Overview

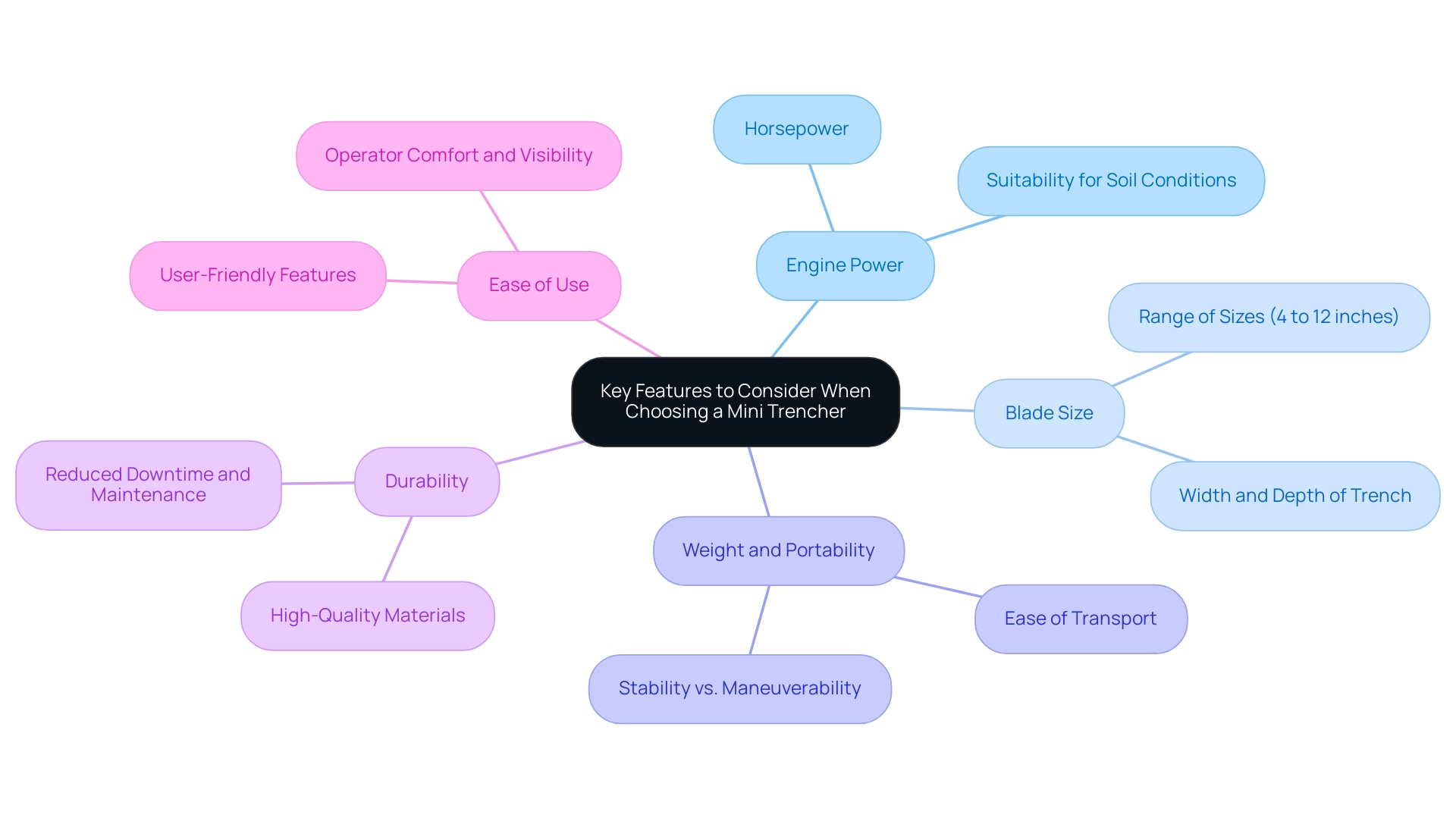

To choose and use a hand-held mini trencher effectively, one should consider key features such as engine power, blade size, weight, durability, and ease of use, while also adhering to essential safety practices during operation. The article supports this by detailing the importance of these features in enhancing performance and efficiency, alongside providing comprehensive safety guidelines to minimize risks during trenching tasks.

Key Highlights:

- Hand-held mini trenchers are portable tools designed for creating narrow ditches for irrigation, electrical lines, and drainage.

- They feature a rotating blade that efficiently cuts through soil and roots, making them ideal for landscaping and small construction tasks.

