Key Highlights:

- Excavators are categorised into four types: Mini (under 6 tonnes), Midi (6-10 tonnes), Standard (10-45 tonnes), and Large (over 45 tonnes).

- Mini excavators are ideal for small tasks and confined spaces due to their portability.

- Midi excavators balance power and size, suitable for medium-sized jobs.

- Standard excavators are commonly used in commercial projects for their power and reach.

- Large excavators are intended for significant excavation and demolition tasks, offering maximum depth and capacity.

- Project requirements must be clearly defined to choose the right excavator type and size.

- Worksite conditions, including terrain and space limitations, significantly influence excavator selection.

- Soil type affects machinery performance; rocky or clay soils may require more robust machines.

- Digging depth and lifting capacity are critical specifications to consider when selecting an excavator.

- Renting equipment allows testing in real-world conditions, aiding in performance evaluation.

- Operator comfort and usability are vital for productivity and safety on the job site.

Introduction

Choosing the right excavator size can be a challenging endeavor, particularly given the wide range of options available in the market. It is essential to understand the various categories - from mini to large excavators - and their specific capabilities to ensure project success. This guide highlights the critical factors that influence excavator selection while addressing the complexities of project requirements and worksite conditions. With numerous variables to consider, how can one ensure they make the most informed decision for their unique excavation needs?

Identify Excavator Categories: Mini, Midi, Standard, and Large

To select the appropriate excavator, it is essential to first identify the various categories available:

- Mini Excavators: Generally weighing under 6 tons, these machines are perfect for small tasks and confined spaces. Their versatility and ease of transport make them a popular choice for many projects.

- Midi Machines: With weights ranging from 6 to 10 tons, midi machines strike a balance between power and size, making them suitable for medium-sized jobs that require a bit more capability.

- Standard Excavators: These machines, weighing between 10 to 45 tons, are the most commonly used for commercial projects. They provide an advantageous combination of power and reach, making them ideal for a variety of applications.

- Large Excavators: Exceeding 45 tons, these heavy-duty machines are designed for significant excavation and demolition tasks. They offer maximum digging depth and lifting capacity, making them indispensable for large-scale operations.

By understanding these categories, you can effectively narrow down your options based on the scale and specific requirements of your project.

Evaluate Key Factors: Project Requirements and Worksite Conditions

When selecting an excavator, several critical factors must be considered to ensure optimal performance and efficiency on the job site.

-

Project Requirements: Clearly define the scope of your project. Identify the specific tasks the machine will perform, such as digging, lifting, or demolition. Understanding these requirements will assist you in choosing the suitable type of machinery and the appropriate excavator sizes.

-

Worksite Conditions: Evaluate the terrain and available space at the worksite. Is the area compact or open? Are there barriers such as trees, buildings, or utility lines that could limit the machine's movement? In congested urban settings, productivity can drop by 30-45% due to the need for careful maneuvering and hand-digging verification. This highlights the importance of selecting a digging machine that can navigate narrow areas efficiently.

-

Soil Type: Various soil conditions significantly affect machinery performance. For example, rocky or clay soils may require a more robust machine to maintain productivity. Research indicates that soil moisture can lead to productivity variations of 30-40%, underscoring the necessity to evaluate soil conditions prior to selection. Additionally, excavation productivity rates can fluctuate by 300% or more based on excavator sizes, soil conditions, and operator experience, making it essential to select the appropriate machinery for the task.

-

Extent and Reach: Determine the necessary digging extent and reach, as this will influence the required excavator sizes and type of digging machine. For instance, foundation digging typically achieves output levels of 80-150 cubic yards per hour due to convenient access and minimal repositioning. Selecting a machine that meets these criteria effectively is crucial.

By thoroughly assessing these factors, you can ensure that the machinery you choose will effectively meet the demands of your project, enhancing productivity and reducing operational delays.

