Overview

To choose the right boom for sale, one should assess key factors such as load capacity, height requirements, operational environment, and frequency of use. The article emphasizes that understanding these elements, along with the types of available booms and their specifications, ensures informed decisions that align with project needs, ultimately enhancing safety and efficiency.

Introduction

Choosing the right boom lift can be a daunting task, especially with the myriad of options available and the specific requirements of each project. From load capacity and height requirements to operational environments and frequency of use, understanding these key factors is essential for making informed decisions.

With the construction industry evolving and the shift towards more sustainable equipment, knowing the differences between articulating, telescopic, and towable boom lifts can significantly impact project efficiency and safety.

Additionally, considering the following aspects can further streamline the selection process:

- Technical specifications

- Compliance requirements

- Budgeting strategies

This article delves into the essential aspects of choosing the perfect boom lift, empowering readers to confidently navigate their options and enhance productivity on their job sites.

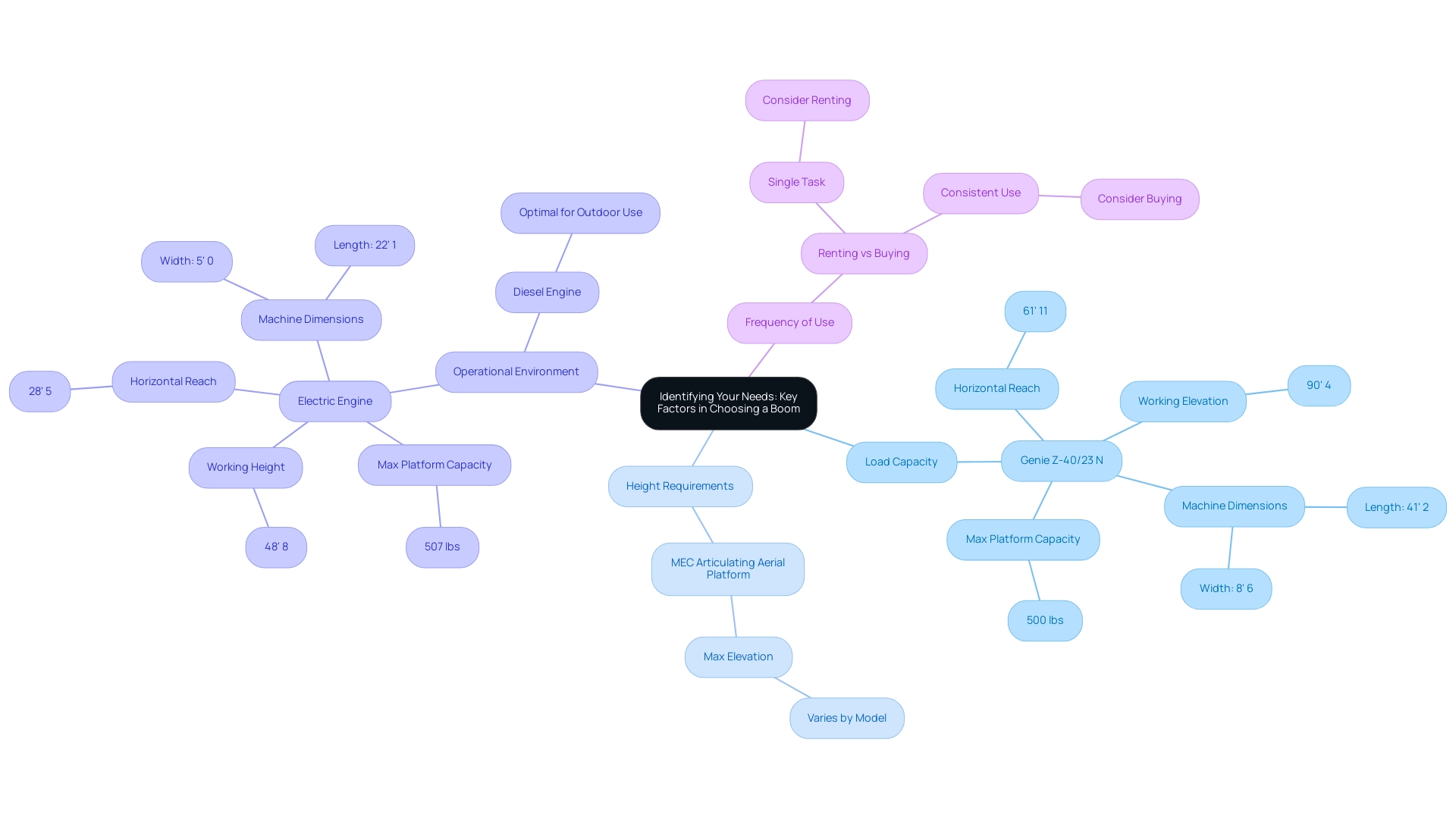

Identifying Your Needs: Key Factors in Choosing a Boom

To effectively select the appropriate boom equipment for your project, start by assessing the specific tasks you plan to carry out. Consider the following key factors:

-

Load Capacity: Evaluate the maximum weight you need to raise.

Boom platforms like the Genie Z-40/23 N provide a maximum platform capacity of 500 lbs, with a working elevation of 90' 4”, a horizontal reach of 61' 11”, a machine width of 8' 6”, and a machine length of 41' 2”. It’s essential to choose a hydraulic platform with a load capacity that meets or exceeds your requirements.

-

Height Requirements: Determine how high you need to reach.

Various aerial platforms offer differing maximum elevations; for instance, some models permit work altitudes up to 90' 4”, whereas others, such as the MEC Articulating Aerial Platform, address particular vertical and reach requirements. The MEC models generally provide dimensions such as platform elevation and horizontal reach, which are crucial to grasp for safe and effective task completion.

-

Operational Environment: Consider the circumstances in which you will use the aerial platform.

Will it be indoors or outdoors? On rough terrain or smooth surfaces? The choice between an electric engine, which is optimal for indoor use with lower height requirements and capacities (like a maximum platform capacity of 507 lbs at a work height of 48' 8”, horizontal reach of 28' 5”, machine width of 5' 0”, and machine length of 22' 1”), versus a diesel engine for outdoor use in tougher conditions can significantly affect performance.

-

Frequency of Use: Assess how often you will employ the boom apparatus.

