Key Highlights:

- Gather operational data from the forklift's hour metre, including total hours operated and frequency of use.

- Analyse usage patterns to identify peak times for forklift operation, aiding in maintenance planning.

- Calculate utilisation rate by dividing total operated time by total available time; a typical rate is around 75%.

- Benchmark usage metrics against industry standards, noting that forklifts typically operate between 1,500 to 2,000 hours annually.

- Maintain detailed records of usage metrics for future reference, aiding in maintenance scheduling and operational assessments.

- High usage for forklifts is typically defined as over 10,000 to 15,000 hours, depending on equipment type and maintenance history.

- Consult manufacturer guidelines for expected lifespans and maintenance schedules based on operational hours.

- Assess the physical condition of the forklift regularly, focusing on critical areas such as tyres and hydraulic systems.

- Evaluate the operating environment, as harsh conditions can lead to increased wear and tear.

- Ensure operators receive comprehensive training to prevent accelerated wear due to inadequate handling.

- Implement telematics systems for real-time insights into forklift operations, optimising productivity and safety.

- Set usage limits based on industry standards to prevent overuse and prolong equipment lifespan.

- Conduct regular inspections to ensure compliance with guidelines and reveal underutilised or overused equipment.

- Develop training programmes for operators to emphasise effective application and maintenance practises.

- Analyse data from telematics systems to identify usage trends and improve fleet management.

Introduction

Understanding the operational lifespan of a forklift is essential for any business that depends on these machines for efficiency and productivity. Industry standards indicate that a forklift is considered to have high usage after reaching 10,000 to 15,000 hours. Therefore, assessing usage metrics is crucial for effective fleet management.

But how can businesses determine if their forklifts are being overused or underutilized? This article explores best practices for evaluating forklift usage, maintenance needs, and the impact of operating conditions, offering insights that can lead to improved decision-making and enhanced operational efficiency.