- The mini trencher market is projected to grow significantly from 2024 to 2029, highlighting their increasing relevance in construction.

- Key features to consider when choosing a mini trencher include engine power, blade size, weight, durability, and ease of use.

- Proper safety practices include reading the manual, wearing protective gear, inspecting equipment, and maintaining stability during operation.

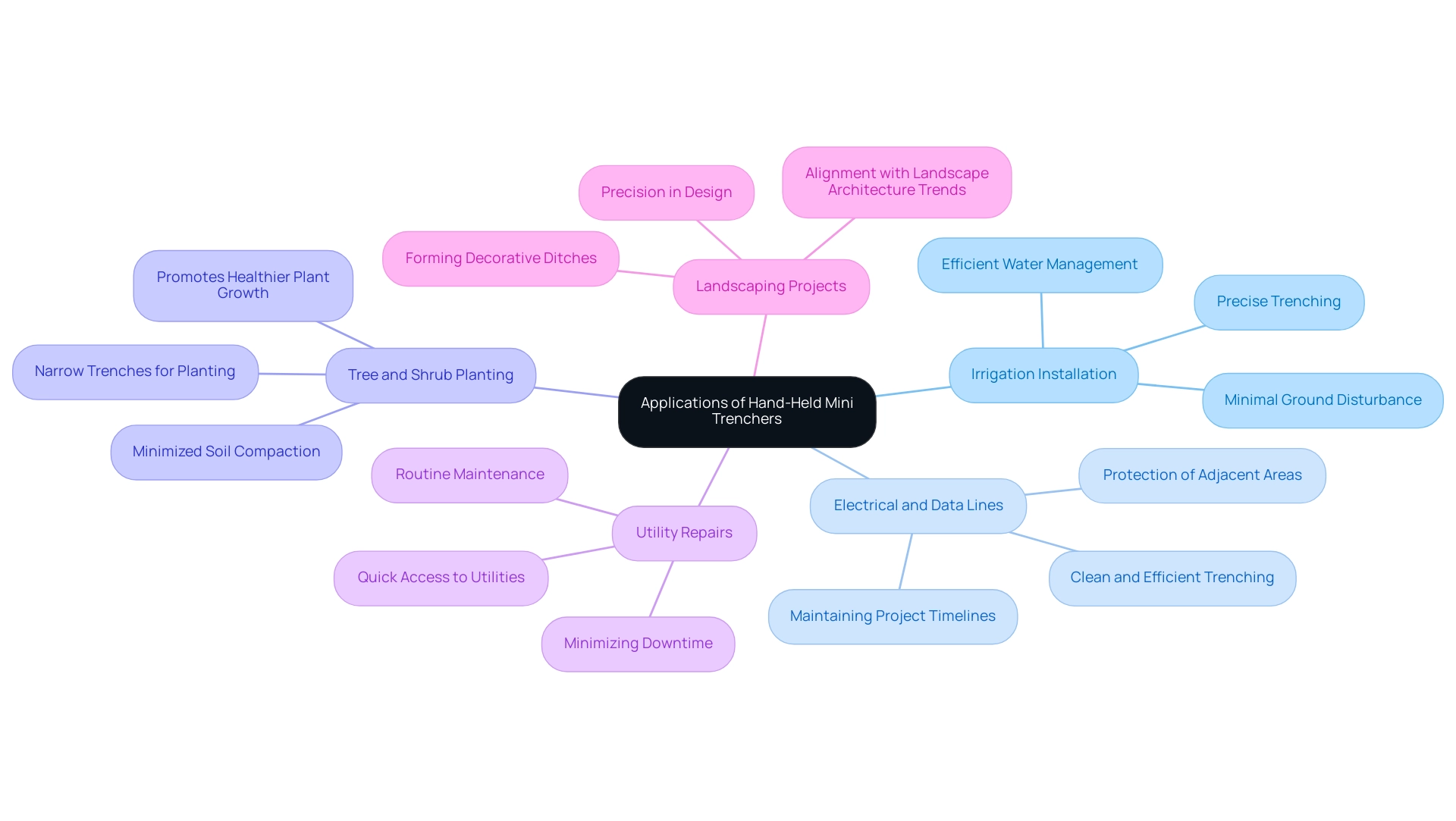

- Mini trenchers are effective for irrigation installation, laying electrical/data lines, planting trees, utility repairs, and landscaping projects.

