Overview

Renting a hydrostatic test pump involves a systematic process that begins with determining project requirements. This is followed by researching rental providers, ensuring that the equipment meets safety standards and compliance throughout the rental period. The importance of selecting reputable companies cannot be overstated, as it directly impacts operational integrity across various industries. Understanding lease terms and adhering to safety protocols are essential to prevent failures and maintain reliability. Engaging with trusted rental providers not only enhances project success but also assures quality and safety in operations.

Key Highlights:

- Hydrostatic testing evaluates the integrity of pipelines, gas cylinders, and pressure vessels by identifying leaks and structural weaknesses.

- The increasing federal infrastructure funding in 2025 is expected to boost demand for reliable pressure assessment methods in construction.

- Neglecting pressure assessments can lead to catastrophic failures, highlighting the critical need for compliance and safety in operations.

- Recent advancements in hydrostatic testing technologies enhance efficiency and safety, aligning with stringent regulations.

- Types of hydrostatic test pumps available for rent include electric, gas-powered, manual, and pneumatic devices, each suited for specific applications.

- The rental process involves determining requirements, researching providers, checking availability, reviewing lease terms, inspecting equipment, and receiving operating instructions.

- Choosing a rental company should consider reputation, equipment quality, customer service, flexible lease terms, and delivery options.

- Challenges in rentals include equipment availability, understanding specifications, logistical issues, technical difficulties, and cost overruns.

- Safety and compliance are paramount, requiring PPE, pressure monitoring, area isolation, emergency procedures, and adherence to regulations.

- The hydrostatic test pump rental market is projected to generate significant revenue growth, emphasizing the importance of safety and compliance in industries like oil and gas.

Introduction

In a world where safety and reliability are paramount, hydrostatic testing emerges as a crucial procedure for safeguarding the integrity of pressure vessels and pipelines. This method, which entails filling systems with liquid and applying pressure to identify leaks or weaknesses, is indispensable across diverse industries, including:

- construction

- oil and gas

- manufacturing

As investments in infrastructure continue to rise, the demand for effective testing methods has never been more urgent, underscoring the necessity for robust practices that avert catastrophic failures and expensive repairs. With technological advancements reshaping the landscape of hydrostatic testing, it is essential for project managers to grasp its significance and the available tools to navigate the complexities of contemporary engineering challenges.

Understanding Hydrostatic Testing and Its Importance

The hydrostatic test pump rental is a critical procedure utilized to evaluate the integrity of pipelines, gas cylinders, boilers, and other pressure vessels. This method involves employing a hydrostatic test pump rental to fill these systems with liquid and apply pressure, effectively identifying leaks or structural weaknesses. Its importance spans various industries, particularly construction, oil and gas, and manufacturing, where operational safety is non-negotiable.

In 2025, the importance of fluid pressure assessment is underscored by the evolving landscape of federal infrastructure funding, which is anticipated to bolster nonresidential construction projects. As these investments continue, the demand for reliable assessment methods will inevitably increase, ensuring that systems can endure operational pressures without failure. A statistic from 2023 revealed that 1,326 new unique recipients benefited from US$2.15 billion in IIJA obligations, reflecting the growing reliance on robust evaluation methods in construction projects and highlighting the essential role of pressure assessment in ensuring safety and compliance.

Neglecting pressure assessments can lead to severe repercussions, including catastrophic breakdowns that pose safety risks and incur substantial repair costs. Recent advancements in fluid pressure evaluation services, such as hydrostatic test pump rental, automated systems, and remote monitoring, have revolutionized the industry. These innovations not only enhance efficiency but also elevate safety compliance, aligning with stringent regulations.

For example, the case study titled "Innovation in Hydrostatic Pressure Testing Services" illustrates how advancements in hydrostatic test pump rental are geared toward improving efficiency and safety in procedures, ultimately reducing operational costs and adhering to strict safety standards.

A Senior Research Analyst remarked, "I have a proven track record of conducting thorough analyses, distilling key insights, and presenting findings in a way that resonates with diverse stakeholders." This perspective underscores the vital role of pressure assessments in safeguarding infrastructure integrity, particularly in light of the shifting policy environment surrounding federal infrastructure funding and tariff adjustments.

Practical examples abound where pressure assessment has successfully prevented failures, reinforcing its significance as a foundational element of project management in construction and engineering. As the sector continues to evolve, staying informed about the latest hydrostatic evaluation methods and their implications for safety will be crucial for project managers aiming for successful outcomes.

