Overview

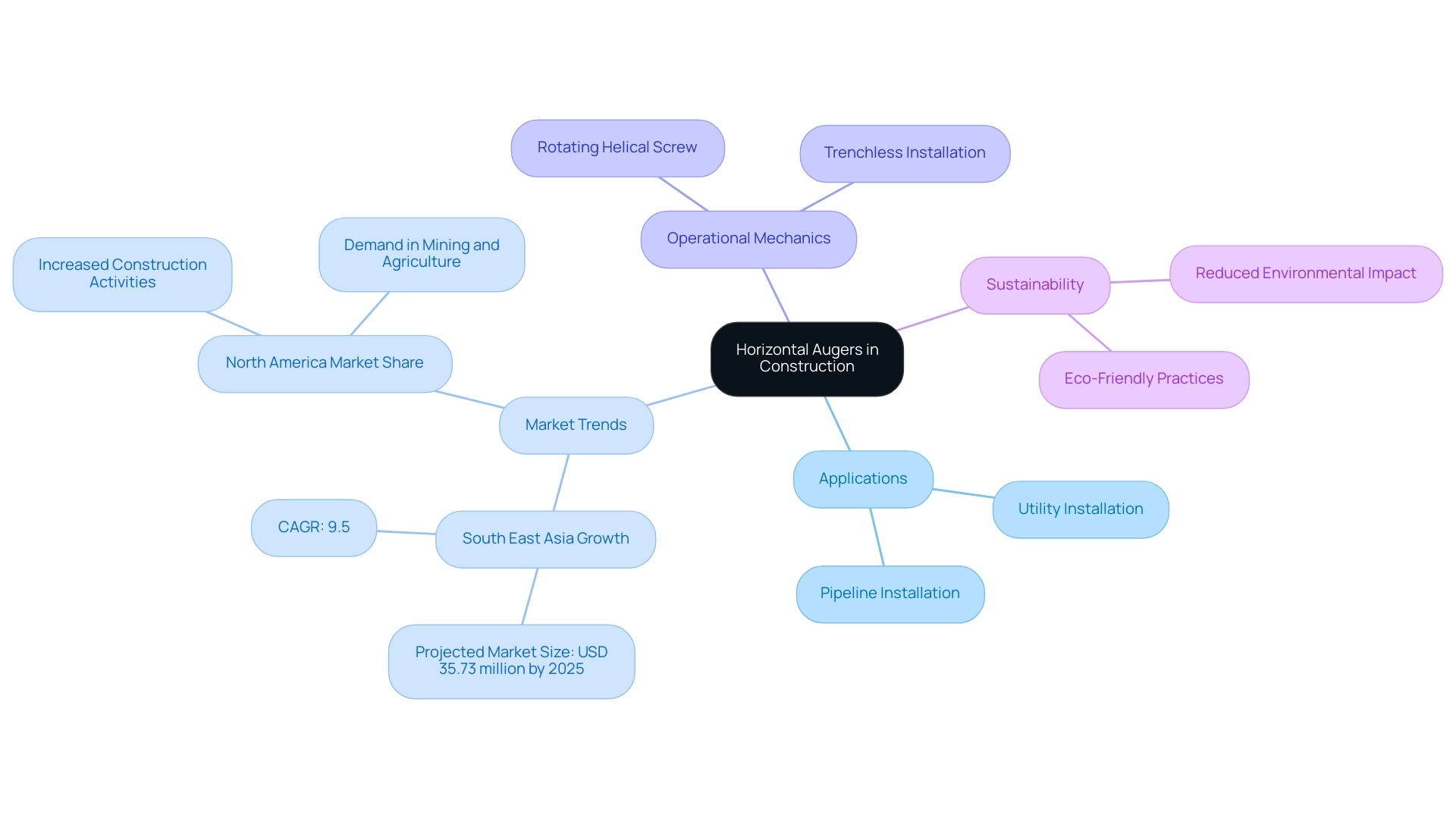

This article delivers essential insights into horizontal auger rental, specifically tailored for construction project managers. It underscores the significance of these rentals for trenchless utility installations and highlights the increasing demand within the Southeast Asian market. By detailing the operational mechanics and best practices for effective project management, it emphasizes the necessity of selecting reliable rental companies. Such choices not only enhance project efficiency but also promote sustainability in construction, ultimately benefiting all stakeholders involved.

Key Highlights:

- Horizontal augers are essential for trenchless utility installations, minimizing surface disruption in urban areas.

- The Southeast Asian drilling market is projected to grow to USD 35.73 million by 2025, indicating high demand for innovative drilling solutions.

