to walk behind saw rental. Recent case studies underscore the growth of construction activities—spanning infrastructure, residential, and commercial projects—as a key factor propelling the concrete saw market.

As urbanization accelerates, the need for precise cutting in diverse construction tasks continues to grow, emphasizing the importance of advanced cutting tools equipped with innovative features. According to a case study titled 'Growth Drivers in the Concrete Cutting Market,' the expansion of these activities is significantly driving the demand for sophisticated concrete cutting tools.

Current statistics reveal that was valued at USD XXX million in 2022 and is expected to reach USD XXX million by 2033, exhibiting a compound annual growth rate (CAGR) of XX% during the forecast period (2025-2033). Experts assert that the integration of automation and robotics into walk-behind saw technology is poised to transform their applications, enhancing productivity and precision on job sites.

Real-world examples illustrate the effectiveness of walk-behind saw features, demonstrating their capability to streamline operations and bolster safety. As construction professionals increasingly recognize the benefits of walk behind saw rental, their usage is projected to rise, establishing walk behind saws as an indispensable asset in any building project.

The Advantages of Renting Walk-Behind Saws

Renting walk behind saws, also referred to as walk behind saw rental, offers numerous advantages for contractors and individuals undertaking specific projects in 2025. One of the most significant benefits is the elimination of hefty upfront costs associated with acquiring tools, which enhances cash flow management. In fact, over 70% of contractors prefer renting tools for specific projects, recognizing the financial flexibility it provides.

This trend aligns with the anticipated growth of in the Middle East and Africa, projected at 5.8%, indicating a broader shift towards rental solutions in the sector.

Moreover, rental agreements typically include maintenance and support services, alleviating the burden of upkeep for users. This aspect is particularly appealing in an industry where machinery reliability is crucial. As GoCodes, a leader in tool tracking, states, "GoCodes ensures our customers achieve success in their tool management projects every time," underscoring the importance of effective tool management in rental scenarios.

By renting, contractors gain access to the latest models and cutting-edge technology, ensuring they can utilize the most efficient and effective tools available. This flexibility is especially beneficial for projects with varying resource requirements or those that occur infrequently, making ownership impractical.

A case study titled "Utilization in Rent vs. Buy Decisions" illustrates this point effectively; it discusses how businesses can graph the costs of ownership against rental expenses based on utilization rates, leading to more informed decisions that balance financial return with operational efficiency.

Additionally, statistics reveal that renting can result in significant cost savings—often up to 30%—when compared to purchasing tools outright. Contractors who have successfully rented walk behind saw rental tools report not only savings but also improved project outcomes due to the availability of high-quality, well-maintained equipment. Furthermore, the relationship with primary dealers significantly impacts fleet health and maintenance efforts, further emphasizing the benefits of renting in terms of equipment reliability and maintenance support.

As the construction rental sector continues to expand, particularly in regions experiencing large-scale projects, the advantages of renting walk behind saw rental equipment will likely become even more apparent.

Safety First: Essential Tips for Using Walk-Behind Saws

Safety is paramount when utilizing a walk behind saw rental. Adhering to best practices can significantly reduce the risk of accidents. Operators must always don suitable personal protective equipment (PPE), including:

- Goggles

- Gloves

- Steel-toed boots

- Hearing protection

Research indicates that a substantial percentage of operators utilize PPE, reflecting a growing awareness of industry standards.

Before commencing work, conducting a thorough inspection of the saw is crucial. This inspection includes checking for any damage or wear on the blade and ensuring that all protective guards are securely in place. Proper training in the use of the saw is essential; operators must be adept at maintaining a straight cutting line while effectively managing the saw's weight and balance.

Incorporating water during cutting operations not only helps control dust but also keeps the blade cool, further enhancing safety. Notably, the construction industry has witnessed a concerning number of accidents, with 809 fatalities involving construction tradespeople reported in 2023. Furthermore, approximately 50,000 power saw-related hand injuries are reported each year from accidents at home or work, underscoring the critical need for rigorous precautionary practices.

Concrete Sawing & Drilling Awareness Week serves as an annual reminder of the hazards linked to these operations, encouraging discussions on protective measures that can avert such incidents. Real-world examples illustrate that improved protective features in tool design can lead to substantial reductions in injuries, as evidenced by the 64.79% decline in injuries from hand gardening tools over the past five years. This emphasizes the significance of adopting for walk behind saw rental tools.

