Overview

This article serves as an authoritative guide for construction managers seeking to rent boring missiles. It outlines the various types of boring tools available, emphasizing the essential considerations necessary for effective rental. Understanding project requirements, evaluating soil conditions, and adhering to a structured rental process are crucial components for ensuring operational efficiency. These practices help minimize common rental issues, such as equipment malfunctions and operator errors, thereby enhancing overall project success.

Furthermore, each type of boring tool offers distinct benefits that can significantly impact project outcomes. For instance, selecting the appropriate equipment tailored to specific soil conditions can lead to improved performance and reduced downtime. The article highlights the importance of reliability and quality in rental equipment, underscoring that the right tools can make all the difference in achieving project goals.

In addition, testimonials from satisfied customers reinforce the claims of reliability and quality, showcasing real-world applications of the equipment. By sharing these insights, the article builds trust and relatability, encouraging construction managers to consider their rental options seriously.

To prompt immediate action, the article concludes with strong calls to action, inviting readers to explore available rental options and consult with experts to find the best solutions for their projects. By following these guidelines, construction managers can ensure a seamless rental experience, ultimately leading to successful project execution.

Key Highlights:

- Boring projectiles, or pneumatic piercing tools, are vital for underground applications, with different types suited for specific tasks.

- Standard unexciting projectiles are versatile for general drilling, holding a 40% market share in rentals by 2025.

- Directional boring missiles provide precise control, reducing risks of damaging existing infrastructure.

- Auger drilling tools are used for larger diameter bores in challenging soil conditions, effective in commercial projects.

- Microtunneling machines are ideal for deep, precise bores with minimal surface disruption, increasingly popular in urban construction.

- Key factors for renting include project scope, soil conditions, depth requirements, rental duration, and operator experience.

- The rental process involves investigating providers, evaluating equipment, reviewing agreements, scheduling delivery, inspecting equipment, receiving training, and returning the equipment.