- Understanding the operational mechanics of horizontal drills enhances project efficiency and aligns with sustainability trends.

- Different styles of horizontal boring attachments (wet and dry) are designed for specific soil conditions, impacting project outcomes.

- Effective boring operations require alignment of drill size with bore diameter, appropriate material for soil conditions, and regular maintenance.

- Earth drills have diverse applications beyond boring, including installing fence posts and anchoring systems, enhancing construction productivity.

- Best practices for horizontal auger rental projects include meticulous planning, soil testing, effective communication, and post-project reviews.

- Selecting a reliable equipment rental company involves researching reputation, ensuring equipment maintenance, and comparing rental rates.

- Embracing technology, such as predictive analytics and digital contracts, optimizes equipment rental processes and enhances efficiency.

Introduction

In the realm of construction, efficiency and innovation reign supreme, particularly when executing complex projects with minimal disruption. Horizontal augers have emerged as indispensable tools, facilitating the seamless installation of utilities beneath the surface while safeguarding the integrity of urban environments. Their trenchless technology not only accelerates the boring process but also significantly reduces environmental impact, establishing them as a preferred choice among project managers.

As the demand for such advanced solutions continues to rise, grasping the mechanics and applications of horizontal augers is essential for optimizing construction practices and ensuring timely project delivery. This article delves into the multifaceted world of horizontal boring, exploring various attachment styles, essential requirements, and the expansive applications of earth drills, all while providing actionable tips for success in this evolving landscape.

Understanding Horizontal Augers: A Key Tool for Construction Projects

Horizontal drilling devices represent advanced tools specifically engineered for boring holes horizontally beneath the surface. These devices are essential for utility installations, including water and sewer lines. Utilizing a rotating helical screw, they efficiently excavate soil to create boreholes of varying diameters. Their trenchless installation capability significantly reduces surface disruption, a critical factor in urban environments where maintaining traffic flow and minimizing environmental impact are paramount.

For example, horizontal drilling devices facilitate the installation of pipelines beneath roads or sidewalks without extensive excavation, conserving both time and costs associated with restoration efforts. As in South East Asia is projected to reach USD 35.73 million in 2025, growing at a CAGR of 9.5%, the demand for such innovative solutions is evident.

Project leaders should take the initiative to understand the operational mechanics and capabilities of horizontal drilling tools. Comprehending these tools not only improves efficiency but also guarantees that practices conform to the latest trends in sustainability and eco-friendliness. Trenchless technology is increasingly acknowledged for its diminished environmental impact compared to conventional drilling techniques. By leveraging the advantages of horizontal drills, project managers can enhance their building initiatives, ensuring timely completion while adhering to contemporary environmental standards.

In fact, a recent case study titled 'Regional Analysis of Drilling Market' highlights that North America holds the largest market share in drilling due to increased building activities and demand in mining and agriculture. This underscores the significance of horizontal drills in addressing the specific requirements of clients in the area. Furthermore, as one client noted, "We were really happy with the final deliverable, and the takeaways from the report," emphasizing the effectiveness of these tools in real-world applications.

The increasing emphasis on sustainability and environmentally friendly practices further encourages the use of horizontal auger rental, making them an essential factor for leaders in today's building environment.

Exploring Different Styles of Horizontal Boring Attachments

Horizontal boring attachments are available in a variety of styles, each meticulously designed for specific applications within the construction industry. Wet drilling attachments excel in softer soil conditions, effectively minimizing dust and enhancing operational efficiency. Conversely, dry drilling attachments are tailored for harder ground, ensuring robust performance even in challenging environments.

Moreover, these attachments accommodate specific bore diameters, catering to everything from small utility lines to larger pipelines. Managers must carefully evaluate both the soil conditions and the specific needs of their assignments when selecting an attachment. As Myron Hofer aptly noted, the interactions and decisions made during this selection process can have vital implications for project outcomes. For example, when installing a water line beneath a busy street, choosing a wet drilling attachment can significantly reduce dust and improve overall efficiency, thereby minimizing disruption to traffic and surrounding areas.

Statistics from the Attachment Style Questionnaire underscore the importance of understanding different attachment styles for effective management. Notably, there is a strong internal consistency in the need for approval (α = 0.72) and relationships as secondary (α = 0.86). This understanding can greatly influence the success of intricate operations and the timely completion of tasks.

EZ Equipment Rental is committed to quality, reliability, and customer satisfaction, positioning itself as a trusted partner for construction supervisors seeking the right equipment. A compelling case study involving the successful use of both wet and dry drilling attachments in illustrated how selecting the appropriate attachment based on soil conditions led to enhanced efficiency and reduced timelines. Grasping the nuances of these attachment styles is crucial for managers aiming for successful outcomes.

