Overview

The article focuses on comparing top models of concrete polishing machines available for rental to assist in selecting the right equipment for various projects. It emphasizes the importance of understanding different machine types, key features such as motor power and pad size, and the implications of renting versus buying, all of which guide users in making informed choices that enhance project efficiency and effectiveness.

Introduction

Navigating the world of concrete polishing can be a daunting task, especially with the myriad of machines available, each designed for specific applications. From the efficient planetary polishers that tackle large commercial spaces to the precise single-head machines ideal for intricate work, understanding the right fit for a project is crucial.

As the demand for polished concrete floors continues to grow, particularly in regions like North America and Europe, the importance of selecting the appropriate equipment cannot be overstated. Factors such as motor power, pad size, and rental versus purchase decisions play significant roles in ensuring project success.

By delving into the various types of concrete polishing machines and their key features, professionals can make informed choices that enhance efficiency and deliver high-quality results.

Exploring Different Types of Concrete Polishing Machines

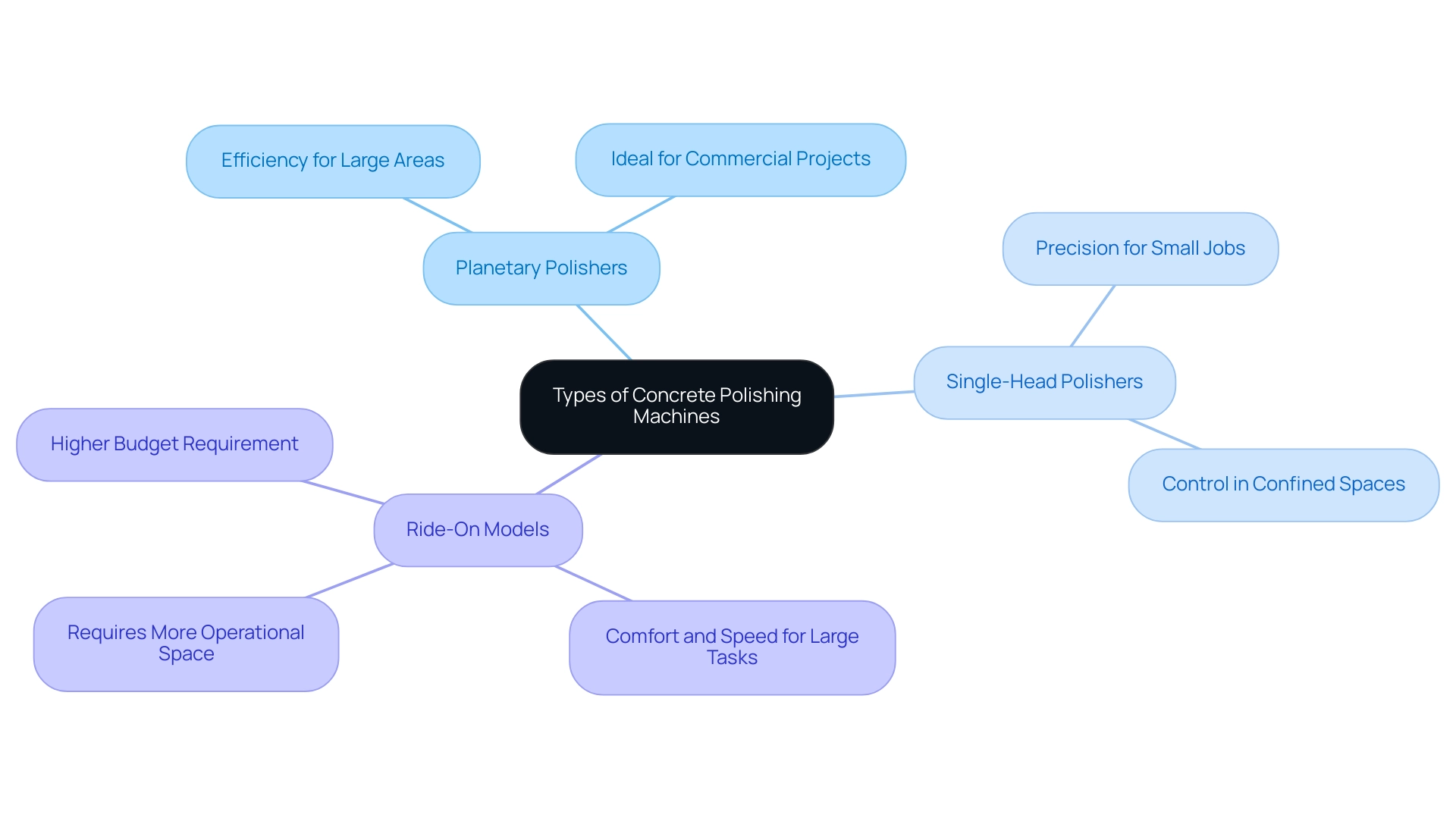

Concrete polishing devices are categorized into three primary types:

- Planetary polishers

- Single-head polishers

- Ride-on models

Each type is designed for specific applications within the construction industry.