Compare Specifications: Digging Depth, Lifting Capacity, and More

To make an informed choice, it is essential to compare the following specifications:

-

Digging Level: The maximum depth a digger can reach varies significantly. Mini diggers, categorized by different excavator sizes, typically achieve depths ranging from 5 to 12 feet, with models like the Yanmar ViO50 reaching up to 12 feet. In contrast, excavator sizes that are larger can exceed depths of 20 feet, making them suitable for extensive excavation tasks.

-

Lifting Capacity: This specification indicates the maximum weight a digging machine can safely lift. Mini diggers generally lift between 1,500 and 2,500 pounds near the cab, while larger excavator sizes can manage lifting capacities exceeding 40,000 pounds, depending on their configuration.

-

Operating Weight: Heavier excavator sizes provide enhanced stability and power, which are crucial for lifting and digging operations. However, they may be less maneuverable in confined spaces, so it is important to consider the project environment when selecting the appropriate operating weight.

-

Bucket Size: The size of the bucket directly affects the efficiency of material movement. Larger buckets can transport more material per scoop, making them ideal for substantial jobs, although they may not fit into tighter spaces. For instance, using a trenching bucket can increase digging depth by 6 to 12 inches, which is advantageous for specific tasks.

By carefully comparing these specifications, you can select a machine with the appropriate excavator sizes that align with your project’s requirements, ensuring optimal performance and efficiency.