If the lift is required for a single task, renting can be a more cost-effective solution than buying. Consistent usage might justify investing in new tools, which could contribute to improved long-term cost management.

By recognizing these factors in advance, you can simplify the selection process and prevent expensive errors, ensuring that the equipment selected aligns perfectly with your requirements. As Tim Forestell, co-founder and CCO of DOZR, points out,

Working with DOZR renters every day gives me a glimpse at the evolution of various initiatives and hearing tales about endeavors being developed from start to finish.

This insight emphasizes the importance of making informed decisions based on specific requirements.

Exploring Different Types of Booms: Options for Sale

When considering boom platforms for your projects, understanding the different types available for sale and rental is essential, as each is designed to meet specific operational needs and enhance construction efficiency:

-

Boom for Sale:

- Articulating boom elevators excel at reaching over obstacles, making them a preferred choice for maintenance and construction tasks, particularly in complex environments. Their ability to navigate urban settings with space limitations is invaluable, allowing for quicker task completion and reduced labor costs.

-

Telescopic Boom Elevators are available for sale, offering an extended reach that makes them ideal for high-rise applications, providing a straight vertical rise to access elevated work areas. Their efficiency in reaching significant heights not only saves time but also minimizes the need for additional equipment, leading to cost savings in large construction projects.

-

- Recognized for their portability, towable aerial platforms can be easily moved between job locations, featuring a compact design ideal for tasks that need mobility and quick assembly. They're ideal for temporary tasks and smaller operations, allowing for efficient use of resources and reduced overhead costs.

-

Crawler Lifts:

- Designed for rugged landscapes, crawler lifts guarantee stability and grip on irregular surfaces, making them a superb option for outdoor tasks where ground conditions present difficulties. Their dependability in such settings aids in prompt task completion and economical operations.

As the market changes with a transition towards electric and hybrid aerial platforms influenced by sustainability trends, grasping these traits is essential for making knowledgeable choices. With the rental market leading due to its cost-efficiency and flexibility, businesses are prioritizing short-term access over ownership. Innovations such as Zoomlion's electric articulating apparatus and JCB's diesel-powered telescopic platform reflect the industry's commitment to eco-friendly operations.

This knowledge will enable you to choose the most appropriate elevating platform for your project needs, ensuring efficiency, safety, and cost savings in every operation.

