Key Highlights:

- Class I electric motor rider trucks are suitable for indoor/outdoor use, with a load capacity of 2,500 to 12,000 pounds, offering zero emissions and low maintenance costs.

- Class II electric motor narrow aisle trucks optimise warehouse storage with a load capacity of 3,000 to 5,000 pounds and can reach heights up to 40 feet.

- Class III electric motor hand trucks excel in short-distance transport, with a load capacity of 1,500 to 5,500 pounds, enhancing efficiency in confined spaces.

- Class IV internal combustion engine trucks, with capacities of 11,000 to 17,600 pounds, are designed for heavy-duty applications on smooth surfaces.

- Class V internal combustion engine trucks feature pneumatic tyres for outdoor use, handling loads from 3,000 to 36,000 pounds, ideal for rugged terrains.

- Class VI tractors are designed for towing, with an average capacity of 60,000 pounds, significantly improving logistics efficiency.

- Class VII rough terrain forklifts are built for rugged surfaces, lifting over 10,000 pounds, essential for construction and agricultural tasks.

- OSHA forklift classifications are crucial for workplace safety, with statistics highlighting the need for proper training and equipment use to prevent injuries.

- Choosing the right forklift involves assessing weight capacity, lift height, terrain, and duration of use to ensure operational efficiency and safety.

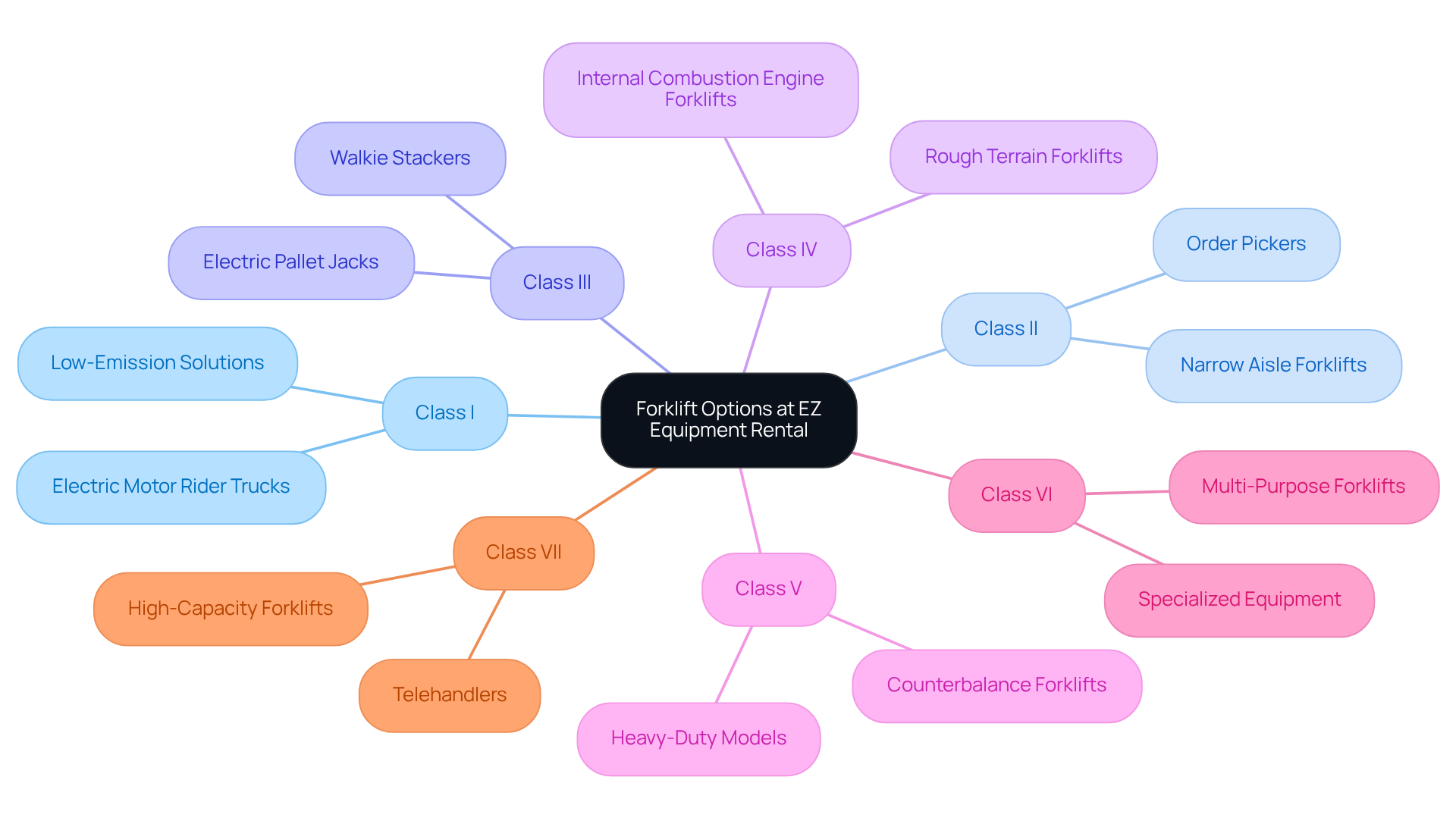

- EZ Equipment Rental offers a diverse range of forklifts across all classes, providing flexible rental terms and expert support for various operational needs.

Introduction

Understanding the diverse landscape of forklift classifications is essential for businesses looking to optimize their material handling operations. Various types of forklifts are designed to meet specific operational needs, and selecting the right equipment can significantly enhance efficiency, safety, and cost-effectiveness. However, navigating the complexities of these classifications raises an important question: how can organizations ensure they choose the most suitable forklift for their unique projects while adhering to safety regulations? This article explores the different types of forklift classifications, providing a comprehensive overview that empowers readers to make informed decisions in their equipment selection.