- Regular maintenance, such as cleaning, inspecting blades, checking fluid levels, and professional servicing, is essential for longevity and performance.

- The average lifespan of a well-maintained mini trencher is around 10 to 15 years, emphasizing the importance of diligent upkeep.

Introduction

In the realm of construction and landscaping, the emergence of hand-held mini trenchers has revolutionized how projects are executed. These compact yet powerful tools are designed to create precise trenches with minimal disruption, making them essential for tasks ranging from irrigation installation to utility repairs.

As the demand for efficient and versatile equipment grows, understanding the capabilities and features of mini trenchers becomes imperative for contractors and DIY enthusiasts alike. With expert insights highlighting their efficiency and the market's projected growth, this article delves into the key aspects of mini trenchers, including their applications, safety guidelines, and maintenance tips, ensuring that users can harness their full potential effectively.

Understanding Hand-Held Mini Trenchers: An Overview

Hand-held mini trenchers are innovative, portable instruments specifically designed for creating narrow ditches across diverse terrains. These machines excel in applications such as:

- Installing irrigation systems

- Laying electrical lines

- Setting up drainage solutions

Equipped with a rotating blade, efficiently cuts through soil and roots, making it essential for both residential landscaping and small-scale building tasks.

The lightweight design and portability of the hand-held mini trencher enable effortless maneuverability, giving it a reputation among contractors and DIY enthusiasts alike. As the market for these tools expands, with projections indicating that the compact excavator market is expected to grow significantly from 2024 to 2029, understanding their operation and capabilities becomes crucial for project managers looking to implement them effectively. Specialist Andreas Knepper from wallmedien AG observes, 'The effectiveness and compact nature of small excavation machines make them a transformative factor in landscaping and building.'

The increase in small excavator usage and the popularity of the hand-held mini trencher reflect broader growth trends in landscaping and construction, highlighting their key advantages in simplifying complex tasks and enhancing productivity. For example, a recent case study illustrated how a landscaping project greatly decreased labor time by employing a hand-held small digging tool for irrigation installation, highlighting their efficiency and importance in practical uses.

Key Features to Consider When Choosing a Mini Trencher

Choosing the appropriate mini excavation tool necessitates thoughtful evaluation of several key characteristics that directly influence performance and efficiency:

- Engine Power: It's crucial to select machines with sufficient horsepower to handle the specific soil conditions you expect. For instance, boasts an impressive 25 hp, making it suitable for various challenging scenarios. Powerful engines not only facilitate quicker work but also enhance the machine's ability to handle tougher terrains.

- Blade Size: The dimensions of the blade play a crucial role in determining the trench's width and depth. Mini excavation tools typically offer blade sizes ranging from 4 inches to 12 inches. Choosing the suitable size is crucial for adhering to your specifications, whether you're installing irrigation lines or telecommunication cables.

- Weight and Portability: The weight of the trencher affects its portability and maneuverability. Lighter models of the hand held mini trencher are easier to transport and manage, making them perfect for smaller tasks or rental situations. However, heavier models can provide greater stability and power during operation. Assess your transportation capabilities to ensure compatibility with your project demands.

- Durability: Given the often rigorous conditions these machines face, durability is a key factor. Look for machines constructed from high-quality materials that can withstand the wear and tear common in excavation tasks. A dependable digging machine will reduce downtime and maintenance expenses.

- Ease of Use: User-friendly features, such as adjustable handles and intuitive controls, can significantly enhance the overall experience for operators. These enhancements make these tools more accessible, particularly for novice users, allowing for efficient operation and reduced learning curves. Contemporary machines, including the hand held mini trencher from Vermeer, are created with operator comfort and visibility as a priority, allowing users to operate efficiently in different environments.

As Ed Malzahn, founder of Ditch Witch, aptly noted,

His innovation paved the way for such equipment across the underground sector.

This legacy persists with contemporary innovations, such as those available in Vermeer’s lineup of walk-behind equipment, which are intended for small- to mid-duty applications, ensuring operational efficiency and versatility across different ground conditions. Furthermore, the Contractor of the Year contest highlights the importance of high standards in construction, underscoring the significance of choosing equipment that meets industry benchmarks.

Essential Safety Tips and Operational Guidelines for Mini Trenchers

Operating a hand held mini trencher with safety and efficiency requires adherence to essential guidelines. Here are key practices to ensure a safe working environment:

- Read the Manual: Begin by thoroughly familiarizing yourself with the manufacturer's instructions and safety warnings. Understanding the equipment's operational functions is crucial for safe use.