Assess Forklift Usage Metrics

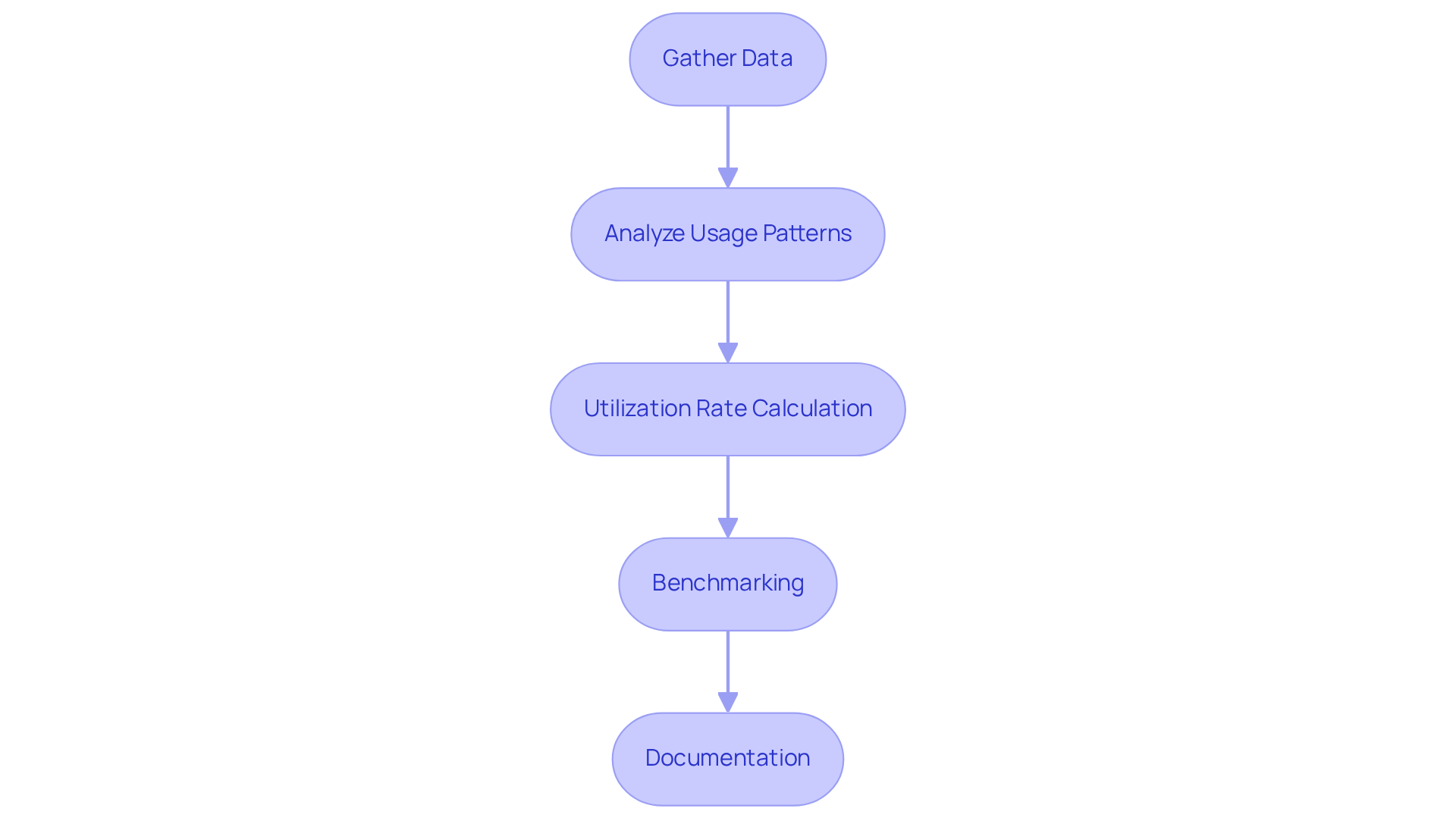

To effectively assess forklift usage metrics, follow these steps:

-

Gather Data: Start by collecting operational data from your lifting vehicle's hour meter. This includes total hours operated, hours per shift, and frequency of use.

-

Analyze Usage Patterns: Next, identify trends in usage. Are there peak times when the forklift is used more frequently? Understanding these patterns is crucial for planning maintenance and enhancing operational efficiency.

-

Utilization Rate Calculation: Calculate the utilization rate by dividing the total time operated by the total available time. For instance, if a forklift is accessible for 40 periods each week and operates for 30 periods, the utilization rate is 75%.

-

Benchmarking: Compare your metrics against industry standards. When considering how many hours on a forklift is a lot, it is typical for forklifts to operate between 1,500 to 2,000 hours annually. This comparison helps assess whether your consumption is above or below average, noting that the construction sector often experiences higher utilization rates due to increased demand.

-

Documentation: Finally, maintain detailed records of all usage metrics for future reference and analysis. This documentation is invaluable for maintenance scheduling and operational assessments, ensuring that your fleet remains efficient and reliable.