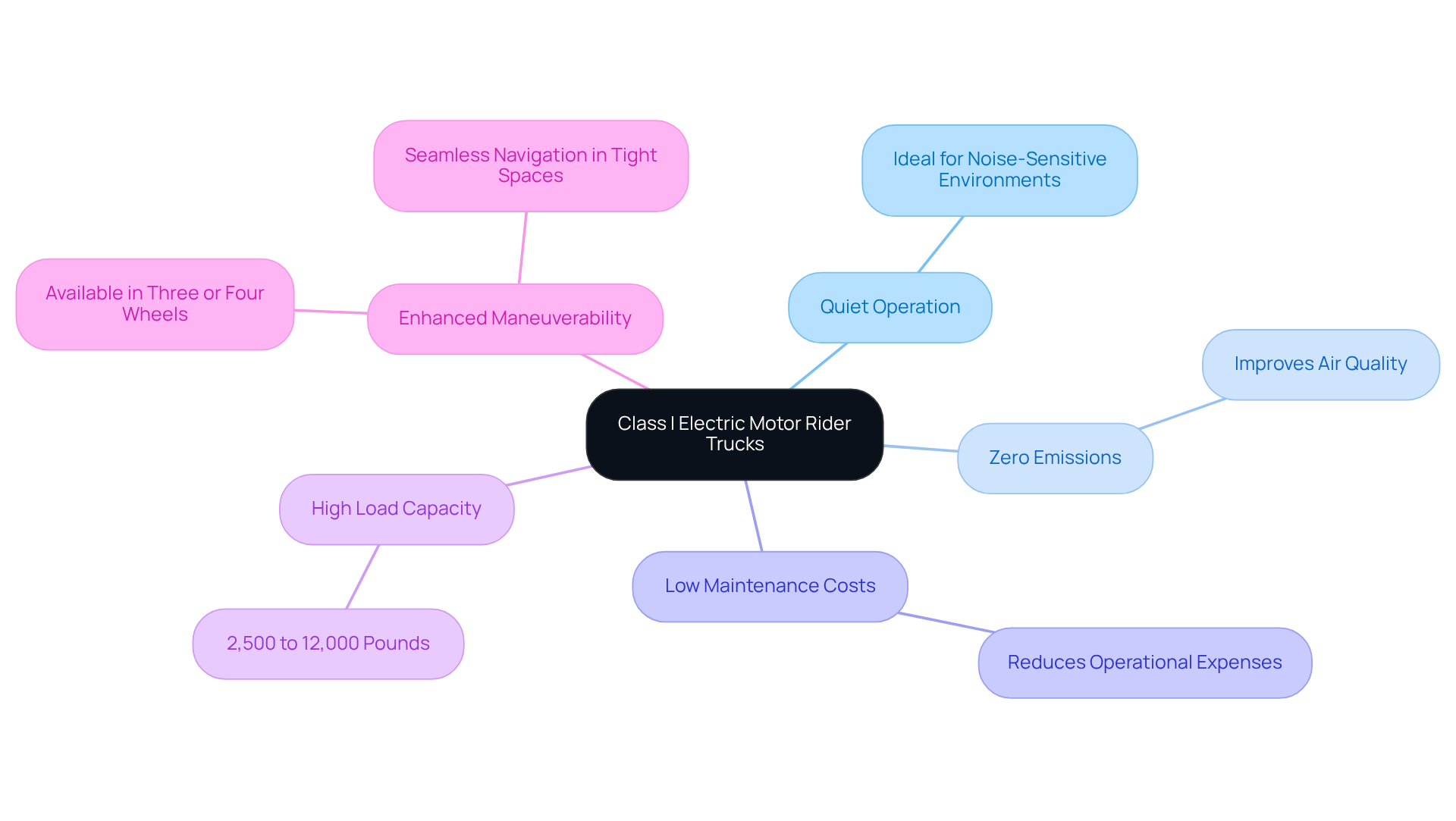

Class I: Electric Motor Rider Trucks

Class I electric motor rider trucks are engineered for both indoor and outdoor applications. Their quiet operation and zero emissions make them particularly well-suited for environments where air quality is crucial. EZ Equipment Rental offers a diverse selection of well-maintained lifting vehicles, ensuring clients find the perfect match for their specific needs. Typically, these machines have a load capacity ranging from 2,500 to 12,000 pounds, catering to various material handling requirements. With options available in three or four wheels, they provide enhanced maneuverability, allowing for seamless navigation in tight spaces-an essential feature in busy warehouses and distribution centers.

The benefits of electric lift trucks extend beyond operational efficiency. They require significantly less maintenance compared to internal combustion models, resulting in lower operational costs. As the industry shifts towards sustainability, the demand for electric lift trucks is projected to rise, with the Type I electric rider lift truck market expected to grow at a CAGR of 4.53% by 2026. Real-world applications of Type I forklifts are evident in distribution centers, particularly within the e-commerce sector, where their efficiency contributes to streamlined operations and increased productivity. As the industry evolves, the adoption of electric motor rider vehicles is set to play a crucial role in addressing the challenges of modern warehousing.

Key Benefits of Class I Electric Motor Rider Trucks:

- Quiet Operation: Ideal for environments sensitive to noise.

- Zero Emissions: Contributes to improved air quality.

- Low Maintenance Costs: Reduces overall operational expenses.

- High Load Capacity: Ranges from 2,500 to 12,000 pounds, suitable for various tasks.

- Enhanced Maneuverability: Available in three or four-wheel configurations for tight spaces.

Class II: Electric Motor Narrow Aisle Trucks

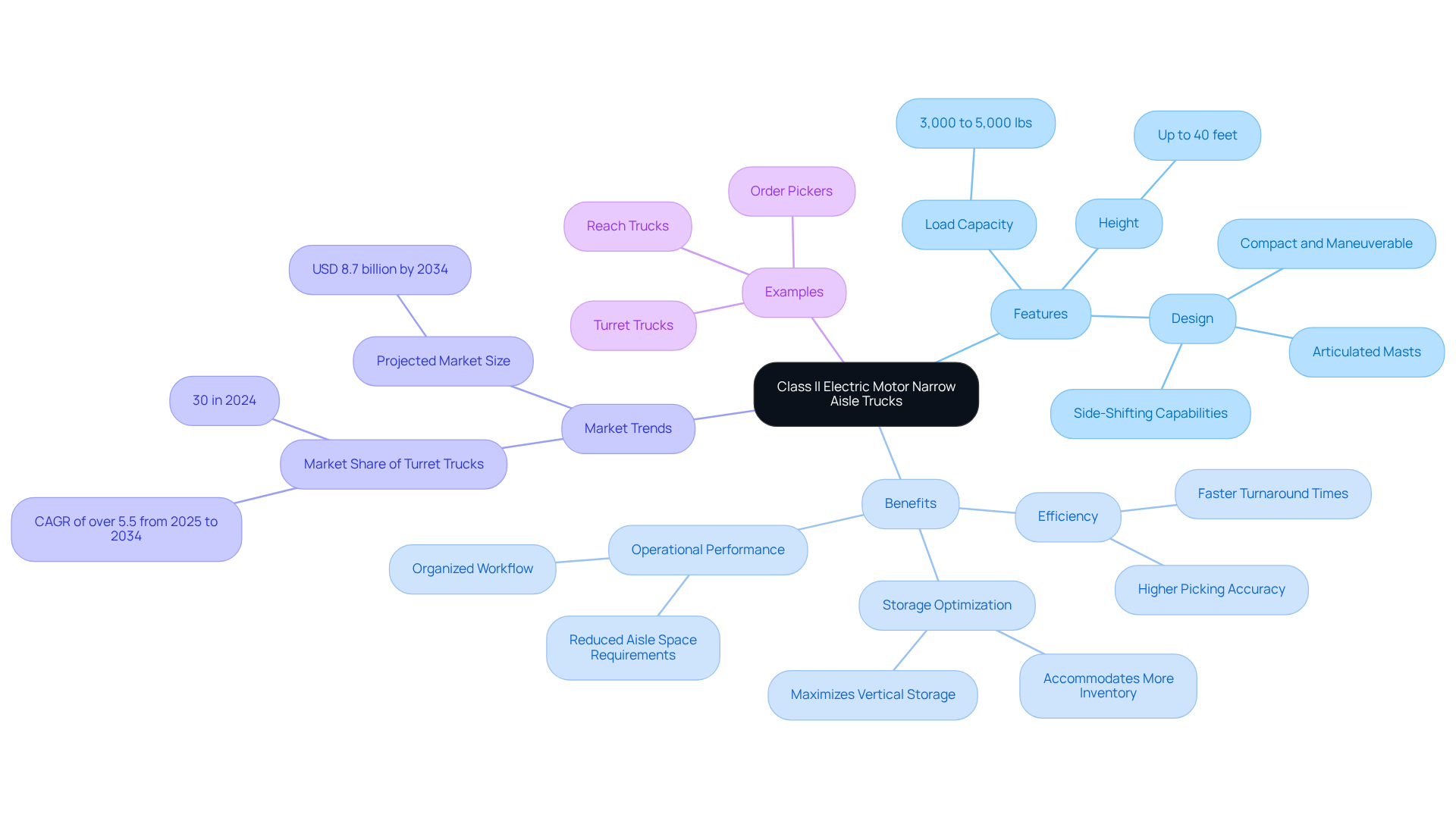

Type II trucks, also known as electric motor narrow aisle vehicles, are essential for tasks in confined areas, optimizing warehouse storage. These lifting machines typically have a load capacity of 3,000 to 5,000 pounds and can reach heights of up to 40 feet. Their compact design, along with advanced features like articulated masts and side-shifting capabilities, allows operators to maneuver efficiently in narrow aisles, significantly enhancing productivity.

