Overview

To buy a boom lift, construction managers should assess key factors such as the type of lift needed, project duration, and cost considerations between new and used models. The article emphasizes that understanding these elements, along with safety training and maintenance requirements, ensures informed decisions that enhance operational efficiency and cost-effectiveness for construction projects.

Key Highlights:

- Boom lifts are categorized into articulating and telescoping models, each suited for different operational needs.

- Key factors for selecting a boom lift include height, load capacity, and working envelope.

- The T 65D model has a load capacity of 450 kg, suitable for heavy-duty tasks.

- North America held 51.9% of the global boom lift market share in 2023, driven by infrastructure developments.

- The Asia Pacific region is projected to grow at a CAGR of 8.4% due to infrastructure initiatives.

- New boom lifts are more expensive but come with the latest technology; used models can offer significant savings.

- Costs for renting a 19-foot electric scissor platform range from $100 to $150 daily.

- Operator training and certification are crucial for safety and compliance, with programs offered by CertifyMeOnline.net.

- Routine inspections and maintenance are essential for safety and performance, with records aiding in compliance.

- Deciding to buy or rent a boom lift depends on the project's duration and frequency of use; ownership is often more cost-effective for long-term projects.

Introduction

In the dynamic landscape of construction and maintenance, boom lifts have emerged as indispensable tools, each tailored to meet specific operational needs. With a variety of configurations, including articulating and telescoping models, these machines offer unparalleled versatility on job sites, whether navigating tight spaces or reaching impressive heights.

As the construction industry continues to evolve, understanding the nuances of boom lift types, costs, safety requirements, and maintenance practices becomes crucial for maximizing efficiency and ensuring safety.

This article delves into the essential aspects of boom lifts, providing insights into their specifications, the financial implications of ownership versus rental, and the importance of operator training, all aimed at empowering project managers and construction teams to make informed decisions that enhance productivity and safety on the job.

Understanding Boom Lift Types and Specifications

Boom platforms are available in various configurations, notably articulating (or knuckle) and telescoping models, each designed to enhance construction efficiency and cater to distinct operational needs. Articulating aerial platforms excel in maneuvering around obstacles, making them an excellent choice for complex job sites, while telescoping models are engineered for maximum vertical reach, ideal for high-rise projects. This adaptability makes aerial platforms crucial tools for different construction and maintenance uses.

When choosing an aerial platform, essential factors to consider include:

- Height

- Load capacity

- Working envelope

For instance, the T 65D model boasts a maximum load capacity of 450 kilograms, suitable for heavy-duty tasks. Terrain evaluation is essential; some devices are designed for rugged environments, while others operate best on flat surfaces.

Examining manufacturer details and discussing with equipment vendors is crucial to guarantee that the selected aerial platform fits the needs of the undertaking. Recent advancements, such as Zoomlion's ZA32RJE electric articulating elevating platform introduced in November 2024 for international markets, exemplify ongoing innovation in elevating technology that enhances task efficiency. Notably, North America accounted for 51.9% of the global market share in 2023, driven by robust infrastructure developments and public investments.

The Asia Pacific area is anticipated to expand at a CAGR of 8.4% owing to increasing infrastructure initiatives and the rise of e-commerce, signifying a growing need for both articulating and telescoping elevating devices. Understanding these factors can significantly enhance efficiency and safety of the endeavor. Significantly, the enhanced effectiveness of aerial platforms makes it wise to buy a boom lift, as they not only facilitate prompt task completion but also generate considerable cost savings, making them a prudent investment for construction endeavors.

Evaluating Costs: New vs. Used Boom Lifts

When assessing the expenses related to obtaining a hydraulic platform, particularly in the DFW Metroplex, it's crucial to take into account the specific project categories and requirements. This area provides a varied selection of equipment rentals and sales services, including:

- Aerial platforms

- Forklifts

- Mini excavators

- More

These play a vital role in deciding whether to rent or buy a boom lift. New aerial platforms usually arrive with the latest technology and guarantees, ensuring reliability but at a considerably higher cost.

