Introduction

Choosing the right 8000 lb excavator is a crucial decision that can significantly impact the efficiency and success of construction projects. With an array of options available, it’s essential to navigate through key considerations such as:

- Project requirements

- Terrain conditions

- Operator skill levels

to find the perfect match. This article delves into the critical factors that influence excavator selection, the importance of understanding features and specifications, and the evaluation of brands and support services. Additionally, it explores the financial implications of buying versus renting, as well as the various attachments that can enhance performance. By equipping oneself with this knowledge, project managers can make informed decisions that lead to optimized operations and successful project outcomes.

Key Considerations for Selecting an 8000 lb Excavator

When selecting an 8000 lb excavator, several key factors must be taken into account to ensure optimal performance and suitability for your specific construction projects:

- Project Requirements: Begin by assessing the nature of your projects. Will the machinery be utilized for activities such as digging, grading, or demolition? A thorough understanding of your primary tasks will significantly narrow down your options, ensuring you select an option that aligns with your operational needs.

- Terrain and Environment: The landscape where the machinery will be operating plays a crucial role in your selection process. For instance, soft or muddy ground may necessitate machines with higher flotation capabilities, while rocky or uneven surfaces may require robust models designed for stability and traction.

- Weight and Size Restrictions: Compliance with weight and dimension regulations is critical, particularly in urban job sites. Machines can weigh over two million pounds, so be sure to verify that their specifications meet local restrictions to avoid potential legal complications or logistical issues during operation.

- Load Capacity: Establish the maximum load capacity required for your projects. This factor is essential, as it influences not only the efficiency of the machinery but also the safety of its operation on site. Choosing a system that can manage your expected loads will improve productivity and decrease downtime.

- Operator Skill Level: Finally, consider the skill level of the operators who will be handling the machinery. Some models are equipped with advanced features that may require experienced operators, while others are designed to be user-friendly for those who are less experienced. As noted by Hewlett-Packard, "I had a great experience working with Fortune Business Insights. The report was very accurate and as per my requirements. Very satisfied with the overall report as it has helped me to build strategies for my business." Aligning the machinery's complexity to the operators' skills will enhance operational efficiency and reduce the likelihood of accidents.

Additionally, it is important to be aware of the challenges faced in the European machinery market, where environmental regulations have impacted sales. Grasping these complexities can assist project managers in making informed choices when selecting machinery for their projects.

Understanding Features and Specifications of 8000 lb Excavators

When assessing 8000 lb excavators, it is crucial to prioritize the following features and specifications to ensure optimal performance and efficiency:

- Engine Power: Opt for models that provide ample horsepower, enabling them to tackle demanding workloads with ease. Recent advancements in engine technology have significantly improved this aspect, allowing for enhanced productivity on site.

- Hydraulic System: A powerful hydraulic system is vital, as it directly influences the machine's digging and lifting capabilities. Pay attention to flow rates and pressure ratings, which can indicate the system's efficiency. Recent industry statistics suggest that higher flow rates correlate with improved performance in various tasks.

- Digging Depth and Reach: It is essential to comprehend the maximum digging depth and reach of the excavator's arm. For instance, some designs boast a maximum reach of up to 46 feet and a maximum dump height of 26' 7", making them suitable for a variety of applications. This understanding ensures that the selected model aligns with your project requirements, particularly in tight spaces or complex site conditions.

- Stability and Maneuverability: Evaluate the machine’s design, focusing on track width and weight distribution, as these factors significantly impact stability on uneven terrain. A well-balanced machine will provide better control and safety during operation, especially in challenging environments.

- Operator Comfort: Features that enhance the operator's experience, such as adjustable seats, climate control, and user-friendly controls, cannot be overlooked. These elements contribute to productivity during long hours of operation, ensuring that operators can maintain focus and efficiency.

As Tim Forestell, co-founder and CCO of DOZR, observes, "Collaborating with DOZR renters daily provides me insight into the evolution of various endeavors and listening to tales about initiatives being developed from beginning to end." By considering these features, you can select an 8000 lb excavator that not only meets your project demands but also enhances overall productivity and safety on the job site. Additionally, the CASE CX750D model is highlighted for its best-in-class dig depth and excellent engine power, designed for faster cycle times and superior performance, positioning it as a top competitor in its weight class.