Incorporating Class II lift trucks, as outlined in the different types forklift classifications chart, into warehouse operations greatly improves efficiency. Their ability to navigate spaces as narrow as 8-9 feet enables businesses to optimize vertical storage, accommodating more inventory without the need for additional physical space. This is particularly advantageous in high-density environments where maximizing storage capacity is crucial.

Logistics experts emphasize that using narrow aisle forklifts can lead to substantial improvements in warehouse operations. As noted, "very narrow aisle vehicles are designed to maximize storage capacity and effectively retrieve pallets in high-intensity operations." By facilitating precise load handling and minimizing the need for extensive aisle space, these vehicles promote a more organized and efficient workflow. Consequently, businesses can achieve higher picking accuracy and faster turnaround times, ultimately enhancing overall operational performance.

The market for extremely narrow aisle vehicles is projected to reach approximately USD 8.7 billion by 2034, expanding at a CAGR of 5.2%. The different types forklift classifications chart includes examples of Class II forklifts, such as turret vehicles and reach vehicles, which illustrate how these machines can optimize storage solutions. Turret trucks, for instance, are engineered to handle weights in extremely narrow aisles, capturing about 30% of the market share in 2024 due to their effectiveness in maximizing warehouse space. Their ability to operate in restricted areas while maintaining high weight capacities makes them a preferred choice across various sectors, including retail and logistics.

In conclusion, Type II lift trucks are vital tools for businesses looking to enhance their storage capabilities and improve warehouse efficiency. Their design and functionality not only support operational goals but also contribute to a more sustainable and cost-effective approach to inventory management.

Class III: Electric Motor Hand Trucks

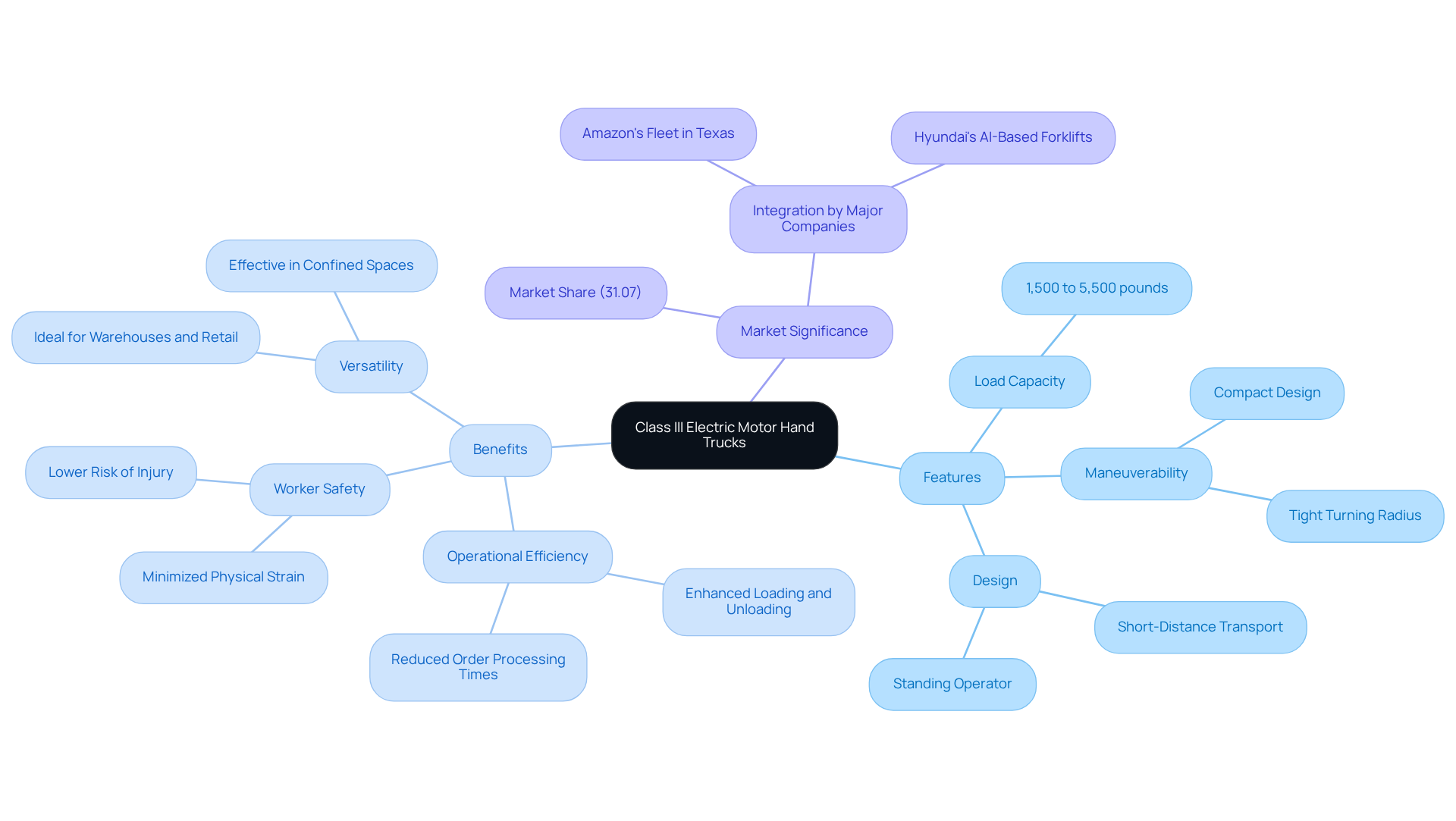

Class III lifting vehicles, commonly referred to as electric motor hand trucks or hand/rider trucks, are specifically engineered for the short-distance transport of items, making them essential in warehouse and retail environments. Typically operated by a standing operator, these forklifts excel at efficiently moving palletized goods. With a load capacity ranging from 1,500 to 5,500 pounds, they offer versatility for various tasks. Their compact design and tight turning radius enhance maneuverability, allowing for seamless navigation in confined spaces. This capability is particularly advantageous for operations that require frequent loading and unloading, solidifying their status as a staple in many logistics operations.