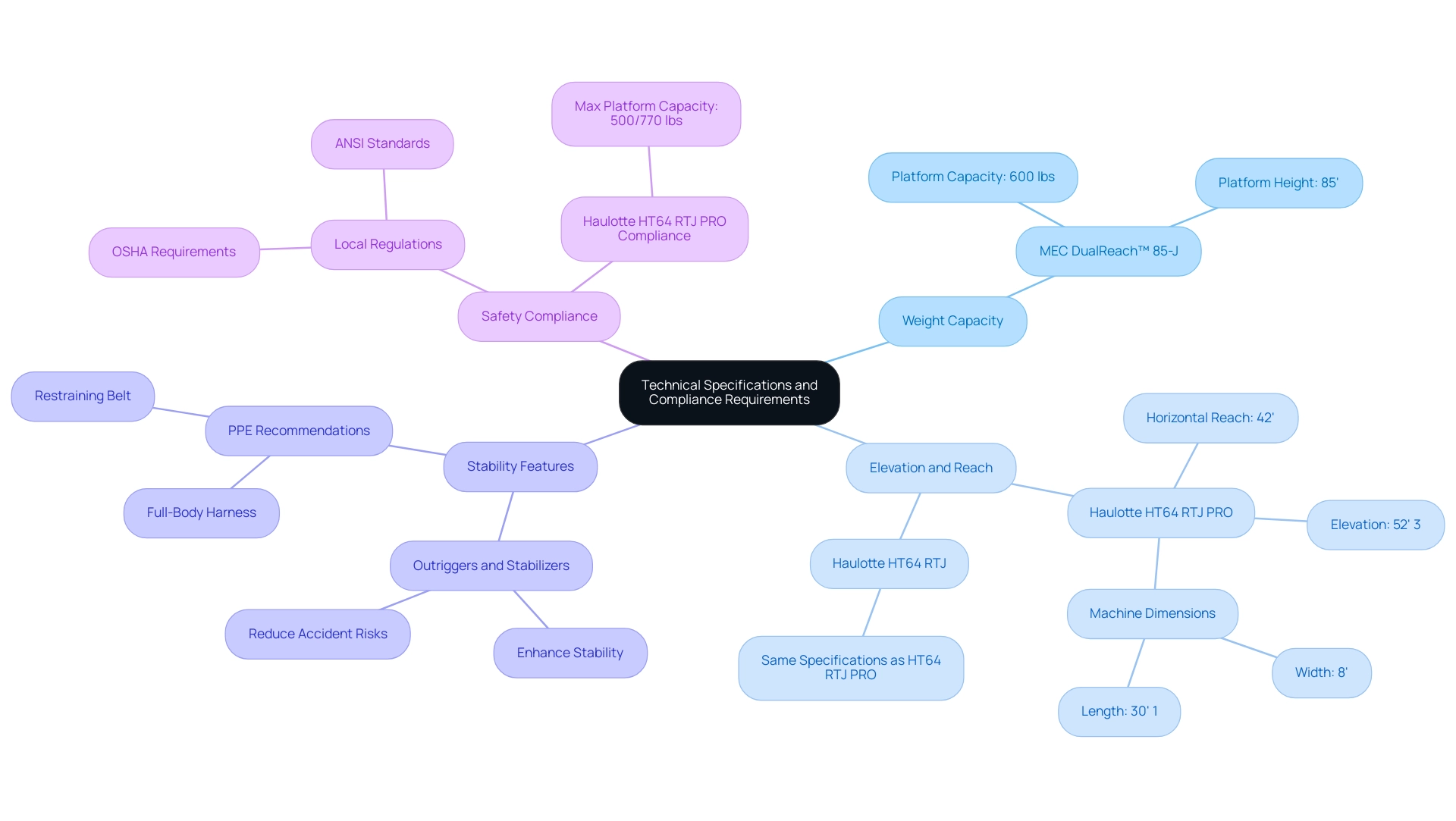

Understanding Technical Specifications and Compliance Requirements

When selecting a boom lift, it is essential to consider the following technical specifications to ensure optimal performance and safety on your construction site:

- Weight Capacity: The typical weight limit of aerial work platforms differs, with numerous models such as the MEC DualReach™ 85-J providing a significant platform capacity of 600 lbs and a platform elevation of 85'. Comprehending the weight capacity is essential to guarantee the equipment can manage the loads you intend to lift without jeopardizing stability or safety.