Evaluating Brands and Support Services for Excavators

Assessing brands for the 8000 lb excavator requires a thorough approach to ensure you make a sound investment. Key factors to consider include:

-

Reputation: Investigate the brand's history and standing within the construction industry.

Look for user reviews and testimonials to gauge reliability and performance. Established brands, which account for about 60-70% of the global machinery market, are often more dependable due to their proven track record.

-

Warranty and Support: Assess the warranty terms provided by the manufacturer, alongside the accessibility of customer support and nearby service centers.

A strong warranty can significantly impact the operational costs and longevity of your 8000 lb excavator. For instance, leading brands like Doosan Bobcat, with sales of 7.48 billion U.S. dollars, typically offer robust warranty and support services.

-

Parts Availability: Confirm that replacement parts are readily available to reduce potential downtime during repairs.

Efficient access to parts is crucial for maintaining productivity on-site.

-

Training and Resources: Some manufacturers provide extensive operator training programs and materials, which can greatly enhance the safe and effective use of the machine.

This support is essential for maximizing the equipment's capabilities.

-

Resale Value: Assess the expected resale value of the machinery.

Certain brands tend to retain value better than others, influencing your overall return on investment.

In light of recent findings, major players dominate the machinery market, indicating that established brands often provide reliable warranty and support services. Understanding the current market dynamics and competitive landscape can further inform your evaluation. As noted, 'Address a colleague undermining your work with open communication, documentation, and involving management if necessary.'

This principle can also apply to addressing warranty issues—open communication with manufacturers can facilitate smoother resolutions.

Financial Considerations: Buying vs. Renting an Excavator

When weighing the decision to purchase or lease an 8000 lb machine, several financial factors warrant careful consideration:

- Initial Cost: Acquiring a digging machine usually necessitates a significant initial expenditure, which can pose an obstacle for certain endeavors. In contrast, renting offers a more manageable initial outlay, making it a compelling option for short-term needs.

- Usage Frequency: If your timeline entails regular use of the machinery, buying may become a more cost-effective option as time progresses. Rhett C., a certified heavy equipment appraiser, emphasizes that the 8000 lb excavator performs exceptionally in specialized activities, particularly in tight areas, enhancing its usefulness for residential endeavors. Significantly, 75% of contractors favor purchasing mini excavators, such as the 8000 lb excavator, which highlights the perceived value of ownership for ongoing requirements. Conversely, for short-term or infrequent tasks, renting can be the more viable solution.

- Maintenance Costs: Ownership carries the responsibility of regular maintenance and repairs, which can range from $6,000 to $18,000 annually. In contrast, rental agreements usually include maintenance, alleviating the financial burden of upkeep for contractors. Implementing strategic approaches, as highlighted in the case study 'Tips for Reducing Excavator Costs,' can lead to significant savings on maintenance and operational expenses for an 8000 lb excavator.

- Financing Options: It's essential to explore various financing avenues available for purchasing equipment, such as loans and leasing arrangements, to determine the best fit for your financial situation.

- Tax Implications: Consulting a tax expert can offer valuable insights into the tax benefits related to buying versus leasing equipment, allowing you to make a more informed choice based on your financial structure.

- Project Schedule Control: Owning a mini digger allows for better control over project schedules, ensuring that equipment is available when needed, which can lead to more efficient project execution.

