Overview

The article focuses on how to choose and effectively use 60/10000 grit sandpaper, highlighting the importance of selecting the right grit for specific tasks in woodworking and construction. It emphasizes that starting with coarser grits for material removal and progressively moving to finer grits enhances the quality of the finish, supported by expert recommendations and best practices for sanding techniques.

Introduction

In the realm of construction and woodworking, the choice of sandpaper can make or break a project. With a vast array of grit levels ranging from coarse 60 to ultra-fine 10000, understanding the nuances of sandpaper is essential for achieving the desired finish.

This article delves into the intricacies of sandpaper selection, offering insights into:

- Grit classifications

- Material considerations

- Effective sanding techniques

By equipping construction project managers with the knowledge to navigate these options, the article aims to enhance the quality of workmanship and streamline project execution. As the demand for precision in sanding grows, mastering these elements is key to unlocking superior results and ensuring project success.

Understanding Grit Levels: From 60 to 10000 Sandpaper

Sandpaper texture is categorized using a numerical system that reflects the size of the abrasive particles. For instance, a particle size number of 60/10000 corresponds to larger particles, which are effective for initial sanding and heavy material removal, making it an ideal choice for rough shaping of wood. On the other hand, as the abrasive number rises, the particle size decreases, with ultra-fine abrasives like 60/10000 being employed for polishing areas to attain a smooth finish.

This hierarchy is crucial for construction project managers who need to select the appropriate material for specific tasks, such as shaping wood or preparing surfaces for finishing. It's important to note that sandpaper is divided into microgrids and microgrits, with microgrids used for coarser applications and microgrits for finer finishes. According to the micron sequence outlined in GOST 9206-80, the progression of abrasive sizes follows:

- 1

- 2

- 3

- 5

- 7

- 10

- 14

- 20

- 28

- 40

- 60

Understanding these classifications helps in making informed decisions, ultimately enhancing the quality of workmanship. As emphasized by Chris Deziel, a freelance service journalist, 'the appropriate abrasive selection can significantly influence the final outcome,' underscoring the importance of precision in abrasive choice for woodworking applications. Furthermore, the intricacies related to value charts, as detailed in the case study, highlight the difficulties in interpreting markings across various standards, which is especially important for construction project managers when choosing the suitable abrasive material for their projects.

Choosing the Right Sandpaper for Your Project

Choosing the right abrasive material is crucial for achieving the desired finish on any project. Begin by evaluating the material at hand and the finish you aim to achieve. For rough shaping tasks, beginning with 60 mesh abrasive is advisable; this texture is effective for removing material quickly.

As you advance to intermediate refinement, switching to 120 mesh enables smoother surfaces. For the ultimate finishing touches, consider using abrasive paper with a texture of 400 or higher to achieve that polished appearance. Industry experts recommend always testing a small area first to ensure compatibility with the material, as this minimizes the risk of damage and ensures satisfaction with the final outcome.

Additionally, be mindful of whether your project requires wet or dry abrasive sheets; using the appropriate type can prevent clogging and improve the overall finishing process. Kristin Salaky, a contributing writer, notes that "extra coarse sandpaper ranges from #24 to #36 grit. This is the most abrasive type and works well for heavy-duty projects and tough jobs."

This recommendation aligns with current trends that prioritize efficiency and quality in surface finishing. Furthermore, pole sanders, which permit smoothing in an upright position, are particularly useful for walls, ceilings, and floors. When selecting the appropriate sandpaper texture, the case study on selecting sandpaper shows that extra coarse paper is effective for industrial work, shaping wood, removing rust, and finishing old hardwood floors, but care must be taken to avoid surface damage.

Comprehending these elements is crucial for construction project managers to remain updated on the latest material selection strategies.

