Overview

This article delivers a comprehensive step-by-step guide on renting and effectively utilizing a concrete buffer, underscoring its critical role in construction and renovation projects. It outlines the various types of buffers available, the rental process, necessary safety precautions, operational tips, and maintenance practices. Renting not only provides cost-effectiveness but also grants access to advanced technology, all while alleviating maintenance responsibilities. By choosing to rent, you ensure that you are equipped with the best tools for your project without the long-term commitment of ownership.

Key Highlights:

- Concrete buffers are machines designed to smooth and polish surfaces, essential in both construction and renovation.

- Key functions of concrete buffers include smoothing imperfections, polishing surfaces for aesthetic appeal, and preparing surfaces for coatings.

- The concrete buffer rental market is expected to grow significantly by 2025, driven by demand for high-quality surfaces.

- Types of concrete buffers include single-disc, dual-disc, propane, and electric polishers, each suited for different tasks and environments.

- Renting concrete buffers offers advantages such as cost-effectiveness, flexibility, and access to the latest technology without maintenance responsibilities.

- Safety precautions for using concrete buffers include wearing PPE, inspecting the work area, and ensuring proper ventilation.

- Common mistakes to avoid when using a concrete buffer include neglecting surface preparation, using the wrong pad, and applying excessive pressure.

- Regular maintenance practices for concrete buffers involve thorough cleaning, inspections, and timely replacement of worn parts to enhance longevity.

Introduction

In the construction and renovation industry, the tools utilized can profoundly influence the quality and durability of the final product. Among these, concrete buffers emerge as indispensable machines, expertly crafted to smooth and polish concrete surfaces to perfection. Their capacity to enhance both aesthetic appeal and structural integrity makes it essential for industry professionals to grasp the functionalities and applications of these machines.

Selecting the appropriate type of buffer for specific tasks, adhering to safety precautions, and implementing maintenance practices are critical. A comprehensive guide on concrete buffers not only empowers project managers with the necessary knowledge for effective equipment rental but also guarantees optimal results in their concrete finishing endeavors.

As the demand for high-quality concrete surfaces escalates, mastering the use of concrete buffers in various construction applications becomes increasingly vital.

Understanding Concrete Buffers: Definition and Purpose

Concrete buffers are specialized machines meticulously engineered to smooth and polish surfaces with precision. By utilizing rotating pads, these machines effectively grind, buff, and finish surfaces, achieving an optimal level of smoothness and shine. Their importance spans both new construction and renovation projects, as they prepare surfaces for coatings, enhance aesthetic appeal, and significantly prolong the lifespan of flooring.

A comprehensive understanding of how materials absorb impacts and their diverse applications is essential for specialists engaged in finishing tasks.

Key Functions of Concrete Buffers:

- Smoothing: Concrete buffers excel at eradicating imperfections and rough patches, resulting in a flawless surface crucial for subsequent treatments.

- Polishing: These machines elevate the shine and aesthetic quality of surfaces, making them indispensable for projects where visual appeal is paramount.

- Preparation: By meticulously preparing surfaces for additional treatments such as sealing or staining, buffers play a vital role in ensuring the durability and longevity of the finished product.

The market for concrete buffer rental is projected to experience substantial growth by 2025, reflecting the rising demand for high-quality surfaces in various construction applications. According to an article published in Sustainability 2024, volume 16, issue 4, article number 1608, this growth signifies the industry's shift towards more efficient and effective finishing solutions. Recent advancements in cement protection technology, particularly in the application of cement shields with integrated layers, have been prominently discussed within the industry.

Experts assert that these innovations not only enhance the efficiency of the polishing process but also improve the overall performance of masonry structures.

Practical applications of solid barriers in renovation projects highlight their efficiency. For instance, a recent case study titled 'Thermal Analysis of Pavement Structure' confirmed the reliability of cementitious materials in managing stress-strain reactions under varying weather conditions. This underscores the importance of employing solid barriers to achieve optimal results in construction endeavors.

As K.W., a sector specialist, emphasizes, "Therefore, a rise in the thickness of the cement surface layer is advised when designing cement pavement structures with protective layers," highlighting the critical role these layers play in maintaining structural integrity.