Essential Attachment Requirements for Effective Boring Operations

To achieve effective boring operations with horizontal drills, it is crucial to address . Firstly, aligning the drill size with the bore diameter specified for the project is vital. This alignment ensures optimal performance and efficiency.

Furthermore, the material and design of the drill should be tailored to the soil conditions. For example, utilizing a hardened steel drill is advisable in rocky environments to enhance durability and performance. Additionally, ensuring that the soil is manageable and maintaining a level guide trench for straight drilling are essential, as these factors significantly contribute to successful horizontal boring operations.

Regular maintenance and thorough inspections of both the auger and its attachments are essential to avert breakdowns during operations. Project managers should implement a comprehensive checklist that verifies equipment compatibility, assesses wear and tear, and confirms that all necessary safety features are operational before initiating work. This proactive strategy not only facilitates smoother operations but also significantly reduces downtime, ultimately contributing to project success.

Notably, the attachment can mix and pour up to 200 pounds (90.7 kg) of dry cement, showcasing its capabilities in various applications. By adhering to these guidelines, teams can maximize the effectiveness of their horizontal auger rental and ensure dependable performance throughout the lifecycle. The importance of reliable equipment is further illustrated by case studies such as Thompson Pump's heavy-duty trash pumps, which provide simple, low-cost maintenance solutions for various water management needs.

Expanding Applications: Beyond Basic Boring with Earth Drills

Earth drills extend far beyond basic boring tasks; their applications in construction are both diverse and impactful. These powerful tools can be effectively utilized for:

- Installing fence posts

- Installing signposts

- Planting small trees and shrubs in landscaping endeavors

Moreover, earth drills can be adapted for:

- Anchoring systems

- Drilling holes necessary for foundations

This showcases their remarkable versatility.

This adaptability empowers managers to leverage earth drills across various assignments, significantly enhancing overall productivity. For example, consider a community park initiative where an earth drill is employed to install fence posts. The time savings compared to manual digging methods can be substantial, allowing teams to complete tasks more efficiently and concentrate on other essential elements of the work.

In 2023, the building sector experienced a significant rise in distinct recipients, with US$2.15 billion designated for infrastructure enhancements under the IIJA. This highlights the necessity of optimizing equipment utilization to satisfy increasing demands.

This statistic emphasizes the urgent need for managers in the building industry to utilize innovative tools like earth drills to maximize efficiency and effectiveness in their endeavors. As Deloitte emphasizes, "We have been working with MarkWide Research for a number of years now, and we have found their market research reports to be invaluable in helping us make strategic decisions for our business." This quote reinforces the value of leveraging market insights and innovative tools in maintaining a competitive edge in the construction industry.

Additionally, the case study titled ' and Its Impact' illustrates the potential risks posed by tariff increases on materials, which could influence delivery and cost-effectiveness when using earth drills. By exploring these expanded uses of earth drills, leaders can not only streamline their operations but also reduce overall timelines. As the industry evolves, adopting innovative tools like earth drills will be essential for maintaining a competitive edge and ensuring successful delivery, especially in the context of modern construction site technologies.

Tips for Achieving Success in Horizontal Boring Projects

To ensure the success of projects, supervisors must adhere to several best practices. First and foremost, meticulous planning is crucial. This entails conducting comprehensive soil tests to assess ground conditions and identify potential obstacles that could impede progress.

As John Cope, an applications engineer, emphasizes, "fluid management is so critical to maximize productivity on a horizontal directional drill jobsite," highlighting the significance of understanding the soil's characteristics.

The demand for horizontal auger rental is on the rise, particularly in densely populated regions, making it essential for managers to stay ahead of industry trends. Furthermore, effective communication with all stakeholders is vital. Clear dialogue mitigates misunderstandings and prevents delays, fostering a collaborative environment that enhances efficiency.

Creating a detailed timeline for the initiative is another key strategy, as it helps keep the team aligned and ensures that each phase of the endeavor is executed smoothly.

Moreover, adopting digital bore plans has become a necessity for contractors to avoid competitive disadvantages. As engineering and construction firms navigate the evolving landscape in 2025, focusing on these best practices will not only enhance results but also position them to capitalize on growth opportunities in a competitive market.

Conducting a post-project review is essential for continuous improvement. This review should document any challenges faced during the tedious operations, providing valuable insights that can guide future endeavors. For example, successful management of horizontal auger rental often hinges on learning from past experiences, enabling teams to adapt and refine their approaches.