In fact, the Segment III category represented 31.07% of the overall market share in 2026, underscoring their significance in the industry. Businesses such as Amazon have effectively integrated Type III lift trucks into their distribution centers, including a fleet of sub-5-ton electric lift vehicles installed in Texas in February 2025, to improve short-distance transport and significantly enhance operational efficiency. The effectiveness of these hand/rider trucks is further highlighted by their ability to reduce physical strain on workers, thereby minimizing the risk of injury and promoting overall safety in the workplace.

Class IV: Internal Combustion Engine Trucks (Cushion Tires)

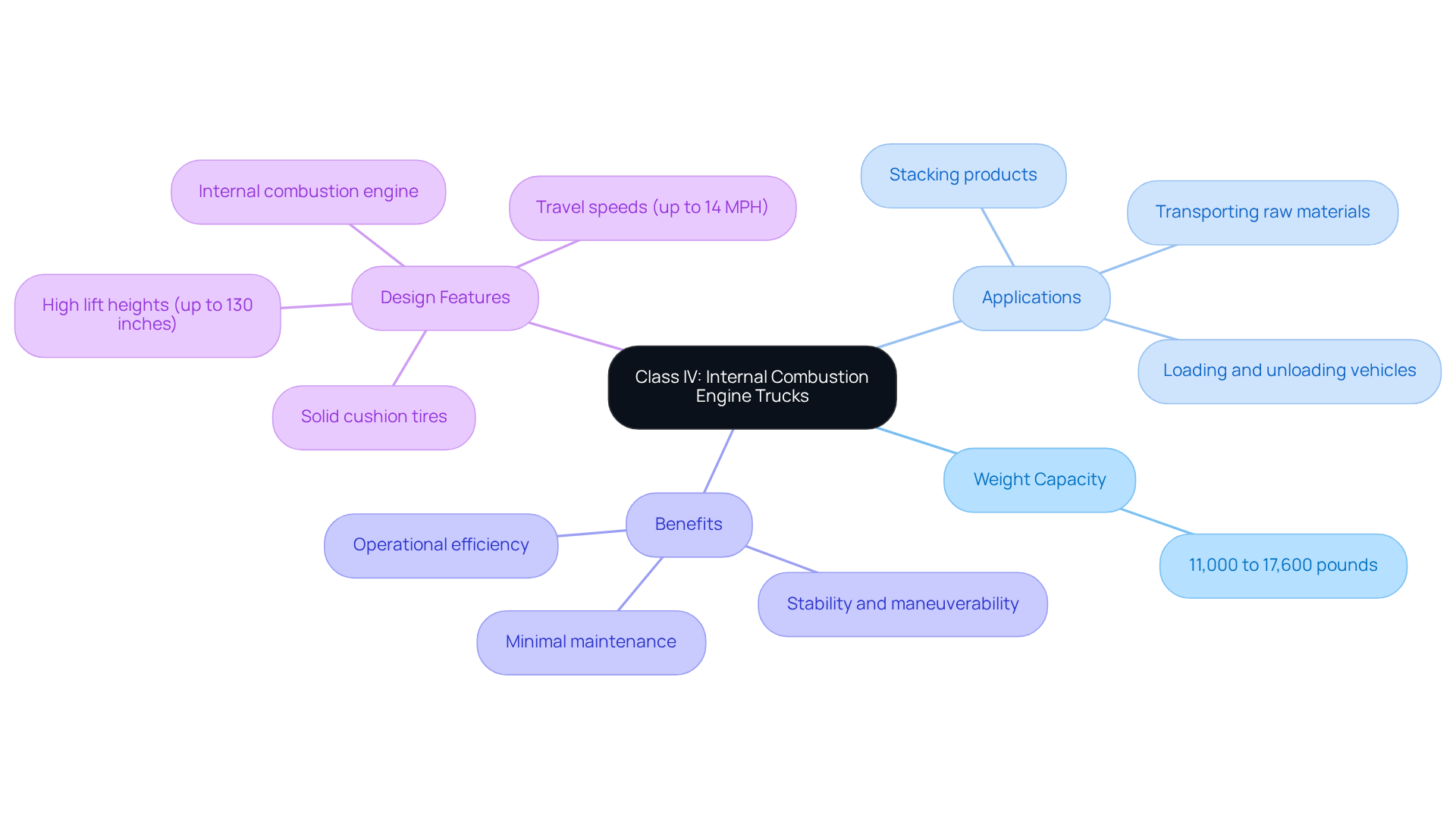

Type IV lift trucks, powered by internal combustion engines and equipped with solid cushion tires, are specifically designed for heavy-duty applications on smooth surfaces. With weight capacities ranging from 11,000 to 17,600 pounds, these lift trucks excel in moving substantial loads in environments such as warehouses, production facilities, and distribution centers. Their cushion tires enhance both stability and maneuverability, making them particularly effective in tight spaces where precision is essential.

In industrial settings, the different types forklift classifications chart shows that Class IV lift trucks are commonly utilized for various tasks, including:

- Loading and unloading vehicles

- Stacking products

- Transporting raw materials

Their robust design enables them to handle heavy loads efficiently, often achieving lift heights of up to 130 inches and travel speeds of 14 MPH. This versatility positions them as a preferred choice for numerous applications, including lumberyards and shipping ports, where reliability and performance are critical.

The benefits of cushion tire lift trucks in manufacturing are significant; they strike a balance between power and operational efficiency, facilitating smooth transitions between indoor and outdoor tasks. Their capability to operate effectively on flat surfaces while minimizing maintenance requirements further cements their role as an essential asset in material handling operations.

