Key Highlights:

- Skid loaders are versatile machines essential for construction, landscaping, and agricultural projects, known for their compact size and manoeuvrability.

- Key functions of skid loaders include lifting, digging, and transporting materials, which enhance productivity on job sites.

- Attachments like buckets, forks, and augers can significantly improve the functionality of skid loaders for specific tasks.

- The weight of skid loaders varies based on size, engine type, and attachments; larger models weigh between 7,000 and 10,000 pounds, while smaller models range from 3,000 to 5,000 pounds.

- Rated Operating Capacity (ROC) indicates the maximum load a skid loader can safely lift, critical for ensuring safety and stability during operation.

- Larger models like the GEHL V260 have an ROC of 2,599 pounds, suited for heavy-duty tasks, while smaller models like the GEHL R135 have an ROC of 1,349 pounds for lighter jobs.

- Understanding ROC and tipping load is vital for safe operation; tipping load refers to the weight at which a skid loader becomes unstable.

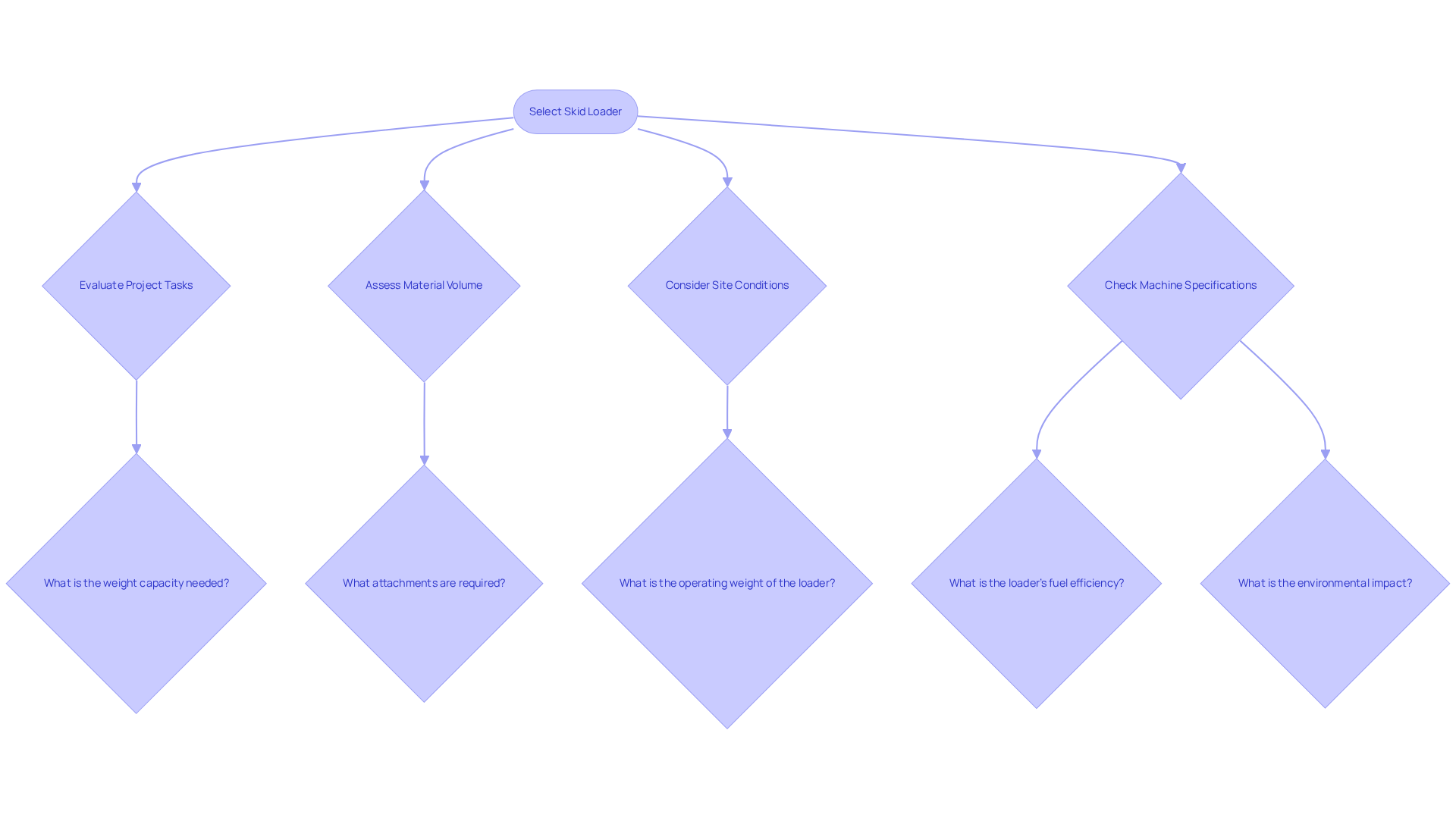

- Selecting the right skid loader involves evaluating project requirements, material volume, and site conditions, as well as considering the availability of attachments.

Introduction

Understanding the weight of a skid loader is essential for project managers navigating the complexities of construction and landscaping tasks. These versatile machines, recognized for their compact design and agility, can significantly boost productivity on job sites. However, the challenge lies in selecting the right model based on its weight and rated operating capacity, which directly influences performance and safety. To ensure they choose the most suitable skid loader that meets both project demands and safety standards, managers must consider various factors.

Understand Skid Loader Basics and Their Importance in Projects

