Introduction

In the dynamic world of construction, boom lifts play a pivotal role in enhancing productivity and safety on job sites. With various types tailored to meet specific needs, understanding the differences between telescopic, articulating, towable, and straight mast boom lifts is crucial for selecting the right equipment. As technology continues to advance, so too does the capability of these machines, making it essential for operators and project managers to stay informed about the latest innovations and safety protocols.

This article delves into the different types of boom lifts, offers guidance on selecting the appropriate lift for specific projects, and outlines essential safety measures to ensure smooth operations, ultimately empowering professionals to make informed decisions in their construction endeavors.

Understanding the Different Types of Boom Lifts

Boom platforms are essential tools in construction, available in several types, each tailored for specific applications:

- Telescopic Boom Elevators: These devices are engineered to extend vertically, making them ideal for accessing elevated areas. The extensive working envelope of the boom lift 60 is particularly advantageous for outdoor construction tasks, allowing for efficient operation in large spaces.

- Articulating Aerial Platforms: Featuring joints that provide enhanced flexibility, articulating aerial platforms excel in maneuvering around obstacles. This versatility makes them suitable for both indoor and outdoor tasks where agility is crucial, such as in complex construction sites.

- Towable Aerial Platforms: Created for portability, towable aerial platforms can be effortlessly towed behind a vehicle, making them highly convenient for smaller tasks or projects that require mobility between different locations. Their lightweight design allows for quick setup and operational efficiency.

- Straight Mast Boom Elevators: These devices focus on vertical reach, making them particularly useful for construction and maintenance tasks that demand height without lateral movement. They are frequently utilized in situations where accurate elevation is crucial.

Recent advancements in aerial work platform technology highlight the continuous development of these tools. For instance, Sinoboom recently launched the world's largest articulating lift, achieving a platform height of 46.3 meters, which expands operational capabilities in construction. Furthermore, J.C. Bamford Excavators Limited (JCB) launched the T 65D-powered telescopic lifting platform in India, highlighting dependability and security in its design.

According to JCB, 'Our T 65D-powered telescopic lift platform is designed to meet the highest standards of reliability and safety, ensuring optimal performance on the job site.' These advancements indicate a wider pattern in the industry, where the expansion in telecommunication and construction fields, along with urbanization in the Asia-Pacific area and eased foreign direct investment regulations in India, acts as essential motivators for the boom lift 60 market despite obstacles presented by the continuing impacts of COVID-19. Comprehending these variations of aerial platforms and their uses will enable you to select the appropriate equipment that corresponds with your requirements and limitations.

Furthermore, it is crucial to take into account particular data concerning the categories of aerial platforms utilized in construction and market share to substantiate the assertions regarding the advancement and development of aerial platform technology.

How to Select the Right Boom Lift for Your Project

To choose the appropriate aerial platform for your project in the DFW Metroplex, follow these steps:

- Assess Your Project Requirements: Determine the height you need to reach, the weight of materials or personnel being lifted, and the working environment (indoor vs. outdoor).

- Consider the crane's capacity: Each aerial platform has a maximum weight limit. Ensure that the elevator you select can manage the weight you intend to raise safely.

- Assess the Landscape: If your undertaking is on irregular terrain, consider an articulating platform that can maneuver around barriers. For flat surfaces, a telescopic apparatus may suffice.

- Check for Power Source Alternatives: Electric aerial platforms are quieter and appropriate for indoor use, while engine-driven hoists are more suitable for outdoor tasks. Choose based on your specific site conditions.

- Review Safety Features: Look for aerial work platforms equipped with safety features such as emergency stop buttons, guardrails, and stability controls to ensure the safety of operators and workers.

- Consult with Equipment Suppliers: Discuss your requirements with local equipment rental companies in Irving, TX. They provide a range of equipment including particular types of aerial platforms, such as telescopic and articulating versions, along with forklifts and mini excavators. They can provide recommendations based on their inventory and your specific requirements.

- Understand the Rental Process: Familiarize yourself with the rental process, including how to reserve equipment, the duration of rentals, and any required deposits or insurance. Ask about cost alternatives to guarantee you remain within your financial plan.