Types of Hydrostatic Test Pumps Available for Rent

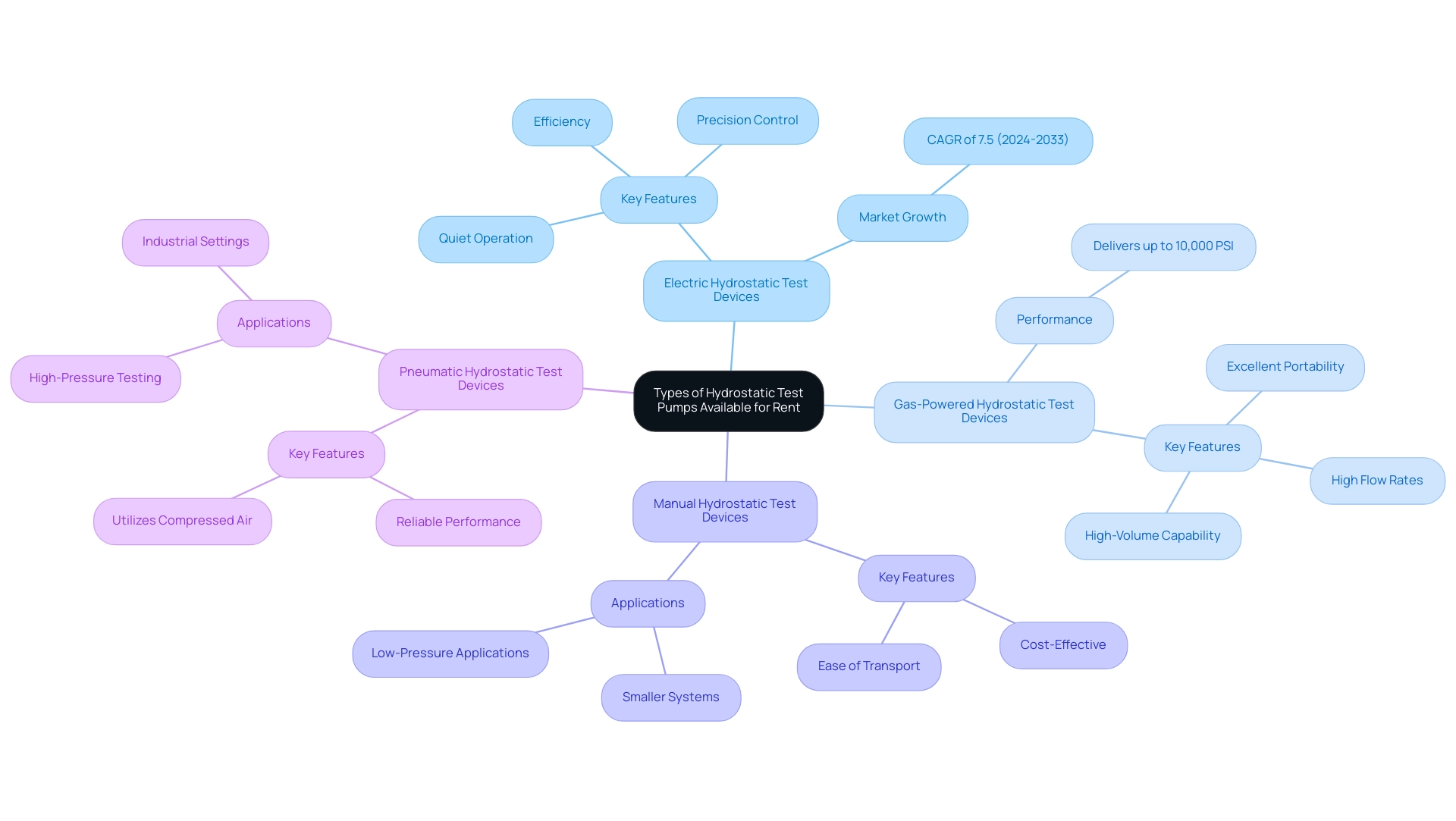

Hydrostatic test pump rental offers essential devices that are crucial tools in various applications, each designed to meet specific pressure requirements and operational needs. The main types available include:

- Electric Hydrostatic Test Devices: Perfect for indoor environments and smaller testing applications, these devices feature quiet operation and efficiency that allow for consistent pressure control. This reliability makes them an ideal choice for projects requiring precision. The electric hydrostatic test devices market is anticipated to show a CAGR of 7.5% from 2024 to 2033, indicating a growing demand for these efficient solutions.