Skid loaders, often known as steer vehicles, are versatile machines commonly used in construction, landscaping, and agricultural projects. Their compact size and exceptional maneuverability make them particularly effective in confined spaces. Understanding the fundamental functions of skid loaders - such as lifting, digging, and transporting materials - is essential for project managers. These machines significantly boost productivity and efficiency on job sites, facilitating quicker task completion. Familiarity with various attachments available for skid loaders, including:

- Buckets

- Forks

- Augers

can further enhance their effectiveness across different project scenarios.

Identify Factors Affecting Skid Loader Weight

The weight of a compact vehicle is influenced by several key factors, including its size, engine type, and construction materials. Generally, when discussing how heavy a skid loader is, larger models equipped with more powerful engines tend to weigh more than their smaller counterparts. For instance, large-frame compact loaders typically weigh between 7,000 and 10,000 pounds, while small-frame models generally range from 3,000 to 5,000 pounds. Understanding how heavy a skid loader is crucial, as the typical mass of compact loaders is roughly 7,500 pounds, highlighting the importance of selecting the appropriate model for specific tasks. Additionally, to understand how heavy a skid loader is, it's important to recognize that the engine type plays a significant role; more robust engines contribute to increased mass, which can affect overall performance and maneuverability.

Attachments further complicate load considerations, as they can significantly affect how heavy a skid loader is overall. For example:

- A standard bucket might add several hundred pounds.

- Specialized attachments like trenchers or augers can add even more weight.

Understanding the implications of these attachments is essential for managers when organizing transportation logistics and ensuring compliance with local regulations for equipment transport. By evaluating the machine's mass in conjunction with its intended function, operators can enhance performance and ensure safety on the job site.