In contrast, choosing pre-owned aerial platforms can provide significant savings; however, it's essential to evaluate their condition, maintenance record, and overall lifespan meticulously. To make an informed decision, obtain quotes from multiple suppliers in the Irving area, such as [Local Rental Company Name], and factor in additional expenses such as:

- Transportation

- Insurance

- Potential repair costs

For example, a case study comparing the expenses of new versus pre-owned aerial work platforms indicated that while new models can cost over $50,000, well-maintained second-hand models can be obtained for approximately $30,000, which is a compelling reason to buy a boom lift for considerable savings.

By conducting comprehensive research and thorough inspections, you can navigate the complexities of this investment and ensure a financially sound choice that meets your specific requirements.

Safety First: Training and Certification Requirements

Before deciding to buy a boom lift for residential construction projects in Dallas, it is imperative that all operators undergo thorough training and certification, especially for services like roofing repairs and exterior painting. This training must encompass a comprehensive understanding of the apparatus's controls, safety features, and operational limits. Effective training programs should include modules on:

- Hazard recognition

- Safe operating procedures

- Emergency response protocols

This ensures that operators are well-prepared for any situation.

CertifyMeOnline.net highlights the availability of a complete range of training courses for aerial devices, scissor platforms, and mobile elevated work platforms (MEWPs), improving both safety and compliance within the industry. Notably, CertifyMeOnline offers a 100% money-back guarantee for unsatisfied customers, making it a risk-free option for construction teams.

Moreover, workers can be trained and certified to operate aerial equipment in as little as one afternoon, making it a practical choice for busy construction schedules. Adherence to OSHA certification is crucial, as it confirms operators' understanding of safe aerial equipment usage and greatly decreases the likelihood of accidents—a vital element for ensuring efficiency in residential tasks. The case study titled 'How to Stay Safe on Aerial Lifts' underscores the importance of understanding hazards and compliance with OSHA certification to prevent accidents.

Routine evaluations of safety protocols and continuous refresher training are crucial for ensuring your team is knowledgeable and ready for any operational challenges, highlighting the importance of elevating equipment, especially when you buy a boom lift, in improving safety and efficiency in Dallas construction projects. Furthermore, renting aerial platforms from EZ Equipment Rental offers construction crews access to top-notch machinery without the responsibility of ownership, allowing them to effectively carry out tasks while upholding safety standards.