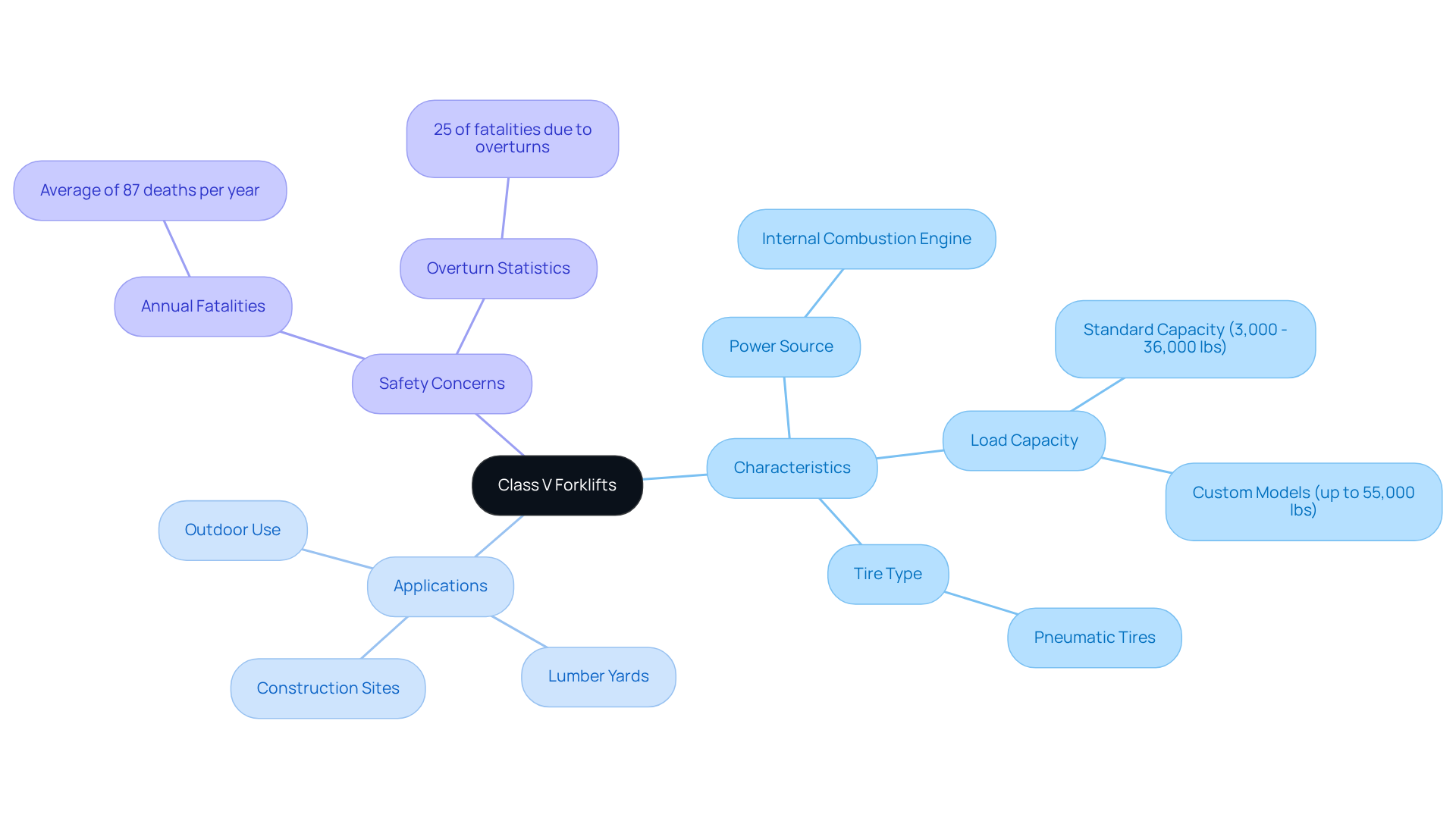

Class V: Internal Combustion Engine Trucks (Pneumatic Tires)

According to the different types forklift classifications chart, Category V forklifts are powered by internal combustion engines and equipped with pneumatic tires, making them suitable for outdoor environments with uneven surfaces. These robust machines can handle substantial loads, typically ranging from 3,000 to 36,000 pounds, with some custom models capable of managing loads up to 55,000 pounds. This showcases their versatility and strength in rugged settings. The pneumatic tires provide superior traction and enhance stability, allowing operators to maneuver confidently over rough terrain.

Class V trucks are commonly utilized in construction sites, lumber yards, and other outdoor applications where durability and power are essential. However, it is crucial to acknowledge that the United States reports an average of 87 forklift-related deaths annually, highlighting the importance of safety when operating these machines. Furthermore, lift truck overturns account for approximately 25 percent of lift truck-related fatalities, underscoring the necessity for adequate training and safety measures.

As Richard Perry noted, while there are concerns regarding the accuracy of annual lifting equipment accident statistics, the significance of enforcing strong safety measures cannot be overstated. The ability of these forklifts to operate efficiently in challenging conditions underscores their value as reliable material handling solutions for businesses that prioritize durability and performance.

Class VI: Electric and Internal Combustion Engine Tractors

Type VI forklifts, often referred to as tractors, are engineered specifically for towing rather than lifting. These adaptable vehicles can be powered by either electric or internal combustion engines, making them ideal for various operational settings, particularly in logistics and manufacturing. With an impressive average towing capacity of up to 60,000 lbs for heavy-duty models, Category VI tractors excel in transporting materials across large facilities or between different locations. They are commonly used in conjunction with trailers or dollies, significantly enhancing the efficiency of goods movement.

For example, Taylor-Dunn's Tiger TC-30/60 models, available in gas, LPG, and diesel, exemplify the robust capabilities of Class VI tractors, providing effective towing solutions for a range of industrial applications. The operational efficiency of these tractors is underscored by their ability to reduce material delivery time by as much as 50% and labor costs by 10% compared to traditional lifting equipment. This efficiency not only streamlines logistics but also results in considerable cost savings, as evidenced by a case where a material handling operation saved $2.6 million over five years by replacing lift trucks with tow tractors.

Moreover, the latest electric tow tractor can tow up to 61,700 lbs, highlighting advancements in towing capabilities within this category. The global tow tractor market was estimated at USD 2.24 billion in 2024 and is projected to grow to USD 3.45 billion by 2033, reflecting an increasing demand for these efficient machines. Additionally, the North American tow tractor market accounted for a 32.5% share of the global market in 2024, emphasizing its importance in the industry.

In conclusion, Grade VI tractors play a crucial role in optimizing logistics and manufacturing processes, offering significant towing capabilities and operational advantages that enhance productivity and safety in material handling.

