Introduction

Embarking on a flooring project can be both exciting and overwhelming, especially when it comes to selecting the right tools for the job. Among these, a flooring nailer stands out as an essential piece of equipment that can significantly impact the quality and efficiency of the installation.

However, navigating the rental process and ensuring the right choice is made can pose challenges for many. From understanding the specifications of different nailers to mastering the techniques for optimal use, this guide offers a comprehensive overview of everything needed to successfully rent and utilize a flooring nailer.

By following these steps and best practices, anyone can transform their flooring project from a daunting task into a seamless and rewarding experience.

Getting Started: The Essentials of Renting a Flooring Nailer

To begin the process of renting a nailer, follow these essential steps:

- Determine Your Project Needs: Assess the size of your surfacing project. Consider the kind of surface and the amount of space you need to cover. This will assist you in determining the kind of fastening tool needed. to find local hardware stores or tool leasing companies that allow you to rent flooring nailers. Check their websites or call them to confirm availability.

- Compare Lease Prices: Different locations may offer varying lease costs. It's advantageous to compare prices and leasing terms to find the best deal.

- Check Lease Policies: Understand the lease policies, including the duration of the lease, deposit requirements, and any additional fees for late returns or damage.

- Prepare for Pickup: Once you have selected a location for the lease, ensure you have the necessary identification and payment method ready for the process. It’s also advisable to bring a vehicle that can accommodate the tool and any other equipment you may need.

- Ask Questions: Don’t hesitate to inquire with the rental staff about the tool's operation, maintenance, and any specific requirements for your project. This will ensure you are well-informed before starting your work.

Understanding the Hardwood Floor Nailer: Specifications and Safety Tips

When you rent flooring nailer tools, it is crucial to understand key specifications and safety practices to ensure both efficiency and safety on the job site.

-

Specifications:

-

Type of Nailer: Flooring nailers generally fall into two categories: manual and pneumatic.

Manual tools are powered by hand, making them suitable for smaller projects or those requiring precision. In contrast, pneumatic tools utilize an air compressor, offering increased power and speed, which can be beneficial for larger installation tasks. Notable manufacturers such as Bostitch are known for their precision and reliability, while Freeman offers innovative designs with ergonomic features.

Hitachi provides powerful options for demanding tasks, and Paslode emphasizes advanced safety features. Selecting the right type depends on your project requirements and personal comfort level.

-

Nail Size Compatibility: Confirm that the nailer accommodates the nail sizes you intend to use. For hardwood installations, nails typically range from 1.5 to 2 inches, with 18-gauge staples being the strongest option available, particularly effective for thick materials or concrete subfloors.

This specification is crucial as it ensures the nailer can handle the demands of your project effectively.

-

Weight and Handling: The weight of the nailer is another critical factor, especially for prolonged use. Opting for a lighter model can significantly enhance maneuverability and reduce fatigue during , especially if you rent a flooring nailer.

-

-

Safety Tips:

-

Wear Protective Gear: It’s essential to don safety goggles and hearing protection to shield against flying debris and the loud noise associated with nailers.

As emphasized by Paslode, > Safety first! Paslode is the gold standard when it comes to nail gun safety <.

-

Follow Manufacturer Instructions: Thoroughly read the user manual provided with the nailer to understand its safe operation and maintenance guidelines. This practice helps mitigate risks associated with improper usage.

-

Check for Damage: Prior to operation, inspect the nailer for any signs of wear or damage.

Utilizing a compromised tool can lead to serious accidents, so it is vital to ensure the equipment is in proper working condition.

-

Maintain a Clean Workspace: Keeping your work area organized and free of debris is crucial for safe operations. A clutter-free environment minimizes tripping hazards and allows for easier navigation while operating the tool.

-

Proper Techniques for Using a Flooring Nailer

To achieve optimal results with a nailer, consider the following best practices:

-

Preparation: Ensure that the surface material has acclimated to the room's temperature and humidity prior to installation. This critical step minimizes the risk of warping after the surface is laid.

Positioning the rent flooring nailer: Hold the rent flooring nailer at a 45-degree angle relative to the flooring surface. This angle facilitates better penetration into the wood, enhancing the overall quality of the installation.