Logistics of Ownership: Inspection and Maintenance Essentials

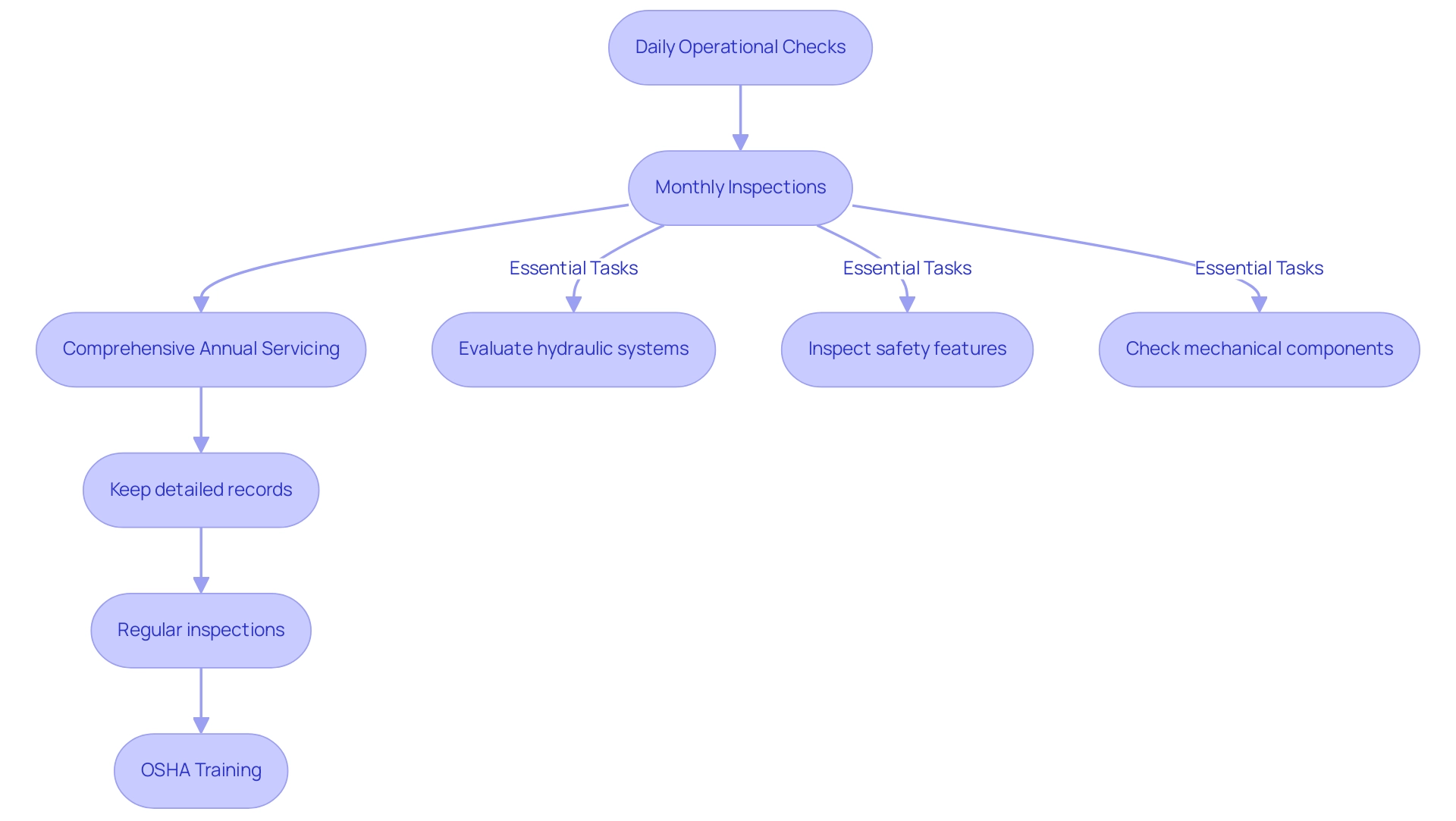

Owning a boom lift requires a serious commitment to ongoing inspections and upkeep to ensure safety and performance. Establishing a solid upkeep schedule is essential, which should include:

- Daily operational checks

- Monthly inspections

- Comprehensive annual servicing carried out by certified technicians

Essential upkeep tasks comprise:

- Thorough evaluations of hydraulic systems

- Meticulous inspections of safety features

- Confirmations that all mechanical components are in optimal working order

According to recent reports, it is advisable to keep detailed records of all inspections and servicing activities, as this not only helps in adhering to safety regulations but also aids in tracking the elevator's performance over time. Service professionals emphasize that regular inspections can significantly lower expenses related to unforeseen repairs, with average upkeep costs expected to be manageable in 2024. In practice, a well-cared-for aerial platform can result in increased longevity and reduced downtime, making adherence to a careful upkeep schedule not just a regulatory requirement, but a wise investment.

Furthermore, industry statistics suggest that inspections should be conducted regularly, with many operators opting for bi-weekly checks to stay ahead of potential issues. Significantly, OSHA training for operators ranges from $30 to $80 per individual, highlighting the necessity of adequate training concerning upkeep and inspections. Furthermore, a case study shows that the expense of manlifts differs greatly; for example, electric scissor devices begin at approximately $12,000 for 19 feet tall versions, whereas aerial platforms can surpass $150,000 for elevations up to 110 feet, emphasizing the financial impacts of upkeep and inspections.

By implementing these best practices, equipment owners can ensure their machinery remains safe and efficient, thus enhancing overall operational productivity. As Rhett C., a Certified Heavy Equipment Appraiser, notes, 'Regular maintenance not only prolongs the life of the equipment but also ensures compliance with safety standards, ultimately protecting your investment.

