Overview

The article provides a detailed, step-by-step guide on how to rent and effectively use a hot pour crack filler machine, emphasizing the importance of project assessment, equipment specifications, and operational procedures. It supports this by outlining essential considerations for rental, operational guidelines, maintenance tips, and common mistakes to avoid, ensuring users can achieve optimal results in asphalt repair while managing costs effectively.

Introduction

Renting a hot pour crack filler machine can be a game-changer for asphalt repair projects, but navigating the rental process can feel overwhelming. With the right approach, however, it becomes manageable and even advantageous.

Understanding the specific needs of a project, from the size of the area to the volume of filler required, is essential in selecting the right machine. Factors such as heating capacity and user-friendliness can significantly influence both efficiency and effectiveness.

Beyond machine specifications, grasping the rental terms, comparing rates, and ensuring adequate support can pave the way for a seamless experience. This article delves into the critical considerations for:

- Renting a crack filler machine

- Operating it effectively

- Maintaining it for optimal performance

All while avoiding common pitfalls that could derail a project. By following these guidelines, asphalt repairs can be executed with confidence, leading to durable and cost-effective results.

Essential Considerations for Renting a Hot Pour Crack Filler Machine

When considering a hot pour crack filler machine rental, it is essential to begin with a comprehensive evaluation of your project requirements. Begin by evaluating the size of the area requiring repair and the expected volume of filler. Pay close attention to the specifications of various devices, particularly focusing on features like heating capacity, tank size, and user-friendliness.

Notably, Gravity Flow models come equipped with automatic temperature control for both oil and material, which enhances operational efficiency and effectiveness.

In addition to understanding equipment specifications, it's important to inquire about the hot pour crack filler machine rental options. This includes:

- Delivery options

- The average rental duration—typically ranging from a few days to several weeks

- Available maintenance support throughout the rental period

EZ Equipment Rental is dedicated to providing expert guidance and exceptional service, ensuring you have the support needed for a seamless hot pour crack filler machine rental experience.

It's also beneficial to compare rental rates for hot pour crack filler machine rental across different suppliers to secure the most competitive offer. For instance, the CrackPro Heated Hose Machine is recognized for its rapid heat-up times, safety features, and the largest air compressor in the industry, boasting a heating capacity of up to 200 degrees Fahrenheit and a tank size of 10 gallons. These attributes can significantly impact project timelines and outcomes.

Moreover, ensure that the rental company provides comprehensive instructions and operational support for the effective use of the hot pour crack filler machine rental. With EZ Equipment Rental's commitment to reliability, you can have confidence in their equipment and services. As noted by Asphalt Kingdom, with these competitive rates, you can recoup your investment in the RY10 PRO in just 15 rental days!

This highlights the financial advantages of making informed rental decisions. Additionally, consider the Hot Air Lance, available for rental at $150 per day, which utilizes vapor propane mixed with super-heated compressed air to clean, dry, and heat pavement gaps. Customers have commended EZ Equipment Rental for their attentive service and the quality of their gear, expressing that 'the CrackPro device made our project not only quicker but also more efficient.'

By integrating these elements into your assessment, you can optimize your project’s success while effectively managing costs.