- Elevation and Reach: Verify that the boom satisfies your vertical requirements. For instance, models such as the Haulotte HT64 RTJ PRO, which are available as a boom for sale, offer an elevation of 52' 3" and a horizontal reach of 42', allowing for versatile operation in various job settings. Additionally, consider the machine's dimensions; for example, its width of 8' and length of 30' 1" can impact maneuverability in tight spaces. Notably, the Haulotte HT64 RTJ PRO has the same specifications as the Haulotte HT64 RTJ, which reinforces the importance of understanding model specifications.

- Stability Features: Look for features that enhance stability, such as outriggers or stabilizers. These elements are vital for maintaining balance, especially when working at heights. A aerial platform equipped with these stability features can significantly reduce the risk of accidents, as highlighted by safety experts who stress the importance of wearing appropriate PPE, such as a full-body harness and restraining belt, to protect against falls.

- Safety Compliance: Verify that the structure meets local safety regulations and standards, such as OSHA or ANSI requirements. Compliance with these standards is crucial for ensuring safe operation on job sites and can often be a deciding factor when choosing between equipment options. For example, the Haulotte HT64 RTJ PRO has a maximum platform capacity of 500/770 lbs, which is an important consideration for compliance and safety.

Comprehending these specifications not only assists you in choosing a platform that fulfills your operational needs but also guarantees that you comply with the latest regulations. Real-world examples, such as the case study involving JLG's Handle parts, demonstrate how timely and effective maintenance of compliance can lead to enhanced operational efficiency and safety. By keeping these considerations at the forefront of your decision-making process, you can significantly mitigate risks and enhance productivity on your projects.

Budgeting for Your Boom Purchase: Pricing Insights

Effective budgeting for your aerial work platform purchase requires careful consideration of several key factors:

- Initial Cost: Begin by researching the average price range for the specific kind of aerial platform you require. As a guideline, prices for new aerial devices can vary widely, with electric scissor platforms starting around $12,000 and larger models exceeding $150,000, while most variants typically range between $25,000 and $75,000. In contrast, the market for pre-owned aerial platforms provides substantial savings, with prices 30-50% lower than their new equivalents. It's important to note that the prices of new manlifts fluctuate based on their size, capacity, and features, which can affect your budget significantly.

- Operating Costs: It's essential to account for ongoing expenses such as maintenance, fuel, and insurance. According to Rhett C., a certified heavy equipment appraiser, aerial work platforms can endure between 10 to 20 years, depending on usage and maintenance practices. Over time, these costs can accumulate and significantly impact your overall budget.

- Rental vs. Purchase: For short-term projects, evaluate the cost-effectiveness of renting versus purchasing. Recent data from Seattle, WA, indicates weekly rental prices for aerial work platforms of various sizes: 30-foot units cost around $1,042, 40-foot units are approximately $838, 45-foot units are about $1,138, and larger models such as 60-foot units range from $1,200 to $1,515. Keep in mind that adding attachments or accessories to a rental of the aerial platform will likely increase the overall rental cost. This information can help you determine if renting may be a more economical choice in certain situations.

- Financing Options: If the purchase price exceeds your budget, explore financing solutions. Numerous providers offer financing options designed to help purchasers handle their financial obligations more efficiently.

By taking these factors into account, you can create an extensive budget that corresponds with both your needs and financial limitations.