Nailing Pattern: Begin nailing from one corner of the room and work systematically outward. Follow a uniform fastening pattern, generally positioning fasteners every 6 to 8 inches along the edges and every 12 inches in the field. This method ensures stability and durability when you rent a flooring nailer for your project.

Pressure Control: Apply consistent pressure while operating the rent flooring nailer. A lower pressure setting, around 40 PSI, has shown effective results in practice, as excessive pressure can lead to bending, while insufficient pressure may prevent proper fastening. As noted by ,

I can't honestly imagine why 80 psi would be needed to drive 1-1/4 nails; this emphasizes the need for appropriate pressure settings to achieve the best results. Additionally, to further enhance the effectiveness of your installation, you can rent a flooring nailer and use smaller brads or staples with lower pressure.

Check Alignment: Continuously monitor the alignment of your surfaces throughout the installation process. Make adjustments as necessary to maintain a straight and professional appearance in the finished product.

For further insights and to engage with the community, consider browsing other questions tagged 'floor coverings' or asking your own questions.

By adhering to these best practices, you can ensure a successful and efficient installation, minimizing issues and enhancing the quality of your work.

Returning the Flooring Nailer: Best Practices

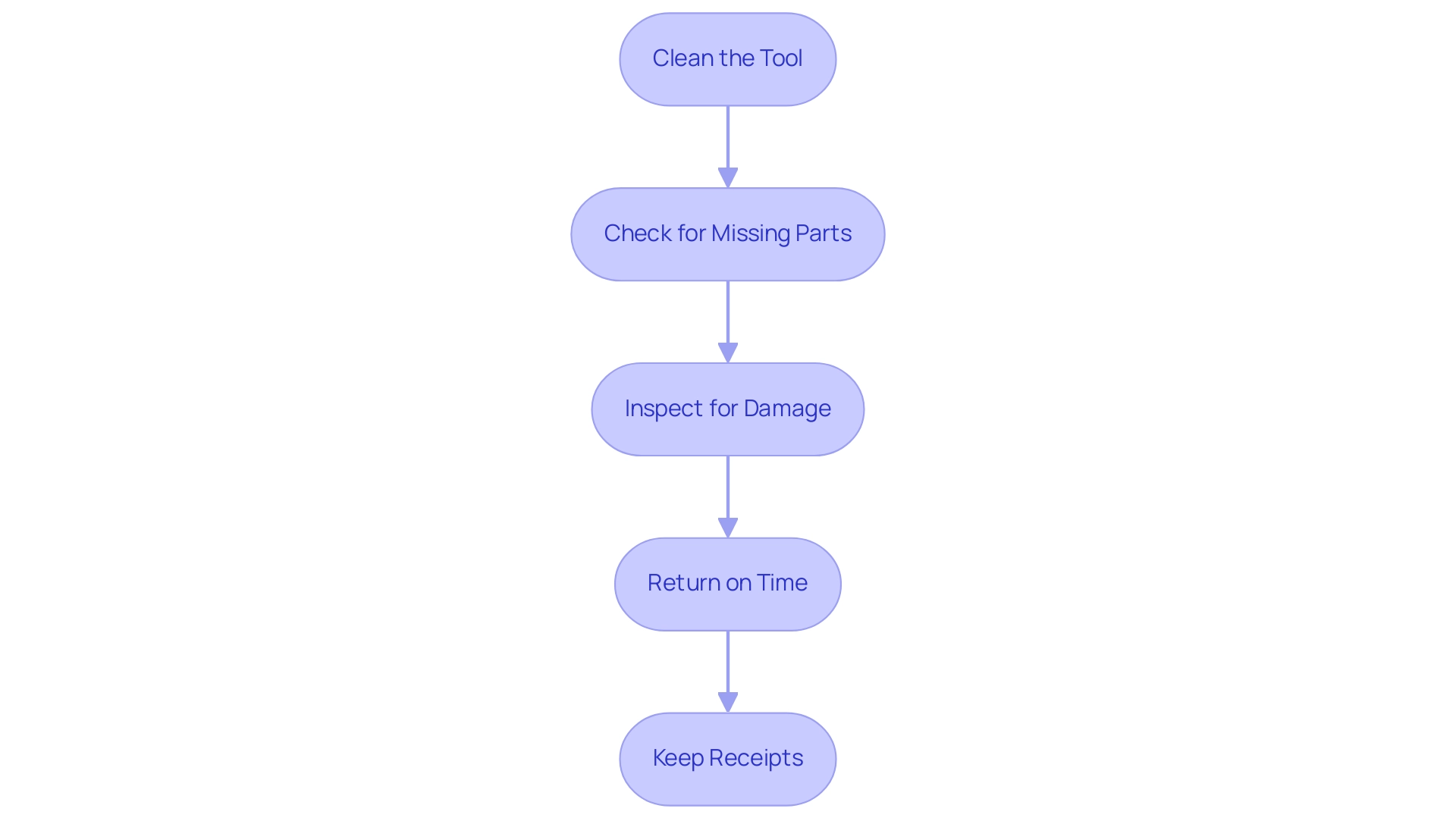

When it's time to return the flooring tool, consider these best practices:

- Clean the tool: Before returning, clean the device to remove any debris or dust. This shows respect for the equipment and avoids cleaning fees.

- Check for Missing Parts: Ensure that all components of the tool are returned, including any accessories or attachments that came with it.

- Inspect for damage: Examine the rent flooring nailer for any damage that may have occurred during your borrowing period. Report any issues to the leasing company to avoid being charged for pre-existing damage.

- Return on Time: Adhere to the agreed-upon return date to avoid late fees. If you require additional time, reach out to the leasing company to discuss prolonging the lease period.

- Keep Receipts: Retain any rental agreements or receipts until you confirm that the nailer has been returned and no additional charges have been incurred.

Conclusion

Successfully renting and using a flooring nailer can transform a flooring project from a daunting task into a smooth and efficient process. By starting with a clear understanding of project needs and conducting thorough research on rental options, individuals can select the right nailer for their specific requirements. Comparing rental rates and familiarizing oneself with the rental policies ensures a hassle-free experience.