Identify High Hour Thresholds

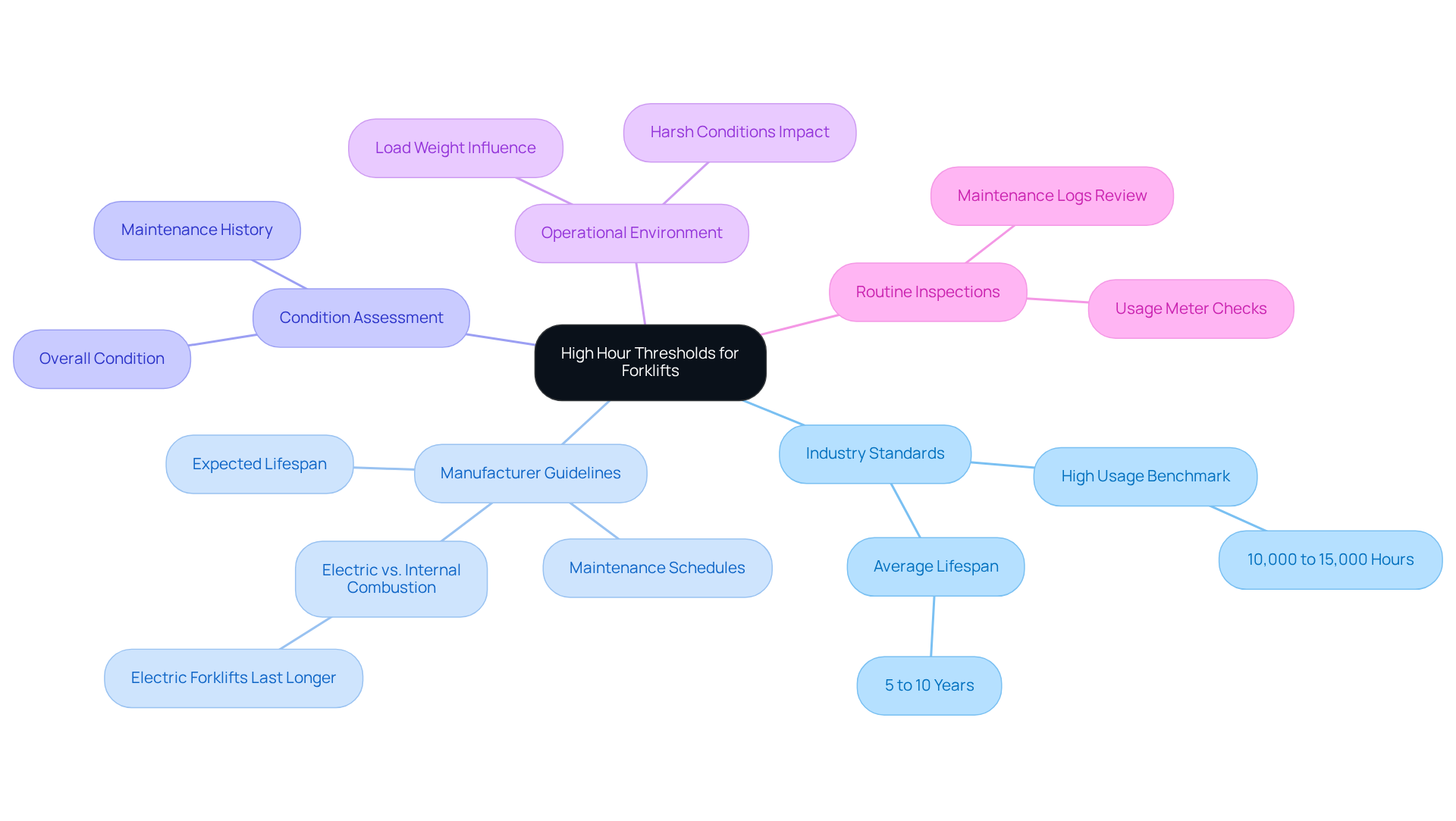

To identify high hour thresholds for forklifts, consider the following key points:

-

According to industry standards, forklifts are usually considered to have high usage when they reach how many hours on a forklift is a lot, specifically over 10,000 to 15,000 hours of operation. This benchmark may vary based on the type of lifting equipment and its maintenance history. The typical lifespan of a lifting truck ranges from 10,000 to 15,000 operating hours, which helps illustrate how many hours on a forklift is a lot, underscoring the importance of tracking usage.

-

Manufacturer Guidelines: It is essential to consult the manufacturer's specifications for your specific lifting equipment model. Many manufacturers provide details on expected lifespans and maintenance schedules based on operational hours, offering valuable insights into longevity and care. Notably, electric lift trucks often last longer than internal combustion models due to having fewer mechanical components and requiring less frequent maintenance.

-

Condition Assessment: The overall condition of the lifting device is critical. A well-maintained unit can continue to operate effectively even when considering how many hours on a forklift is a lot, while a poorly maintained machine may exhibit wear and tear sooner, impacting its reliability. Maintenance history plays a vital role in assessing the remaining life of a lifting vehicle.

-

Operational Environment: The environment in which the lifting device operates significantly influences its lifespan. Forklifts operated under harsh conditions or heavy loads may reach how many hours on a forklift is a lot more quickly, requiring more frequent servicing. Understanding how the lifting vehicle was utilized can provide insights into potential wear and tear.