In conclusion, concrete buffer rental services are indispensable tools within the construction industry, offering essential functions that enhance both the quality and durability of surfaces. Their contribution to improving the aesthetic and functional aspects of structures makes them a vital consideration for any construction manager. With EZ Equipment Rental's unwavering commitment to quality, reliability, and customer satisfaction, managers can confidently select their services for all finishing equipment needs.

Types of Concrete Buffers Available for Rent

When renting a concrete barrier, it is essential to understand the various types available to achieve optimal outcomes in your task.

Single-Disc Buffers are perfect for small areas and light polishing tasks. Their lightweight design allows for easy maneuverability, making them an excellent choice for residential projects where precision is key.

Dual-Disc Polishers are designed for larger areas, enhancing efficiency and providing a more uniform finish. Their robust performance makes them a popular choice in commercial settings, where time and quality are of the essence.

Propane Buffers, operating on propane, are powerful machines ideal for outdoor use. They excel in heavy-duty polishing and grinding tasks, making them suitable for extensive commercial applications where durability and performance are required.

Electric Polishers are versatile and eco-friendly, usable both indoors and outdoors. Their quieter operation and zero emissions render them especially fitting for residential and commercial endeavors, where noise and environmental impact are factors.

Choosing the suitable type of pad depends on the size of the area to be polished and the desired finish. Understanding these differences will assist in making the appropriate selection for your specific requirements. Integrating the correct tools is crucial for safety and efficiency in construction projects.

As emphasized in a case study, pedestrian deaths in construction areas frequently involve laborers participating in road maintenance, highlighting the significance of utilizing suitable tools such as barriers to improve safety. Furthermore, as former U.S. Secretary of Transportation James Burnley stated, 'Repeal of the Proprietary Rule liberates state DOT’s to use their own procurement procedures to acquire innovative products that will enhance safety, reduce congestion and enhance the resilience of our highways.' For your concrete buffer rental needs, EZ Equipment Rental is here to help.

Reach out to us at (214) 951-7800 to discover more about our available choices and ensure you possess the correct tools for your task.

Step-by-Step Guide to Renting a Concrete Buffer

Leasing a solid barrier involves several essential steps to ensure you choose the appropriate equipment for your project:

-

Assess Your Needs: Begin by evaluating the size of the area you need to buff and the desired finish. This evaluation will assist you in choosing the suitable type and size of the support.

Research Rental Companies: Identify reputable rental firms in your vicinity, such as EZ Equipment Rental, recognized for their extensive selection of well-maintained concrete polishers, air compressors, and tools, along with their commitment to customer satisfaction. Their expert guidance ensures you choose the right tools for your specific needs.

-

Check Availability: Contact EZ Equipment Rental to confirm the availability of the particular equipment you need for your project dates. Given the increasing rental penetration in the construction sector, expected to approach 55 percent in 2023, timely communication is crucial.

-

Review Rental Terms: Carefully examine the rental agreement, paying attention to the duration, costs, and any additional fees for accessories or insurance. Understanding these terms will help you avoid unexpected expenses. It's also important to consider the total cost of ownership (TCO) and return on investment (ROI) for the assets, as highlighted in recent case studies, to ensure your financial strategies are effective.

Inspect the Equipment: Prior to finalizing your rental, examine the device for any signs of damage or wear. Ensuring the equipment is in optimal working condition is vital for achieving the best results on your project.

-

Complete the Rental Process: Fill out the necessary paperwork, provide identification, and make the payment to secure your rental. This step is essential to confirm your reservation and avoid any last-minute issues.

-

Schedule Pickup or Delivery: Finally, arrange for either the pickup or delivery of the item to your job site. Efficient logistics are key to maintaining your project timeline. Using rental software with availability dashboards can significantly improve your capability to oversee and monitor tools effectively.

By adhering to these steps, you can simplify the concrete buffer rental procedure and ensure you have the appropriate material for your construction requirements. As Tom Doyle, ARA vice president, noted, understanding rental revenue forecasts can provide valuable insights into the market, making your rental experience more informed and effective. With the right preparation and the support of EZ Equipment Rental, which offers a wide selection of well-maintained equipment and flexible rental options, renting equipment can be a straightforward and efficient experience.