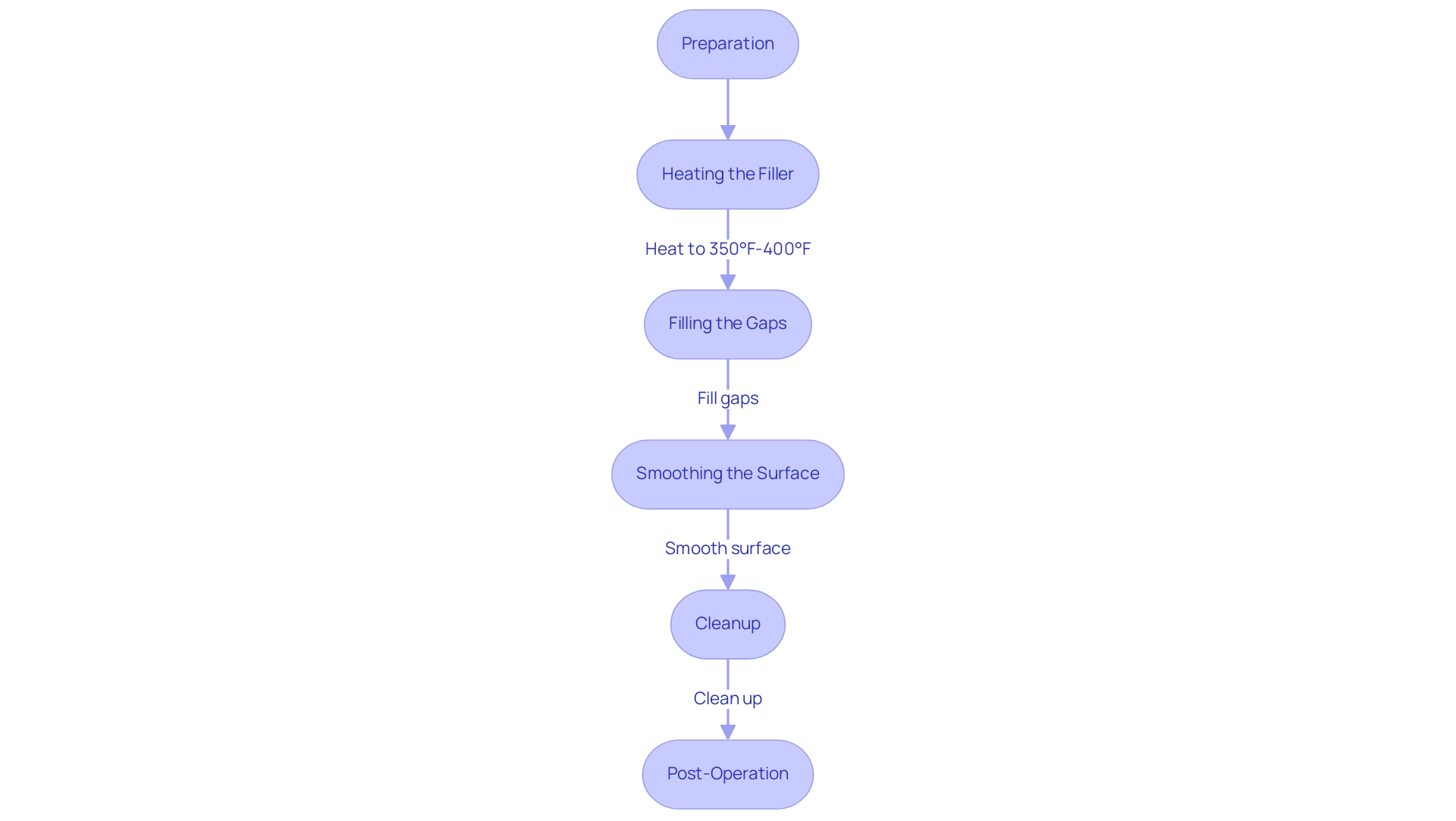

Step-by-Step Guide to Operating a Hot Pour Crack Filler Machine

- Preparation: Start by thoroughly cleaning the work area, ensuring it is free from debris and any loose materials. It is crucial that the cracks are completely dry and devoid of moisture to promote optimal bonding of the material.

- Heating the Filler: Activate the hot pour crack filler machine rental and adjust it to the recommended heating range of 350°F to 400°F. Monitor the material closely as it heats to achieve a pourable consistency, taking care not to exceed 12 to 15 hours of heating without introducing fresh substance, as prolonged heat can compromise its effectiveness. As noted by O’Driscoll, "Overworked sealant can break down, reducing adhesion and the life of your melter pot."

- Filling the Gaps: Utilize the machine's nozzle to carefully fill the gaps, ensuring to slightly overfill each one to allow for settling and effective sealing. Specialty substances such as mastic or Gator Patch can be especially effective based on the size and kind of damage—mastic is perfect for larger openings while Gator Patch tackles alligator damage. When selecting the appropriate crack substance for a hot pour crack filler machine rental, consider factors such as crack size, severity, climate conditions, and traffic levels to ensure the best results.