- Gas-Powered Hydrostatic Test Devices: Designed for outdoor use, these units provide excellent portability and high flow rates, making them ideal for large-scale projects. Their robust performance ensures they can handle demanding tasks effectively. High-Volume Hydrostatic Test Units can deliver up to 10,000 PSI, showcasing their capabilities in high-pressure applications.

- Manual Hydrostatic Test Devices: Operated manually, these devices are typically used for low-pressure applications or smaller systems. Their cost-effectiveness and ease of transport make them a practical option for budget-conscious projects.

- Pneumatic Hydrostatic Test Devices: Utilizing compressed air, these mechanisms are efficient for high-pressure testing and are often favored in industrial settings due to their reliability and performance.

Every category of pressure testing device, including hydrostatic test pump rental, provides unique benefits suited to various project needs. As noted by a Senior Research Analyst at Cognitive Market Research, "Through collaboration with cross-functional teams, I played a pivotal role in shaping business strategies rooted in robust research," emphasizing the importance of informed equipment selection.

Furthermore, the case study titled 'Market Research Methodology for Test Devices' describes the research approach utilized to collect information on the test devices market, guaranteeing the precision and dependability of results.

By understanding these options, users can choose the most appropriate device, including a hydrostatic test pump rental, for their specific applications, ensuring optimal performance and efficiency in their testing processes. For more information and to reserve the equipment needed, contact EZ Equipment Rental at (214) 951-7800.

Step-by-Step Process for Renting a Hydrostatic Test Pump

Renting a hydrostatic test pump involves several essential steps to ensure a smooth and efficient process.

- Determine Your Requirements: Begin by assessing the specific needs of your project. Consider elements such as the kind of device needed, pressure ratings, and the length of the lease. Understanding these parameters will help you select the right equipment for your task.

- Research Equipment Providers: Identify trustworthy equipment providers in your region, such as EZ Equipment Hire, recognized for their extensive inventory of hydrostatic test pump rental devices. With the significant shift to e-commerce, where 60% of global sales occur online, utilizing digital platforms can enhance your search for reliable leasing options. A company with a strong reputation can provide peace of mind regarding equipment quality and customer service.

- Check Availability: Once you have identified potential leasing companies, contact them to confirm the availability of their hydrostatic test pump rental for your specified duration. This step is crucial, as demand for specific equipment can fluctuate based on project timelines and seasonal needs.

- Review Lease Terms: Before finalizing your agreement, thoroughly understand the terms. Pay attention to costs, deposit requirements, and insurance options. Knowing the total product cost, which includes maintenance and overhead, is vital for budgeting. For instance, a piece of equipment purchased at $1,500 incurs yearly maintenance and overhead costs of $250, bringing the total cost to $1,750. As Mircea 'Mig' Dobre emphasizes, managing costs and cash flow is essential in the cyclical leasing industry, especially during downturns. Additionally, consider insights from the case study on cost per lease, which suggests aligning lease prices with market averages to remain competitive.

- Inspect the Equipment: Upon pickup, examine the device for any damages or issues. Ensure that it meets your specifications and is in working order. This step is critical to avoid any disputes regarding equipment condition upon return.

- Receive Operating Instructions: Request a demonstration or detailed operating instructions from the leasing company. Understanding how to properly use the equipment is essential for safety and efficiency during your project.

- Complete the Lease: After utilizing the device, return it according to the leasing agreement. Ensure it is in the same condition as when rented to avoid incurring additional fees. Following these steps will help you navigate the leasing process effectively, ensuring you have the right equipment for your project needs.

Choosing the Right Rental Company for Your Hydrostatic Test Pump

When selecting a rental company for your hydrostatic test pump, several critical factors should guide your decision-making process.

- Reputation and Reviews: Investigate customer reviews and testimonials to assess the reliability and quality of service offered by the company. Positive feedback can indicate a strong track record in customer satisfaction, especially in a market where 79% of consumers trust online reviews as much as personal recommendations. This trust is vital, particularly in light of the recent manufacturing construction surge, which has increased competition among leasing firms.