- Planetary polishers are renowned for their efficiency and capability to cover extensive areas quickly, making them especially fitting for commercial endeavors where time and output are crucial.

- Single-head polishers, while slower, excel in smaller jobs or detailed work in confined spaces, allowing for precision and control that larger devices may lack.

- Ride-on equipment merges comfort and speed, perfect for large flooring tasks; however, they require more operational space and involve a greater budget.

Comprehending these distinctions is crucial, particularly given the regional dynamics emphasized in the recent evaluation of concrete polishing equipment, which identifies North America and Europe as leaders in the market due to their established construction industries and high demand for polished concrete floors. The Asia Pacific region is also poised for significant growth, driven by rapid urbanization and infrastructure development.

This context emphasizes the significance of choosing the appropriate concrete polishing machine rental based on your initiative's scope, budget, and regional demands. As Vinayak Bali, Senior Research Analyst at Cognitive Market Research, states, 'Through collaboration with cross-functional teams, I played a pivotal role in shaping business strategies rooted in robust research,' emphasizing the need for informed decision-making. Additionally, companies like Clarke and Minuteman are noted for their quality and innovative solutions in the market, further influencing equipment selection.

By familiarizing yourself with these types, you can optimize your choice and enhance project efficiency.

Key Features to Consider When Renting Concrete Polishers

When evaluating concrete polishing machine rental options, several key features warrant careful consideration. Chief among these is motor power, typically measured in horsepower, which significantly influences the device's efficiency and its capability to tackle challenging surfaces. For instance, many concrete polishing machines, such as those offered by BETTERI, showcase robust motors designed for optimal performance.

The plate compactor, for example, is equipped with a 6.5HP/4.8KW 4-Stroke engine, illustrating the importance of motor power in achieving effective results. As BETTERI emphasizes,

Every decision you make means your trust in BETTERI, which is the driving force behind our continuous development and innovation.

This trust is crucial, especially when dealing with demanding tasks.

Pad size is another vital aspect to consider; larger pads can efficiently cover expansive areas, but they may not be ideal for detailed or intricate work. Therefore, it's essential to strike a balance based on the specific task requirements. Additionally, effective dust collection systems are critical for maintaining a clean work environment, which is not only beneficial for visibility but also for health and safety compliance.

Furthermore, the Stonechat's 10-year motor warranty enhances customer confidence, ensuring that any motor failures under normal conditions can be addressed quickly, reinforcing the reliability of rented assets. Finally, prioritize user-friendliness features such as adjustable handles and intuitive controls, which can significantly enhance operational efficiency and comfort during use. These elements collectively contribute to a smoother, more effective polishing process, ensuring that managers can deliver high-quality results while navigating the challenges of concrete floor preparation and finishing.

Moreover, current trends, such as the Stonecrete SC-Q2510P operating on 220-240 volts and weighing 606 lbs, highlight the evolving specifications in the market that managers should consider when opting for concrete polishing machine rental.

Choosing the Right Concrete Polisher for Your Project

Choosing the right concrete polishing machine rental is vital for the success of your endeavor, and it starts with a comprehensive evaluation of your undertaking's scope. For expansive commercial spaces, renting a concrete polishing machine, especially a planetary polisher, stands out as the ideal choice due to its impressive speed and efficiency, allowing you to cover large areas swiftly. For instance, the ROG-60+ Ride-On Grinder, priced at $1,490.00, exemplifies a reliable option for large-scale applications.

In contrast, if your endeavor requires intricate designs or involves smaller spaces, a single-head polisher is preferable, as it offers greater maneuverability and precision. The S-940E from Somero Enterprises, for example, provides eight hours of runtime and can cover up to 35,000 sq. ft. per full charge, making it an excellent choice for concrete polishing machine rental.

Additionally, the type of finish you aim to achieve plays a significant role in your decision. Some machines are specifically engineered for high-gloss finishes, while others are better suited for achieving a matte appearance. The case study on Electric Trowels for Large Undertakings demonstrates that electric trowels can be adapted for finishing with the right diamonds, making them suitable for large tasks over 20,000 square feet, offering high production rates but requiring a wet method, which may not be practical for all types of work.

Finally, consider your level of experience with concrete finishing. If you are relatively new to the process, choosing user-friendly models with robust support systems can significantly alleviate the learning curve, ensuring better results and increased confidence in your work. Considering these factors will assist you in choosing the appropriate concrete polishing machine rental that suits both your requirements and your skill level.

Renting vs. Buying: What’s Best for Your Concrete Polishing Needs

Leasing a concrete polishing machine rental is often the most beneficial option for short-term projects or cost-aware operations, particularly in Dallas, where rental services are plentiful. This approach offers the flexibility to utilize the latest technology without the burden of long-term commitments. As Martin Port aptly notes,

Avoiding upfront costs: Leasing allows businesses to utilize resources without a significant initial investment.

However, for those engaged in regular concrete polishing tasks, investing in a machine can prove to be more cost-effective over time. Ownership not only facilitates customized maintenance schedules but also ensures instant access to machinery when necessary. Additionally, leasing can introduce complexities such as storage and transportation responsibilities, which may add to the overall cost and complexity of the arrangement, as highlighted in the case study titled 'Cons of Leasing Heavy Equipment.'