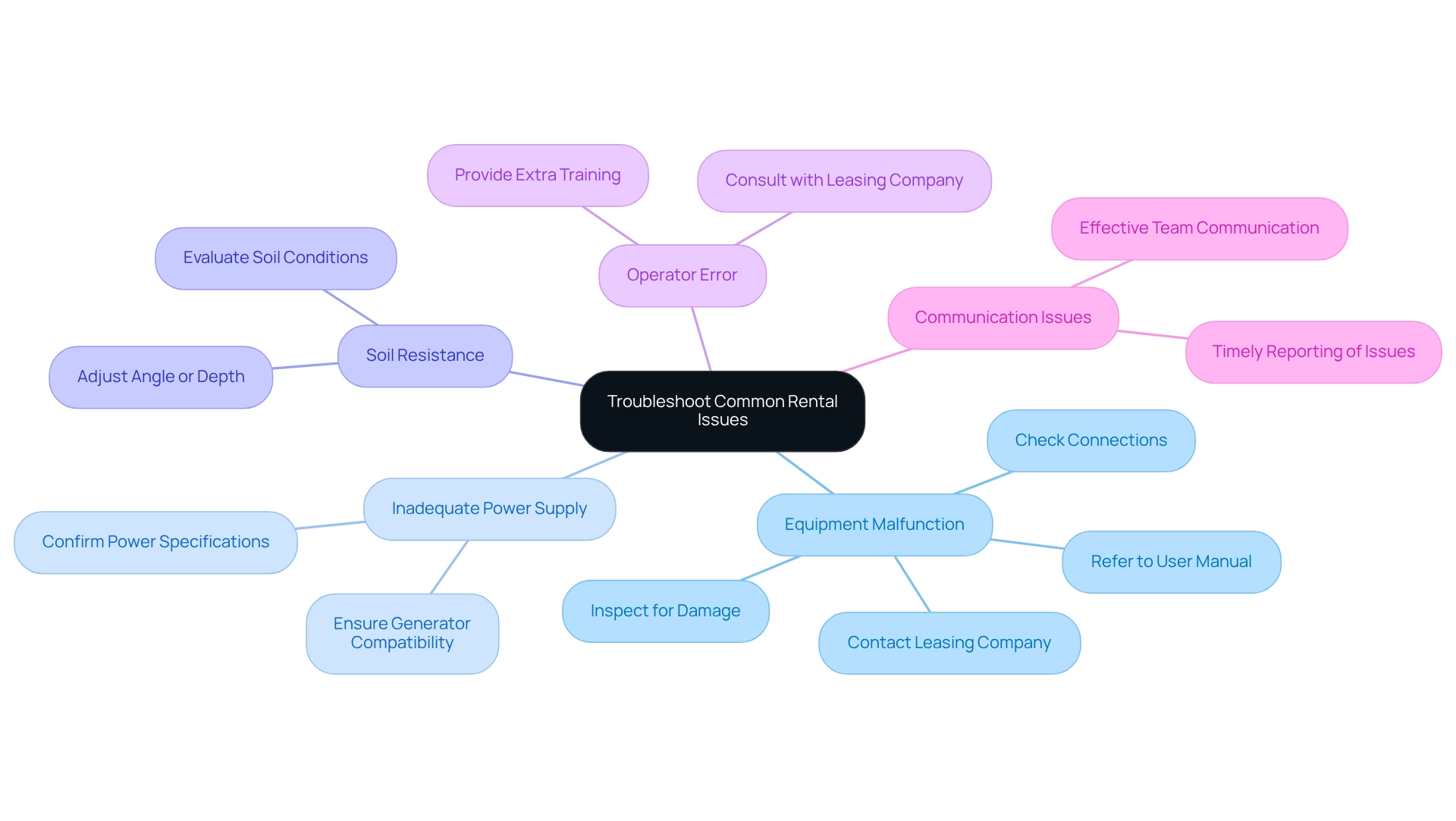

- Common rental issues include equipment malfunction, inadequate power supply, soil resistance, operator error, and communication issues, all of which require proactive troubleshooting.

Introduction

In the realm of underground construction, boring missiles serve a pivotal role, fundamentally transforming the installation of utility lines and the development of infrastructure. These pneumatic piercing tools are available in various types, each meticulously designed to address specific challenges beneath the surface. From standard boring missiles that manage general tasks to advanced microtunneling machines that excel in precision, understanding the diverse applications of these tools is essential for any construction project.

As the demand for efficient and effective boring operations increases, the necessity for informed decision-making when selecting the right equipment becomes paramount. This article explores the following topics:

- Types of boring missiles available

- Key considerations for rental

- A step-by-step rental process

- Common troubleshooting tips

All aimed at empowering project managers and operators to navigate the complexities of underground boring with confidence.

Understand Boring Missiles: Types and Applications

Boring projectiles, commonly referred to as pneumatic piercing tools, are essential for various underground applications, with each type meticulously tailored to specific tasks. Let’s delve into the most prevalent types:

- Standard Unexciting Projectiles: Designed for general underground drilling tasks, these projectiles excel in placing utility lines beneath roads or driveways. Their versatility allows them to penetrate various soil types effectively, particularly over short to medium distances. Recent statistics indicate that boring missile rental represents approximately 40% of the market share in 2025, underscoring their extensive application in construction endeavors.

- Directional Boring Missiles: These tools offer precise control over drilling direction, making them ideal for tasks that require navigation around existing underground utilities or obstacles. Their accuracy is vital for minimizing disruptions in urban environments. Experts in the field have noted that directional drilling missiles significantly reduce the risk of damaging current infrastructure, thereby enhancing task efficiency.

- Auger Drilling Tools: Suitable for larger diameter bores, auger drilling tools are adept at tackling challenging soil conditions. They are frequently employed in commercial projects where the installation of larger conduits is necessary, delivering efficiency in demanding environments. A recent case study highlighted the successful application of auger boring tools in a significant infrastructure project, showcasing their effectiveness in difficult conditions.

- Microtunneling Machines: For projects that necessitate deep and precise bores, microtunneling machines are the preferred choice. Equipped with advanced technology, they ensure accuracy while minimizing surface disruption, making them particularly suitable for sensitive areas. Recent advancements in microtunneling technology have led to improved efficiency and reduced costs, making the boring missile rental increasingly popular in urban construction initiatives.