- Equipment Quality: It is essential to ensure that the company provides well-maintained and modern equipment. High-quality pumps are crucial to preventing failures that could postpone your project and raise expenses, especially given the unprecedented demand for hydrostatic test pump rental noted by experts in the leasing sector.

- Customer Service: Choose a company with informed personnel who can assist you in selecting the appropriate equipment and provide support during the usage period. Exceptional customer service can significantly enhance your leasing experience, particularly in a cyclical industry where customer needs may fluctuate.

- Flexible Lease Terms: Select a company that offers adaptable terms tailored to your project timelines and budget constraints. This flexibility can be vital, especially in the dynamic construction environment where project scopes may change.

- Delivery and Pickup Options: Evaluate whether the company provides delivery and pickup services. This convenience can save you valuable time and effort, allowing you to focus on your project rather than logistics.

In 2025, customer reviews play a pivotal role in influencing company selection, with statistics indicating that 79% of consumers trust online reviews as much as personal recommendations. As Mircea “Mig” Dobre, a senior analyst in machinery and diversified industrial equities, emphasizes, the cyclical nature of the leasing industry necessitates that companies not only manage expenses but also prepare for future growth opportunities. Insights from the case study titled "Future Growth Prospects for the Leasing Industry" highlight the importance of selecting a trustworthy leasing company amidst these challenges.

Additionally, the upcoming Equipment Finance Connect event on May 14-15, 2025, in Nashville, TN, will provide valuable industry insights and networking opportunities. By considering these factors, you can make an informed choice that aligns with your project needs and expectations.