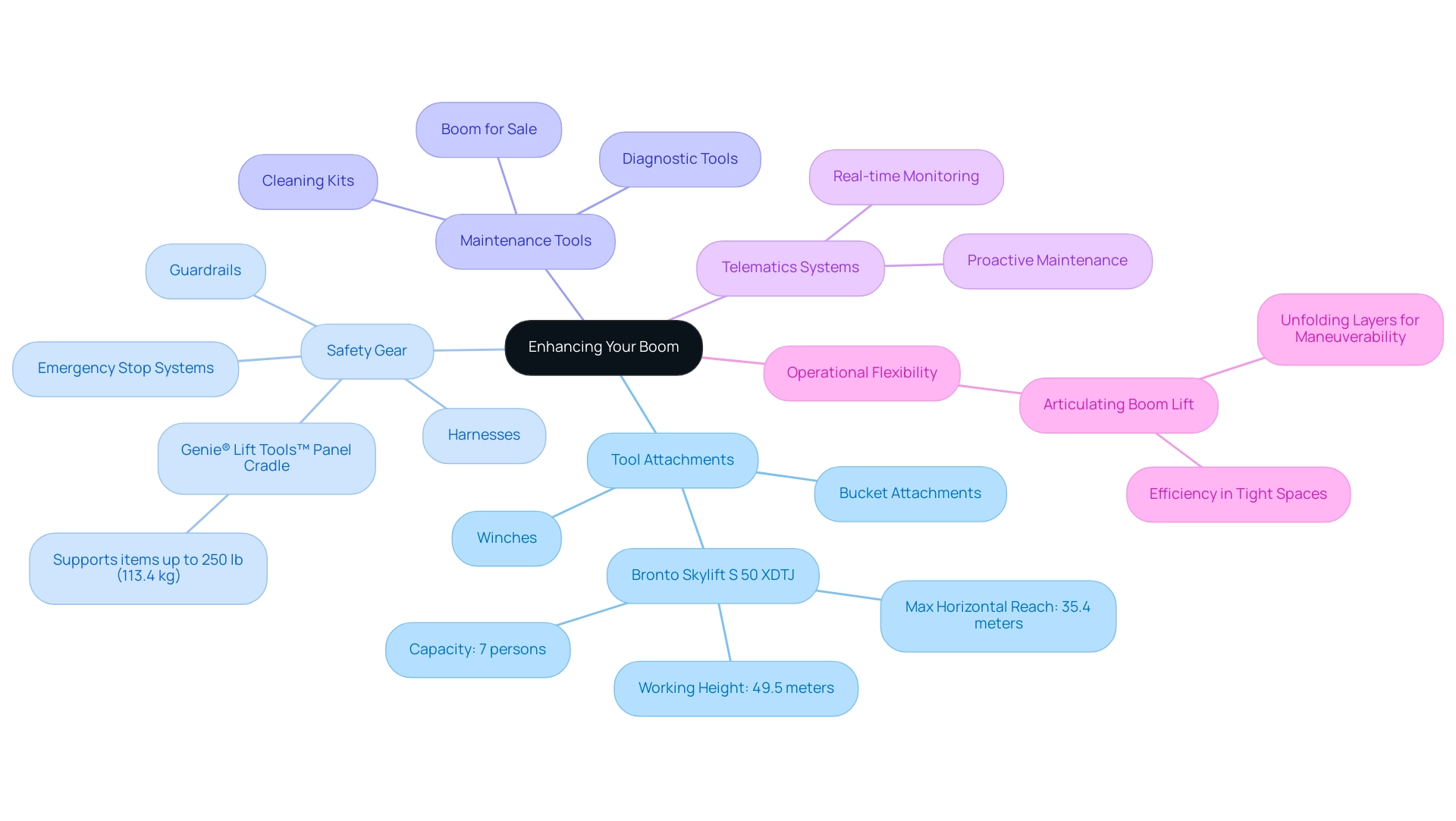

Enhancing Your Boom: Accessories and Additional Features

To enhance the performance of your aerial platform and adjust to the varied requirements of your tasks, think about adding the following accessories and features:

-

Tool Attachments: Improve your aerial platform's functionalities with different attachments designed for your specific tasks. For example, bucket attachments and winches greatly enhance the versatility of your equipment, allowing it to manage a broader array of requirements. The Bronto Skylift S 50 XDTJ, featuring a maximum horizontal reach of 35.4 meters, illustrates how sophisticated aerial platforms facilitate various tasks, rendering them crucial for both construction and maintenance activities. This versatility allows teams to complete jobs faster, reducing labor costs and project timelines.

-

Safety Gear: Prioritize safety by investing in essential accessories such as harnesses, guardrails, and emergency stop systems. These elements are essential for guaranteeing the secure functioning of elevated platforms in high-altitude work settings. As noted by a seasoned contractor,

I’ve had a Genie and JLG. JLG is far superior in terms of ease of use and durability,

highlighting the importance of selecting equipment that integrates safety features effectively. The Genie® Lift Tools™ Panel Cradle, for example, allows operators to access materials outside the platform, reinforcing the necessity of safety gear in enhancing operational safety and preventing costly accidents.

-

Maintenance Tools: Regular maintenance is key to prolonging the lifespan of your boom lift. Consider a boom for sale along with accessories that facilitate upkeep, such as cleaning kits and diagnostic tools, which help prevent downtime and ensure optimal performance. Reducing downtime directly contributes to efficiency and cost savings.