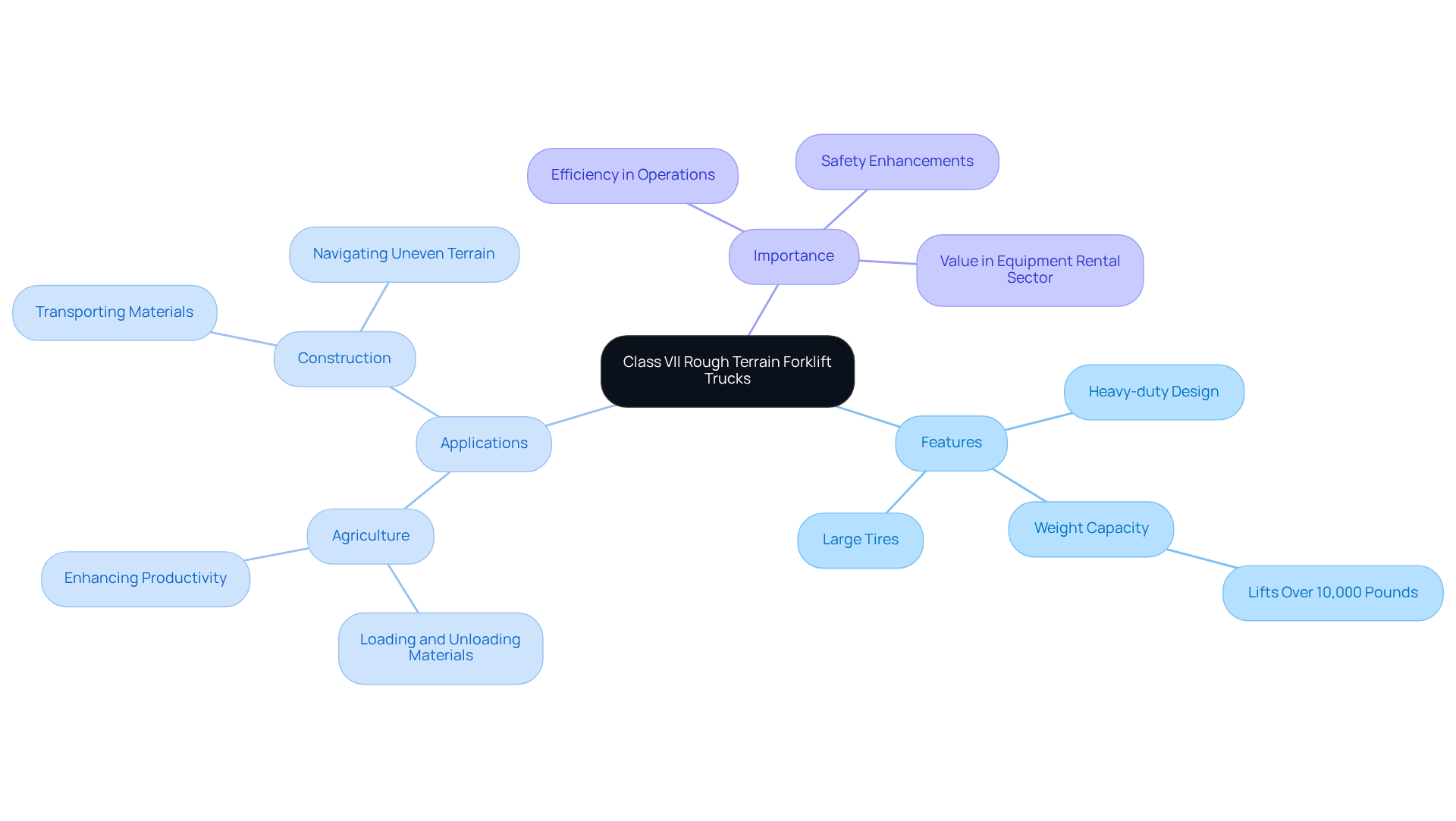

Class VII: Rough Terrain Forklift Trucks

Type VII lift trucks, commonly known as rough terrain handling equipment, are specifically engineered for operation on uneven and rugged surfaces. These heavy-duty machines, typically powered by internal combustion engines, feature large, durable tires that provide exceptional traction and stability. With the capability to lift weights often exceeding 10,000 pounds, Class VII lifting devices are indispensable in construction sites, agricultural operations, and outdoor material handling tasks.

In agricultural settings, for instance, these lifting machines facilitate the loading and unloading of heavy materials, significantly enhancing productivity and efficiency. Their robust design enables them to navigate challenging terrains, making them vital for operators working in demanding environments. Moreover, the average load capacity of these machines is critical for construction projects, where they are frequently utilized to transport materials across uneven ground.

The importance of Class VII lift trucks in construction cannot be overstated. They greatly improve the efficiency and safety of operations, particularly in challenging environments where standard models may falter. By providing reliable performance and robust capabilities, these lift trucks ensure that tasks are completed effectively, reinforcing their value in the equipment rental sector.

Understanding OSHA Forklift Classifications

The Occupational Safety and Health Administration (OSHA) has established a comprehensive classification system for lifting equipment, which is vital for ensuring safety and compliance in the workplace. This system utilizes a different types forklift classifications chart to categorize lift trucks into seven distinct classes based on their power source, design, and intended use. Understanding the different types forklift classifications chart is essential for both employers and operators, as it ensures that the appropriate equipment is utilized for specific tasks and that operators receive the necessary training.

Compliance with OSHA regulations significantly enhances workplace safety, reducing the risk of accidents and injuries. Statistics reveal that improper use of lifting machines results in approximately 34,900 serious injuries and 85 fatalities each year in the U.S. alone, with OSHA estimating that between 35,000 and 62,000 injuries occur annually involving these devices. Furthermore, forklift-related injuries to pedestrians have the highest median days away from work at 20 days, underscoring the severity of such incidents. The trade, transportation, and utilities industry reported the highest number of DART cases, emphasizing the critical need for adherence to safety protocols.

Real-world examples illustrate the effectiveness of proper vehicle classification in enhancing safety. For instance, implementing training programs tailored for specific types of lift trucks has led to a significant reduction in accidents. By fostering a culture of safety awareness and ensuring compliance with OSHA guidelines, businesses can mitigate risks, protect employees, and improve operational efficiency. Additionally, it is important to recognize that every lift truck injury requiring medical care costs businesses an average of $41,000, highlighting the financial implications of inadequate safety protocols.