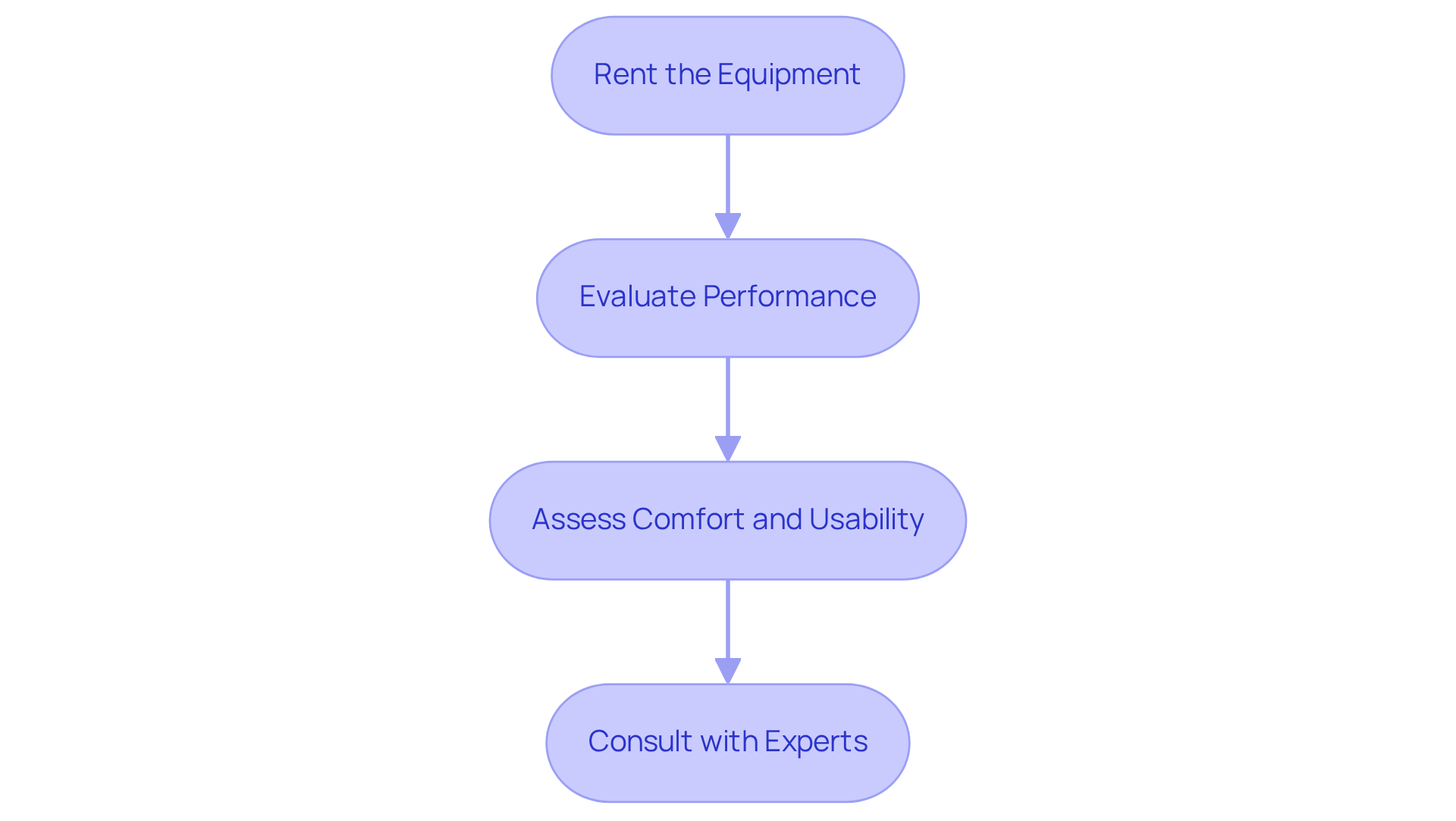

Test and Rent: Experience the Excavator Before You Buy

Before making a purchase, it’s essential to follow these steps to ensure you choose the right excavator for your project:

-

Rent the Equipment: Renting allows you to test the machinery in real-world conditions, which is crucial for evaluating its performance and suitability for your specific tasks. The global equipment rental market is projected to reach USD 13.8 billion by 2025, highlighting the growing importance of rental options in the industry.

-

Evaluate Performance: During the rental period, monitor how well the machine meets your operational needs. Key performance metrics to consider include digging distance, lifting capacity, and overall maneuverability. For instance, typical dig depths for residential or light utility work range from 8 to 12 feet, making it vital to select a machine that meets these specifications.

-

Assess Comfort and Usability: Ensure that the controls are intuitive and that the operator feels comfortable and confident while using the machine. Operator comfort significantly impacts productivity and safety on the job site. As Josh Nickell, Vice President of the American Rental Association, notes, effective planning and analytics are essential in equipment management to eliminate guesswork.

-

Consult with Experts: Engage with experienced operators or knowledgeable staff from the rental company to gain insights into the machinery's performance and reliability. Their firsthand experiences can provide valuable context that aids in your decision-making process. Additionally, be aware that if the excavator rental exceeds 10,000 lbs., a Commercial Driver's License (CDL) may be required to tow it, depending on state regulations regarding excavator sizes.

Testing an excavator before purchase not only facilitates an informed choice but also conserves time and resources, ensuring that the equipment aligns seamlessly with your project requirements.

Conclusion

Choosing the right excavator size is essential for the success of any construction project, as it directly affects efficiency and productivity. Understanding the various categories of excavators - mini, midi, standard, and large - enables project managers to align their equipment choices with the specific demands of their tasks. This guide underscores the importance of assessing project requirements, worksite conditions, and the specifications of different excavators to ensure the selected machine is the most suitable for the job.

Key factors such as:

- Digging depth

- Lifting capacity

- Soil type

significantly influence excavator performance. Comparing specifications helps narrow down choices based on project needs. Additionally, the guide highlights the value of renting equipment before making a purchase, allowing for a practical evaluation of performance and comfort, which are crucial for operational success.

Ultimately, making informed decisions regarding excavator selection enhances project outcomes and optimizes resource allocation. By considering the insights shared in this guide, stakeholders can confidently navigate the excavator size selection process, ensuring they choose the most effective machinery for their specific applications. Embracing these practices leads to improved efficiency and reduced risks on the job site, paving the way for successful project execution.

Frequently Asked Questions

What are the different categories of excavators?

The different categories of excavators are Mini, Midi, Standard, and Large.

What characteristics define Mini Excavators?

Mini Excavators generally weigh under 6 tons and are ideal for small tasks and confined spaces. They are known for their versatility and ease of transport.

What is the weight range for Midi Excavators, and what are they suitable for?

Midi Excavators weigh between 6 to 10 tons and are suitable for medium-sized jobs that require a balance of power and size.

What defines Standard Excavators, and what are their common uses?