Overcoming Challenges in Hydrostatic Test Pump Rentals

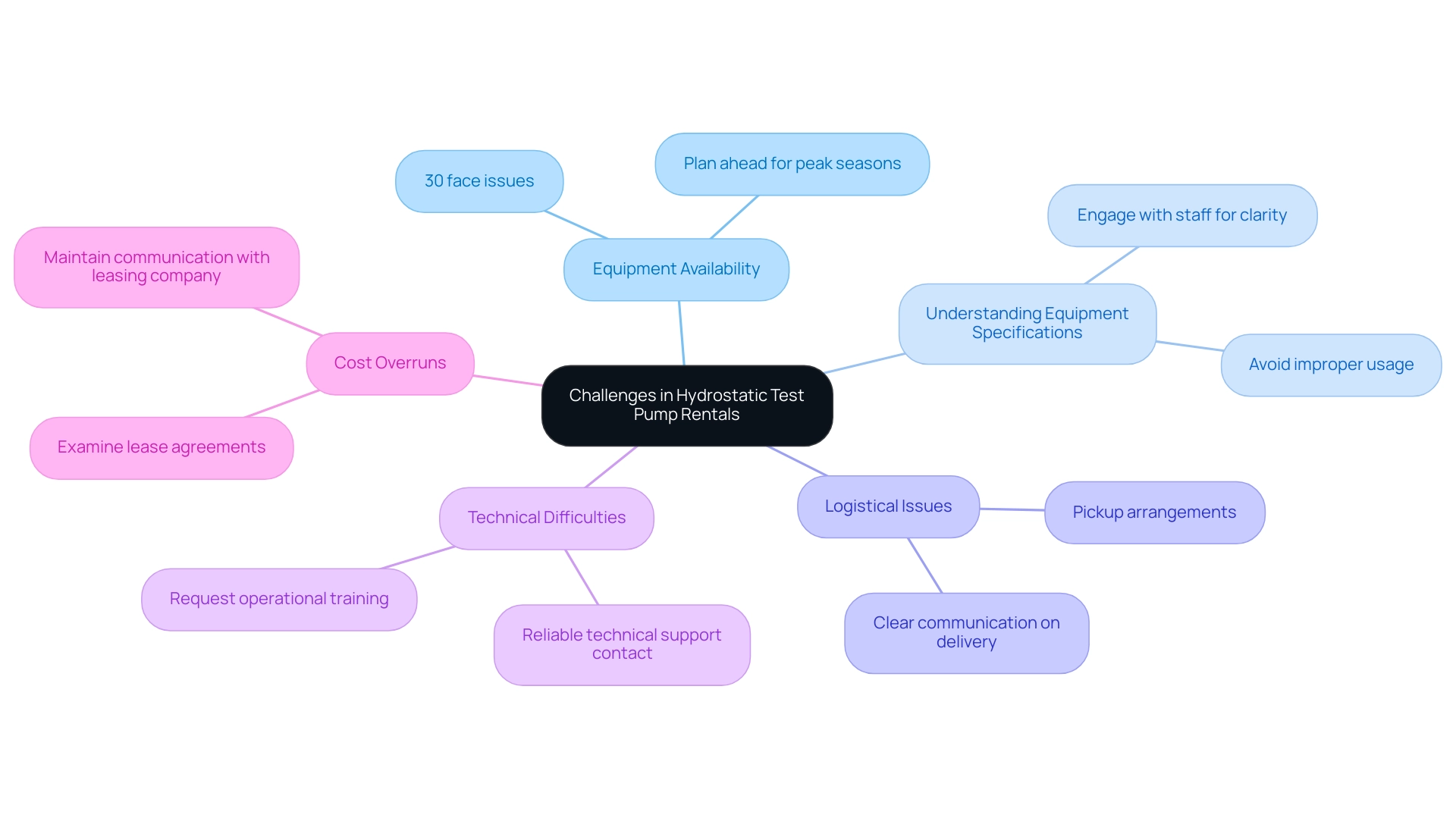

Common challenges encountered during hydrostatic test pump rentals include:

- Equipment Availability: The demand for specific model types frequently surpasses supply, leading to unavailability. Recent statistics indicate that approximately 30% of customers report facing equipment availability issues. To mitigate this, it is advisable to plan ahead and secure your accommodation well in advance, particularly during peak construction seasons.

- Understanding Equipment Specifications: A common hurdle arises from misunderstandings regarding pump specifications, which can lead to improper usage. To avoid this, always engage with the staff to clarify any uncertainties about the capabilities and requirements of the hydrostatic test pump rental.

- Logistical Issues: The transportation and delivery of leased equipment can pose significant challenges. Clear communication with the leasing company regarding delivery schedules and pickup arrangements is essential to ensure smooth operations for hydrostatic test pump rentals.

- Technical Difficulties: Equipment malfunctions can occur, impacting project timelines. It is crucial to request operational training upon leasing the hydrostatic test pump and to have a reliable contact number for technical support during the rental period to address any issues promptly.

- Cost Overruns: Unexpected fees can lead to budget overruns. To prevent this, thoroughly examine the lease agreement to understand all potential costs involved with the hydrostatic test pump rental. Maintaining open lines of communication with the leasing company can help clarify any ambiguities and avoid financial surprises.

In light of current trends, such as the anticipated decline in private non-residential construction spending, understanding these challenges becomes even more critical. According to Access International's Confidence Survey, despite economic uncertainties, there is cautious optimism in the leasing market, with 48% of leasing firms planning to invest in new equipment. Mircea “Mig” Dobre, a senior analyst in machinery and diversified industrial sectors, emphasizes this need for adaptability: "That’s why I think you almost have to flip the switch from being in ultra-growth mode where you’re growing fleet as fast as you can and you’re growing your employee base to keep up with that."

This perspective underscores the importance of strategic planning and adaptability in the face of evolving market conditions. Furthermore, the rental industry is inherently sustainable, and operators are increasingly communicating this to customers, aligning with the growing demand for environmentally responsible practices.

Safety and Compliance Considerations for Hydrostatic Testing

Safety and compliance are vital elements of hydrostatic evaluations. Utilizing a hydrostatic test pump rental ensures not only the integrity of the systems being assessed but also the well-being of personnel involved. Key considerations include:

- Personal Protective Equipment (PPE): It is essential that all personnel involved in the evaluation process are equipped with appropriate PPE. This includes safety glasses, gloves, and hard hats, which serve as the first line of defense against potential hazards.

- Pressure Monitoring: Continuous observation of pressure levels during evaluation is vital. Over-pressurization can result in catastrophic equipment failure or accidents, highlighting the necessity for vigilant oversight throughout the evaluation process.

- Area Isolation: Securing the examination area is imperative to prevent unauthorized access. By isolating the area, the risks associated with high-pressure assessments are significantly minimized, protecting both personnel and bystanders.

- Emergency Procedures: Establishing clear emergency protocols is essential in the event of equipment failure or accidents. All personnel should be trained and familiar with their roles in these scenarios, ensuring a swift and effective response to any incidents.

