Introduction

Navigating the world of pallet stacker rentals can be a daunting task, especially for those unfamiliar with the intricacies of equipment selection and operational requirements. With the demand for efficient material handling on the rise, understanding how to choose the right pallet stacker is essential for any project manager. From assessing project specifications and budgeting to ensuring safety and compliance, each decision carries weight. As the rental market continues to expand, it becomes increasingly important to grasp the essential considerations that can streamline the rental process and contribute to overall project success.

This guide will illuminate the critical steps and factors to consider, empowering individuals and organizations to make informed choices in their pallet stacker rental journey.

Essential Considerations Before Renting a Pallet Stacker

Renting a pallet stacker involves several critical considerations to ensure that your choice aligns with project demands and operational efficiency. Here are essential factors to evaluate:

-

Project Requirements: Carefully assess the specific needs of your project, including the weight and dimensions of the containers you will be handling.

Comprehending the load specifications will assist you in choosing the suitable equipment type, whether it's an electric, manual, or high-lift stacker.

-

Duration of Rental: Evaluate how long you will require to rent a pallet stacker. Leasing companies often offer discounts for prolonged usage periods, making it essential to forecast your timeline accurately.

-

Budget: Establish a clear budget for the lease to rent pallet stacker, including potential additional costs such as delivery, insurance, and any required accessories. This will help you avoid unexpected expenses that could impact your project’s financials.

-

Reputable Lease Firm: To ensure you select a reputable lease firm for equipment, conduct thorough research on those recognized for providing high-quality options, such as the ability to rent pallet stacker and offer exceptional customer service.

Insights from recent strategic acquisitions in the construction leasing industry, such as Trench Shore Rentals selling its assets to Sunstate Equipment Co., and Boels Rental acquiring BAS Maskinutleie, highlight the importance of selecting a company with a strong market presence. Reviews and testimonials can guide you in making an informed decision.

-

Equipment Availability: Verify the availability of the platform lifter you require, particularly during high demand seasons when the need to rent a pallet stacker can exceed supply.

With the platform lifter leasing market expected to expand, especially in fields such as construction, early booking can ensure your preferred apparatus.

-

Delivery and Pickup Options: Investigate whether the company provides convenient delivery and pickup services. Employing these services can save you precious time and minimize logistical difficulties on-site.

As the equipment leasing market is expected to expand, with notable activity observed in industries such as construction—where retail and e-commerce used over 32,570 thousand units in 2022—comprehending these elements will prepare you for effective equipment leasing that fulfills your project’s specific requirements.