-

Routine Inspections: Regularly check your lift truck's usage meter and maintenance logs. This proactive approach helps identify potential issues related to high usage, ensuring that the equipment remains in optimal working condition. Additionally, it's worth noting that Toyota lifting devices are known for retaining their resale value even after 10,000 operating hours, highlighting their reliability.

Evaluate Maintenance and Operating Conditions

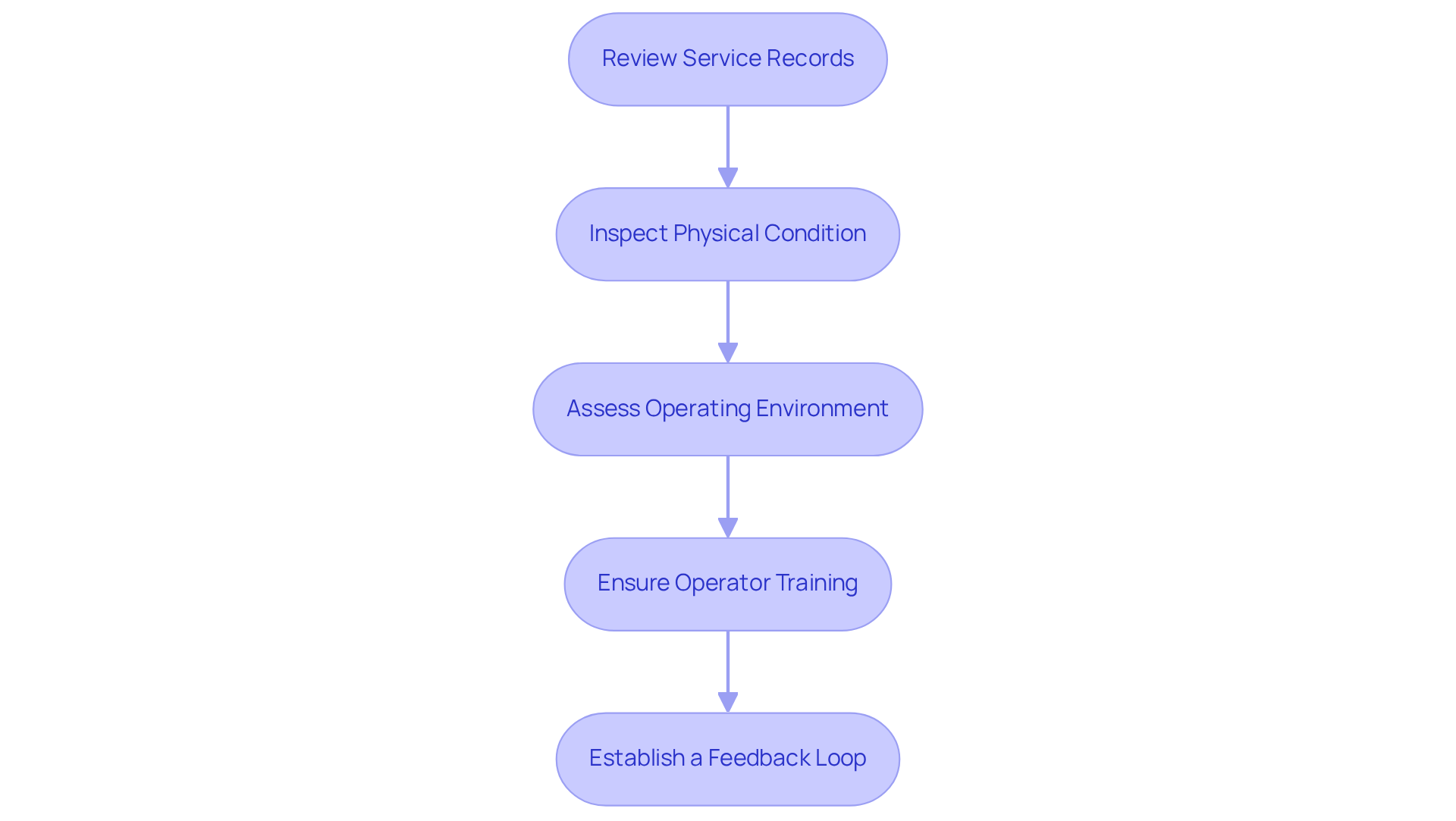

To effectively evaluate maintenance and operating conditions for forklifts, follow these essential steps:

-

Review Service Records: Begin by assessing the vehicle's service history. Regular upkeep should occur every 200-250 hours on a forklift, which raises the question of how many hours on a forklift is a lot for proper maintenance. Renting from a reputable company like EZ Equipment Rental guarantees access to well-maintained lifting machines, which have a history of consistent maintenance that minimizes the risk of breakdowns during critical operations. Be sure to identify any missed services or repairs that could affect performance.