- Wear Protective Gear: Always don appropriate protective gear, including safety goggles, durable gloves, and sturdy footwear. This equipment safeguards against debris and sharp objects that may be encountered during excavation.

- Inspect the Equipment: Prior to operation, conduct a comprehensive inspection of the machinery. Look for any signs of damage or wear, and verify that all safety features are operational to minimize risks during use.

- Clear the Area: Ensure the worksite is free from obstacles such as rocks, roots, and underground utilities. Clearly marking the digging area not only enhances visibility but also aids in preventing accidental strikes on hidden obstructions.

- Maintain Stability: Keep both hands firmly on the controls and take a stable stance throughout the operation. This helps prevent slips and falls, which are common hazards in excavation work.

- Avoid Overreaching: Be cautious not to lean excessively forward or to the side while operating the trencher. Overreaching can compromise your balance and lead to potential accidents.

The importance of following these guidelines is emphasized by the fact that, in 2022, the building sector reported 169,600 cases of injury and illness, highlighting the critical need for . Furthermore, awareness of hazards such as noise is crucial; according to BigRentz, "Of workers exposed to noise on the job, 16% had hearing impairment in both ears." By adhering to these operational guidelines, which correspond with safety compliance standards for small excavation machines like the hand held mini trencher, you can contribute to a safer working environment and decrease the likelihood of accidents related to small machinery operations.

Furthermore, the case study on non-fatal building injuries illustrates that many injuries go unreported, emphasizing the need for stringent safety practices in the field.

Applications of Hand-Held Mini Trenchers in Construction and Landscaping

Hand-held compact excavators, such as the hand held mini trencher, have proven to be invaluable tools in both construction and landscaping projects, offering versatility and efficiency in various applications. Their effectiveness can be summarized in the following areas:

- Irrigation Installation: Hand held mini trenchers are exceptionally suited for digging precise trenches for sprinkler systems and drainage pipes.

They facilitate installation with minimal ground disturbance, ensuring efficient water management without compromising the surrounding landscape. - Electrical and Data Lines: When it comes to laying electrical cables and data lines, mini excavators excel.

They ensure clean and efficient trenching using a hand held mini trencher while protecting adjacent areas from damage—key for maintaining project timelines and budget. - Tree and Shrub Planting: The hand held mini trencher is ideal for creating narrow trenches necessary for planting trees and shrubs.

This method not only establishes root systems effectively but also minimizes soil compaction, promoting healthier plant growth. - Utility Repairs: Hand held mini trenchers provide quick access to underground utilities, making them advantageous for urgent repairs and routine maintenance.

This capability is critical for minimizing downtime and maintaining service continuity. - Landscaping Projects: In landscaping, are utilized to form decorative ditches that improve visual aspects, such as borders and pathways.

Their precision enables innovative designs that correspond with landscape architecture trends.

The market demand for hand held mini trenchers continues to grow as their applications expand, particularly in landscaping projects, where they are increasingly acknowledged for their efficiency and effectiveness. Based on industry knowledge, a hand held mini trencher is an excellent compact walk-behind machine for creating trenches that are 3 to 4 feet deep, while its capacity to dig trenches up to six feet deep renders it perfect for utility cable and pipeline installation, highlighting its importance in contemporary building methods.

As noted by Mastenbroek Limited, this digging machine has the capability to excavate a trench up to a depth of six feet, which is the standard requirement for utility cable and pipeline installation in the US.

This versatility positions the hand held mini trencher as an essential tool in the construction field, effectively addressing diverse task requirements.

Furthermore, the excavation equipment market is segmented by digging mechanism, mode of movement, size, operator, application, and region, providing valuable context for understanding the various options available to construction managers.

Lastly, it is crucial to implement safety measures when operating earth-moving equipment. Before using a digging machine, it is essential to contact utility companies to mark utility lines, select the appropriate type of equipment for the project, and establish safety measures to prevent injuries.

Implementing these safety precautions ensures a safer working environment and reduces the risk of accidents during trenching operations.

Maintenance Tips for Ensuring Longevity of Your Mini Trencher

To ensure your mini digging machine remains in peak condition and to protect your investment, which can range from $10,000 to $16,000 for walk-behind models, adhere to :

- Regular Cleaning: After each use, thoroughly clean the equipment to eliminate dirt and debris. This step is crucial to prevent buildup that can compromise performance and efficiency.