By adhering to these guidelines and utilizing the equipment rental services offered in the DFW Metroplex, you can assuredly choose a crane that fulfills your project requirements, ensuring efficiency and security throughout the construction process.

Preparing for Boom Lift Operation

Prior to using an elevating platform, it is vital to adhere to these important preparation steps to ensure security and compliance:

-

Conduct a Pre-Operation Inspection: Thoroughly check the aerial platform for any visible damage or wear. Pay particular attention to the hydraulic systems, tires, and controls, ensuring that everything functions correctly and safely.

-

Read the Operator's Manual: Acquaint yourself with the specific model's operating instructions and safety guidelines. Each boom lift may feature unique mechanisms and requirements that are vital for safe operation.

-

Ensure Proper Training: It is illegal for anyone to operate an aerial platform without the correct training. All operators must be adequately trained and certified, covering essential safety protocols and emergency procedures. The Rental Guys provide OSHA-compliant training programs that integrate theoretical knowledge with practical experience, addressing proper equipment control, mechanics, pre-operational inspections, and emergency protocols. This comprehensive approach ensures that trainees gain a well-rounded certification demonstrating their ability to operate hoists safely and efficiently. As The Rental Guys emphasize,

Choose The Rental Guys for your certification journey, and ascend to new heights in occupational well-being and career advancement.

-

Establish a Work Zone: Create a designated work area that is free of obstacles and hazards. Employ barriers or cones to prevent unauthorized individuals from entering the working zone of the elevator, improving protection for all present.

-

Plan for Emergency Situations: Develop a robust emergency response plan that outlines procedures for potential accidents or equipment failures. Ensure all operators are knowledgeable about this strategy to respond swiftly and efficiently if problems occur.

By executing these preparatory measures, you not only boost security but also enhance the effectiveness of aerial platform operations on your project site.

Operating the Boom Lift Safely

Using a boom lift 60 securely requires strict adherence to established precautionary guidelines. Here are essential practices to follow:

-

Wear Appropriate Personal Protective Equipment (PPE): It is essential to equip yourself with necessary PPE, including a hard hat and harness.

These protective measures help mitigate risks associated with falls and other workplace hazards. As Iman Nordin, a Transportation Electrification Manager, emphasizes, raising awareness about equipment security through NIOSH's educational tools and products is vital to preventing accidents. Always operate the boom lift 60 in accordance with the manufacturer's instructions.

Familiarize yourself with the controls, operational limits, and safety features. Proper adherence to these instructions minimizes the likelihood of mishaps during operation.

-

Maintain a Safe Distance from Hazards: Ensure the boom lift 60 apparatus is kept a safe distance from power lines, edges, and other potential hazards.

Being acutely aware of your surroundings while using the elevator is critical to preventing accidents. Statistics reveal that 48 fatalities in aerial operations stemmed from slips, trips, and falls, underscoring the need for vigilance and the importance of comprehensive training and strict adherence to ANSI and OSHA standards.

-

Use Proper Operating Techniques: Smooth, deliberate movements are essential when operating the boom lift 60 apparatus.

Avoid abrupt actions and always elevate or lower the mechanism gradually to maintain stability and control during operations.

-

Communicate with Ground Personnel: Establish clear communication with ground personnel using hand signals or radios.

Effective coordination ensures everyone comprehends the elevator's movements, thus decreasing the likelihood of incidents.

By applying these precautionary measures, operators can significantly minimize the chance of accidents and foster a more secure working environment. Moreover, continuous education and compliance with ANSI and OSHA standards are essential to strengthen safe practices in aerial platform operations. The NIOSH Aerial Equipment Hazard Recognition Simulator serves as a valuable tool in helping operators recognize common dangers associated with aerial operation and emphasizes the necessity of formal training, highlighting the importance of continuous education in promoting safety.