-

Telematics Systems: Implementing telematics technology allows for real-time monitoring of equipment performance and location. This capability enhances operational efficiency and enables proactive maintenance, reducing the risk of unforeseen issues on-site. By identifying potential issues early, endeavors can avoid costly delays.

-

Operational Flexibility: The case study on the Articulating Platform illustrates how its unfolding layers provide greater basket maneuverability compared to other types of aerial equipment. This feature enhances operational flexibility in tight or complex work environments, allowing for quicker adjustments and more efficient task completion. For instance, in a recent undertaking, the Articulating Boom Lift allowed a crew to maneuver around obstacles swiftly, saving hours of labor and significantly lowering costs.

By equipping your boom lift with the appropriate accessories, you not only enhance its versatility but also guarantee that your boom for sale meets the rigorous demands of your construction tasks. The integration of these features is essential for maintaining safety and efficiency, ultimately streamlining project completion and enhancing overall productivity while delivering significant time and cost savings.

Conclusion

Selecting the right boom lift is a multifaceted decision that requires careful consideration of various factors to ensure optimal performance and safety on the job site. Understanding load capacity, height requirements, and the operational environment is crucial in aligning equipment capabilities with specific project demands. Additionally, recognizing the frequency of use can guide decisions on whether to rent or purchase, ultimately affecting budget allocations.

Exploring the different types of boom lifts — articulating, telescopic, towable, and crawler — highlights the unique advantages each offers, catering to diverse operational needs and enhancing efficiency. By familiarizing oneself with technical specifications and compliance requirements, users can make informed choices that prioritize safety and operational effectiveness.

Budgeting for a boom lift involves evaluating initial costs, ongoing operating expenses, and potential financing options. This comprehensive approach enables project managers to align equipment decisions with financial constraints while maximizing resource allocation. Moreover, enhancing boom lifts with the right accessories and features not only improves functionality but also reinforces safety and productivity on-site.

In conclusion, making an informed decision about boom lifts can significantly impact project efficiency and safety. By thoroughly assessing needs, exploring options, and understanding financial implications, stakeholders can confidently select the most suitable equipment, ensuring successful project outcomes.

Frequently Asked Questions

What should I consider when selecting boom equipment for my project?

When selecting boom equipment, consider the following key factors: load capacity, height requirements, operational environment, and frequency of use.

How do I determine the load capacity needed for my boom equipment?

Evaluate the maximum weight you need to raise. For example, the Genie Z-40/23 N has a maximum platform capacity of 500 lbs. Ensure the hydraulic platform you choose meets or exceeds your load requirements.

Why is it important to assess height requirements for boom equipment?

Different aerial platforms offer varying maximum elevations. Knowing how high you need to reach is crucial for selecting the right equipment, as some models can reach heights up to 90' 4”.

How does the operational environment affect the choice of boom equipment?

The choice between electric and diesel engines depends on whether the platform will be used indoors or outdoors, and on the terrain type. Electric engines are ideal for indoor use, while diesel engines are better suited for tougher outdoor conditions.

Should I buy or rent boom equipment based on frequency of use?

If you need the lift for a single task, renting may be more cost-effective. However, consistent use might justify purchasing new tools for better long-term cost management.

What types of boom platforms are available for sale and rental?

There are several types of boom platforms, including articulating boom elevators for complex environments, telescopic boom elevators for high-rise applications, towable aerial platforms for mobility, and crawler lifts for rugged landscapes.

What are the advantages of articulating boom elevators?

Articulating boom elevators excel at reaching over obstacles, making them ideal for maintenance and construction tasks in complex environments, particularly in urban settings.

How do telescopic boom elevators benefit high-rise applications?

Telescopic boom elevators provide an extended reach for straight vertical rises, saving time and minimizing the need for additional equipment in large construction projects.

What are the benefits of towable aerial platforms?

Towable aerial platforms are portable and compact, making them ideal for temporary tasks and smaller operations that require mobility and quick assembly.

Why are crawler lifts suitable for outdoor tasks?

Crawler lifts are designed for rugged landscapes, providing stability and grip on irregular surfaces, which makes them dependable for outdoor tasks in challenging ground conditions.

How is the boom equipment market evolving?

The market is shifting towards electric and hybrid aerial platforms influenced by sustainability trends, with a growing preference for rental options due to cost-efficiency and flexibility.