Insights from the case study titled "Key Strategies for Engineering and Construction Firms" illustrate how firms are managing labor mismatches and increasing technological integration to remain agile and competitive in a changing landscape.

Choosing the Right Equipment Rental Company for Your Needs

When selecting an equipment rental firm, construction supervisors must prioritize reliability and quality to ensure success. Conduct thorough research on potential rental providers, paying close attention to customer reviews that reflect their reputation in the industry. It is crucial to confirm that the company maintains its equipment to high safety standards, as well-maintained tools are essential for both efficiency and safety on the job site.

In today's market, numerous companies are adopting electronic contracts and online booking systems to enhance the rental experience, simplifying the process for managers to obtain the equipment they require. Additionally, customer support is another vital aspect to consider; a knowledgeable team can significantly enhance the rental experience by assisting with equipment selection and troubleshooting throughout the rental period. For example, a rental firm that offers training on equipment operation not only enhances efficiency but also encourages safety among team members.

Furthermore, embracing predictive analytics can optimize equipment maintenance schedules and minimize downtime, ensuring that the tools are always ready for use. Comparing rental rates and terms is essential to ensure they fit within your budget and timeline. Notably, the revenue analysis of major rental companies, such as United Rentals, which reported $9.7 billion in revenue, underscores the importance of choosing a reputable provider in a competitive market.

As Adam, co-founder of ProjectionHub, states, "If you have any questions about the data or how to utilize the data in your financial forecasting process please don’t hesitate to reach out to us!" This emphasizes the significance of data in decision-making for leaders when choosing rental companies. Additionally, understanding the largest business expenses for , including material costs and depreciation, can provide insight into the operational challenges faced by rental companies and how this might affect service quality.

By carefully evaluating these factors, project managers can make informed decisions that contribute to the overall success of their projects, ultimately leading to smoother operations and better outcomes.

Conclusion

The exploration of horizontal augers and their applications underscores their critical role in modern construction projects. These advanced tools streamline the installation of utilities with minimal disruption, aligning perfectly with the industry's growing emphasis on sustainability. By grasping the mechanics and various attachment styles, project managers can enhance operational efficiency, reduce environmental impact, and ensure timely project delivery.

Furthermore, the importance of selecting the right equipment and rental companies cannot be overstated. Reliable partnerships and well-maintained tools are essential for achieving optimal performance on job sites. Embracing best practices, such as meticulous planning and effective communication, will bolster project success and foster a collaborative environment among stakeholders.

As the demand for innovative solutions continues to rise, integrating horizontal augers and earth drills into construction practices will be vital for maintaining a competitive edge. By leveraging these technologies and adhering to industry best practices, project managers can navigate the complexities of modern construction with confidence, paving the way for a more efficient and sustainable future.

Frequently Asked Questions

What are horizontal drilling devices used for?

Horizontal drilling devices are advanced tools designed for boring holes horizontally beneath the surface, primarily for utility installations such as water and sewer lines.

How do horizontal drilling devices operate?

They utilize a rotating helical screw to efficiently excavate soil, creating boreholes of varying diameters while minimizing surface disruption.

What are the advantages of using horizontal drilling in urban environments?

The trenchless installation capability of horizontal drilling significantly reduces surface disruption, which is crucial for maintaining traffic flow and minimizing environmental impact in urban areas.

What is the projected market growth for horizontal drilling in South East Asia?

The drilling market in South East Asia is projected to reach USD 35.73 million by 2025, growing at a CAGR of 9.5%.

Why should project leaders understand the mechanics of horizontal drilling tools?

Understanding the operational mechanics and capabilities of horizontal drilling tools improves efficiency and ensures practices align with the latest sustainability and eco-friendliness trends.

How do horizontal drilling tools compare to conventional drilling techniques?

Horizontal drilling tools are recognized for their reduced environmental impact compared to traditional drilling methods.

What are the two main styles of horizontal boring attachments?

The two main styles are wet drilling attachments, which are effective in softer soil conditions, and dry drilling attachments, which are designed for harder ground.

Why is it important to select the appropriate attachment for drilling?

Selecting the right attachment based on soil conditions can significantly enhance operational efficiency and minimize disruption during projects, such as when installing utility lines beneath busy streets.

What role does EZ Equipment Rental play in the construction industry?

EZ Equipment Rental is committed to providing quality, reliability, and customer satisfaction, serving as a trusted partner for construction supervisors in need of the right equipment.

What did a recent case study reveal about the use of drilling attachments?

The case study demonstrated that selecting the appropriate wet or dry drilling attachment based on soil conditions led to enhanced efficiency and reduced project timelines.