Introduction

The decision between electric and gas cement saws can significantly impact the efficiency and success of construction projects. As project managers navigate the complexities of selecting the right equipment, understanding the key differences in performance, maintenance, and operational requirements becomes crucial.

- Electric saws offer advantages in indoor settings, providing a quieter, user-friendly alternative for residential jobs,

- Gas saws excel in heavy-duty applications, delivering the power and mobility needed for larger outdoor tasks.

With the construction equipment market evolving rapidly, informed choices can lead to substantial cost savings and enhanced project outcomes. This article delves into the unique features of both saw types, offering insights that empower project managers to make strategic decisions tailored to their specific project needs.

Electric vs. Gas Cement Saws: Key Differences

Cement saw rental offers numerous benefits, particularly in indoor settings or home projects. Their lighter weight and quieter operation make them user-friendly, reducing the disturbance to nearby occupants. While they require a power source, which can limit mobility, this dependency alleviates the complexities associated with fuel management.

In contrast, gas cement tools excel in heavy-duty applications, especially in outdoor settings where mobility and power are paramount. These models operate independently of electrical outlets, enabling extended use in remote locations. However, they tend to be heavier, noisier, and demand regular maintenance, including fuel replenishment and engine checks.

According to industry insights, the market share of electric saws is around 10% of the overall construction equipment market in 2024, indicating their growing acceptance. As Ed Varel, an engineering manager at Stone Construction Equipment, notes,

It might cost you 25-percent more to buy a domestic saw with higher quality versus an import, but you'll get five, six, seven years longer life than what you might see with the less expensive saw.

Moreover, firms such as Megasaw provide a varied selection of electric and gas cutting machines for masonry, highlighting the present market options that managers can investigate.

Furthermore, progress in heavy machinery design, demonstrated in the case study of heavy equipment cab redesigns, emphasizes the significance of operator comfort and productivity, which can also affect the selection of concrete cutting tools. By understanding the key differences between electric and gas cement cutters, along with the implications of cost and longevity, managers can better assess which cement saw rental option aligns with their specific requirements, ultimately balancing convenience and performance effectively.

Considerations for Renting Cement Saws: Costs and Availability

When renting a cement saw rental, it is essential to evaluate a range of factors, including rental costs, duration, and the specific terms of the rental agreement. Generally, electric tools tend to have lower rental fees due to their less complex technology, making them an economical choice for short-term projects. In contrast, gas-powered tools often incur higher costs related to fuel and maintenance, which can accumulate over time.

The availability of these tools can also differ significantly by region; for instance, electric versions are typically more accessible in urban areas, while gas models are preferred in rural settings where mobility and power are critical. According to recent regional analysis, North America leads the cement saw rental market due to advanced technology and high consumer demand, while the Asia-Pacific region is rapidly growing, fueled by urbanization and rising disposable incomes. Rental companies typically offer different pricing structures—varying from hourly to daily rates—so grasping the scope and timeline is essential for choosing the most economical option.

Mr. Edwyne Fernandes notes, 'Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets.' Furthermore, managers should be aware of potential risks related to renting concrete cutting tools, such as machine malfunctions, operator errors, and exposure to hazardous materials. Proper training and safety measures are essential to mitigate these risks.

By carefully assessing these factors, project managers can achieve substantial savings and ensure the right equipment is on hand when needed, thus enhancing overall project efficiency.