- Regulatory Compliance: Understanding and following pertinent regulations and standards overseeing pressure assessments is essential. Compliance not only helps avoid penalties but also reinforces safety measures, fostering a culture of responsibility within the team. A Senior Research Analyst emphasized this point, stating, "Through collaboration with cross-functional teams, I played a pivotal role in shaping business strategies rooted in robust research," highlighting the collective effort required to maintain high safety standards.

In 2025, compliance rates with pressure assessment regulations are anticipated to be closely observed, with industry leaders highlighting the significance of following safety protocols. Furthermore, the hydrostatic test pump rental sector of the pressure assessment market is expected to generate an absolute dollar opportunity exceeding USD 180.2 million from 2022 to 2028, fueled by their essential function in maintaining the integrity of water systems. This growth reflects the increasing emphasis on safety and compliance in the industry, particularly within sectors such as oil and gas, which is expected to present significant opportunities with an estimated dollar opportunity of more than USD 108.5 million by 2028.

Additionally, the recent rise in acquisitions and growth activities in the pressure examination market highlights the sector's current dynamics and the increased emphasis on safety and compliance initiatives. Real-world instances of adherence in fluid pressure evaluation procedures demonstrate the effectiveness of these safety measures, reinforcing the importance of PPE and strict monitoring practices. As the industry evolves, staying informed about safety statistics and regulations will be paramount for successful project management.

For those seeking further insights, sample reports on the hydrostatic testing market can be requested, with 24/7 support available for inquiries.

Conclusion

Hydrostatic testing is crucial for ensuring the safety and integrity of pressure vessels and pipelines across industries such as construction, oil and gas, and manufacturing. By effectively detecting leaks and weaknesses, this procedure plays a vital role in preventing catastrophic failures, especially as federal infrastructure investments continue to rise.

Selecting the right hydrostatic test pumps and understanding the rental process can greatly enhance project efficiency. Addressing challenges such as equipment availability and logistics is essential for maintaining smooth operations, ensuring that projects proceed without unnecessary delays.

Safety and compliance are paramount in hydrostatic testing. The proper use of personal protective equipment, continuous pressure monitoring, and strict adherence to regulatory standards safeguard personnel and minimize risks. As the industry evolves, the focus on safety and compliance will only intensify, highlighting the critical role of hydrostatic testing in preserving infrastructure integrity.

In conclusion, with increasing infrastructure investments and an urgent need for dependable testing methods, hydrostatic testing stands out as a key practice that mitigates risks and fosters safety. Staying informed about the latest technologies and practices is vital for project managers striving for successful and compliant outcomes.

Frequently Asked Questions

What is the purpose of hydrostatic test pump rental?

Hydrostatic test pump rental is used to evaluate the integrity of pipelines, gas cylinders, boilers, and other pressure vessels by filling them with liquid and applying pressure to identify leaks or structural weaknesses.

Why is hydrostatic testing important in various industries?

Hydrostatic testing is crucial in industries like construction, oil and gas, and manufacturing to ensure operational safety and compliance with regulations, preventing catastrophic breakdowns and costly repairs.

How is the demand for pressure assessment expected to change in the future?

The demand for reliable pressure assessment methods is anticipated to increase due to evolving federal infrastructure funding, which is expected to bolster nonresidential construction projects.

What are the consequences of neglecting pressure assessments?

Neglecting pressure assessments can lead to severe repercussions, including safety risks and substantial repair costs due to catastrophic failures.

What advancements have been made in hydrostatic testing services?

Recent advancements include automated systems and remote monitoring, which enhance efficiency and safety compliance in hydrostatic testing.

What types of hydrostatic test devices are available for rental?

The main types of hydrostatic test devices available for rental include: 1. Electric Hydrostatic Test Devices: Ideal for indoor use and smaller applications with quiet operation. 2. Gas-Powered Hydrostatic Test Devices: Suitable for outdoor use with high flow rates for large-scale projects. 3. Manual Hydrostatic Test Devices: Cost-effective and portable, used for low-pressure applications. 4. Pneumatic Hydrostatic Test Devices: Efficient for high-pressure testing, commonly used in industrial settings.

What factors should be considered when selecting a hydrostatic test device?

Users should consider the specific pressure requirements and operational needs of their projects to choose the most appropriate hydrostatic test device for optimal performance.

How can one reserve hydrostatic testing equipment?

To reserve hydrostatic testing equipment, contact EZ Equipment Rental at (214) 951-7800 for more information.