Buying vs. Renting: Making the Right Choice for Your Project

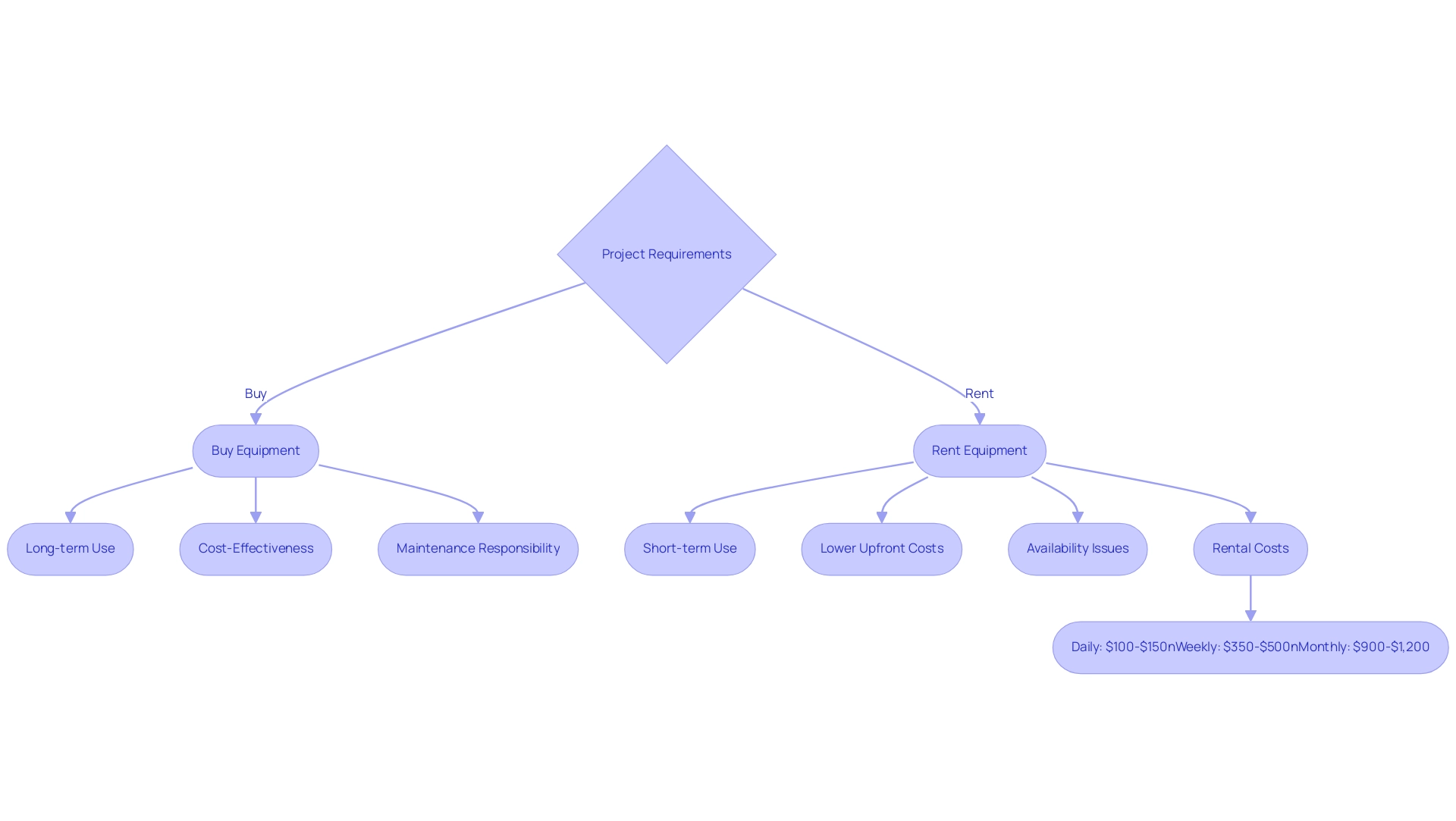

When considering whether to buy a boom lift or lease a hydraulic platform, it’s essential to assess your task’s length and the frequency with which you expect to utilize the equipment. According to CEIC data, Germany's urban population reached 65.7 million in 2023, marking a 0.97% annual growth, which reflects the increasing demand for construction machinery such as boom devices in urban areas. For projects requiring consistent elevation access over an extended period, ownership often proves to be more cost-effective.

In contrast, for shorter-term tasks, renting can significantly reduce upfront expenditures and alleviate maintenance obligations. For instance, renting a 19-foot electric scissor platform typically incurs costs ranging from:

- $100 to $150 daily

- $350 to $500 weekly

- $900 to $1,200 monthly

Understanding these rental rates is essential in balancing your budget against operational needs.