Maintenance and Operational Considerations

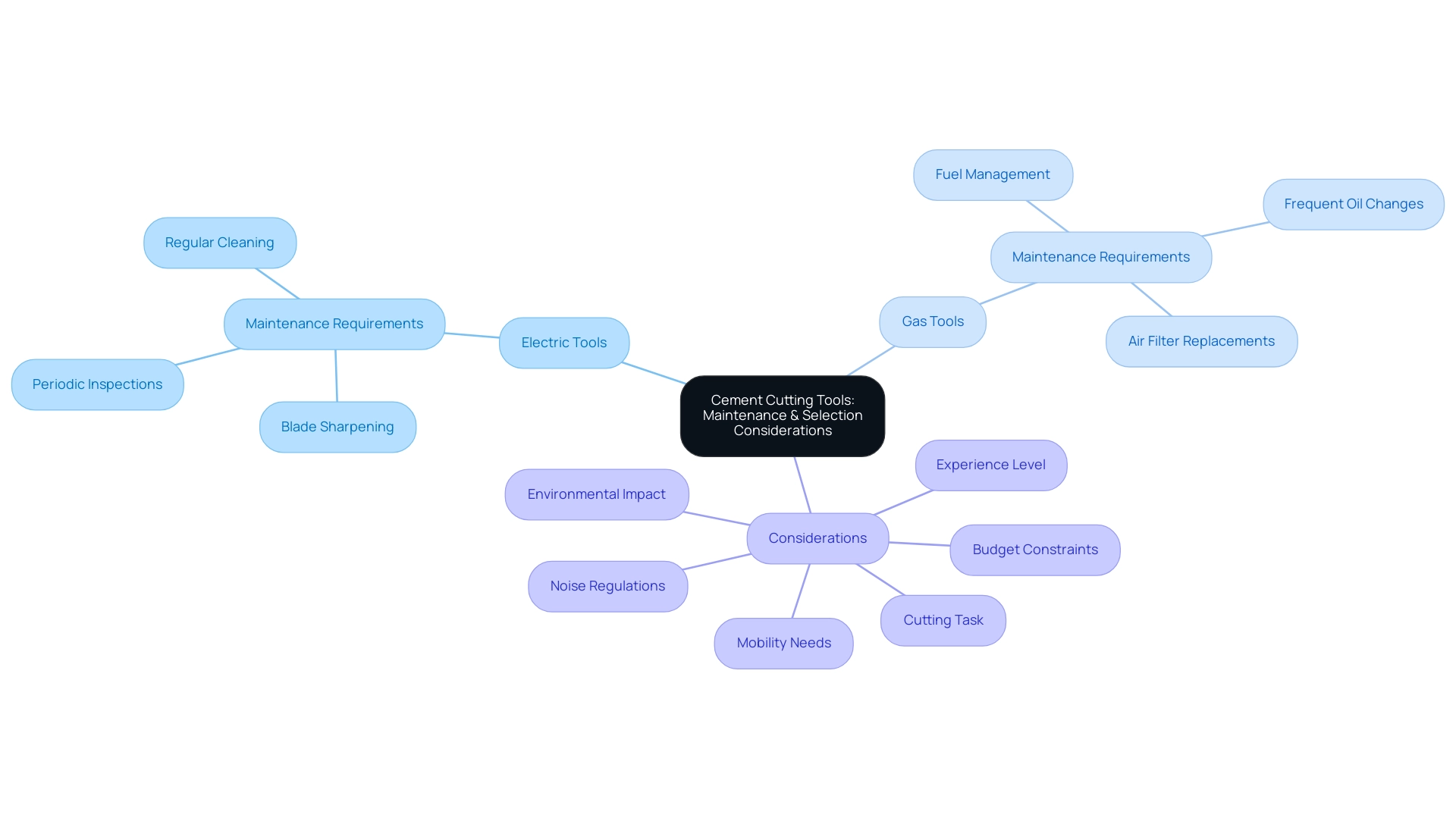

Electric cement cutting tools typically demand less maintenance than their gas counterparts, requiring only periodic inspections of the power cord and blade condition. To sustain optimal cutting efficiency, users should regularly clean the saw and sharpen the blade. In contrast, gas cement cutters necessitate more rigorous upkeep, including frequent oil changes, air filter replacements, and careful fuel management to avert engine complications.

Although gas-powered machines may have lower upfront costs, they can be more expensive to operate and maintain over time. Furthermore, it is crucial for operators to adhere to safety protocols, as gas tools emit fumes and require adequate ventilation. When selecting between electric and gas tools, construction project managers should consider factors such as:

- The nature of the cutting task

- Mobility needs

- Environmental impact

- Experience level

- Budget constraints

- Noise regulations

As highlighted by BISON, a prominent producer of masonry saws, > Select BISON for dependable masonry saw solutions <. A clear understanding of these maintenance requirements is essential for preventing operational disruptions and maximizing the effectiveness of cement saw rental services. For instance, The Cat® Rental Store offers a comprehensive selection of concrete tools, including cement saw rental, and expert assistance, providing flexible rental terms and on-site maintenance, which can enhance the overall experience for users.

By adopting best practices for both types, construction managers can significantly enhance their operational efficiency and ensure a safer working environment.