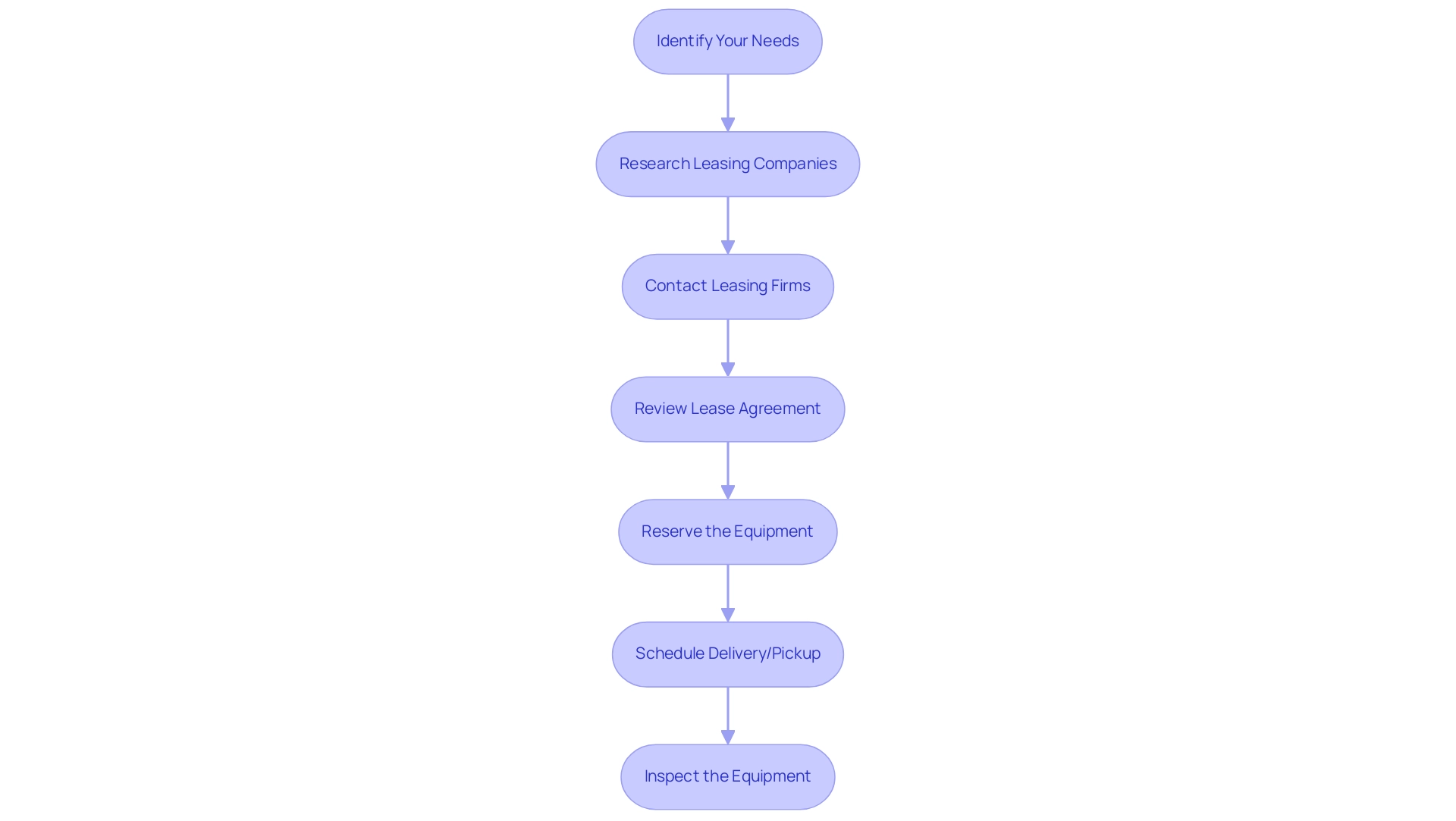

Step-by-Step Guide to Renting a Pallet Stacker

To successfully rent a lifting platform for your project, follow these essential steps:

- Identify Your Needs: Begin by determining the specifications required for your project, including weight capacity and lift height.

- Research Leasing Companies: Investigate local leasing companies that rent pallet stackers, comparing their rates, services, and customer reviews to ensure you find the best fit.

- Contact Leasing Firms: Reach out to your shortlisted companies to inquire about availability of gear, pricing options, and specific terms for hire.

- Review Lease Agreement: Scrutinize the lease agreement thoroughly, noting terms related to liability, insurance, and maintenance responsibilities. Understanding these details can prevent potential disputes later.

- Reserve the Equipment: Once you’ve found a suitable option, proceed to reserve the rent pallet stacker for your required usage dates, ensuring you secure the machinery well in advance.

- Schedule Delivery/Pickup: Arrange for the delivery or pickup of the items, confirming transportation logistics to avoid any delays. Consider that the leasing market has experienced considerable growth, with the US machinery leasing market rising by $1.6 billion over the past year, which may affect availability.

- Inspect the Equipment: Upon receiving the rent pallet stacker, conduct a thorough inspection for any damage or operational issues before you approve the agreement. This step is essential to guarantee that you obtain equipment in optimal condition, protecting your project timeline.

Budgeting Considerations: When calculating your daily leasing rates, remember to account for additional expenses such as software, website maintenance, marketing, payment processing fees, and miscellaneous costs. For example, if the basic leasing cost is $1,200 per month with a 20% profit margin, the final rate would be $1,440 per month.

Utilizing Technology: To simplify these calculations, consider using tools like Sourcetable, an AI-powered spreadsheet designed to enhance precision and reduce errors in leasing rate calculations. This technology can be invaluable in managing your rental process effectively.

Following these steps will help streamline your rental process, allowing you to focus on managing your project efficiently.

Understanding Different Types of Pallet Stackers

When evaluating loading equipment for rent, it's essential to comprehend the different categories available, each addressing specific operational requirements:

- Manual Pallet Stackers: These hand-operated units are practical for lighter loads and are particularly effective in confined spaces, providing a cost-effective solution for smaller warehouses.