-

Inspect Physical Condition: Conduct a thorough examination of the lifting vehicle, focusing on critical areas such as tire condition, hydraulic systems for leaks, and overall engine performance. Address any visible damage immediately to prevent further issues.

-

Assess Operating Environment: Evaluate the conditions in which the lifting vehicle operates. Equipment used in extreme temperatures, moist conditions, or on rugged terrain typically requires more frequent maintenance and may experience a shortened lifespan.

-

Ensure Operator Training: Confirm that operators receive comprehensive training in safe and efficient vehicle operation. Inadequate handling can lead to questions about how many hours on a forklift is a lot, resulting in accelerated wear and tear and compromising the equipment's longevity.

-

Establish a Feedback Loop: Create a system for operators to report any irregularities or issues they observe during operation. This proactive approach enables early detection of potential problems, enhancing overall safety and efficiency.

Routine checks and maintenance are crucial, as data indicates that vehicles in proper condition operate more efficiently, consume less fuel, and manage loads more effectively. By utilizing a structured inspection checklist, operators can systematically verify the vehicle's physical condition, ensuring compliance with safety standards and reducing the risk of accidents. Furthermore, EZ Equipment Rental's team provides comprehensive support, addressing any issues promptly to minimize downtime. As Burns notes, 'Scheduled upkeep avoids major harm to your lifting machines, guaranteeing their longevity.