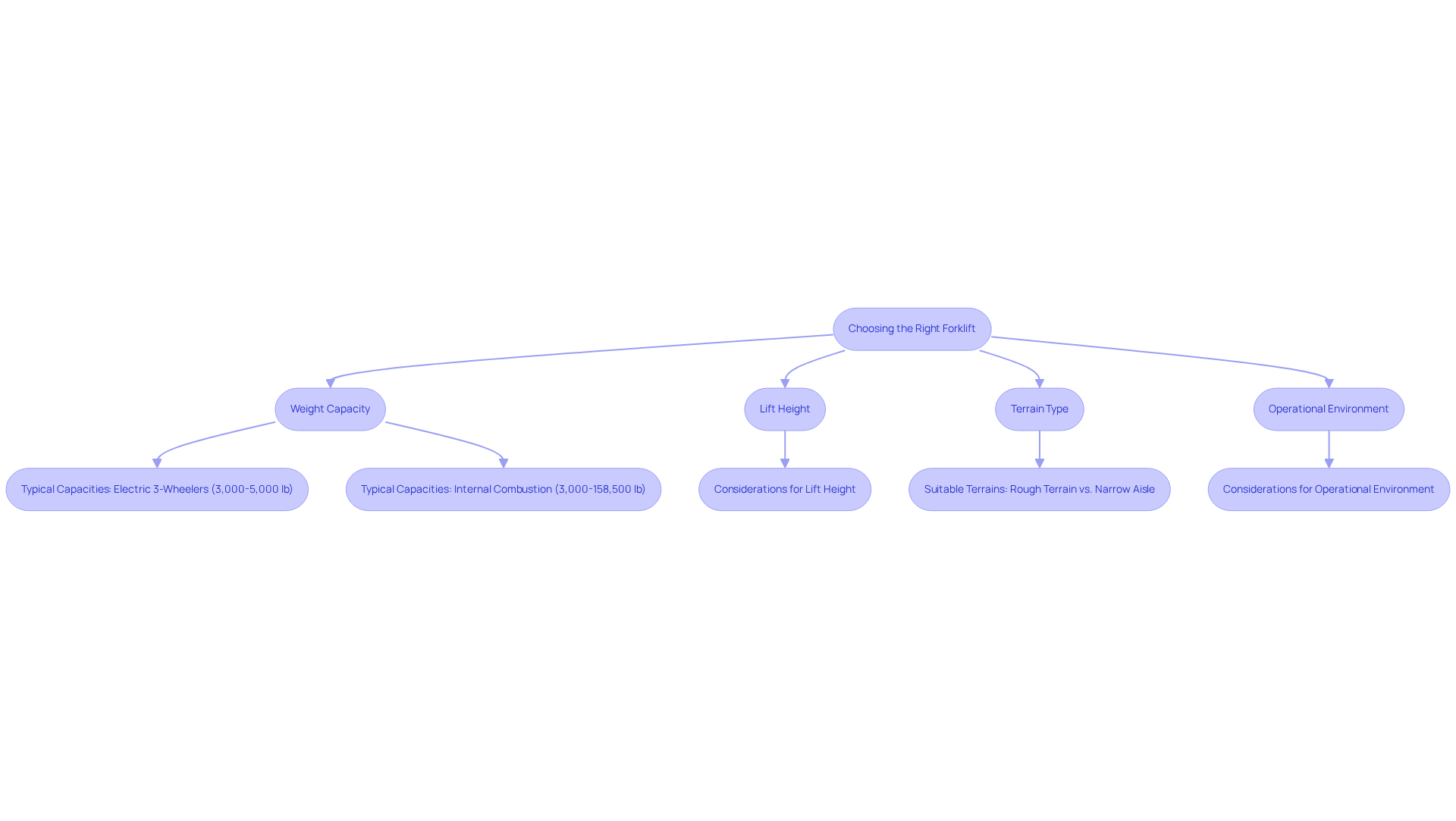

Choosing the Right Forklift for Your Project

Choosing the right lift truck for your project involves several critical factors, including weight capacity, lift height, terrain type, and operational environment. Begin by assessing the weight of the materials you need to lift, ensuring that the lift truck you select can handle that weight efficiently. For instance, typical lift capacities vary significantly: Electric 3-Wheelers can elevate between 3,000 lb and 5,000 lb, while Internal Combustion Sit-Down Counterbalance vehicles can manage weights up to 158,500 lb. It is essential to recognize that exceeding these capacity limits can result in substantial fines and safety hazards, underscoring the importance of adhering to established guidelines.

Next, consider the height to which you need to lift materials, as outlined in the different types forklift classifications chart, since various lift trucks possess varying lift capabilities. A lift truck rated for 5,000 lb at a 24-inch load center may only raise 4,000 lb at maximum height due to stability concerns. Operators should also be vigilant for mechanical warning signs of overloading, such as unusual sounds or movements, which may indicate that the lifting vehicle is nearing its capacity limits.

Terrain is another vital consideration; rough terrain vehicles excel in outdoor applications, whereas narrow aisle trucks are tailored for indoor operations. The choice of lifting equipment should align with the specific conditions of your worksite to ensure both safety and efficiency. The Darwin Steel Bundle Incident serves as a poignant reminder of the consequences of neglecting lifting equipment capacity limits, highlighting the necessity for proper capacity management.

Lastly, take into account the duration of use and rental costs. Understanding these factors will empower you to make an informed decision that meets your project needs while optimizing operational efficiency. By thoroughly evaluating these elements, you can select a lifting machine that enhances productivity and safety on the job site.

EZ Equipment Rental: Your Source for Diverse Forklift Options

EZ Equipment Rental stands out as your premier choice for a wide array of lifting machines tailored for various applications. Whether you need electric motor rider trucks for indoor tasks or rough terrain lift trucks for outdoor projects, EZ Equipment Rental has the ideal equipment to fulfill your requirements. Their extensive inventory features a different types forklift classifications chart that includes Class I, II, III, IV, V, VI, and VII lifting machines, guaranteeing that you will find the perfect solution for your specific project needs.

Leasing handling equipment from EZ Equipment Rental comes with numerous advantages, including flexible rental terms and competitive pricing. This allows you to access top-quality machinery without the financial burden of ownership. Their knowledgeable team is committed to providing expert guidance and support, ready to assist you in selecting the right forklift to boost your operational efficiency. Experience the difference with EZ Equipment Rental, where quality machinery and exceptional customer support are our foremost priorities.

Conclusion

Understanding the various types of forklift classifications is essential for optimizing material handling operations and ensuring workplace safety. Each class of forklift, from electric motor rider trucks to rough terrain forklifts, serves specific applications and offers unique benefits tailored to different operational environments. Recognizing the distinctions among these classes enables businesses to make informed decisions that enhance productivity and efficiency.

This article delves into the specifics of each forklift classification, highlighting their load capacities, operational advantages, and ideal use cases. For instance, electric motor rider trucks are known for their quiet operation and zero emissions, while narrow aisle trucks excel in maximizing storage in confined spaces. Additionally, the discussion on internal combustion engine trucks emphasizes their robust capabilities in heavy-duty applications, showcasing the importance of selecting the right equipment for the job.

The significance of adhering to OSHA forklift classifications cannot be overstated. By prioritizing safety and compliance, organizations can mitigate risks and foster a culture of safety awareness. As the industry evolves, embracing the right forklift technology not only boosts operational efficiency but also ensures a safer working environment. Choosing the appropriate forklift is not merely a matter of equipment selection; it is a strategic decision that impacts overall business performance and employee well-being.

Frequently Asked Questions

What are Class I electric motor rider trucks designed for?

Class I electric motor rider trucks are engineered for both indoor and outdoor applications, featuring quiet operation and zero emissions, making them suitable for environments where air quality is crucial.

What is the load capacity range for Class I electric motor rider trucks?

The load capacity for Class I electric motor rider trucks ranges from 2,500 to 12,000 pounds, catering to various material handling requirements.

What are the key benefits of Class I electric motor rider trucks?

Key benefits include quiet operation, zero emissions, low maintenance costs, high load capacity, and enhanced maneuverability with options available in three or four-wheel configurations.

How do Class II electric motor narrow aisle trucks optimize warehouse storage?

Class II trucks, or electric motor narrow aisle vehicles, are designed for confined areas, allowing them to navigate spaces as narrow as 8-9 feet and reach heights of up to 40 feet, significantly enhancing productivity.

What is the load capacity of Class II electric motor narrow aisle trucks?

Class II trucks typically have a load capacity of 3,000 to 5,000 pounds.

What advantages do Class II trucks offer in high-density environments?

Class II trucks help maximize vertical storage and facilitate precise load handling, leading to higher picking accuracy and faster turnaround times in warehouse operations.

What is the market projection for extremely narrow aisle vehicles?

The market for extremely narrow aisle vehicles is projected to reach approximately USD 8.7 billion by 2034, expanding at a CAGR of 5.2%.

What are Class III electric motor hand trucks used for?

Class III electric motor hand trucks are specifically engineered for the short-distance transport of items, making them essential in warehouse and retail environments.

What is the load capacity range for Class III electric motor hand trucks?

The load capacity for Class III electric motor hand trucks ranges from 1,500 to 5,500 pounds.

How do Class III hand trucks enhance workplace safety?

Class III hand trucks reduce physical strain on workers during transport tasks, thereby minimizing the risk of injury and promoting overall safety in the workplace.