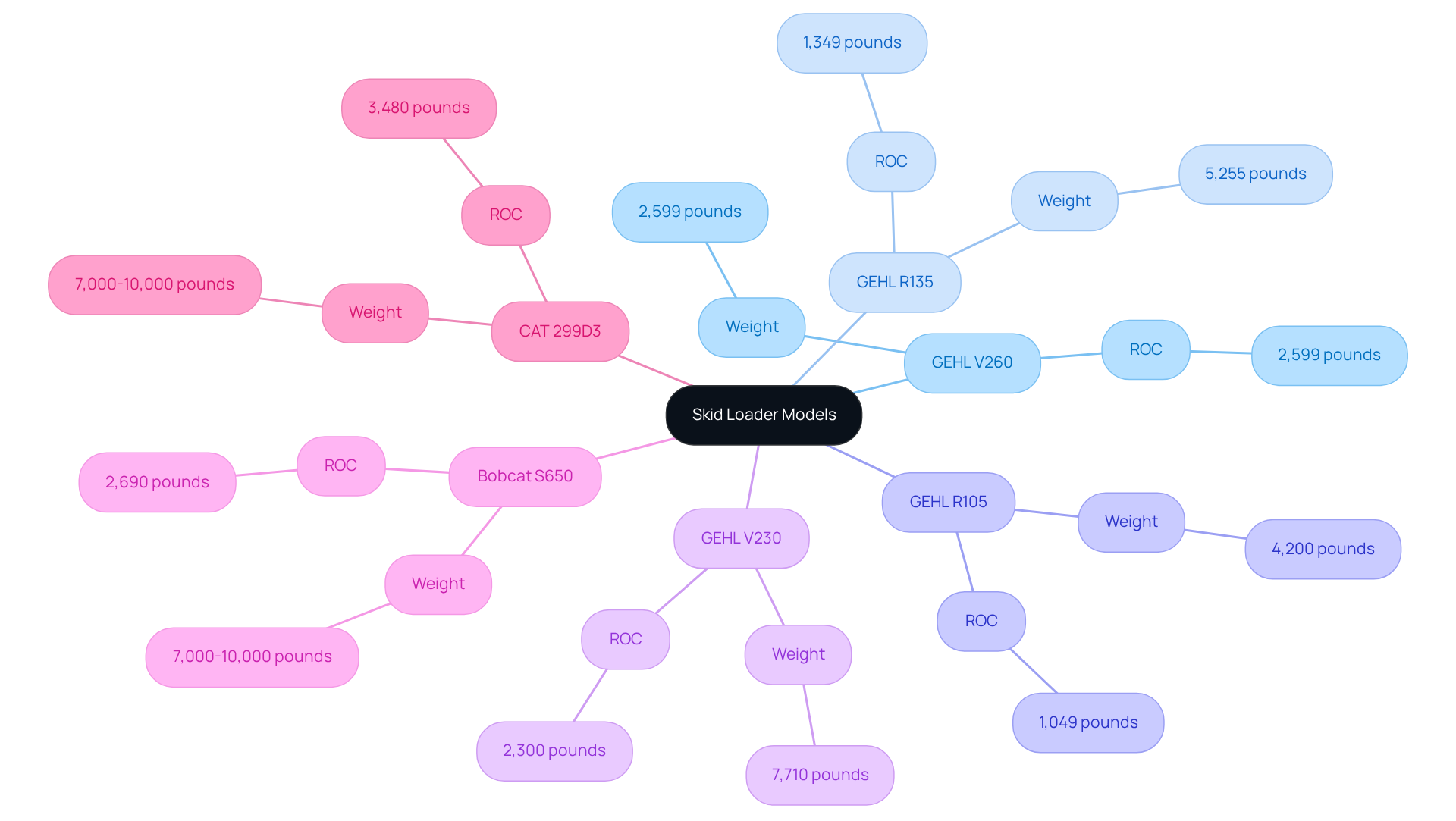

Evaluate Skid Loader Models Based on Weight and Capacity

When evaluating compact vehicle models, managers must prioritize both the mass and the rated operating capacity (ROC) of each unit. The ROC signifies the maximum load a loader can safely lift and transport, making it crucial for ensuring the equipment can handle the materials involved in various projects. For instance, larger models like the GEHL V260, with an ROC of 2,599 pounds, are ideal for heavy-duty tasks, while smaller models, such as the GEHL R135, with an ROC of 1,349 pounds, may suffice for lighter jobs. Additionally, the GEHL R105 loader, with an operating weight of 4,200 pounds and a ROC of 1,049 pounds, illustrates the capabilities of lighter models in specific applications. The GEHL V230, weighing 7,710 pounds with a ROC of 2,300 pounds, serves as a good example of a medium-sized model suitable for various tasks.

Understanding the ROC is critical; it typically ranges from 30 to 50 percent of the tipping load limit, which directly impacts stability and maneuverability. For example, the Bobcat S650 has a ROC of 2,690 pounds, making it suitable for a variety of construction applications. In contrast, the CAT 299D3, with a ROC of 3,480 pounds, is better suited for more demanding tasks.

Real-world examples illustrate the significance of ROC in heavy-duty construction. Large frame skid steers, which weigh between 7,000 and 10,000 pounds and have ROCs exceeding 2,200 pounds, are designed for substantial earthmoving and road building. These machines not only enhance productivity but also ensure safety when handling heavy materials. Furthermore, project managers should consider job site conditions, as access limitations may necessitate the use of compact models.

To make informed decisions, managers should compare manufacturer specifications and consider user reviews, which can provide insights into the performance and reliability of various models. Additionally, understanding the two types of lift paths:

- Radial lift, which is better for digging and grading

- Vertical lift, ideal for loading and lifting to higher heights

can further inform equipment choices. Evaluating the ROC alongside the question of how heavy is a skid loader will lead to better equipment choices that align with specific project requirements.