Post-Operation Procedures

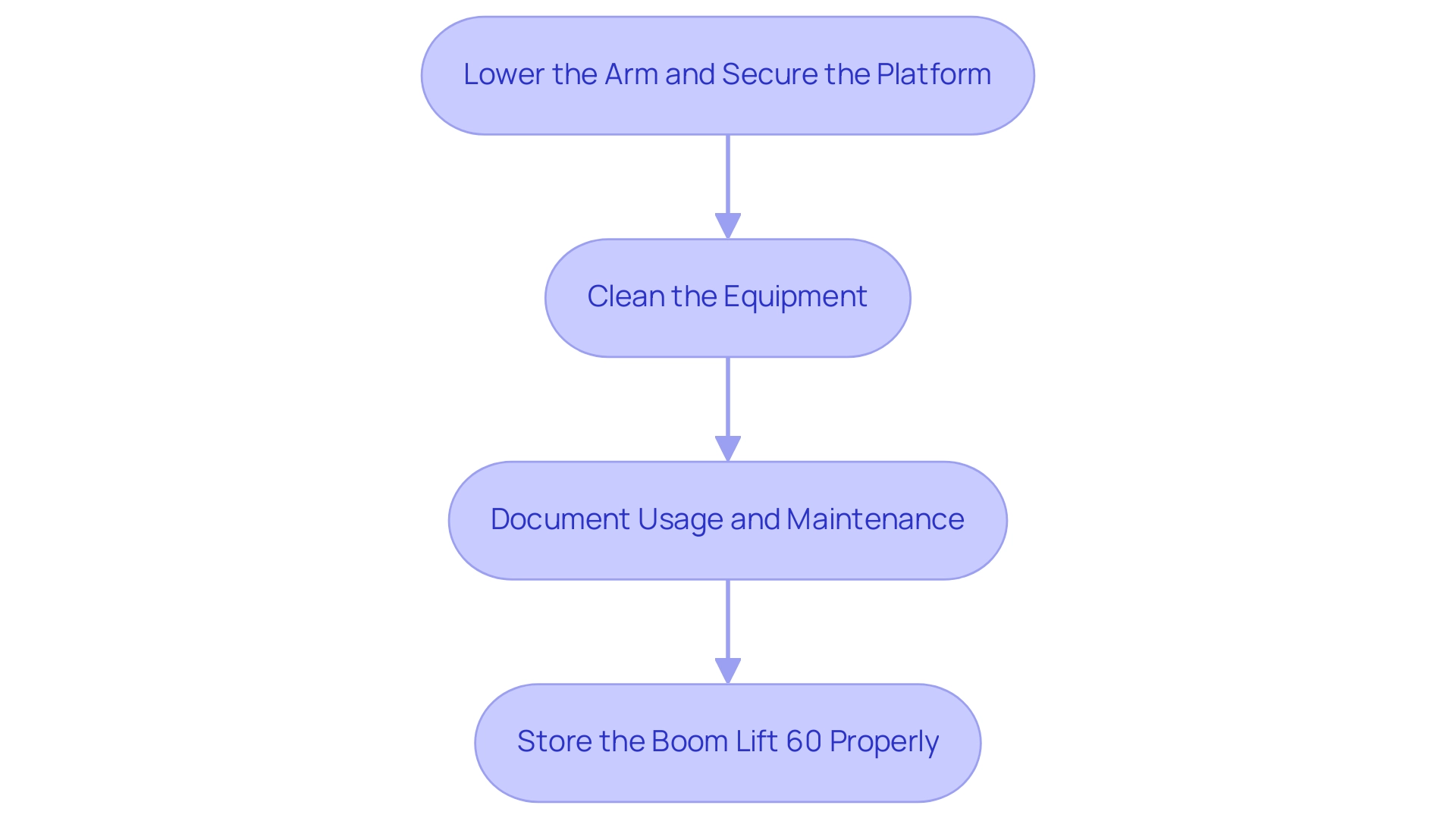

After utilizing a hydraulic platform, adhere to these post-operation procedures:

-

Lower the Arm and Secure the Platform: Always lower the arm to its resting position and ensure the platform is secure before leaving the area.