List of Sources

- Class I: Electric Motor Rider Trucks

- Forklift Trucks Market Statistics, Insights, and Growth Trends (https://skyquestt.com/report/forklift-trucks-market)

- Forklift Trucks Market Size, Share, Trends | Growth Report [2034] (https://fortunebusinessinsights.com/industry-reports/forklift-trucks-market-101541)

- Results from the 2024 Lift Truck Usage Survey: Reliability, Service as Important as Prices - Industrial Forklifts (https://industrialforklifts.com/results-from-the-2024-lift-truck-usage-survey-reliability-service-as-important-as-prices)

- Forklift Market | Global Market Analysis Report - 2035 (https://factmr.com/report/forklift-market)

- Class II: Electric Motor Narrow Aisle Trucks

- Narrow Aisle Forklift Market Size, Share & Forecast to 2032 (https://researchandmarkets.com/report/narrow-aisle-truck-market?srsltid=AfmBOorMaJ1lpVkmBknKoWpCwsr1aFueYqWDbT4kFwTx1rYXcaeXZeSA)

- Forklift Classes: Class 2 Forklifts Complete Overview - Hy-Tek Intralogistics (https://hy-tek.com/resources/class-2-forklifts)

- Very Narrow Aisle Trucks Market Size, Global Report 2025-2034 (https://gminsights.com/industry-analysis/very-narrow-aisle-trucks-market)

- Class III: Electric Motor Hand Trucks

- Different Types of Forklifts and Their Applications (https://roisafetyservices.com/different-types-of-forklifts-and-their-applications)

- Forklift Trucks Market Statistics, Insights, and Growth Trends (https://skyquestt.com/report/forklift-trucks-market)

- Forklift Trucks Market Size, Share, Trends | Growth Report [2034] (https://fortunebusinessinsights.com/industry-reports/forklift-trucks-market-101541)

- Traditional Hand Trucks vs. Electric Hand Trucks: How to Choose the Best Tool for Your Needs (https://riosoc.com/blogs/news/traditional-vs-electric-hand-trucks?srsltid=AfmBOoruiSeQf3l-fX0pHdRz-s3L9y5rBDI4ZmduWgr6hSXc87G9mrle)

- Forklift Trucks Market Hit Valuation of US$ 102.87 Billion by 2033 | Astute Analytica (https://globenewswire.com/news-release/2025/05/07/3076314/0/en/Forklift-Trucks-Market-Hit-Valuation-of-US-102-87-Billion-by-2033-Astute-Analytica.html)

- Class IV: Internal Combustion Engine Trucks (Cushion Tires)

- The 7 Classes of Forklifts: A Breakdown (https://clockworktraining.ca/the-7-classes-of-forklifts)

- The Different Types Of Forklifts: Classes I Through V (https://hy-tekmaterialhandling.com/blog/the-different-types-of-forklifts)

- A Quick Guide to Class 4 Forklifts - SANY Group (https://sanyglobal.com/blog/class-4-forklift)

- What are Class IV Forklifts? Exploring Class 4 Internal Combustion Cushion Forklifts (https://liftow.com/blogs/news/the-ultimate-solution-for-your-material-handling-needs-class-iv-toyota-forklifts?srsltid=AfmBOopiXoRULIk-yAy__gc1v0kvUtHzIhdy9QW8y7FYj8-7oyEAQHsU)

- 5 Forklift Carriage Classes & Their Lifting Capacities | BigRentz (https://bigrentz.com/blog/forklift-carriage?srsltid=AfmBOooiSB2EbNlOQMCOerhtn9jxolySAmsGgnsKIdcffrX68pOXcu5i)

- Class V: Internal Combustion Engine Trucks (Pneumatic Tires)

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- The Different Types Of Forklifts: Classes I Through V (https://hy-tekmaterialhandling.com/blog/the-different-types-of-forklifts)

- 18 Important Forklift Statistics | BigRentz (https://bigrentz.com/blog/forklift-statistics?srsltid=AfmBOopH8bnhmCRyLl91t9LrgOZl_TFRKLC2RA4Z5DXFTs6XHWfM2VvA)

- Forklift Sizes: What to Know About Types, Capacities and Dimensions (https://unitedrentals.com/project-uptime/equipment/forklift-sizes-what-know-about-types-capacities-and-dimensions)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Class VI: Electric and Internal Combustion Engine Tractors

- Electric Tow Tractors - Tow Tugs | Jungheinrich (https://logisnextamericas.com/en/jungheinrich/forklifts-pallet-trucks/tow-tractors)

- Tow Tractor Market Size And Share | Industry Report, 2033 (https://grandviewresearch.com/industry-analysis/tow-tractor-market-report)

- The Best Tow Tractors for Material Handling and Manufacturing (https://lillyforklifts.com/blog/tow-tractors-tuggers)

- – Market Intelligence | ProcurementIQ (https://procurementiq.com/market-intelligence/tow-tractors)

- 33 “Motivational” Transportation Quotes to Make Your Day (https://scmdojo.com/motivational-transportation-quotes?srsltid=AfmBOoq5viC9TZFPrhrbFEz0AVwuEpabLI_Nm_E3gj3pJ8Ov-8J2_omf)

- Class VII: Rough Terrain Forklift Trucks

- 2025 Forklift Sales Statistics And Market Trends – A Comprehensive Analysis (https://herculift.com/forklift-facts-stats-2025-in-depth-analysis-of-accidents-market-trends-safety)

- Rough Terrain Forklift Market Research Report 2033 (https://growthmarketreports.com/report/rough-terrain-forklift-market)

- Rough Terrain Forklift Industry Growth Trends and Analysis (https://marketreportanalytics.com/reports/rough-terrain-forklift-127924)

- Rough Terrain Forklift Market Analysis 2026, Market Size, Share, Growth, CAGR, Forecast, Trends, Revenue, Industry Experts, Consultation, Online/Offline Surveys, Syndicate Reports (https://cognitivemarketresearch.com/rough-terrain-forklift-market-report)

- 7 Benefits of Choosing an All-Terrain Forklift (https://intellaparts.com/blog/7-benefits-of-choosing-an-all-terrain-forklift?srsltid=AfmBOorC58nQ5NNtpMVbc2AmjoMLNRcaK2QtRDpySFqHzYYjpu_0d5er)

- Understanding OSHA Forklift Classifications

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- Forklift Accidents in Warehouses (https://greenbergrubylaw.com/forklift-accident-warehouse)

- Occupational Injuries, Illnesses, and Fatalities Involving Forklifts (https://bls.gov/iif/factsheets/fatal-occupational-injuries-forklifts-2017.htm)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Safety and Statistics - Hit Not (https://hitnot.com/forklift-safety-and-statistics)

- Choosing the Right Forklift for Your Project

- How High Can Your Forklift Go? (https://zonemfc.com/forklift-lifting-height)

- 5 Forklift Carriage Classes & Their Lifting Capacities | BigRentz (https://bigrentz.com/blog/forklift-carriage?srsltid=AfmBOoqj2XLwDgeWb-5Tf3t8h-r6m6Qb_2_8cckYUNMXdrfbm0xPIWDo)

- Understanding Forklift Capacity Limits - FQT (https://forkliftqualitytraining.com/understanding-forklift-capacity-limits-a-guide-to-safe-operation)

- Forklift Capacity Ratings Insights | Abel Womack, Inc. (https://abelwomack.com/forklift-capacity-ratings-blog)

- Forklift Weight Capacity: Everything You Need to Know (https://conger.com/forklift-weight-capacity)

- EZ Equipment Rental: Your Source for Diverse Forklift Options

- Forklift Rental Market Report: Trends, Forecast and Competitive Analysis to 2030 (https://lucintel.com/forklift-rental-market.aspx)

- Forklift Rental Market Growth, Trend & Forecast 2035 (https://transparencymarketresearch.com/forklift-rental-market.html)

- Forklift Rental Market Size, Share, Trends | Growth Report [2034] (https://fortunebusinessinsights.com/forklift-rental-market-114879)

- Forklift Rental Market Size & Share | Industry Report, 2030 (https://grandviewresearch.com/industry-analysis/forklift-rental-market-report)

- North America Forklift Rental Market Size | Mordor Intelligence (https://mordorintelligence.com/industry-reports/north-america-forklift-rental-market)