By prioritizing protection and utilizing appropriate personal protective gear, operators can mitigate hazards and ensure a more secure working environment when using a walk behind saw rental.

For those seeking a walk behind saw rental, EZ Rental stands ready to assist. Reach out today at (214) 951-7800 to learn more and secure the necessary tools.

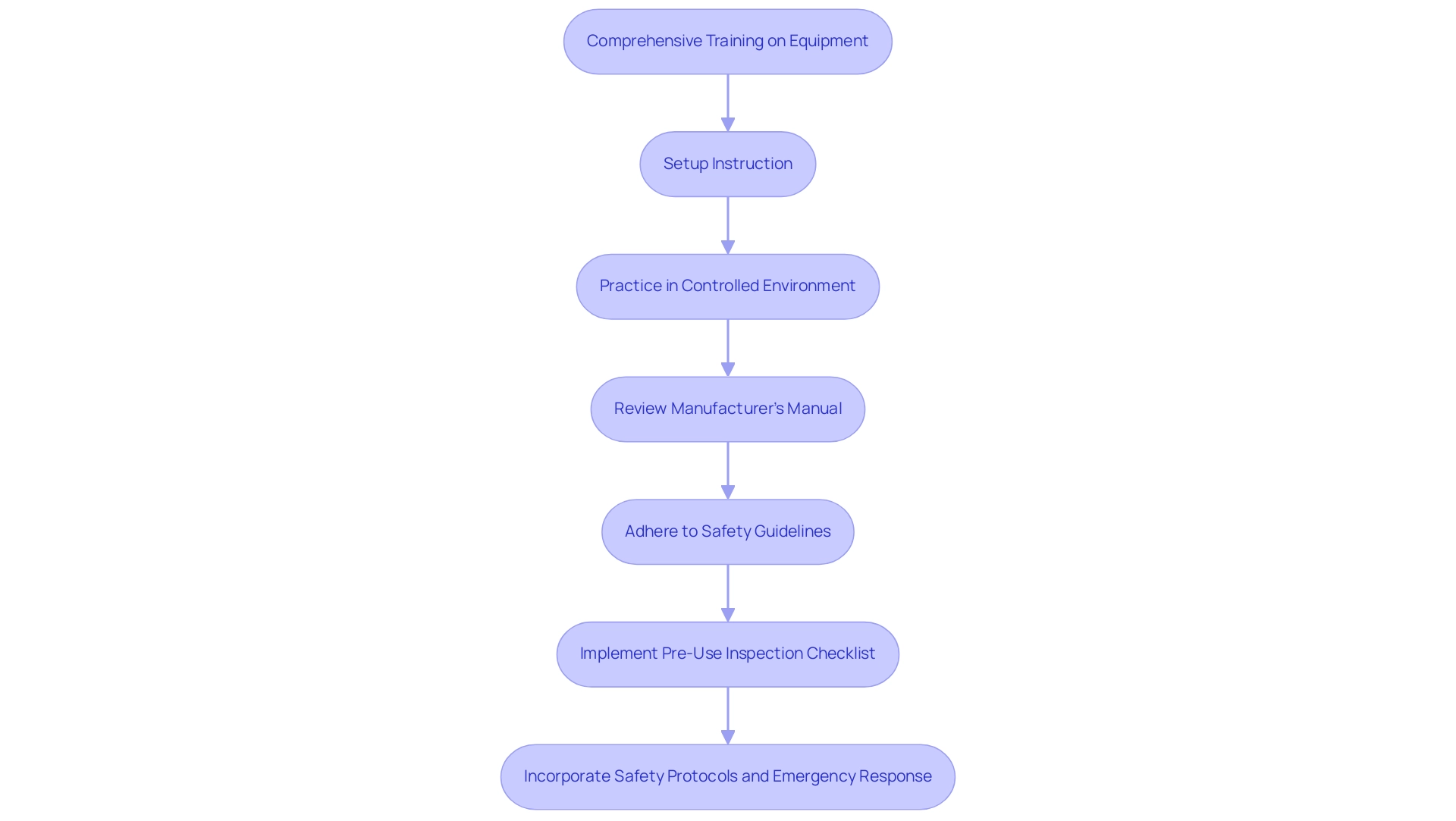

Training and Preparation: Key Steps Before Using Walk-Behind Saws

Before utilizing a walk-behind saw rental, it is essential for operators to undergo comprehensive training that encompasses both the equipment's functionality and its protective features. This training must include thorough instruction on the proper setup of the saw, such as adjusting the blade depth and ensuring the water system is fully operational. Practicing in a controlled environment allows operators to build confidence and become adept at handling the saw.