Exploring Attachments and Accessories for Enhanced Performance

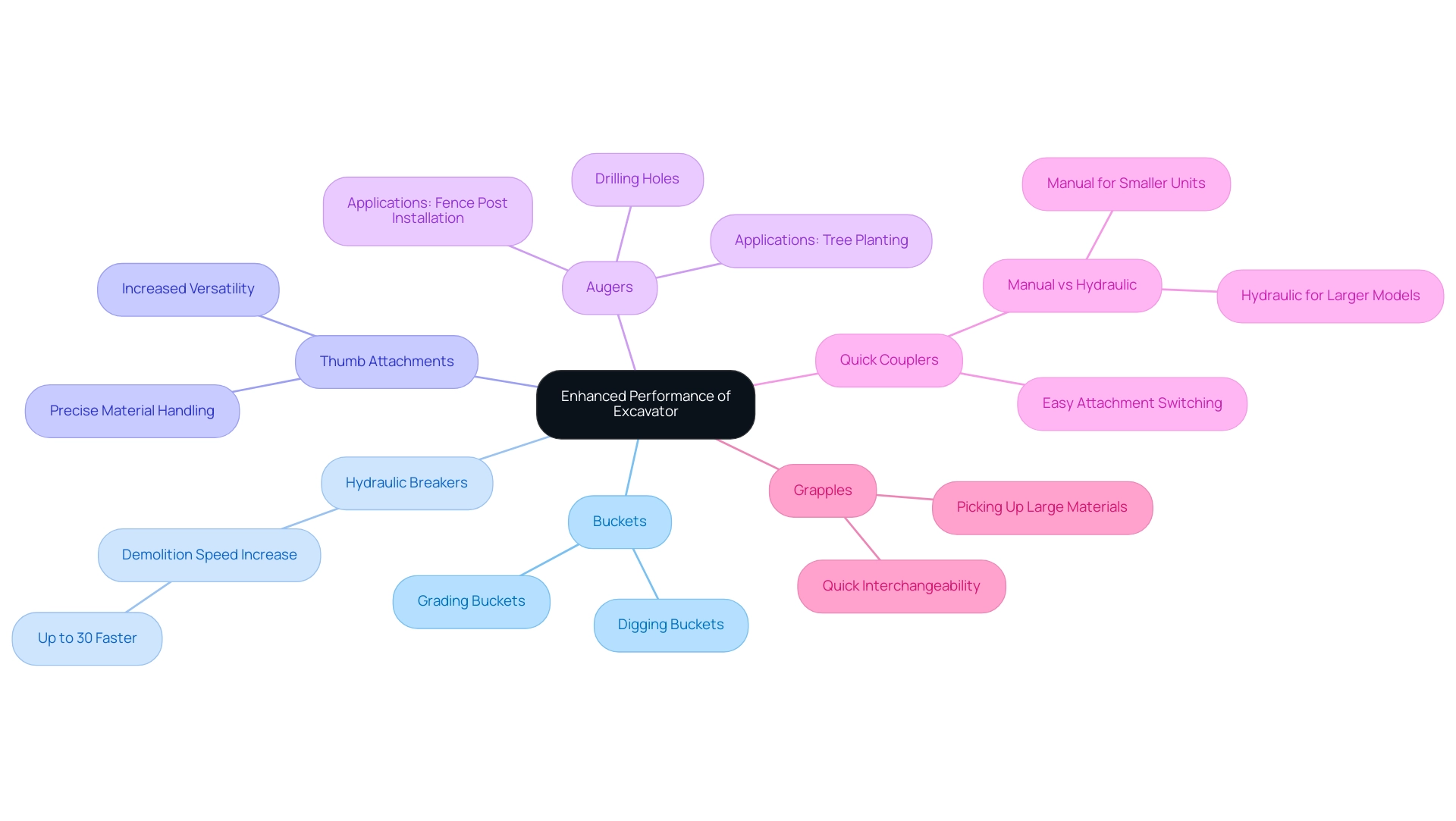

To maximize the performance of your 8000 lb excavator, consider incorporating the following attachments and accessories:

- Buckets: Various bucket sizes and types, ranging from digging buckets to grading buckets, are essential for activities such as excavation and landscaping. Selecting the right bucket can significantly enhance efficiency and productivity on the job site.

- Hydraulic Breakers: Specifically designed for demolition tasks, hydraulic breakers allow heavy machinery to efficiently break through concrete and other tough materials. Statistics suggest that these attachments can enhance demolition speed by up to 30%, rendering them essential for time-sensitive tasks.

- Thumb Attachments: Adding a thumb to your digger's bucket enhances its capability to grasp and manipulate materials, effectively increasing its versatility. This attachment allows for more precise handling of various materials, which is crucial for complex projects that require a higher degree of precision.