- Inspect the Blade: Regularly examine the blade for signs of wear or damage. Keeping it sharp is vital; replace it as necessary to sustain optimal cutting performance. As Chris Thompson from Ditch Witch advises,

Monitor digging chain tension and adjust as needed. This attention to detail can significantly enhance the machine's performance.

- Check Fluid Levels: Maintain adequate oil and fuel levels, replacing fluids according to the manufacturer's guidelines. Regular fluid checks not only promote efficiency but also extend the equipment's lifespan, which averages around 10 to 15 years with proper maintenance. This connection underscores how diligent upkeep can lead to achieving that lifespan.

- Store Properly: Store the tool in a dry, protected area when not in use. This practice prevents rust and deterioration, safeguarding your investment.

- Schedule Professional Servicing: An annual professional servicing is advised to identify and rectify any potential issues. Austin Bonnema, Director of Sales at Vermeer, emphasizes that

Getting those small details right will make for a better working experience and can help drive repeat business.

This proactive strategy guarantees that your compact digging machine functions efficiently and dependably.

Additionally, consider the upcoming Maynards auction, which presents an excellent opportunity to acquire quality excavation equipment at fair prices. By following these maintenance strategies, you can maximize the longevity of your mini trencher and enhance its performance, ensuring it remains an invaluable part of your excavation toolkit.

Conclusion

The versatility and efficiency of hand-held mini trenchers have made them indispensable tools in the construction and landscaping sectors. From facilitating precise irrigation installations to ensuring clean trenching for electrical and data lines, these compact machines cater to a wide array of applications. Their lightweight design and portability enhance maneuverability, while their powerful engines and durable construction allow them to tackle various soil conditions effectively.

Understanding the key features when selecting a mini trencher—such as engine power, blade size, and ease of use—is crucial for maximizing performance. Adhering to safety guidelines is equally important, as the construction industry continues to face challenges related to injuries. By following operational best practices, users can create a safer working environment, ensuring that the benefits of mini trenchers are fully realized without compromising safety.

Moreover, regular maintenance is essential for prolonging the life of these machines. Simple practices like:

- Cleaning after use

- Inspecting the blade

- Ensuring proper fluid levels

can significantly enhance performance and extend the equipment's lifespan. As the market for mini trenchers continues to grow, embracing these tools not only improves project efficiency but also positions users at the forefront of modern construction practices.

In conclusion, mini trenchers represent a significant advancement in excavation technology, offering unmatched efficiency and versatility. By understanding their applications, adhering to safety standards, and committing to regular maintenance, contractors and DIY enthusiasts can harness the full potential of these innovative tools, paving the way for successful and productive projects.

Frequently Asked Questions

What are hand-held mini trenchers used for?

Hand-held mini trenchers are designed for creating narrow ditches and excel in applications such as installing irrigation systems, laying electrical lines, and setting up drainage solutions.

How do hand-held mini trenchers operate?

These machines are equipped with a rotating blade that efficiently cuts through soil and roots, making them essential for residential landscaping and small-scale building tasks.

What advantages do hand-held mini trenchers offer?

Their lightweight design and portability allow for easy maneuverability, making them popular among contractors and DIY enthusiasts. They simplify complex tasks and enhance productivity.

What is the expected market trend for mini excavators?

The compact excavator market is projected to grow significantly from 2024 to 2029, reflecting an increase in small excavator usage and the popularity of hand-held mini trenchers.

What key characteristics should be considered when choosing a mini excavation tool?

Important characteristics include engine power, blade size, weight and portability, durability, and ease of use.

Why is engine power important in mini trenchers?

Sufficient horsepower is crucial for handling specific soil conditions. More powerful engines facilitate quicker work and improve the machine's ability to navigate tougher terrains.

How does blade size affect performance?

The dimensions of the blade determine the trench's width and depth, with sizes typically ranging from 4 inches to 12 inches. Choosing the right size is essential for specific installation tasks.

How does weight impact the usability of a mini trencher?

The weight of the trencher affects its portability and maneuverability. Lighter models are easier to transport, while heavier models provide greater stability and power during operation.

What role does durability play in mini trenchers?

Durability is key due to the rigorous conditions these machines face. High-quality materials ensure the machine can withstand wear and tear, reducing downtime and maintenance costs.

Why is ease of use important for mini trenchers?

User-friendly features, such as adjustable handles and intuitive controls, enhance the overall experience for operators, making the tools more accessible and efficient, especially for novice users.