Understanding these types of tedious tools will empower you to select the most appropriate instrument for your task, enhancing both efficiency and effectiveness in your operations. By incorporating these insights and statistics, you will be better positioned to make informed decisions when renting equipment for your construction needs.

Evaluate Key Considerations Before Renting

Before considering a boring missile rental, it is essential to evaluate several key factors to ensure optimal performance and efficiency.

- Project Scope: Clearly define the project scope, including the required length and diameter of the bore. This information is crucial for selecting the suitable weapon type.

- Soil Conditions: Conduct a thorough assessment of the soil type and conditions at the job site. Various projectiles are engineered to function best in particular soil types, making this assessment crucial for informed decision-making.

- Depth Requirements: Identify the necessary depth for the boring operation. Some missiles are engineered for shallow applications, while others are capable of handling deeper installations, which can significantly influence your choice regarding boring missile rental. Compare leasing rates across providers and factor in additional costs such as delivery and insurance to avoid unexpected expenses when considering boring missile rental.

- Rental Duration: Estimate the duration for which you will need the equipment. Numerous leasing firms provide attractive prices for prolonged hire durations, which can result in cost reductions. Additionally, with the construction equipment rental market expected to exhibit a CAGR of 5.04% during 2025-2033, understanding rental duration can help you capitalize on market trends.

- Operator Experience: Ensure that the operator has experience with the specific type of projectile you intend to rent. With the industry needing around 650,000 skilled workers in the coming years, having a proficient operator is essential for the success of the drilling operation. Adequate training and knowledge of the equipment can significantly improve operational effectiveness.

By thoughtfully evaluating these elements, you can choose the most appropriate drilling device for your project, thus reducing risks and increasing operational efficiency. Furthermore, advancements in technology, such as telematics and IoT, are enhancing equipment maintenance and minimizing downtime, which is crucial for ensuring that your leased equipment performs at its best.

Follow the Step-by-Step Rental Process

To effectively lease an unexciting projectile, follow these steps:

- Investigate Equipment Providers: Begin by locating nearby equipment leasing firms, such as EZ Equipment Rental, that specialize in drilling tools. It is essential to check reviews and reliability ratings to ensure you choose a reputable provider. In the DFW area, statistics indicate that leasing company reliability ratings are crucial for making informed choices. Contact rental providers to reach out to your selected companies and inquire about the availability, pricing, and any specific requirements related to boring missile rental. EZ Equipment Rental offers a diverse range of machinery, including boom lifts, excavators, and forklifts, with flexible terms and pricing options tailored to your needs.

- Evaluate Equipment Choices: Discuss your project requirements with the leasing provider. They can recommend the most suitable boring missile rental based on your project scope and soil conditions, ensuring optimal performance. Notably, telematics integration is transforming the management of construction equipment, enhancing operational efficiency and monitoring.

- Review Lease Agreement: Carefully read the lease agreement, focusing on terms related to duration, costs, and responsibilities for maintenance and damages. Understanding these details is vital for a seamless rental experience.

- Schedule Delivery: Arrange for the equipment's delivery to your job site. Confirm the delivery date and time to align with your project schedule, minimizing downtime. EZ Equipment Rental provides convenient access for customers in Irving, TX, ensuring timely delivery of equipment across the DFW Metroplex.

- Inspect the Equipment: Upon delivery, examine the boring device for any signs of damage or wear. Ensure it meets your specifications before accepting it to avoid issues later.

- Receive Training: If necessary, obtain training on how to operate the missile safely and effectively. This training may be offered by the leasing company or through your own resources, ensuring your team is well-prepared.

- Return the Equipment: After completing your assignment, return the equipment as per the leasing agreement. Ensure it is clean and in good condition to avoid incurring extra fees.

By following these steps, you can facilitate a smooth rental process and successfully complete your tedious project, contributing to the overall efficiency of your construction operations.

Troubleshoot Common Rental Issues

When dealing with a boring missile rental, several common issues may arise that require effective troubleshooting. Equipment Malfunction is a primary concern; if the missile is not functioning as expected, inspect for visible damage or loose connections. Refer to the user manual for troubleshooting advice or contact the leasing company for assistance. Statistics indicate that equipment malfunctions can occur at rates of 15% to 20% in boring missile rental tools, underscoring the critical need for reliability.