Implement Tracking and Management Strategies

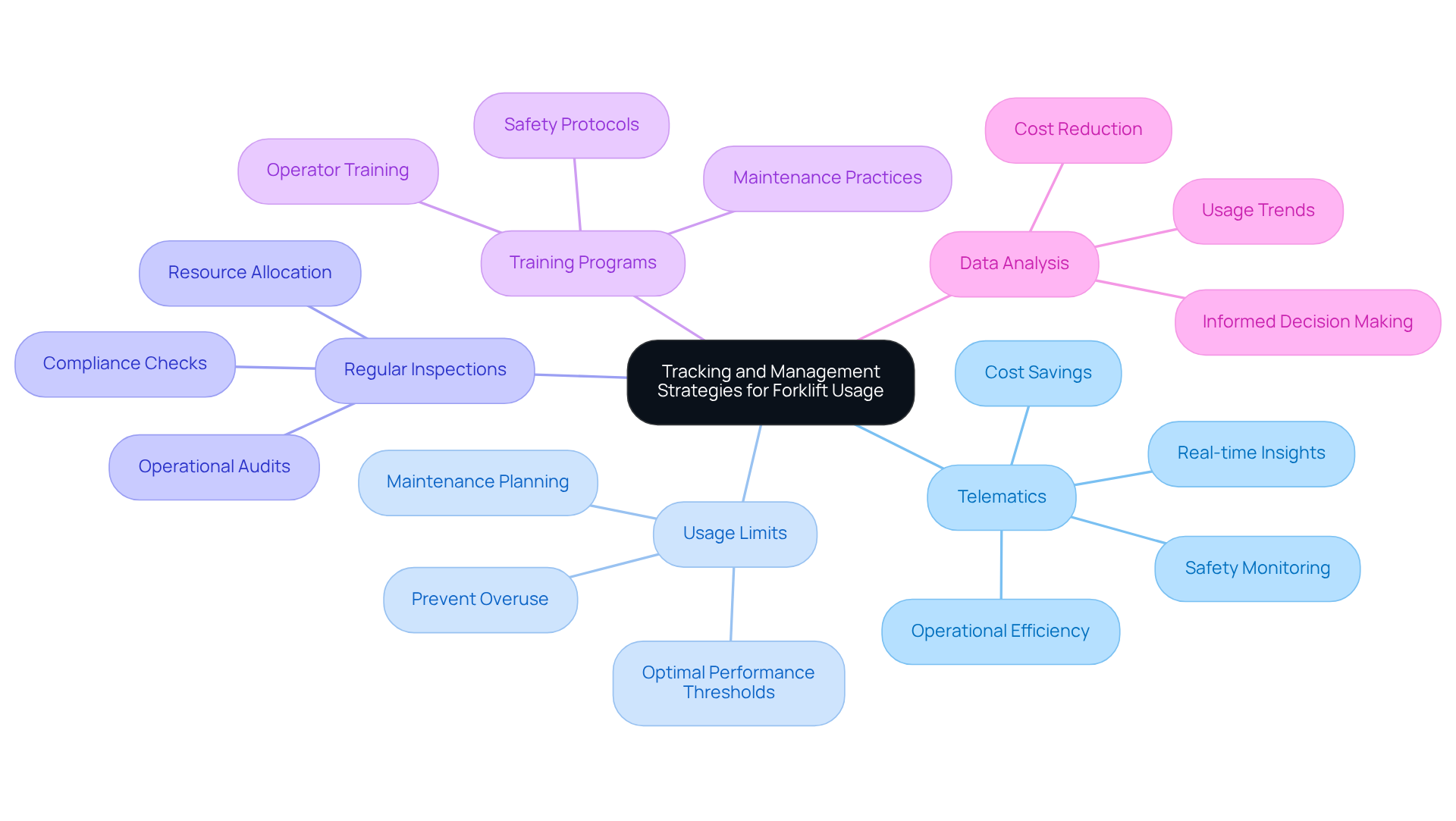

To implement effective tracking and management strategies for forklift usage, consider the following approaches:

-

Utilize Telematics: Investing in telematics systems provides real-time insights into material handling equipment operations, including usage duration, idle periods, and maintenance notifications. Industry data indicates that forklift telematics can identify inefficiencies by analyzing idle times and operational patterns, ultimately optimizing productivity. This technology enhances fleet management and improves safety by monitoring driving behaviors and operational efficiency.

-

Set usage limits based on industry standards, which typically indicate that how many hours on a forklift is a lot is a maximum of 2,000 to 3,000 hours per year for optimal performance. Setting these thresholds aids in planning maintenance and prevents overuse, thereby prolonging the lifespan of the equipment. As noted by Flux Power, "Telematics data is utilized to enhance efficiency, lower operating expenses, track safe (or unsafe) driving behaviors, and keep up with maintenance schedules."

-

Regular Inspections: Conduct routine evaluations of lift truck operations to ensure compliance with established guidelines. These audits can reveal underutilized or overused equipment, allowing for better resource allocation and operational efficiency. A case study titled "Strengthening Forklift Fleet Management with Telematics" illustrates how telematics systems enable managers to make informed decisions based on hard data, improving safety and compliance.

-

Training Programs: Develop comprehensive training programs for operators that emphasize the importance of effective application and maintenance practices. Well-trained operators are essential for extending the life of forklifts and ensuring adherence to safety protocols.

-

Data Analysis: Regularly analyze data collected from telematics systems to identify usage trends and make informed decisions regarding fleet management. This analysis can lead to optimized operations, reduced costs, and improved compliance with safety regulations. By leveraging insights from telematics, managers can proactively address maintenance needs and enhance overall productivity.

Conclusion

Assessing forklift usage is essential for maintaining operational efficiency and maximizing the lifespan of this vital equipment. Understanding what constitutes high usage in terms of hours is not merely about tracking numbers; it requires a thorough evaluation of usage patterns, maintenance practices, and operational conditions. By implementing structured metrics and benchmarks, organizations can ensure their forklifts remain reliable and effective in meeting operational demands.

Key insights emphasize the importance of:

- Data collection

- Usage pattern analysis

- Benchmarking against industry standards

Forklifts typically operate between 1,500 to 2,000 hours annually, with high usage often defined as exceeding 10,000 to 15,000 hours. Regular maintenance, operator training, and the use of telematics systems are crucial strategies that support effective management and tracking of forklift usage. These practices enhance safety and compliance while contributing to cost savings and improved productivity.