Safety Precautions and Preparation for Using a Concrete Buffer

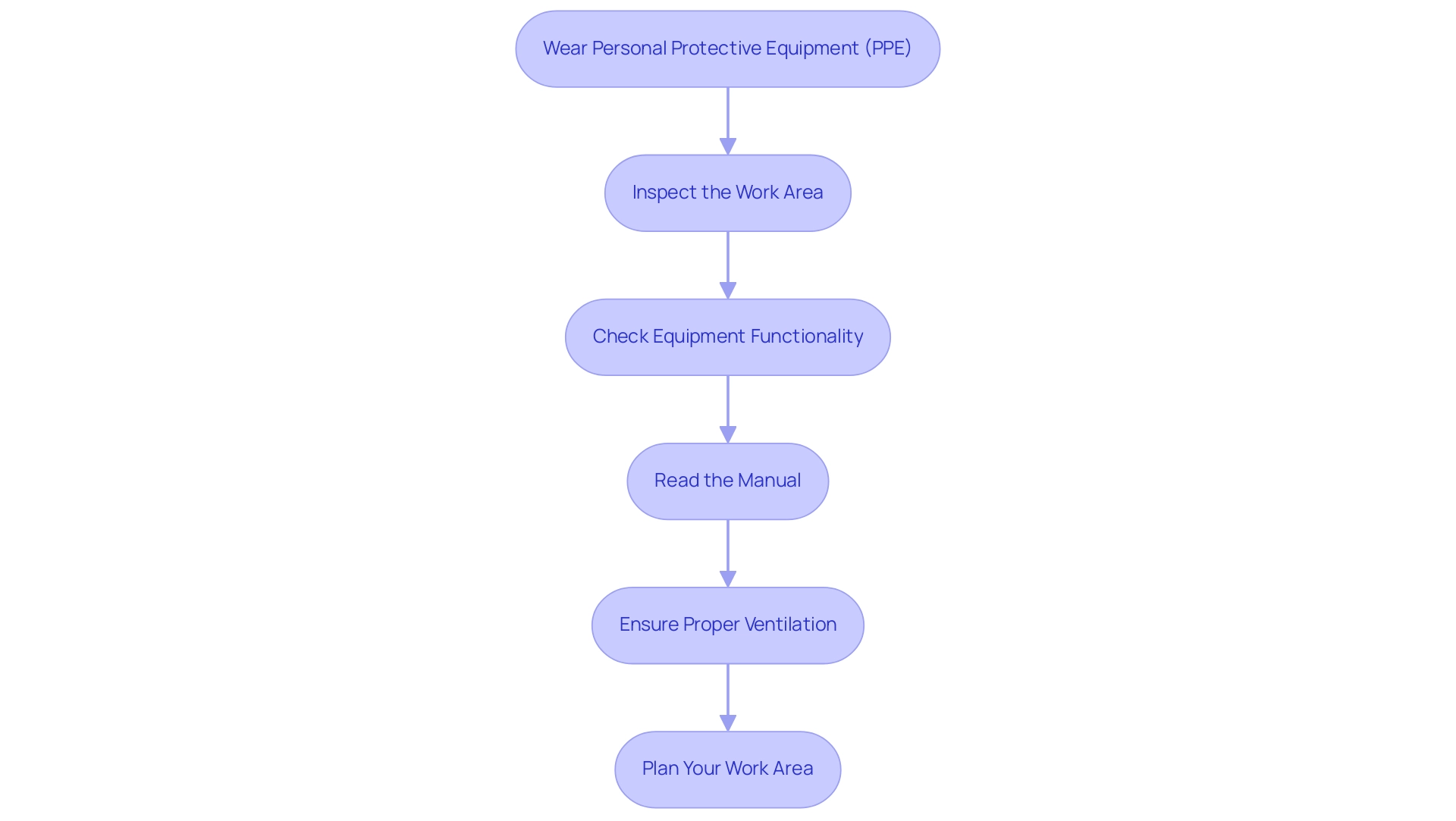

Before using a solid separator, it is vital to follow important safety measures to guarantee a secure working environment and avoid injuries. Here are key steps to follow:

- Wear Personal Protective Equipment (PPE): Always don safety goggles, gloves, and ear protection. These items are essential for shielding against flying debris and excessive noise, which can lead to serious injuries. Safety experts indicate that proper PPE usage can reduce the risk of injury by up to 70%.