Performance in Different Applications

For residential projects, interior renovations, and smaller-scale jobs, cement saw rental tools are particularly advantageous, especially where concerns about noise and emissions are paramount. Their design enables accurate cuts, making them ideal for materials like tile and stone. Conversely, gas cement tools excel on larger construction sites, outdoor applications, and challenging tasks that require significant power and mobility.

These tools can effortlessly handle thicker materials and exhibit faster cutting speeds, which is essential for extensive concrete work. An expert in the field, Franny K., emphasizes the efficiency of gas tools, stating, 'The MS500i cuts more wood per unit of fuel than the MS441C, running about 35 minutes on a fill-up versus 45 minutes for the latter, yet accomplishing more in that time frame.' The rule of thumb seems to be about 13 times as much energy per unit mass for gasoline as for lithium-ion batteries.

- Comprehending the performance advantages of both electric and gas alternatives enables users to choose the most efficient saw for their particular uses, thereby ensuring optimal outcomes in their endeavors.

- As the U.S. market for cutting tools continues to expand—valued at USD 142.8 million in 2023 and estimated to grow at a CAGR of over 4.9% due to robust infrastructure development and significant government investments under the Infrastructure Investment and Jobs Act (IIJA)—making an informed choice between electric and gas equipment becomes increasingly critical for project managers aiming to achieve efficiency and effectiveness in their operations.

- Key companies in the concrete saws market held a combined market share of 50-55% in 2023, focusing on innovation and geographic expansion to stay competitive.

Conclusion

Choosing the right cement saw—whether electric or gas—plays a pivotal role in the success of construction projects. Electric saws stand out for their user-friendly operation in indoor settings, where noise and emissions are concerns. Their lightweight design and lower maintenance needs make them ideal for residential tasks and smaller jobs. Conversely, gas saws provide the power and mobility required for heavy-duty applications, particularly on larger outdoor sites, despite their higher operational costs and maintenance demands.

When considering rental options, cost and availability are crucial factors. Electric saws typically present more economical rental fees, making them suitable for short-term projects, while gas saws may incur additional expenses due to fuel and maintenance requirements. An understanding of regional availability also aids project managers in making informed decisions that align with their specific needs.

Maintenance and operational considerations further differentiate these saw types. Electric saws require less upkeep, focusing primarily on cord and blade inspections, whereas gas saws demand regular maintenance to ensure optimal performance. The choice between the two should factor in the nature of the project, budget constraints, and environmental considerations.

Ultimately, the decision between electric and gas cement saws hinges on the specific requirements of the project. By carefully evaluating performance, costs, and maintenance needs, project managers can select the most suitable equipment, leading to enhanced efficiency and successful project outcomes. Making an informed choice not only optimizes operations but also contributes to long-term savings and effectiveness in construction efforts.

Frequently Asked Questions

What are the benefits of renting a cement saw for indoor projects?

Renting a cement saw for indoor projects offers benefits such as lighter weight and quieter operation, making them user-friendly and reducing disturbance to nearby occupants.

What is the main limitation of electric cement saws?

Electric cement saws require a power source, which can limit mobility, but this dependency simplifies fuel management.

In what scenarios are gas cement tools more advantageous?

Gas cement tools excel in heavy-duty applications, particularly outdoors, where mobility and power are essential. They operate independently of electrical outlets, allowing for extended use in remote locations.

What are some drawbacks of gas cement tools?

Gas cement tools tend to be heavier, noisier, and require regular maintenance, including fuel replenishment and engine checks.

What percentage of the construction equipment market do electric saws hold in 2024?

Electric saws hold approximately 10% of the overall construction equipment market in 2024, indicating their growing acceptance.

How does the cost of domestic saws compare to imports?

According to Ed Varel, a higher quality domestic saw may cost about 25% more than an import, but it can last five to seven years longer than less expensive options.

Where can managers find a variety of cutting machines?

Managers can explore a varied selection of electric and gas cutting machines offered by companies such as Megasaw for masonry projects.

Why is operator comfort important in the selection of concrete cutting tools?

Progress in heavy machinery design emphasizes operator comfort and productivity, which can significantly influence the choice of concrete cutting tools.

How can managers determine the best cement saw rental option for their needs?

By understanding the key differences between electric and gas cement cutters, along with considerations of cost and longevity, managers can assess which rental option aligns best with their specific requirements, balancing convenience and performance.