Techniques for Effective Sanding with 60/10000 Grit Sandpaper

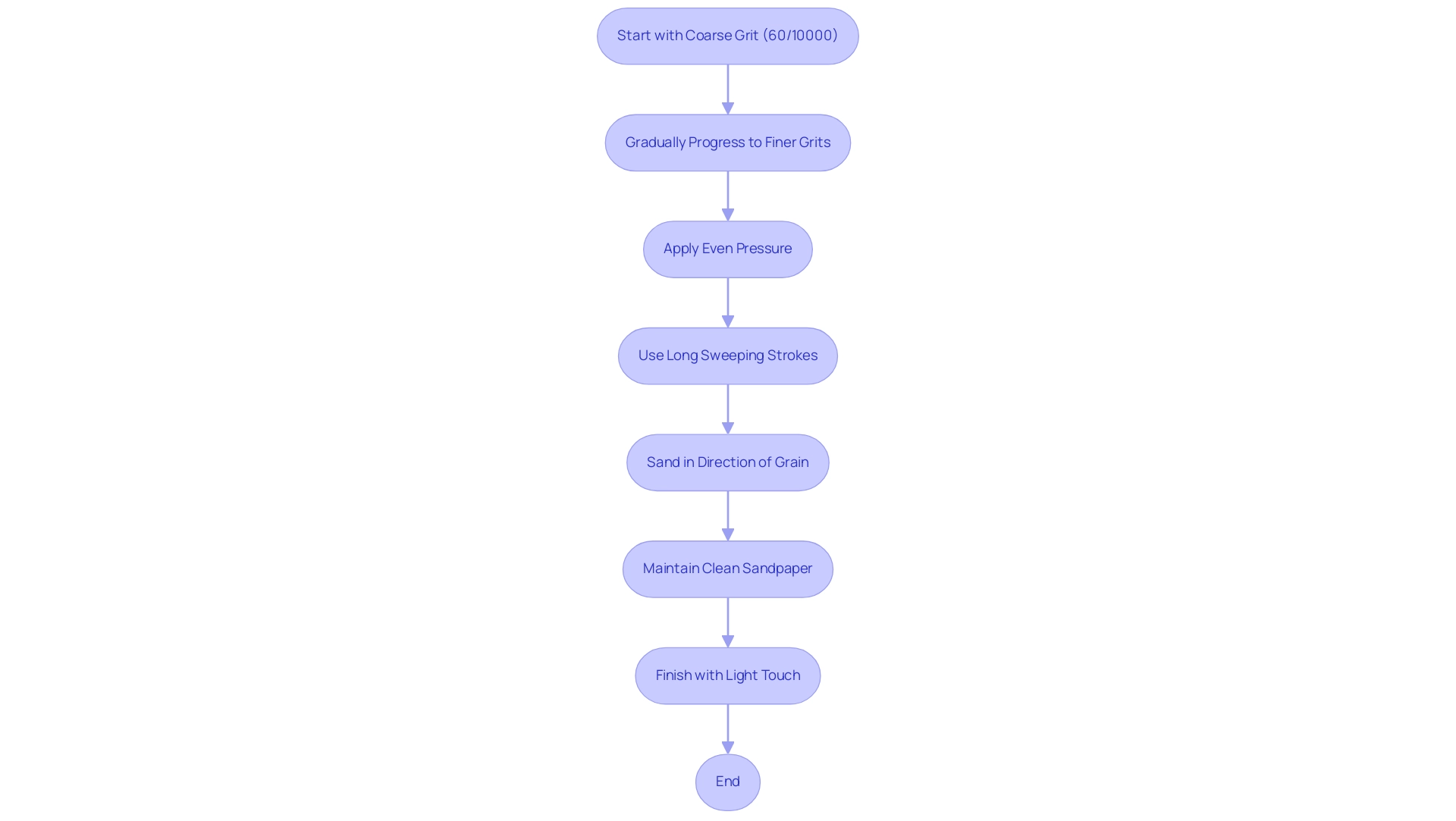

To achieve optimal sanding results, it is essential to start with the coarsest grit, such as 60/10000, and gradually progress to finer grits. This method enables the efficient elimination of material while minimizing the risk of damage to the exterior. Apply even pressure and long, sweeping strokes to achieve a consistent finish and avoid irregularities.

When working with extremely fine grits like 60/10000, apply a light touch to polish the area without excessively removing material. Always sand in the direction of the grain to avoid unsightly scratches and maintain the wood's natural beauty. To ensure maximum efficiency, keep the abrasive paper clean; periodically tap it against a hard surface to dislodge dust buildup.

This practice will help maintain the sandpaper's performance throughout the preparation process, ultimately leading to higher-quality results. Experts highlight the significance of these techniques, noting that proper smoothing not only enhances the aesthetics of the wood but also contributes to its durability. For example, a recent study emphasized that using the correct smoothing methods can produce substantial enhancements in finish quality, showcasing the importance of careful preparation in woodworking.

In terms of technical credibility, typical end-grain SEM micrographs demonstrate that using P100-120-grit and P100-150-grit sandpapers results in optimal coated red oak finishes, highlighting the effectiveness of these grit levels. Moreover, a quote from woodworking experts reinforces this point, indicating that proper smoothing techniques can lead to an 18% increase in shear strength and a 31% increase in impact strength when applied correctly, as seen in the study involving rGO in PA66 nanofiber. Furthermore, the case study on plasma treatment optimization demonstrates the critical role of treatment processes, linking effective sanding techniques to enhancements in quality and durability.

Material Matters: The Role of Silicon Carbide in Sandpaper

Silicon carbide stands out as a preferred option for sandpaper, celebrated for its exceptional sharpness and durability. This abrasive material excels across a range of substrates, including wood, metal, and plastic. Unlike aluminum oxide, which is often recommended for wood applications, silicon carbide is particularly suited for achieving a fine finish on harder surfaces.

Its unique properties make it an excellent choice for wet abrasion, as it effectively resists clogging and maintains consistent performance under damp conditions. When choosing abrasive paper, it’s crucial to consider the specific material you’re working with; silicon carbide's versatility and effectiveness in various sanding scenarios make it a valuable asset in your toolkit. Given the tight deadlines often faced in construction projects, the efficiency of silicon carbide can significantly enhance productivity.