Reviewing the manufacturer's manual and adhering to safety guidelines is critical, as these documents provide specific instructions tailored to the particular model in use. Furthermore, implementing a pre-use inspection checklist can significantly mitigate risks by identifying potential issues before work commences. The importance of operator training cannot be overstated, especially in reducing accidents related to walk-behind saw rentals. In 2025, the construction industry continues to emphasize the need for skilled operators, with statistics indicating that heavy and civil engineering construction employs 29% of . Additionally, excavating and loading machine operators have a median salary of $50,050, underscoring the vital role of effective training programs in ensuring safety and efficiency on job sites.

Expert recommendations advocate that training programs should not only concentrate on operational skills but also incorporate safety protocols and emergency response strategies. Trainers emphasize that thorough preparation before using saws is crucial for minimizing risks and enhancing productivity. For instance, mobile heavy machinery mechanics, who identify and repair devices used in building projects, earn a median salary of $61,900, reflecting the growing demand for skilled professionals in the field. This highlights the significance of training for walk-behind saw rental operators, as their capabilities are essential for ensuring safe and efficient operations.

Moreover, the job outlook for machinery operators is promising, with a projected growth rate of 4% from 2023 to 2033, according to Fortune. This reinforces the necessity for robust training programs to equip operators for the evolving demands of the industry. In summary, effective training and preparatory steps are paramount for operators of walk-behind saw rental equipment. By prioritizing these elements, construction teams can ensure safer work environments and enhance overall operational efficiency.

For more details on tool rental and training resources, contact EZ Equipment Rental at (214) 951-7800.

Maintaining Your Rental: Care Tips for Walk-Behind Saws

Maintaining walk-behind saw rental equipment is crucial for ensuring efficiency and longevity. Users must adhere to essential care tips to maximize performance and minimize issues. After each use, it is vital to clean the saw thoroughly, removing any concrete slurry or debris that could hinder operation. A well-maintained saw not only performs better but also significantly reduces the risk of mechanical failures.

Regular inspections of the water system are necessary to confirm proper functioning. Check for any cracks or leaks in the hoses, as these can lead to significant operational challenges. Additionally, the blade should be inspected for wear; replacing a dull blade is essential, as it can cause inefficient cutting and increase strain on the saw, potentially leading to costly repairs.

Lubrication of all moving parts according to the manufacturer's guidelines is another critical maintenance step. Proper lubrication helps prevent mechanical failures and extends the lifespan of the machinery. Statistics indicate that a significant percentage of construction machinery users report that effective maintenance practices directly correlate with improved performance and reduced downtime. For example, in 2025, a survey revealed that 42% of respondents rated their primary dealer's service and support as 'excellent' or 'very good,' underscoring the importance of . As Rod Sutton, editorial lead, noted, the ability of dealers to collaborate with users on service and support is essential for maintaining devices effectively.

Real-world examples highlight the effectiveness of these maintenance practices. Companies that implement rigorous cleaning and inspection protocols for their walk-behind saw rentals often experience fewer operational disruptions and enhanced productivity. Furthermore, the emergence of digital platforms for tool rentals, as demonstrated in the case study on online rental solutions, is improving convenience for businesses and individuals seeking to rent machinery.

By prioritizing maintenance, users can ensure that their walk-behind saw rental remains in optimal condition, ready to tackle any project efficiently. This is particularly important across various sectors, including oil and gas, manufacturing, and mining, where the reliability of construction machinery is paramount.