Standard Excavators weigh between 10 to 45 tons and are the most commonly used for commercial projects. They offer a good combination of power and reach for various applications.

What are Large Excavators designed for?

Large Excavators exceed 45 tons and are designed for significant excavation and demolition tasks. They provide maximum digging depth and lifting capacity, making them essential for large-scale operations.

How can understanding excavator categories help in selecting the right machine?

By understanding the excavator categories, you can effectively narrow down your options based on the scale and specific requirements of your project.

List of Sources

- Identify Excavator Categories: Mini, Midi, Standard, and Large

- Mini Excavators Market Trends | Size & CAGR of 7.71%. (https://industryresearch.biz/market-reports/mini-excavators-market-102829)

- Global Mini Excavators market size is expected to reach $11.08 billion by 2030 at 5.4%, booming construction sector fuels surge in mini excavator market growth (https://thebusinessresearchcompany.com/report/mini-excavators-global-market-report)

- Mini Excavator Market Size Forecast [Latest] (https://businessresearchinsights.com/market-reports/mini-excavator-market-111027)

- Excavator Market Size, Share & 2030 Growth Trends Report (https://mordorintelligence.com/industry-reports/global-excavator-market)

- Mini and Mid Excavators Market Size, Share & Industry Analysis Report By Type, By End User, By Operating Weight, By Regional Outlook and Forecast, 2025-2032 (https://researchandmarkets.com/reports/6174596/mini-mid-excavators-market-size-share-and?srsltid=AfmBOopSjK4-dLaJYRbph8f0R-ok3-f-Iq_wqT-0Yuu7bOIC3OF6QsIs)

- Evaluate Key Factors: Project Requirements and Worksite Conditions

- Measuring and benchmarking the productivity of excavators in infrastructure projects: A deep neural network approach (https://sciencedirect.com/science/article/abs/pii/S0926580520311122)

- Average Excavation Productivity Rate: 2025 Benchmarks & Data (https://kitchingco.com/uncategorized/average-excavation-productivity-rate-2025-industry-benchmarks)

- Excavator Market Size & Industry Growth 2030 (https://futuredatastats.com/excavator-market?srsltid=AfmBOooQ_KDY95OHLwpJuUJFKnZ5i-7dzsR4HRR652OEPAXOnIQ1-7rn)

- 73 Must-Know Construction Statistics (2024) (https://bigrentz.com/blog/construction-statistics?srsltid=AfmBOoqXmRvSldnDewd_TYO0Xmrytc2Q7vQcnXVgIfiHlW3zjmi4AB-Q)

- Compare Specifications: Digging Depth, Lifting Capacity, and More

- Understanding your excavator's lifting capacity to protect your equipment (https://mechandlink.com/en/news-article/Understanding-your-excavator-s-lifting-capacity-to-protect-your-equipment)

- Evaluating Lifting Capacity for Excavators | Gregory Poole (https://gregorypoole.com/lifting-capacity-excavators)

- How Deep Will a Mini Excavator Dig? - Pengde Machinery (https://pengdemachinery.com/en/how-deep-will-a-mini-excavator-dig)

- How Deep Can a Mini Excavator Dig? (https://ahmcorp.com/blogs/news/how-deep-can-a-mini-excavator-dig?srsltid=AfmBOoqw35CAcfYdtrtYLGHng4HtjPWV1Y9qkHZGAVm5D-T9tSufGGy8)

- Test and Rent: Experience the Excavator Before You Buy

- Construction Equipment Rental Market Statistics 2025-2034 (https://statifacts.com/outlook/us-construction-equipment-rental-market)

- Excavator Rental Guide: 5 Specs That Matter for Your Job (https://miltonrents.com/blog/excavator-rental-guide-5-specs-that-matter-for-your-job)

- 7 Must-Know Statistics About Equipment Rentals (https://gocodes.com/construction/equipment-rentals-statistics)

- Heavy Equipment Operator Quotes (https://pinterest.com/ideas/heavy-equipment-operator-quotes/905446338086)

- Excavator Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/excavator-rental-market)