- Conduct a Post-Operation Inspection: Check the aerial platform for any damage or issues that may have arisen during operation. Report any problems to the maintenance team immediately.

-

Clean the Equipment: Remove any debris or materials from the apparatus to maintain its condition. Regular cleaning helps prevent wear and tear.

-

Document Usage and Maintenance: Keep a log of the aerial platform's usage, including any inspections, maintenance, and repairs conducted. This documentation is crucial for tracking the equipment's condition and history.

-

Store the Boom Lift 60 Properly: If the boom lift 60 will not be used for an extended period, store it in a safe, dry place to protect it from the elements and potential damage.

By following these post-operation procedures, you can help ensure the boom lift 60 remains in good working condition and is ready for future use.

Conclusion

Understanding the variety of boom lifts available and their specific applications is essential for maximizing efficiency and safety on construction sites. Telescopic, articulating, towable, and straight mast boom lifts each serve unique purposes, catering to the diverse needs of projects. Keeping abreast of technological advancements further enhances the ability to select the right equipment that aligns with project requirements.

Selecting the appropriate boom lift involves a thorough assessment of project needs, including height requirements, load capacity, and terrain conditions. By considering these factors and leveraging local equipment rental services, operators can confidently choose the right lift, ensuring smooth operations and adherence to safety protocols.

Preparation and operational safety are paramount when working with boom lifts. Conducting pre-operation inspections, following manufacturer guidelines, and maintaining effective communication with ground personnel are critical steps in preventing accidents. Additionally, post-operation procedures, such as inspections and proper storage, contribute to the longevity and reliability of the equipment.

Ultimately, informed decision-making regarding boom lift selection, operation, and maintenance not only enhances productivity but also fosters a culture of safety on construction sites. By prioritizing safety and efficiency, professionals can navigate the complexities of construction projects with confidence, leading to successful outcomes and a safer work environment.

Frequently Asked Questions

What are the different types of boom platforms used in construction?

The main types of boom platforms include: 1. Telescopic Boom Elevators: Extend vertically for accessing elevated areas, ideal for outdoor tasks. 2. Articulating Aerial Platforms: Feature joints for flexibility, suitable for maneuvering around obstacles in complex sites. 3. Towable Aerial Platforms: Portable and lightweight, easily towed behind a vehicle for smaller tasks. 4. Straight Mast Boom Elevators: Focus on vertical reach with minimal lateral movement, often used for precise elevation needs.

What recent advancements have been made in aerial work platform technology?

Recent advancements include the launch of the world's largest articulating lift by Sinoboom, which has a platform height of 46.3 meters, and J.C. Bamford Excavators Limited (JCB) introducing the T 65D-powered telescopic lifting platform in India, emphasizing reliability and safety.

How can I choose the appropriate aerial platform for my project?

To choose the right aerial platform, follow these steps: 1. Assess project requirements including height, weight, and environment. 2. Consider the crane's capacity to ensure it can safely lift the intended weight. 3. Review safety features of the platform. 4. Consult with local equipment suppliers for recommendations. 5. Understand the rental process, including costs and reservations.

What are the important preparation steps before using an elevating platform?

Important preparation steps include: 1. Conducting a pre-operation inspection of the platform. 2. Reading the operator's manual for specific operating instructions. 3. Ensuring operators are properly trained and certified. 4. Establishing a designated work zone free of hazards. 5. Planning for emergency situations with a clear response strategy.

What safety practices should be followed while using a boom lift?

Essential safety practices include: 1. Wearing appropriate personal protective equipment (PPE) such as hard hats and harnesses. 2. Maintaining a safe distance from hazards like power lines. 3. Using proper operating techniques for smooth movements. 4. Communicating effectively with ground personnel.

What post-operation procedures should be followed after using a hydraulic platform?

Post-operation procedures include: 1. Lowering the arm and securing the platform before leaving. 2. Conducting a post-operation inspection for any damage. 3. Cleaning the equipment to maintain its condition. 4. Documenting usage and maintenance activities. 5. Storing the boom lift properly if not in use for an extended period.