Understand Rated Operating Capacity and Tipping Load for Safety

The rated operating capacity (ROC) of a skid loader answers the question of how heavy a skid loader can safely lift without the risk of tipping over. The tipping load, which determines how heavy a skid loader can be before it tilts if the cargo is not balanced properly, refers to the mass at which the machine becomes unstable. Understanding these metrics is crucial for project managers to ensure safe operation.

It is advisable to always operate within the ROC and to distribute loads evenly to maintain stability. Familiarizing oneself with the manufacturer's guidelines and safety protocols is essential for mitigating risks associated with equipment operation.

Select the Right Skid Loader for Your Project Requirements

Selecting the right machine for your project necessitates a careful evaluation of the specific tasks at hand, the volume of materials to be handled, and the conditions of the site. It is crucial to assess how heavy is a skid loader and the weight and capacity of various compact vehicle models to ensure they meet your project requirements. For instance, compact vehicles with an operating capacity ranging from 2,001 to 3,000 lbs are prevalent in the market, making them suitable for a diverse array of construction activities. Additionally, the availability of attachments, such as augers and buckets, can significantly enhance the machine's functionality for specialized tasks.

Research indicates that projects utilizing appropriately selected machinery tend to achieve higher success rates, underscoring the importance of making informed choices. Engaging with equipment rental specialists can provide tailored insights and recommendations, including understanding how heavy is a skid loader, ensuring that the selected skid loader aligns with your specific needs. By prioritizing these considerations, you can boost productivity and facilitate the successful completion of your project.

Conclusion

Understanding the weight of a skid loader is crucial for project managers aiming to optimize their operations. Selecting the right skid loader depends not only on its weight but also on its rated operating capacity and the specific project requirements. This knowledge enables managers to make informed decisions that enhance productivity and safety on job sites.

Key factors influencing the weight of skid loaders include:

- Size

- Engine type

- Attachments used

Generally, larger models are heavier and can handle more substantial loads, while smaller models are better suited for lighter tasks. The rated operating capacity (ROC) is vital for maintaining stability and ensuring safe operation, as it dictates how much weight a skid loader can lift without tipping over. By evaluating these aspects, project managers can choose the most suitable skid loader for their needs.

Ultimately, making educated choices regarding skid loader selection can lead to increased efficiency and project success. Engaging with equipment specialists and thoroughly assessing project requirements will ensure that the right skid loader is utilized. This reinforces the importance of understanding the weight of a skid loader within the context of construction and project management.

Frequently Asked Questions

What are skid loaders and their primary uses?

Skid loaders, also known as steer vehicles, are versatile machines used in construction, landscaping, and agricultural projects. They are effective in confined spaces due to their compact size and exceptional maneuverability.

What are the fundamental functions of skid loaders?

The fundamental functions of skid loaders include lifting, digging, and transporting materials, which significantly boost productivity and efficiency on job sites.

What attachments are available for skid loaders?

Common attachments for skid loaders include buckets, forks, and augers, which enhance their effectiveness across different project scenarios.

What factors influence the weight of a skid loader?

The weight of a skid loader is influenced by its size, engine type, and construction materials. Larger models with more powerful engines generally weigh more than smaller models.

What is the typical weight range for skid loaders?

Large-frame compact loaders typically weigh between 7,000 and 10,000 pounds, while small-frame models usually range from 3,000 to 5,000 pounds. The typical mass of compact loaders is roughly 7,500 pounds.

How do engine type and attachments affect skid loader weight?

The engine type significantly impacts the weight of a skid loader, as more robust engines contribute to increased mass. Additionally, attachments can add considerable weight; for example, a standard bucket may add several hundred pounds, while specialized attachments like trenchers or augers can add even more.

Why is understanding skid loader weight important for project managers?

Understanding the weight of a skid loader is crucial for selecting the appropriate model for specific tasks, organizing transportation logistics, and ensuring compliance with local regulations for equipment transport. Evaluating the machine's mass in conjunction with its intended function enhances performance and ensures safety on the job site.