- Smoothing the Surface: After filling, employ a squeegee or trowel to smooth the surface of the filler, ensuring it blends seamlessly with the surrounding pavement. This step is vital for aesthetics and functionality.

- Cleanup: Once the operation is complete, switch off the machine and meticulously clean any residue from the nozzle and surrounding areas to prevent clogging and maintain the machine's longevity. Additionally, adhere to safety best practices by avoiding operation in confined spaces and keeping fire extinguishers nearby to minimize risks associated with equipment operation.

- Post-Operation: Allow the filled gaps to cool and set adequately before permitting any traffic on the surface. Adhering to these guidelines will assist in achieving effective sealing and prolonging the lifespan of the pavement.

Advantages of Hot Pour Crack Fillers for Asphalt Repair

Hot pour crack fillers present numerous advantages for effective asphalt repair:

- Durability: Research indicates that hot-pour sealants have an average service life of approximately 3.5 years, significantly outlasting cold-pour options, which average around 2.2 years. This longevity ensures that repairs can withstand extreme temperatures and heavy traffic, making them a reliable choice.

- Flexibility: One of the standout features of hot pour substances is their ability to remain flexible after curing. This adaptability allows them to expand and contract with temperature fluctuations, minimizing the risk of cracking over time.

- Quick Application: The heating process associated with hot pour materials enables rapid application and curing, which is particularly beneficial for larger projects where time is of the essence. This efficiency was highlighted in recent studies that demonstrated how the hot pour crack filler machine rental outperforms cold-pour counterparts in effectiveness and application speed.

- Cost-Effectiveness: Although the upfront expenses for hot pour crack materials may be higher, their longevity and the decreased requirement for regular maintenance often result in greater cost savings over time. Insights from the case study titled "Novel Modification of Soft Asphalt for Use in Infrastructure Applications" reveal a cost-effective approach to producing durable materials suitable for various infrastructure uses, further supporting the case for hot pour substances. Additionally, Natalie Camille Brush emphasizes that this new system will expedite construction and reduce disturbances to the traveling public, highlighting the broader public benefits of using these advanced materials for asphalt restoration. Overall, the long-term durability statistics and performance advantages of hot pour crack filler machine rental solidify hot pour materials as a superior choice in the asphalt repair industry.