- Inspect the Work Area: Conduct a thorough examination of the workspace to eliminate obstacles, debris, and any potential hazards that could disrupt the operation of the machine. A clear area minimizes the risk of accidents.

- Check Equipment Functionality: Prior to use, inspect the concrete buffer rental device for any loose parts or signs of damage. Ensure that all safety guards are intact and functioning properly, as this can significantly reduce the risk of injury during operation.

- Read the Manual: Familiarize yourself with the manufacturer's instructions and safety guidelines specific to the device model you are using. Understanding the equipment's features and limitations is essential for safe operation.

- Ensure Proper Ventilation: When working indoors, ensure the area is well-ventilated to prevent the inhalation of dust and fumes, which can pose health risks. Adequate airflow is critical for maintaining a safe working environment.

- Plan Your Work Area: Clearly mark the area you will be buffing to ensure comprehensive coverage without missing any sections. A carefully organized strategy not only improves efficiency but also decreases the chance of incidents.

Moreover, it's vital to acknowledge that incorrect use of protective barriers can result in frequent injuries like cuts, abrasions, and hearing impairment. Safety experts emphasize that adherence to PPE guidelines and operational protocols can significantly mitigate these risks. For example, a recent study highlighted that appropriate safety measures have resulted in a significant reduction in incidents related to barrier usage, demonstrating the efficacy of proactive safety practices.

Furthermore, EZ Equipment Rental, recognized as the leading option for equipment leasing in the DFW metro region, offers premium concrete buffer rental options and underscores the significance of safety in their rental contracts. By emphasizing safety, operators can guarantee a successful and injury-free experience when utilizing protective barriers.