Additionally, consider rental terms, including delivery and pickup fees, and juxtapose these with the total cost of ownership. However, rental options may be restricted by local stock levels or regional demand, potentially requiring substitutes, which can disrupt timelines. As highlighted in the case study titled 'Drawbacks of Renting Aerial Lifts,' while renting has benefits, it can become costly over time, especially for long-term use, and availability issues during peak times can impact productivity.

As the boom lift rental market continues to evolve, particularly in regions like Germany, project managers should thoroughly assess their timelines and budgets to make informed decisions on when to buy a boom lift that align with their operational requirements. Such considerations not only enhance efficiency but also mitigate potential disruptions caused by rental availability during peak demand periods.

Conclusion

Boom lifts play a pivotal role in the modern construction and maintenance landscape, offering unmatched versatility through various configurations tailored to specific operational needs. Understanding the differences between articulating and telescoping models is essential for maximizing efficiency, as each type excels in distinct environments. Additionally, careful evaluation of costs—whether opting for new or used equipment—enables project managers to make financially sound decisions that align with their budget and project requirements.

Safety and training are paramount when operating boom lifts. Comprehensive training programs ensure that operators are well-prepared to handle the equipment responsibly, minimizing risk and enhancing workplace safety. Compliance with OSHA standards not only safeguards workers but also promotes operational efficiency, making it crucial for teams involved in construction projects.

Moreover, the logistics of ownership, including regular maintenance and inspection, cannot be overlooked. A robust maintenance schedule not only prolongs the lifespan of boom lifts but also ensures compliance with safety regulations, ultimately protecting investments in equipment. For teams weighing the options of buying versus renting, understanding project timelines and usage frequency is key to making informed choices that optimize resource allocation.

In conclusion, the strategic use of boom lifts significantly enhances productivity and safety on job sites. By considering the nuances of equipment selection, costs, training requirements, and maintenance practices, construction teams can effectively navigate the complexities of their projects. Embracing these insights will empower project managers to harness the full potential of boom lifts, ensuring both successful project outcomes and a commitment to safety in the ever-evolving construction industry.

Frequently Asked Questions

What types of boom platforms are available and what are their main features?

Boom platforms come in two main types: articulating (or knuckle) and telescoping models. Articulating platforms excel in maneuverability around obstacles, making them suitable for complex job sites. Telescoping models are designed for maximum vertical reach, ideal for high-rise projects.

What factors should be considered when choosing an aerial platform?

Essential factors to consider include height, load capacity, and working envelope. For example, the T 65D model has a maximum load capacity of 450 kilograms, suitable for heavy-duty tasks.

How does terrain affect the choice of an aerial platform?

Terrain evaluation is crucial as some aerial platforms are designed for rugged environments while others operate best on flat surfaces.

Why is it important to examine manufacturer details and discuss with equipment vendors?

It is important to ensure that the selected aerial platform fits the specific needs of the project, which can vary widely based on operational requirements.

What recent advancements have been made in aerial platform technology?

Recent advancements include the introduction of Zoomlion's ZA32RJE electric articulating elevating platform in November 2024, which enhances task efficiency.

What is the market trend for aerial platforms in North America and the Asia Pacific?

North America accounted for 51.9% of the global market share in 2023, driven by infrastructure developments. The Asia Pacific region is expected to grow at a CAGR of 8.4% due to increasing infrastructure initiatives and the rise of e-commerce.

What are the financial considerations when obtaining a hydraulic platform?

It's important to assess project categories and requirements, considering whether to rent or buy a boom lift. New aerial platforms come with the latest technology but at a higher cost, while pre-owned platforms can offer significant savings.

What additional expenses should be factored in when purchasing a boom lift?

Additional expenses may include transportation, insurance, and potential repair costs.

How does the cost of new aerial platforms compare to pre-owned models?

New aerial platforms can cost over $50,000, whereas well-maintained second-hand models can be obtained for approximately $30,000, highlighting significant savings when choosing used equipment.

What should be done to ensure a financially sound choice when investing in aerial platforms?

Conduct comprehensive research, thorough inspections, and obtain quotes from multiple suppliers to navigate the complexities of the investment and meet specific requirements.