List of Sources

- Understand Skid Loader Basics and Their Importance in Projects

- Amazing Versatility of Skid Steers for Today’s Landscaping Projects - Monster Tires - Industrial Tires, Rubber Tracks & Over The Tire Tracks (https://monstertires.com/versatility-of-skid-steers-for-todays-landscaping-projects?srsltid=AfmBOopGv6-e7MIcSq_CXpzXTa69OsNYQIqQHnTJiUoocwMkOdbPRmll)

- Skid Steer Loader Market Share and Statistics 2025-2035 (https://factmr.com/report/389/skid-steer-loader-market)

- Skid Steer Loaders Market Size, Share & Growth Report, 2032 (https://gminsights.com/industry-analysis/skid-steer-loaders-market)

- Skid Steer Loaders Market Size, Share, Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/skid-steer-loaders-market)

- Skid Steer Loader Market Size & Forecast 2025 to 2035 (https://futuremarketinsights.com/reports/skid-steer-loader-market)

- Identify Factors Affecting Skid Loader Weight

- Mini Skid Steer Weight: How Much Does a Skid Steer Weigh? - Boleo (https://boleous.com/blog/mini-skid-steer-weight)

- How Much Does a Skid Steer Weigh? | BigRentz (https://bigrentz.com/blog/how-much-does-a-skid-steer-weigh?srsltid=AfmBOorhblYw5wbc-bEKMho0f2km6G-YZrhOakXVZuS6PK6nEIEawsoE)

- Skid Steer Weight & Dimensions Guide | Skid Steers Direct (https://skidsteersdirect.com/blogs/news/how-much-does-a-skid-steer-weigh-skid-steer-weight-amp-dimensions?srsltid=AfmBOoqqfHjdHeR9p67YVMyuzxIOUzVj1qj3Evd2PkrvB1hjQpOzpg8s)

- Skid Steer Weight & Dimensions Guide | Skid Steers Direct (https://skidsteersdirect.com/blogs/news/how-much-does-a-skid-steer-weigh-skid-steer-weight-amp-dimensions?srsltid=AfmBOorekNF1i28XktE8-aP3owL_mT5vVvgrJwTyWG-TeYAoMeHfU_1G)

- Understanding Skid Steer Weight: How Much Does a Skid Steer Weigh? (https://dozr.com/blog/how-much-does-a-skid-steer-weigh)

- Evaluate Skid Loader Models Based on Weight and Capacity

- (https://skidsteers.com/blog/skid-steer-sizes?srsltid=AfmBOoqIq6--oqWAWkl2UBa_nVymDO74saFXdjObjOLBzWTnUnED4UhY)

- The Ultimate Skid Steer Specifications, Weight, and Dimensions Guide (https://dozr.com/blog/the-ultimate-skid-steer-spec-guide)

- Skid Steer Size Guide: How to Choose the Right Loader for Your Job | Newman Tractor (https://newmantractor.com/news/skid-steer-sizes)

- Understanding Rated Operating Capacity for Skid Steers (https://gregorypoole.com/operating-capacity-skid-steers)

- Understand Rated Operating Capacity and Tipping Load for Safety

- Skid Loader Lift Capacity: ROC, Tipping Load & Performance - SANY Group (https://sanyglobal.com/blog/skid-loader-lift-capacity)

- Skid Steer Lift Capacity: What You Need to Know (https://fivestarequipment.com/skid-steer-lift-capacity-what-you-need-to-know)

- Skid-Steer Safety for Farm and Landscape (https://extension.psu.edu/skid-steer-safety-for-farm-and-landscape)

- Skid-Steer Loaders - Bobcat Company (https://bobcat.com/na/en/equipment/loaders/skid-steer-loaders)

- Understanding Rated Operating Capacity for Skid Steers (https://gregorypoole.com/operating-capacity-skid-steers)

- Select the Right Skid Loader for Your Project Requirements

- Skid Steer Loader Market Size & Forecast 2025 to 2035 (https://futuremarketinsights.com/reports/skid-steer-loader-market)

- Skid-steer Loaders Market Analysis - US, Canada, China, Germany, UK - Size and Forecast 2024-2028 (https://technavio.com/report/skid-steer-loaders-market-industry-analysis)

- Skid Steer Loaders for Construction Market Size, Share, and Analysis Report 2032 (https://databridgemarketresearch.com/reports/global-skid-steer-loaders-for-construction-market?srsltid=AfmBOorAAvV0RC81qxdDylyer5q2pp8MNsT2omCaRmABwad0gUpEJEVO)

- Skid Steer Loader Market Share and Statistics 2025-2035 (https://factmr.com/report/389/skid-steer-loader-market)