Operating a Concrete Buffer: Instructions and Tips

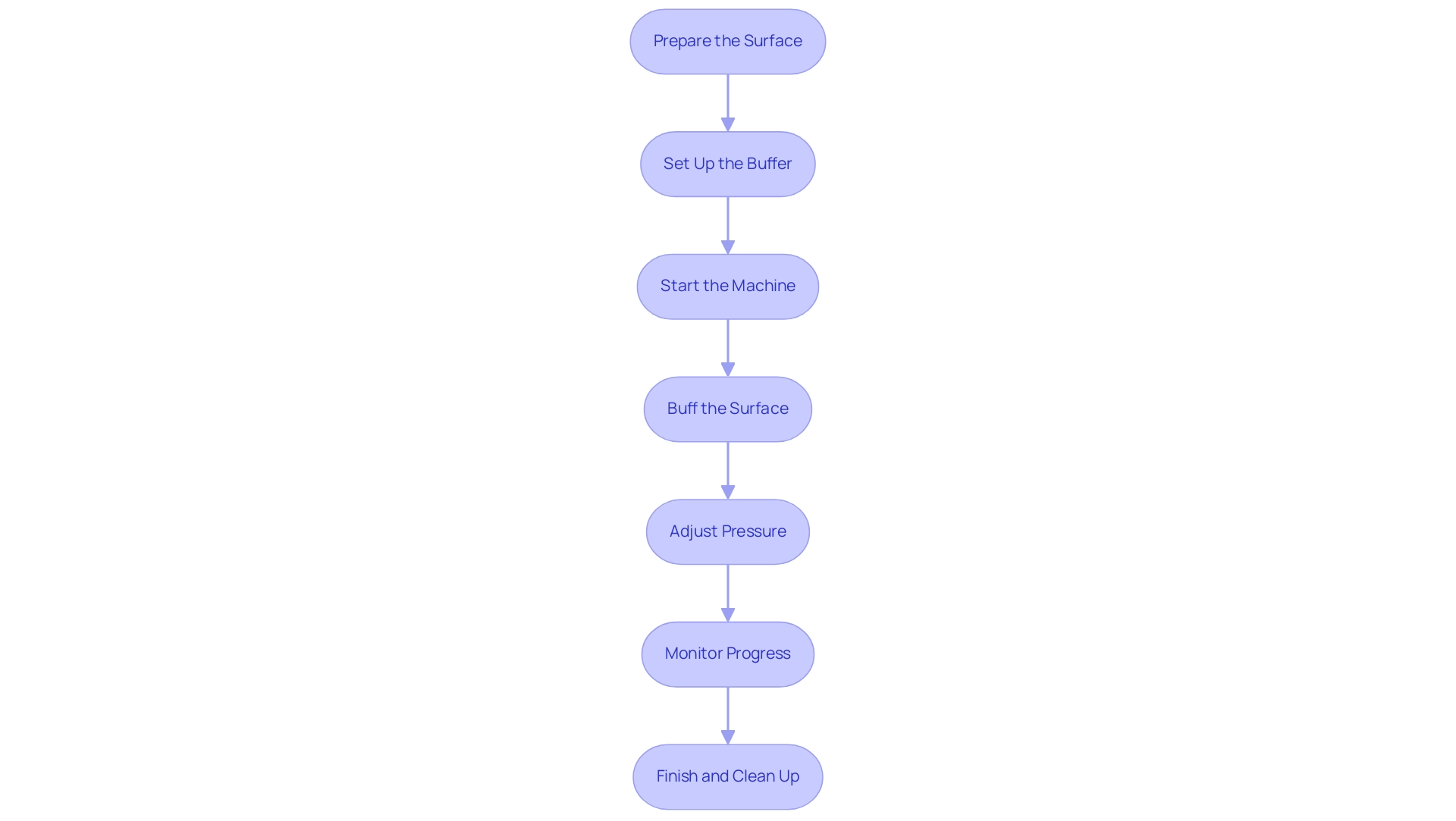

To operate a concrete buffer effectively, follow these essential steps:

- Prepare the Surface: Begin by sweeping or vacuuming the area to eliminate loose debris and dust. This ensures a clean workspace for optimal results.

- Set Up the Buffer: Select and securely attach the appropriate pad for your specific task, whether it’s grinding, polishing, or another application.

- Start the Machine: Power on the storage unit and allow it to reach its full operational speed before commencing work. This step is crucial for achieving a consistent finish.

- Buff the Surface: Employ a slow, steady motion while moving the polishing tool across the surface. Overlap each pass slightly to guarantee even coverage and avoid missed spots.

- Adjust Pressure: Apply gentle pressure to the support. It’s essential to let the machine do the work rather than forcing it down, which can lead to uneven results or damage.

- Monitor Progress: Frequently check the surface to ensure you are achieving the desired finish. Be prepared to adjust your technique based on the results you observe.

- Finish and Clean Up: After completing the buffing process, turn off the machine and thoroughly clean the area of any dust or debris to maintain a safe and tidy workspace.

Integrating these professional suggestions will significantly enhance your efficiency and effectiveness when utilizing surface protectors, ensuring high-quality outcomes for your projects.

Additionally, consider the durability of the surfaces being buffed. For instance, the highest tensile stress of cement pavement under low temperature is 2.6 MPa, emphasizing the necessity for suitable tools to uphold quality. As Phil Purnell, a professor of materials and structures, states, "The raw materials are virtually limitless and it will be in demand for as long as we build roads, bridges and anything else that needs a foundation."

This highlights the significance of utilizing high-quality tools, such as cement polishers, to achieve the best results.

Moreover, insights from resource allocation studies underscore the importance of efficient resource utilization in construction projects, which is crucial for project managers. For those seeking concrete buffer rental, EZ Equipment Rental is your primary source in the Dallas-Fort Worth region. They offer a diverse selection of tools, including boom lifts, forklifts, mini excavators, and more to meet your needs. Situated at 1307 W Airport Fwy, Irving, TX, you can reach them at (214) 951-7800 to book your physical barrier today.