Inadequate Power Supply is another potential issue. Confirm that the power supply aligns with the equipment's specifications. Insufficient power can hinder performance, so ensure your generator or power source meets the necessary requirements to avoid complications.

Soil Resistance can also pose challenges. If the missile encounters unexpected resistance while boring, evaluate the soil conditions. Adjusting the angle or depth of the bore may help overcome this challenge, ensuring a smoother operation.

Operator Error is a factor that should not be overlooked. Inexperienced operators may struggle with proper equipment usage, which can lead to inefficiencies. Offering extra training or consulting with the leasing company can significantly improve operational efficiency and overall performance.

Communication Issues can further complicate operations. Effective communication with your team and the boring missile rental service provider is crucial. Timely reporting of any issues can enable swift solutions and reduce disruptions to the work, ensuring that your project stays on track.

By proactively addressing these common issues, you can enhance operational efficiency and keep your project on schedule. As Cesar Pelli said, "Construction is a matter of optimism; it’s a matter of facing the future with confidence." Notably, implementing predictive maintenance strategies can lead to cost savings of 30% to 40% and significantly reduce equipment breakdowns, which can occur at alarming rates without proper maintenance. This highlights the importance of reliability in rental operations and the urgent need for improved internal efficiency in maintenance practices.

Conclusion

Understanding the various types of boring missiles and their specific applications is essential for enhancing efficiency in underground construction projects. From standard boring missiles that handle general tasks to advanced microtunneling machines that ensure precision, each tool presents unique advantages tailored to different challenges. Familiarizing oneself with these options empowers project managers to make informed decisions that align with their project's specific requirements.

Before renting equipment, careful consideration of critical factors can significantly impact the success of boring operations. Evaluating project scope, soil conditions, depth requirements, and budget constraints ensures the selection of the right equipment. Furthermore, recognizing the importance of operator experience can greatly influence the overall efficiency and effectiveness of the operation.

Following a systematic rental process—from researching rental companies to inspecting the equipment upon delivery—can streamline the experience and minimize potential issues. Additionally, being prepared to troubleshoot common problems, such as equipment malfunctions or inadequate power supply, helps maintain project momentum and prevents costly delays.

Ultimately, the key to successful underground boring operations lies in thorough preparation and informed decision-making. By leveraging the insights provided in this article, project managers and operators can navigate the complexities of boring missile rentals with confidence, leading to smoother, more efficient construction processes. Embracing these practices not only enhances project outcomes but also contributes to the overall advancement of infrastructure development in urban environments.

Frequently Asked Questions

What are pneumatic piercing tools, and what are they used for?

Pneumatic piercing tools, commonly known as boring projectiles, are essential for various underground applications, with each type designed for specific tasks such as drilling utility lines beneath roads or driveways.

What are Standard Unexciting Projectiles, and what are their applications?

Standard Unexciting Projectiles are designed for general underground drilling tasks. They excel in placing utility lines and can effectively penetrate various soil types over short to medium distances. They represent about 40% of the boring missile rental market in 2025.

What are Directional Boring Missiles, and why are they important?

Directional Boring Missiles provide precise control over drilling direction, making them ideal for navigating around existing underground utilities or obstacles. Their accuracy helps minimize disruptions in urban environments and reduces the risk of damaging current infrastructure.

What are Auger Drilling Tools used for?

Auger Drilling Tools are suitable for larger diameter bores and are adept at tackling challenging soil conditions. They are frequently used in commercial projects for the installation of larger conduits, showcasing their efficiency in demanding environments.

What are Microtunneling Machines, and when are they used?

Microtunneling Machines are preferred for projects that require deep and precise bores. They use advanced technology to ensure accuracy while minimizing surface disruption, making them suitable for sensitive areas. Recent advancements have improved their efficiency and reduced costs.

How can understanding these types of boring tools benefit construction operations?

Understanding the different types of boring tools allows for the selection of the most appropriate instrument for specific tasks, enhancing both efficiency and effectiveness in construction operations.