- Electric Pallet Lifters: Battery-operated and designed for heavier loads, electric lifters minimize manual effort, making them ideal for larger warehouse environments where efficiency is key. Their incorporation of lithium-ion batteries offers a longer lifespan and lower operating costs than traditional lead-acid options. Industry leaders like Toyota Material Handling Europe have acknowledged the growing market demand for electric load lifters, introducing innovations such as the Toyota BT Levio LSI200 and BT Staxio series, which are engineered for high-intensity load handling and stacking.

- Semi-Electric Pallet Lifters: Combining manual and electric functionalities, these versatile devices adapt well to various tasks, appealing to operations that require both flexibility and power.

- High-Lift Forklift Trucks: Essential for environments with vertical storage needs, high-lift trucks are specifically designed to elevate loads to higher shelves, maximizing space utilization in warehouses.

- Straddle Forklift Systems: These units can easily straddle platforms, providing adaptability for different sizes and configurations, making them a versatile choice for diverse applications.

Additionally, the walkie lifter, a type of pedestrian walk-behind lifter, exemplifies the practical application of these systems in real-world settings. These units are driven by an operator and fitted with a mast for raising loads, demonstrating their usefulness in different warehouse situations.

As the market for load lifters continues to change, warehouse managers are progressively considering whether to rent pallet stackers based on the unique requirements of their operations. The market share for electric lifting trucks is expected to grow considerably in 2024, propelled by advancements in technology and efficiency. With warehouse shelving systems enabling bulk storage of items, the incorporation of efficient loading devices becomes essential for maximizing space use and access to inventory.

Safety Tips for Operating a Pallet Stacker

To ensure the safe operation of a pallet lifter, it is crucial to adhere to the following safety tips:

- Read the Manual: Familiarize yourself with the operator's manual and safety guidelines prior to use, as this is essential for understanding operational protocols.

- Wear Protective Gear: Always wear appropriate personal protective equipment (PPE) such as helmets, gloves, and safety shoes. The importance of PPE cannot be overstated; safety experts consistently emphasize that proper gear can significantly reduce injury risk.

- Inspect the Equipment: Conduct a thorough pre-operation inspection to identify any damages or malfunctions. This proactive measure is vital in preventing accidents, as statistics show that since 1970, workplace-related injuries have declined by 42 percent due in part to improved safety practices.

- Maintain Clear Visibility: Ensure your path is unobstructed, and you can see around the equipment while operating it. This step is critical in avoiding collisions, particularly in busy areas with pedestrian traffic.

- Use Proper Lifting Techniques: Always adhere to proper lifting techniques to mitigate the risk of strain or injury. This practice is integral to maintaining a safe work environment.

- Avoid Overloading: Never exceed the specified weight limit for the platform lifter to maintain stability and ensure safe operation. Overloading is a common factor in material handling equipment accidents.

- Stay Alert: Be vigilant about your surroundings and aware of other personnel when using the equipment. As highlighted in recent case studies, awareness of aisle widths, indoor/outdoor transitions, surface conditions, load manipulation, and pedestrian traffic is essential to prevent accidents.

With the recent statistics revealing 40,513 forklift-related incidents from 2021 to 2022, including 143 fatalities, the need for improved safety measures such as effective training and maintenance is evident. This data, drawn from the National Forklift Safety Day Statistics, underscores the urgency of implementing comprehensive safety practices. Resources provided by organizations like MHEDA can be instrumental in enhancing employee safety through training and certification programs. By adhering to these safety guidelines and emphasizing proper training, you can aid in creating a safer workplace and assist in decreasing the occurrence of accidents when using a rent pallet stacker.

Frequently Asked Questions About Pallet Stacker Rentals

Here are some frequently asked questions about pallet stacker rentals:

-

What is the price of renting a loading machine?

- The rental cost of a pallet stacker can vary significantly based on the type of stacker, load capacity, rental duration, and location. As a general guideline, project managers should always request detailed quotes from leasing companies to obtain accurate pricing tailored to their specific needs. With 106 rental locations near New York, NY, accessing a variety of options is more convenient than ever.

-

Do I need a license to operate a pallet stacker?