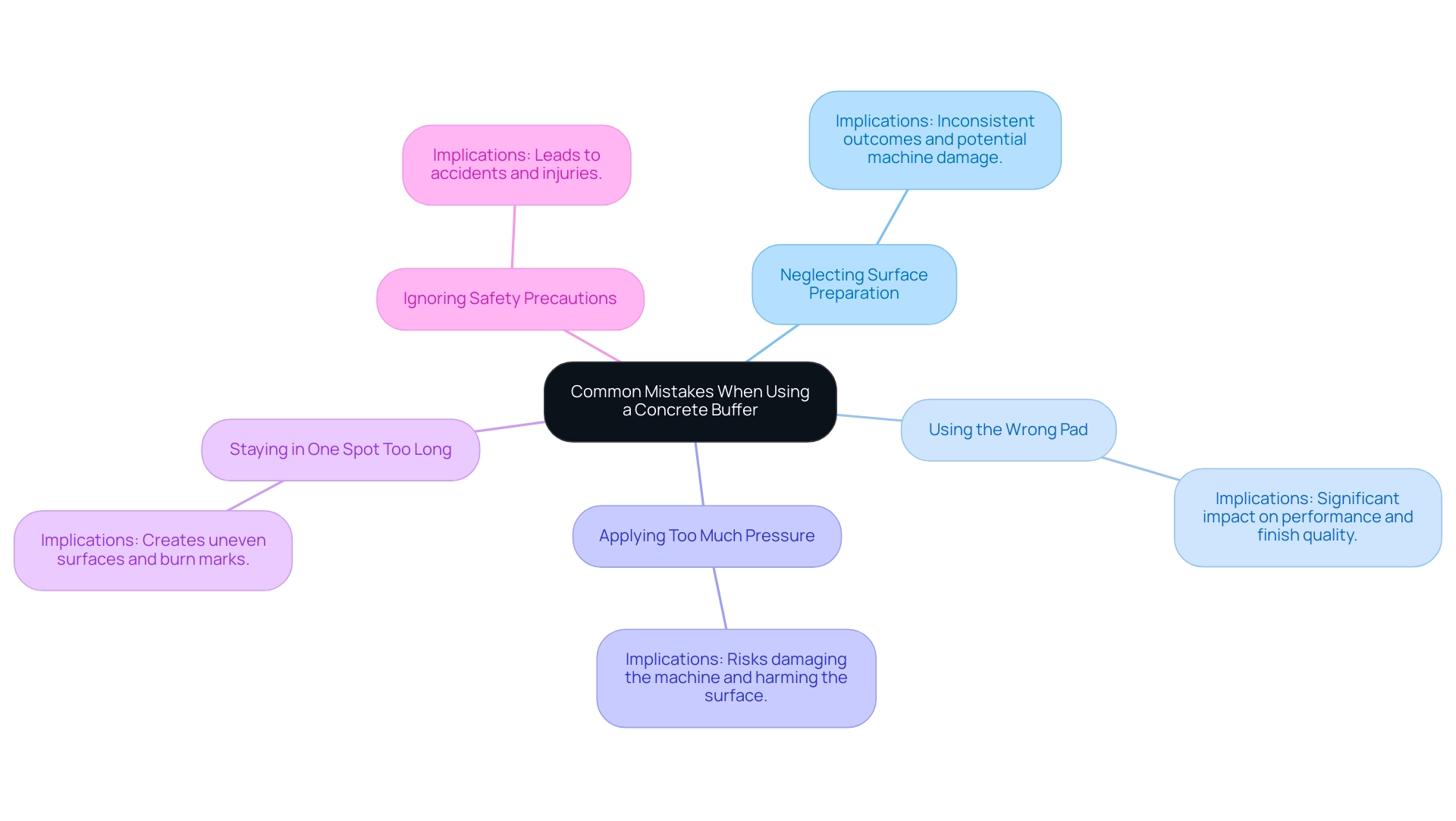

Common Mistakes to Avoid When Using a Concrete Buffer

When utilizing a concrete buffer, avoiding common mistakes is crucial to ensure optimal results and maintain equipment integrity.

- Neglecting Surface Preparation: Proper surface preparation is essential. Neglecting to clean the area prior to polishing can lead to inconsistent outcomes and may even damage the machine itself. A clean surface allows for better adhesion and a smoother finish, which is vital for achieving the desired outcome.