- Augers: For drilling holes in the ground, augers can be effortlessly connected to the digging machine, making it suitable for applications like fence post installation or tree planting. This versatility makes augers a popular choice among contractors looking to expand their operational capabilities.

- Quick Couplers: These devices facilitate easy switching between attachments, significantly improving efficiency and reducing downtime on the job site. As noted in a recent case study on choosing a quick hitch for digging machines, selecting the right coupler—manual for smaller units and hydraulic for larger models—reflects a balance between cost and functional efficiency.

- Grapples: Grapples are designed for picking up large materials and can be quickly interchanged with other attachments, further enhancing the versatility of your machinery.

Additionally, advancements in engine technology are making digging machines smaller yet more powerful and efficient than ever before. As Kramlich states, "Improved engine technology is creating engines that are smaller yet more powerful and efficient than ever before, enabling smaller machines to perform a broader range of activities."

By carefully selecting these attachments, you can unlock the full potential of your excavator, ensuring that it performs effectively across a variety of tasks.

Conclusion

Selecting the right 8000 lb excavator is a multifaceted decision that can profoundly influence the success of construction projects. As outlined, understanding project requirements, terrain conditions, operator skill levels, and the excavator's features are pivotal in making an informed choice. By meticulously evaluating these factors, project managers can ensure that the excavator aligns with operational needs, thereby enhancing productivity and safety on job sites.

Moreover, the evaluation of brands and support services plays an essential role in securing a reliable investment. Established brands with robust warranties and accessible parts can minimize downtime and maintenance costs, contributing to smoother project execution. Understanding the financial implications of buying versus renting also empowers decision-makers to choose the most economical option based on project frequency and budget constraints.

Finally, incorporating the right attachments can significantly boost the excavator's versatility and efficiency, further optimizing performance across various tasks. By leveraging this comprehensive knowledge, project managers are equipped to make strategic choices that lead to successful project outcomes and improved operational efficiency.

Frequently Asked Questions

What key factors should be considered when selecting an 8000 lb excavator?

Key factors include project requirements, terrain and environment, weight and size restrictions, load capacity, and operator skill level.

How do project requirements influence the selection of an excavator?

Understanding the nature of your projects, such as whether the excavator will be used for digging, grading, or demolition, helps narrow down options to machines that align with specific operational needs.

Why is terrain and environment important in selecting an excavator?

The landscape affects the choice of machinery; for example, soft or muddy ground may require machines with better flotation, while rocky or uneven surfaces may need more robust models for stability and traction.

What should be considered regarding weight and size restrictions?

It is crucial to ensure that the excavator's specifications comply with local weight and dimension regulations, especially in urban job sites, to avoid legal complications or logistical issues.

How does load capacity affect excavator selection?

Establishing the maximum load capacity needed for projects is essential for ensuring the efficiency and safety of the machinery. Choosing a machine that can handle expected loads improves productivity and reduces downtime.

How does the skill level of operators impact the choice of excavator?

Some excavator models have advanced features that require experienced operators, while others are designed to be user-friendly for less experienced operators. Aligning machine complexity with operator skills enhances efficiency and reduces accident risks.

What features should be prioritized when assessing 8000 lb excavators?

Important features include engine power, hydraulic system efficiency, digging depth and reach, stability and maneuverability, and operator comfort.

Why is engine power significant for excavators?

Ample horsepower allows excavators to handle demanding workloads effectively, contributing to enhanced productivity on site.

How does the hydraulic system affect excavator performance?

A powerful hydraulic system influences digging and lifting capabilities, with higher flow rates and pressure ratings indicating better efficiency.

What is the importance of understanding digging depth and reach?

Knowing the maximum digging depth and reach ensures that the excavator can meet project requirements, especially in tight spaces or complex site conditions.

How does stability and maneuverability impact excavator operation?

The design of the machine, including track width and weight distribution, affects stability on uneven terrain, which is crucial for control and safety during operation.

What operator comfort features should be considered?

Features like adjustable seats, climate control, and user-friendly controls enhance the operator's experience, improving focus and efficiency during long hours of work.