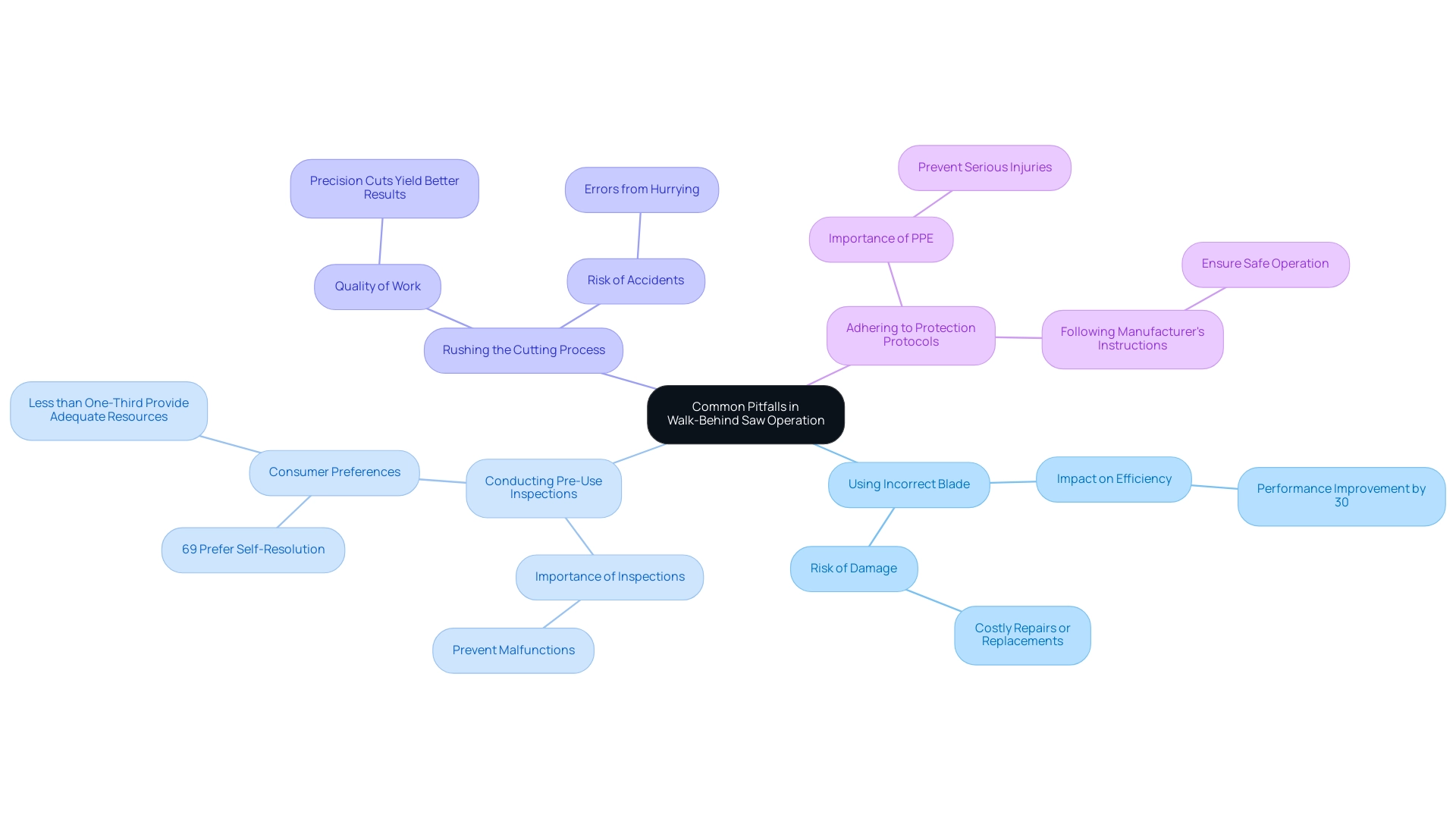

Avoiding Common Pitfalls: Mistakes to Steer Clear Of

Careful attention is paramount when renting a walk-behind saw and operating these tools to avoid several common pitfalls that can compromise both security and efficiency. One of the most significant mistakes is using an incorrect blade for the material being cut. This oversight hampers cutting efficiency and can lead to damage to the saw itself, resulting in costly repairs or replacements.

Research indicates that using the right blade can improve cutting performance by up to 30%, underscoring the critical importance of blade selection. Furthermore, the adoption of SawStop technology is limited due to high costs and the necessity for for different blades, highlighting the need for using the correct equipment.