Understanding the key specifications of the flooring nailer, including type, nail size compatibility, and safety practices, is crucial for both efficiency and safety. Following best practices when operating the nailer, such as:

- Proper positioning

- Maintaining a consistent nailing pattern

- Monitoring pressure settings

will lead to a high-quality installation. Keeping safety at the forefront, including wearing protective gear and maintaining a clean workspace, further enhances the overall experience.

Finally, adhering to best practices when returning the nailer, such as:

- Cleaning

- Inspecting for damage

ensures a smooth conclusion to the rental process. By following these guidelines, anyone can approach their flooring project with confidence, resulting in a successful installation that meets both aesthetic and functional needs. Embracing these steps not only simplifies the task at hand but also empowers individuals to achieve professional-quality results in their flooring endeavors.

Frequently Asked Questions

What are the initial steps to take when renting a nailer?

The initial steps include determining your project needs, comparing lease prices, checking lease policies, preparing for pickup, and asking questions to rental staff about the tool.

How do I determine my project needs for renting a nailer?

Assess the size of your surfacing project, consider the type of surface, and the area you need to cover to identify the appropriate fastening tool.

Why is it important to compare lease prices when renting a nailer?

Different rental locations may have varying lease costs, so comparing prices and terms can help you find the best deal.

What should I check regarding lease policies before renting?

Understand the duration of the lease, deposit requirements, and any additional fees for late returns or damage.

What preparations should I make before picking up the rented nailer?

Ensure you have the necessary identification, payment method, and a vehicle that can accommodate the tool and any other equipment needed.

What specifications should I consider when renting a flooring nailer?

Consider the type of nailer (manual or pneumatic), nail size compatibility, and the weight of the nailer for ease of handling.

What safety practices should I follow when using a nailer?

Wear protective gear, follow manufacturer instructions, check for damage before use, and maintain a clean workspace.

What best practices should I follow during the installation with a nailer?

Ensure the surface material has acclimated, hold the nailer at a 45-degree angle, follow a uniform nailing pattern, control pressure, and check alignment continuously.

What should I do before returning the rented nailer?

Clean the tool, check for missing parts, inspect for damage, return it on time, and keep receipts of the rental agreement.

What are the consequences of not adhering to the return policies for the nailer?

You may incur late fees, cleaning fees, or charges for any missing or damaged parts.