This study indicates that leasing can be more costly than renting for infrequent use and that lessees are accountable for damages and cannot modify leased items. For example, the ABI Mobilram TM22 piling rig, a German vibratory pile driver, illustrates specialized tools that may be pertinent for construction endeavors needing a concrete polishing machine rental. Furthermore, consider how renting additional items, such as trailers and dock ramps, can save you time and money, and boost your project efficiency in Dallas.

Explore our latest posts to discover more about the advantages of plumbing tool rentals and other services that can enhance your operations.

Best Practices for Using Rented Concrete Polishing Equipment

To achieve optimal results when using a concrete polishing machine rental, meticulous preparation is essential. Begin by inspecting the machine for any signs of wear or damage, ensuring it operates safely and effectively. Familiarize yourself with its controls and settings to avoid operational errors.

Always prioritize safety by wearing appropriate gear, including masks and eye protection, which are crucial for protecting against dust and debris. Notably, statistics indicate that using safety gear can reduce the risk of injury in construction environments by up to 50%, underscoring the importance of proper safety measures.

Runyon Surface Prep emphasizes the significance of readiness:

'We can even ship consumables and equipment out the same day you place an order, ensuring that you can get back up and running as quickly as possible.'

This highlights the efficiency of utilizing concrete polishing machine rental services for immediate project needs.

When beginning the smoothing process, initiate with a coarse grit pad to tackle imperfections, gradually transitioning to finer grits for a flawless finish. Monitoring the dust collection system is vital; regular checks will maintain efficiency and prevent clogs that could hinder performance. After polishing, ensure the machine is thoroughly cleaned.

This not only extends its lifespan but also prepares it for the next rental, reducing the likelihood of malfunction.

Moreover, just as regular training and adherence to cybersecurity protocols are crucial in preventing breaches, ensuring compliance with safety standards in equipment use is equally important. Implementing these best practices will enhance both safety and effectiveness, allowing construction project managers to complete their tasks with confidence.

Conclusion

Understanding the various types of concrete polishing machines and their key features is paramount for achieving success in any concrete polishing project. From the efficiency of planetary polishers suited for large commercial spaces to the precision offered by single-head machines for intricate tasks, selecting the right equipment based on project scope is essential. Additionally, considering factors such as motor power, pad size, and effective dust collection systems can significantly influence the overall quality of the finish.

When it comes to renting versus buying, each option presents distinct advantages that cater to different project needs. Renting can provide flexibility and access to the latest technology without the burden of ownership costs, making it an ideal choice for short-term projects. However, for those engaged in regular polishing tasks, purchasing equipment may become more cost-effective in the long run.

Ultimately, careful preparation and adherence to best practices when using rented equipment can enhance operational efficiency and ensure high-quality results. By prioritizing safety, conducting thorough inspections, and following a structured polishing process, project managers can navigate the complexities of concrete polishing with confidence. Making informed decisions not only streamlines the project workflow but also elevates the final outcome, paving the way for successful concrete polishing endeavors.

Frequently Asked Questions

What are the main types of concrete polishing devices?

The main types of concrete polishing devices are planetary polishers, single-head polishers, and ride-on models.

What are the characteristics of planetary polishers?

Planetary polishers are known for their efficiency and ability to cover large areas quickly, making them ideal for commercial projects where time and output are critical.

When should single-head polishers be used?

Single-head polishers are best suited for smaller jobs or detailed work in confined spaces, as they provide precision and control that larger devices may lack.

What are the advantages of ride-on models?

Ride-on models combine comfort and speed, making them suitable for large flooring tasks, although they require more operational space and come with a higher budget.

Why is it important to understand the distinctions between concrete polishing machines?

Understanding these distinctions is crucial for selecting the appropriate machine rental based on the project's scope, budget, and regional demands.

Which regions are leading in the concrete polishing equipment market?

North America and Europe are the leaders in the concrete polishing equipment market due to their established construction industries and high demand for polished concrete floors. The Asia Pacific region is also expected to see significant growth.

What key features should be considered when evaluating concrete polishing machine rentals?

Key features to consider include motor power, pad size, effective dust collection systems, user-friendliness, and warranty options.

How does motor power affect concrete polishing machines?

Motor power, typically measured in horsepower, significantly influences the machine's efficiency and its ability to handle challenging surfaces.

What is the importance of pad size in concrete polishing?

Larger pads can efficiently cover expansive areas but may not be suitable for detailed or intricate work, so it's essential to balance pad size with the specific task requirements.

Why are effective dust collection systems important?

Effective dust collection systems maintain a clean work environment, which is beneficial for visibility and health and safety compliance.

What user-friendly features should be prioritized in concrete polishing machines?

Prioritize features such as adjustable handles and intuitive controls to enhance operational efficiency and comfort during use.

What recent trends should managers consider when renting concrete polishing machines?

Managers should consider evolving specifications, such as voltage requirements and machine weight, as highlighted by current trends in the market.