Another critical aspect is the necessity of conducting thorough pre-use inspections. Overlooking this step can lead to risks and heighten the chance of malfunction during operation. A study found that 69% of consumers prefer to resolve issues independently, yet less than one-third of companies provide adequate self-service resources. This gap emphasizes the need for operators to be proactive in ensuring their equipment is in optimal condition before use.

Operators should also resist the temptation to rush the cutting process. Taking the time to make precise cuts not only yields better results but also significantly reduces the risk of accidents. Expert operators highlight that patience is crucial; hurrying can result in errors that undermine both the quality of work and personal well-being. As emphasized by Pasternack Tilker Ziegler Walsh Stanton & Romano LLP, protection is vital in saw operations, and operators must remain vigilant.

Lastly, adherence to protection protocols is essential. Failing to wear suitable personal protective gear (PPE) or disregarding the manufacturer's instructions can lead to serious injuries. Experienced operators often stress the importance of following these guidelines to ensure a safe working environment.

By being mindful of these common mistakes and implementing best practices, operators can enhance their efficiency and security when using a walk-behind saw rental. For quality equipment rentals that adhere to safety standards, contact EZ Equipment Rental at (214) 951-7800 to learn more and reserve the equipment needed.

Conclusion

In conclusion, walk-behind saws stand as indispensable tools within the construction and masonry sectors, renowned for their robustness and efficiency in tackling challenging materials such as concrete and asphalt. The growing trend towards electric and battery-powered models highlights a commitment to sustainability, while also enhancing operational convenience. It is essential for contractors and DIY enthusiasts to understand the features and applications of these saws, as well as the financial and operational advantages that renting offers over purchasing.

Renting walk-behind saws alleviates the burden of upfront costs, granting users access to cutting-edge technology and maintenance support that ensures optimal performance. Furthermore, comprehensive training and adherence to safety protocols are critical for minimizing risks associated with their operation. Operators must prioritize preparation and maintenance to keep the equipment in peak condition, which ultimately leads to enhanced productivity and safety on job sites.

By recognizing common pitfalls and implementing best practices, operators can significantly maximize the efficiency and safety of their cutting tasks. As the construction landscape continues to evolve, the reliance on advanced tools like walk-behind saws is set to increase, making it imperative for users to remain informed and skilled in their operation. Emphasizing training, safety, and proper maintenance not only protects operators but also contributes to successful project outcomes in a demanding industry.

Frequently Asked Questions

What are walk behind saws used for?

Walk behind saws are used for cutting through concrete, asphalt, and other resilient materials, making them essential for tasks such as creating expansion joints, cutting trenches, and executing repairs on roads and sidewalks.

What are the key features of walk behind saws?

Key features include adjustable blade depth, water attachments for dust control, and ergonomic handles designed for user comfort during prolonged use.

What is driving the shift towards electric and battery-powered walk behind saws?

The shift is driven by an increasing focus on sustainability and efficiency, which minimizes emissions and enhances operational convenience.

How is the market for electric walk behind concrete saws expected to grow?

The global electric walk-behind concrete saw market was valued at USD XXX million in 2022 and is expected to reach USD XXX million by 2033, with a compound annual growth rate (CAGR) of XX% during the forecast period (2025-2033).

What advantages does renting walk behind saws offer?

Renting walk behind saws eliminates hefty upfront costs, enhances cash flow management, provides access to the latest models, and typically includes maintenance and support services.

Why do over 70% of contractors prefer renting tools?

Contractors prefer renting tools for specific projects because it offers financial flexibility and reduces the burden of equipment maintenance.

What potential savings can be achieved by renting walk behind saws compared to purchasing?

Renting can result in significant cost savings—often up to 30%—when compared to purchasing tools outright.

How does renting impact project outcomes for contractors?

Contractors who rent walk behind saw rental tools report improved project outcomes due to access to high-quality, well-maintained equipment.

What is the projected growth of the construction rental industry in the Middle East and Africa?

The construction rental industry in the Middle East and Africa is projected to grow at a rate of 5.8%.

How does the relationship with primary dealers affect the benefits of renting?

The relationship with primary dealers significantly impacts fleet health and maintenance efforts, emphasizing the reliability and support benefits of renting equipment.