- Using the Wrong Pad: Selecting an inappropriate pad for the specific task can significantly impact performance and finish quality. Different pads are designed for various surfaces and finishes; using the correct one is imperative for optimal results.

- Applying Too Much Pressure: One of the most frequent errors is forcing the buffer down too hard. This not only risks damaging the machine but can also harm the surface. It is important to allow the machine to operate at its designed pressure, enabling it to perform effectively.

- Staying in One Spot Too Long: Remaining stationary for extended periods can create uneven surfaces and burn marks on the concrete. To avoid this, keep the pad moving steadily across the surface, ensuring an even finish and preventing overheating.

- Ignoring Safety Precautions: Skipping safety gear or failing to check the tools before use can lead to accidents and injuries. Always wear suitable personal protective gear (PPE) and conduct a thorough check of the buffer to ensure it is in safe working condition.

Comprehending these common mistakes is essential for construction managers, as it directly relates to the types of errors that can influence outcomes. EZ Equipment Rental emphasizes its commitment to quality and customer satisfaction, making it a reliable choice for equipment rental in the DFW metro area.

Furthermore, professionals in various roles, such as data analysts and program managers, benefit from a strong understanding of types of errors, which enhances the accuracy and reliability of their work. As Sharin Fritz from Personio noted, "For data engineering & analytics, understanding the nuances of errors is essential for effective decision-making."

By being aware of these common pitfalls, operators can enhance their efficiency and the quality of their finishing work, ultimately leading to better project outcomes.

Maintenance Tips for Concrete Buffers: Ensuring Longevity

To maximize the lifespan of your concrete buffer, it is essential to adhere to the following maintenance practices:

- Thorough Cleaning After Use: After each use, meticulously clean the machine to eliminate dust and debris. This practice prevents accumulation that can hinder performance and prolong the lifespan of the apparatus.

- Regular Inspections: Conduct routine checks for signs of wear or damage, particularly on pads and electrical components. Early detection of issues can prevent costly repairs and minimize downtime.

- Proper Storage: Store the material in a dry, clean environment. Protecting it from moisture and dust is crucial for maintaining functionality and preventing rust or corrosion. Research indicates that maintaining specimens at controlled temperatures, such as 30, 40, and 50 °C, significantly impacts their performance and longevity.

- Timely Replacement of Worn Parts: Regularly assess and replace pads and any components showing signs of wear. This proactive approach ensures optimal performance and efficiency during operation.

- Adherence to Manufacturer Guidelines: Follow the manufacturer's maintenance recommendations closely. These guidelines are designed to ensure the equipment operates at peak performance and longevity.

By adopting these practices, you can greatly enhance the longevity and dependability of your equipment, ensuring it remains a valuable resource for your projects. Furthermore, a recent validation study confirmed that consistent maintenance practices align with theoretical models for stress distribution, underscoring the importance of regular upkeep in achieving optimal performance. As K.W. noted, "an increase in the thickness of the cement mix surface layer is recommended when designing cement pavement structures with protective layers," highlighting the critical relationship between maintenance and performance. Proper maintenance can lead to a notable increase in the longevity of devices, with some users reporting extended lifespans through diligent care.

Renting vs. Buying: The Advantages of Renting a Concrete Buffer

When evaluating the decision to rent or buy a concrete buffer, several compelling advantages of renting stand out.

- Cost-Effectiveness: Renting significantly reduces the financial burden associated with high upfront costs of acquiring tools. This makes it an appealing choice for short-term endeavors, allowing for better budget management.

- Flexibility: Renting offers the freedom to choose the most appropriate tools for each particular task, enabling managers to adapt to diverse job requirements without the long-term commitment of ownership.

- No Maintenance Hassles: Rental firms typically handle upkeep and repairs, saving time and decreasing unforeseen costs. This allows teams to focus on task execution rather than asset maintenance.

- Access to Latest Technology: Renting ensures access to the latest models and advanced technology, enhancing efficiency and outcomes without necessitating a significant capital investment.

- Storage Savings: By renting, you eliminate the need for additional storage space, as tools are only on-site for the duration of the project. This can lead to further cost savings and operational efficiency.