Maintenance Tips for Your Hot Pour Crack Filler Machine

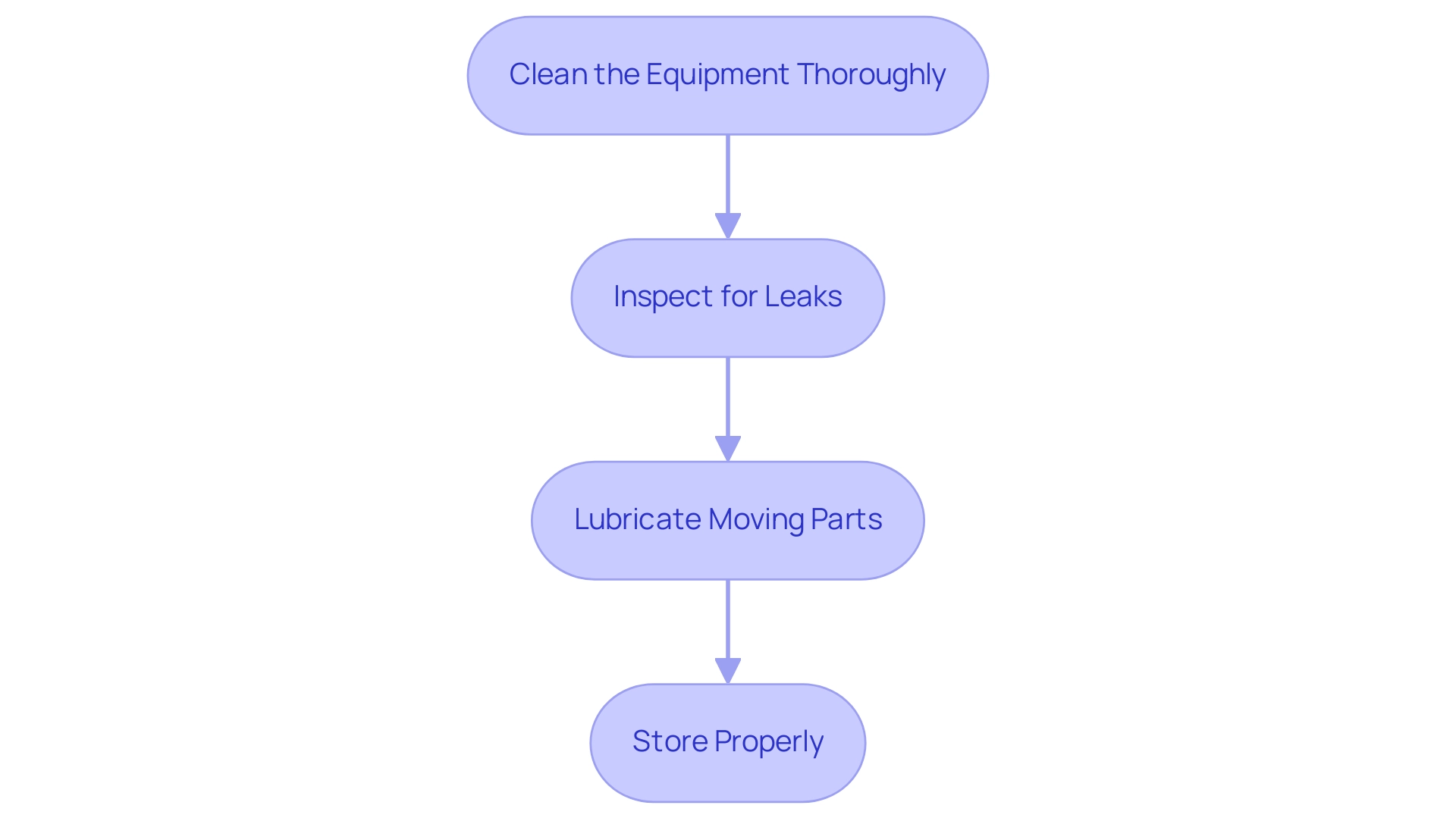

To ensure that your hot pour filler apparatus remains in peak operating condition, follow these essential maintenance practices:

- Clean the Equipment Thoroughly: After every use, it is crucial to clean the nozzle and tank to eliminate residual filler. This prevents buildup, which can hinder performance during future applications. Proper maintenance is especially important considering that using a hot pour crack filler machine rental can help hot applied crack sealant withstand extreme weather conditions, including freezing temperatures and heavy rain, but only if the equipment is in optimal condition.

- Inspect for Leaks: Conduct regular inspections of hoses and connections for signs of leaks or wear. Addressing any damage immediately is vital, as neglecting this can lead to operational inefficiencies and costly repairs.

- Lubricate Moving Parts: To promote smooth operation, apply lubricant to moving components according to the manufacturer's recommendations. Regular lubrication minimizes friction and extends the lifespan of the machine.

- Store Properly: Proper storage is key to maintaining your equipment. When the device is not in operation, it should be kept in a dry, temperature-controlled environment. This practice helps protect it from extreme weather conditions, which can lead to deterioration. Additionally, it is essential to apply sealant when the pavement is dry to avoid trapping moisture, which can lead to further issues.

An expert in pavement preservation, Etkin Yildirim, emphasizes the need for rigorous maintenance standards, stating,

A minimum acceptance level is defined, and if the cracked treatment effectiveness falls below this point, the treatment is considered to have failed.

Furthermore, a case study on hot poured rubberized asphalt sealer highlights that proper maintenance not only minimizes repair needs and costs but also preserves pavement integrity, making it a superior choice for sealing. By following these best practices, you can significantly decrease the chances of common issues stemming from insufficient maintenance, ensuring your equipment operates effectively when you need it most.