Ultimately, effectively assessing and managing forklift usage metrics is integral to ensuring long-term operational success. Organizations are encouraged to adopt these best practices and leverage technology to track and optimize forklift performance. By doing so, they can mitigate risks associated with high usage, enhance safety protocols, and ensure their fleet operates at peak efficiency. Embracing these strategies fosters a more sustainable and productive operational environment, benefiting both the workforce and the bottom line.

Frequently Asked Questions

What is the first step in assessing forklift usage metrics?

The first step is to gather operational data from the forklift's hour meter, including total hours operated, hours per shift, and frequency of use.

How can I analyze forklift usage patterns?

Analyze usage patterns by identifying trends in usage, such as peak times when the forklift is used more frequently. This understanding is crucial for planning maintenance and enhancing operational efficiency.

How do I calculate the utilization rate of a forklift?

The utilization rate is calculated by dividing the total time the forklift has operated by the total available time. For example, if a forklift is accessible for 40 periods each week and operates for 30 periods, the utilization rate would be 75%.

What is the typical annual operating range for forklifts?

Forklifts typically operate between 1,500 to 2,000 hours annually.

Why is benchmarking important in forklift usage assessment?

Benchmarking is important because it allows you to compare your metrics against industry standards, helping you assess whether your forklift usage is above or below average.

What should be done with the usage metrics once collected?

It is essential to maintain detailed records of all usage metrics for future reference and analysis, which is invaluable for maintenance scheduling and operational assessments.

List of Sources

- Assess Forklift Usage Metrics

- US Forklift Market Size, Industry Trends & Share Report 2025 - 2030 (https://mordorintelligence.com/industry-reports/us-forklift-market)

- Forklift Forecast Sharply Revised: What Is Driving Growth? (https://interactanalysis.com/insight/forklift-forecast-sharply-revised)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Forklift Statistics and Facts (2026) (https://news.market.us/forklift-statistics)

- Identify High Hour Thresholds

- Buying a Used Forklift - Do Hours Matter? (https://total-ind.com/blog/purchasing-a-used-forklift-buying-tips?srsltid=AfmBOopCo7KmJTzNprgsHe07ewGN1I1ISFh4oHB3kS0Xdbkel6A5rHI5)

- What Is Considered High Hours on a Forklift? -IAUTA (https://iautamech.com/what-is-considered-high-hours-on-a-forklift)

- What Is Considered High Hours On A Forklift? | Tag Forklifts (https://tagforklifttrucks.co.uk/what-is-considered-high-hours-on-a-forklift)

- How Many Miles and Hours Does a Forklift Travel Per Year? | Forklift Lifespan & Maintenance Tips (https://certifyme.net/osha-blog/how-many-miles-does-an-average-forklift-travel-in-a-year)

- Evaluate Maintenance and Operating Conditions

- Forklift Truck Checklist Analysis: Enhancing Operational Safety - SANY Group (https://sanyglobal.com/blog/forklift-truck-checklist)

- Top Forklift Maintenance Best Practices for Safety and Efficiency (https://nwforklift.com/post/top-forklift-maintenance-best-practices-for-safety-and-efficiency-1)

- The Importance of Regular Forklift Maintenance | Burns (https://burnslift.com/blog/the-importance-of-regular-forklift-maintenance)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- How Often Should You Service Your Forklift? (https://shslift.com/how-often-should-you-service-your-forklift)

- Implement Tracking and Management Strategies

- Key Benefits of Forklift Telematics (https://linkedin.com/pulse/key-benefits-forklift-telematics-precision-installs-llc-0kc5c?trk=public_post)

- How Fleet Telematics Improves Forklift Operations (https://fluxpower.com/blog/how-fleet-telematics-improves-forklift-operations)

- The Benefits of Telematics in Forklift Management | Access Control Group (https://theaccessway.com/the-benefits-of-telematics-in-forklift-management)

- Data-Driven Decision Making: Leveraging Telematics for Fleet Optimization - MH Equipment (https://mhequipment.com/blog/data-driven-decision-making-leveraging-telematics-for-fleet-optimization)