In fact, a recent survey conducted with 81 respondents from various construction firms indicated that approximately 70% of contractors prefer renting over purchasing tools, highlighting the growing trend towards rental solutions in the construction industry. Financial experts emphasize the cost benefits of renting, particularly in 2025, where the demand for material handling machinery is projected to grow at a compound annual rate of 4% through 2030. This trend underscores the significance of adaptability and cost-efficiency in equipment management, particularly for solid barriers.

Real-world examples further illustrate the advantages of concrete buffer rental. For example, a case study on Rental Services of Texas demonstrated how utilizing modern rental management solutions led to enhanced operational efficiency, showcasing the positive impact of renting on results. This case study reinforces the notion that renting can be a strategic choice for construction managers aiming to optimize resources and achieve successful completions.

As Holt of California states, "We offer a comprehensive inventory of equipment for purchase and rent, so we can help you decide which option best suits your business needs, whether that be rental, ownership or a mix of both." This perspective highlights the importance of considering rental options in the decision-making process for project managers.

Conclusion

Concrete buffers are indispensable tools in the construction and renovation industry, playing a pivotal role in the smoothing and polishing of concrete surfaces. Their capacity to enhance both the aesthetic and structural qualities of concrete underscores the necessity for professionals to comprehend their functionalities and applications. With options ranging from single-disc to propane models, the diverse array of buffers available for rent empowers project managers to select the most suitable equipment tailored to their specific needs.

Safety precautions, proper operational techniques, and regular maintenance are essential factors that contribute to the effective use of concrete buffers. Adhering to these practices not only guarantees optimal results but also safeguards the well-being of operators and the integrity of the equipment. Avoiding common pitfalls, such as neglecting surface preparation or utilizing inappropriate pads, can significantly elevate the quality of the finished product.

Ultimately, choosing to rent rather than purchase concrete buffers offers numerous advantages, including cost-effectiveness, flexibility, and access to cutting-edge technology. As the demand for high-quality concrete surfaces continues to escalate, grasping the significance of these machines and the best practices for their utilization will empower project managers to achieve exceptional results in their construction endeavors. By leveraging the resources available through reputable rental companies, such as EZ Equipment Rental, professionals can ensure they possess the right tools at their disposal to effectively meet the challenges of modern construction projects.

Frequently Asked Questions

What are concrete buffers and what do they do?

Concrete buffers are specialized machines designed to smooth and polish surfaces with precision. They utilize rotating pads to grind, buff, and finish surfaces, achieving a high level of smoothness and shine.

Why are concrete buffers important in construction?

Concrete buffers are crucial for both new construction and renovation projects as they prepare surfaces for coatings, enhance aesthetic appeal, and significantly prolong the lifespan of flooring.

What are the key functions of concrete buffers?

The key functions of concrete buffers include smoothing imperfections, polishing surfaces for aesthetic quality, and preparing surfaces for additional treatments like sealing or staining.

What is the projected market trend for concrete buffer rental?

The market for concrete buffer rental is expected to experience substantial growth by 2025, driven by rising demand for high-quality surfaces in various construction applications.

What advancements have been made in cement protection technology?

Recent advancements include the application of cement shields with integrated layers, which enhance the efficiency of the polishing process and improve the overall performance of masonry structures.

What types of concrete buffers are available for rental?

The types of concrete buffers available for rental include: Single-Disc Buffers (ideal for small areas and light polishing tasks), Dual-Disc Polishers (designed for larger areas, providing a more uniform finish), Propane Buffers (powerful machines for heavy-duty polishing and grinding, suitable for outdoor use), and Electric Polishers (versatile and eco-friendly, usable indoors and outdoors with quieter operation).

How does one choose the right type of concrete buffer?

Choosing the suitable type of concrete buffer depends on the size of the area to be polished and the desired finish. Understanding these factors is essential for making the appropriate selection.

What safety considerations are associated with using concrete buffers?

Utilizing suitable tools such as barriers is important for improving safety in construction areas, particularly to prevent accidents involving laborers.

How can I learn more about concrete buffer rental options?

For more information about available concrete buffer rental options, you can contact EZ Equipment Rental at (214) 951-7800.