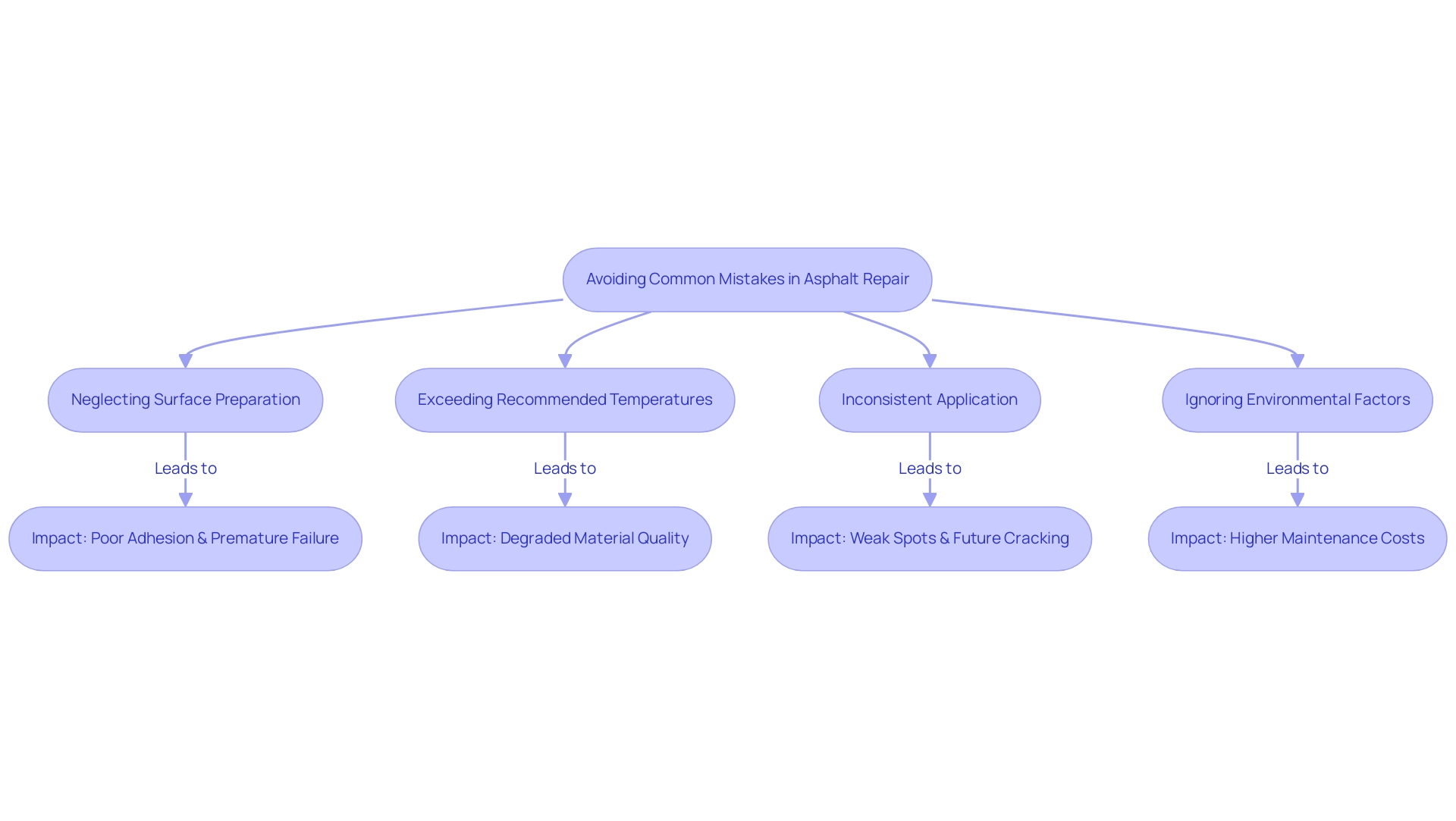

Common Mistakes to Avoid When Using a Hot Pour Crack Filler Machine

To ensure the optimal performance of your hot pour repair machine, it is crucial to avoid several common pitfalls:

- Neglecting Surface Preparation: Properly cleaning and drying the gaps before application is non-negotiable. Failing to prepare the surface can significantly hinder adhesion and lead to premature failure of the repair. Azam Amir's research highlights that effective surface preparation is essential, as it directly impacts the longevity and reliability of the crack sealant. The study found that rutting, raveling, alligator, and transverse cracking exhibited the highest probabilities of occurrence, highlighting the need for thorough preparation to mitigate these issues.