The market share of silicon carbide in abrasive production continues to grow at a rate of 60/10000, with recent insights indicating a notable increase in market volume and value, reinforcing its position as a top choice for professionals in the construction industry. Experts, including material scientists, have noted that 'the performance of silicon carbide in demanding applications is unmatched, particularly when precision and finish quality are paramount.' Recent research highlights its benefits over aluminum oxide, further solidifying its reputation as a superior material for construction project managers seeking effective solutions.

![]()

Purchasing Sandpaper: Packaging, Delivery, and Customization Options

For construction project managers, purchasing abrasives in bulk can lead to substantial cost savings, particularly for larger projects. Analysts forecast a CAGR of 6% by 2028 for the ultra-fine abrasive paper market, indicating significant growth potential. Many suppliers, including major companies like 3M Company and MSC Industrial Direct Co., Inc., are now providing customizable packs, allowing you to select specific grits tailored to your project requirements.

This trend aligns with the growing consumer demand for health and wellness features in various tools and materials, as highlighted in a recent case study focusing on this shift. Market Research Intellect observes that current trends in the dry abrasive market include significant technological innovations and changing consumer preferences. When considering your options, evaluate delivery timelines carefully; some suppliers may offer expedited shipping to meet urgent project deadlines.

Additionally, local hardware stores can be a valuable resource, providing instant access to abrasive sheets without the prolonged wait times often linked to online orders. Always verify packaging details to ensure that you source the correct quantity and type of sandpaper needed for your tasks, maximizing efficiency and minimizing waste.

Conclusion

Selecting the right sandpaper is crucial for achieving high-quality finishes in construction and woodworking projects. The article has outlined the importance of understanding grit levels, emphasizing that starting with coarse grits, such as 60, and progressively moving to finer grits, like 10000, can significantly enhance the quality of the final product. Each grit serves a specific purpose, from heavy material removal to delicate polishing, and knowing when to use each type is essential for project managers aiming for precision.

Material choice also plays a pivotal role in sanding effectiveness. Silicon carbide, with its superior sharpness and durability, is ideal for a variety of substrates, including wood and metal. Its performance in both dry and wet conditions makes it a preferred option among professionals, ensuring that the sanding process is efficient and effective, even under tight deadlines.

Finally, purchasing strategies can impact the overall efficiency of project execution. Bulk buying and customizable packaging options allow for tailored solutions that meet specific project needs while optimizing costs. By considering delivery timelines and local resources, project managers can ensure they have the right materials at the right time, enhancing productivity and project outcomes.

In conclusion, mastering the selection and application of sandpaper is vital for achieving superior results in construction and woodworking. Understanding grit classifications, choosing the appropriate materials, and implementing effective purchasing strategies are key components that can lead to enhanced quality and efficiency. As the demand for precision continues to grow, equipping oneself with this knowledge will undoubtedly contribute to the success of any project.

Frequently Asked Questions

How is sandpaper texture categorized?

Sandpaper texture is categorized using a numerical system that reflects the size of abrasive particles. A lower particle size number, like 60, corresponds to larger particles suitable for heavy material removal, while higher numbers indicate smaller particles for finer finishes.

What is the significance of the particle size number in sandpaper?

The particle size number is crucial for selecting the appropriate sandpaper for specific tasks. Lower numbers are used for rough shaping, while higher numbers are used for polishing and achieving a smooth finish.

What are microgrids and microgrits in sandpaper?

Sandpaper is divided into microgrids for coarser applications and microgrits for finer finishes. This classification helps users choose the right type of sandpaper based on their project needs.

What is the micron sequence for abrasive sizes according to GOST 9206-80?

The micron sequence for abrasive sizes includes: 1, 2, 3, 5, 7, 10, 14, 20, 28, 40, and 60. This progression helps in understanding the different levels of abrasiveness.

What is the recommended approach for selecting abrasive materials for woodworking?

Start by evaluating the material and desired finish. For rough shaping, use 60 mesh abrasive; for intermediate refinement, switch to 120 mesh; and for final finishing touches, use 400 mesh or higher.

Why is it important to test a small area before using sandpaper?

Testing a small area ensures compatibility with the material, minimizes the risk of damage, and helps achieve satisfaction with the final outcome.

What should be considered when choosing between wet or dry abrasive sheets?

The type of abrasive sheet affects clogging and the overall finishing process, so selecting the appropriate type is essential for optimal results.

What is the range of grit for extra coarse sandpaper, and what is its typical use?

Extra coarse sandpaper ranges from #24 to #36 grit and is suitable for heavy-duty projects, tough jobs, and industrial work.

How do pole sanders enhance the sanding process?

Pole sanders allow for smoothing surfaces while standing upright, making them particularly useful for walls, ceilings, and floors.

What are the key steps in the sandpaper selection process?

The key steps include evaluation of the material, rough shaping, intermediate refinement, and final touches, each represented by different stages in the selection process.