- While a specific license may not be mandatory, proper training is imperative for ensuring safe operation. Proficiency in handling tools not only reduces risks but also improves overall site safety.

-

What if the machinery malfunctions during the leasing duration?

- Most reputable rental companies provide robust support for equipment issues. It is crucial to review the lease agreement for specific terms regarding maintenance responsibilities and the procedures for addressing breakdowns, ensuring minimal disruption to your project timeline.

-

Can I extend my lease period?

- Yes, most rental companies typically allow for extensions. However, it is advisable to communicate your needs as early as possible to avoid incurring additional fees or complications.

-

Are delivery and pickup services included?

- This can vary between rental companies. Before finalizing your rental agreement, confirm whether delivery and pickup services are included in the price or if there will be additional charges associated with these services. Understanding these logistical details can aid in budget management and project planning.

-

What are the advantages of renting compared to buying tools?

- According to Faisal Ur Rehman, content editor of ForkliftRevolution.net, renting forklifts often proves more beneficial than purchasing. This approach allows access to modern models and tailored equipment without the significant initial costs associated with buying, which can greatly impact a project's budget.

-

What documents do I need before renting a pallet stacker?

- Before renting a forklift, it is essential to have necessary documents ready, such as proof of insurance and a payment method. Being prepared with documentation can facilitate a smoother rental process, as highlighted in the case study titled "Get Your Documents in Order.

Conclusion

Navigating the complexities of pallet stacker rentals is crucial for ensuring project success. By carefully evaluating project requirements, rental duration, and budget considerations, individuals can make informed decisions that align with operational needs. Researching rental companies and understanding the different types of pallet stackers available further empowers project managers to select the most suitable equipment.

Safety should never be overlooked; adhering to operational guidelines and utilizing protective gear significantly reduces the risk of accidents. By following a structured rental process, including:

- Timely reservations

- Thorough equipment inspections

organizations can minimize disruptions and maintain efficiency on-site.

Ultimately, the right approach to pallet stacker rentals not only enhances productivity but also ensures safety and compliance throughout the project lifecycle. With the rental market poised for growth, understanding these essential factors will enable individuals and businesses to optimize their equipment rental strategies and achieve successful outcomes in their material handling operations.

Frequently Asked Questions

What are the key considerations when renting a pallet stacker?

Key considerations include assessing project requirements, determining the duration of rental, establishing a budget, selecting a reputable lease firm, checking equipment availability, and investigating delivery and pickup options.

How do I assess my project requirements for renting a pallet stacker?

You should evaluate the specific needs of your project, including the weight and dimensions of the containers you will handle, to choose the appropriate type of equipment (electric, manual, or high-lift stacker).

Why is the duration of rental important?

The duration of rental is important because leasing companies often provide discounts for longer rental periods, making it essential to accurately forecast your timeline.

What should I include in my budget for renting a pallet stacker?

Your budget should include the leasing cost, potential additional expenses like delivery, insurance, and any required accessories, to avoid unexpected financial impacts on your project.

How can I find a reputable leasing firm for pallet stackers?

Conduct thorough research on leasing firms recognized for high-quality options and customer service. Reviews and testimonials can help guide your decision.

Why is equipment availability a factor in renting a pallet stacker?

Equipment availability is crucial, especially during high-demand seasons, as the need for pallet stackers can exceed supply. Early booking can help secure your preferred equipment.

What delivery and pickup options should I consider when renting?

Investigate whether the leasing company provides convenient delivery and pickup services, as this can save time and reduce logistical difficulties on-site.

What steps should I follow to successfully rent a pallet stacker?

Steps include identifying your needs, researching leasing companies, contacting firms for availability and pricing, reviewing the lease agreement, reserving the equipment, scheduling delivery/pickup, and inspecting the equipment upon receipt.

What should I check in the lease agreement?

Scrutinize the lease agreement for terms related to liability, insurance, and maintenance responsibilities to prevent potential disputes later.

How can I manage budgeting for the rental process?

When budgeting, account for additional expenses such as software, marketing, and payment processing fees. Using tools like Sourcetable can help enhance precision in calculations.

What technology can assist in the rental process?

Tools like Sourcetable, an AI-powered spreadsheet, can simplify calculations and reduce errors in leasing rate calculations, facilitating effective rental management.