- Exceeding Recommended Temperatures: Adhering to the manufacturer's heating guidelines is essential. Using a hot pour crack filler machine rental, overheating the material not only degrades its quality but also compromises its ability to bond effectively, leading to subpar results.

- Inconsistent Application: Applying the filler unevenly can create weak spots that are susceptible to future cracking. Take your time to ensure an even application, as rushing this process often results in neglected areas that may fail under stress.

- Ignoring Environmental Factors: Weather conditions play a crucial role in the effectiveness of asphalt restoration. Utilizing the machine in extreme temperatures or during wet conditions can profoundly affect the quality of the restoration. Recent studies have shown that such conditions can exacerbate pavement distress types, ultimately leading to higher maintenance costs. For instance, the probability of potholes occurring is greater in hilly areas than in plain areas, which underscores the importance of considering environmental factors. By prioritizing these considerations, you can significantly enhance the durability of your asphalt repairs and avoid costly errors associated with hot pour crack filler machine rental.

Conclusion

Renting a hot pour crack filler machine can significantly enhance the efficiency and effectiveness of asphalt repair projects when approached with careful consideration. By thoroughly assessing project needs, including area size and filler volume, the right machine can be selected, ensuring optimal heating capacity and user-friendliness. Understanding rental terms and comparing rates can lead to more informed decisions, ultimately saving time and money while achieving durable results.

Operating the machine effectively requires attention to detail throughout each step, from preparation and heating to filling and post-operation cleanup. Following best practices not only ensures a successful application but also contributes to the longevity of the pavement. Additionally, regular maintenance of the machine is essential to prevent costly repairs and preserve its performance, reinforcing the importance of cleanliness, inspections, and proper storage.

Avoiding common mistakes is equally crucial in maximizing the benefits of using a hot pour crack filler machine. By prioritizing surface preparation, adhering to manufacturer's guidelines, and being mindful of environmental factors, the risk of premature failure can be minimized. Embracing these strategies will lead to successful asphalt repairs that stand the test of time, making the investment in a hot pour crack filler machine a wise choice for any repair project.

Frequently Asked Questions

What should I evaluate before renting a hot pour crack filler machine?

Begin by assessing the size of the area needing repair and the expected volume of filler. Pay attention to the specifications of various devices, focusing on features like heating capacity, tank size, and user-friendliness.

What are the benefits of Gravity Flow models for hot pour crack filler machines?

Gravity Flow models feature automatic temperature control for both oil and material, which enhances operational efficiency and effectiveness.

What rental options should I inquire about when considering a hot pour crack filler machine?

Inquire about delivery options, the average rental duration (typically ranging from a few days to several weeks), and available maintenance support throughout the rental period.

How can I ensure a good rental experience with EZ Equipment Rental?

EZ Equipment Rental provides expert guidance and exceptional service to ensure a seamless rental experience, including comprehensive instructions and operational support for the machine.

What should I consider when comparing rental rates for hot pour crack filler machines?

It is beneficial to compare rental rates across different suppliers to secure the most competitive offer, considering features such as rapid heat-up times and safety features.

What is notable about the CrackPro Heated Hose Machine?

The CrackPro Heated Hose Machine is recognized for its rapid heat-up times, safety features, and the largest air compressor in the industry, with a heating capacity of up to 200 degrees Fahrenheit and a tank size of 10 gallons.

What additional equipment can I rent to aid in the crack filling process?

The Hot Air Lance is available for rental at $150 per day and utilizes vapor propane mixed with super-heated compressed air to clean, dry, and heat pavement gaps.

What are the steps to effectively use a hot pour crack filler machine?

The steps include preparation (cleaning the area), heating the filler (to 350°F to 400°F), filling the gaps, smoothing the surface, cleanup, and allowing the filled gaps to cool before permitting traffic.

What safety precautions should I take when operating a hot pour crack filler machine?

Avoid operation in confined spaces, keep fire extinguishers nearby, and ensure thorough cleaning of the machine after use to prevent clogging and maintain its longevity.