Introduction

Renting an excavator can be a daunting task, especially for those unfamiliar with the intricacies of construction equipment. With the global market for construction equipment rental projected to reach an impressive US$ 131.2 billion by 2024, the stakes are high for project managers who must navigate a competitive landscape while ensuring they select the right machinery for their specific needs.

From assessing project requirements and site conditions to understanding excavator specifications and avoiding common pitfalls, the process demands careful consideration and strategic planning. By following a structured approach, individuals can streamline their rental experience, minimize costs, and ultimately enhance the efficiency of their projects.

Key Considerations Before Renting an Excavator

When planning to rent a digging machine, several critical factors warrant careful consideration:

- Project Requirements: Begin by clearly defining the specific tasks the digging machine will undertake. Will it be engaged in digging, grading, or demolition? A comprehensive understanding of the project scope is essential for determining the appropriate type of machinery, ensuring it aligns with the demands of the job.

- Site Conditions: Thoroughly evaluate the site conditions, including terrain type and access points. Is the ground primarily soft or hard? Are there space constraints that could impact equipment maneuverability? These elements directly influence the size and type of the machinery needed, making it imperative to assess them accurately.

- Excavator Size: Choosing a machine that is suitably sized for your project is essential. An undersized machine may hinder efficiency and prolong the job, while an oversized piece of equipment could prove cumbersome and even damage the site. Striking the right balance is key.

- Rental Duration: Determine the duration for which you will be renting the excavator. Leasing firms usually provide different pricing models for renting excavators depending on the duration of the lease, and having this information in advance can result in considerable cost reductions.

- Budget Constraints: Establish a comprehensive budget that encompasses not just the leasing cost but also additional expenses such as transportation, fuel, and any required attachments. A clear budget helps narrow down your options effectively, ensuring alignment with your financial resources.

The global market for construction equipment leasing is projected to reach a staggering US$ 131.2 billion in 2024, highlighting the growing demand and competitiveness in this sector. Major players like United Rentals, which recently acquired General Finance Corp. for US$ 996 million, and H&E Equipment Services significantly influence market trends. As noted in industry discussions,

Telematics Integration Revolutionizes Construction Equipment Management,

showcasing the importance of staying updated with rental market conditions and trends.

The presence of these key companies illustrates a competitive market that is essential for meeting the diverse needs of construction endeavors. Being aware of these factors will enable managers to make improved choices in selecting the appropriate machinery for their specific requirements.

Steps to Successfully Rent the Right Excavator

Successfully renting an excavator requires a strategic approach that addresses both project needs and machinery quality. Here are the essential steps to follow:

-

Research Leasing Firms: Start by pinpointing nearby leasing companies that focus on heavy machinery.

Utilize online reviews and ratings to assess their reliability and customer service quality. EquipmentShare has emerged as a notable player in the market, leveraging advanced telematics to track assets during shipping and ensuring that customers can monitor their equipment's condition. Established in 1949, the Liebherr Group is famous for its high-quality, heavy-duty machinery, making it a trustworthy choice to consider when selecting a leasing company.

-

Contact Leasing Providers: Reach out to multiple leasing companies to discuss your project's specific requirements. Ask about the availability and pricing of tools, and seek their suggestions on the most appropriate type of digger for your requirements. Experts emphasize the importance of clear communication in this stage to ensure alignment between your requirements and the offered services.

-

Inspect Equipment: Whenever feasible, carry out a comprehensive examination of the machinery before concluding the rental agreement. Review maintenance records to confirm that the machinery has been properly cared for. Look for signs of wear and tear and ensure that all necessary attachments are included.

This step is crucial to prevent operational issues later on, as noted in various customer reviews highlighting the importance of equipment condition. For instance, Liebherr excavators have been utilized in significant projects like the Gotthard Base Tunnel, demonstrating their exceptional performance in challenging conditions.

-

Understand Leasing Terms: Carefully examine the leasing agreement, focusing on terms related to insurance, liability, and damage policies.

Gaining a clear understanding of your responsibilities during the leasing period helps prevent misunderstandings and potential disputes.

-

Schedule Delivery and Pickup: Coordinate logistics with the rental company to arrange for the machine's delivery to your job site. Confirm the pickup arrangements to ensure that you have the machinery for the required duration without interruptions.

-

Training and Safety: Prioritize safety by ensuring that operators are adequately trained to use the machinery effectively. Familiarize them with the machine’s controls and safety features, as this knowledge is vital for preventing accidents and equipment damage during operation. Larry Silber, President and CEO of Liebherr Group, underscores this by stating,

Continued investments in our premium fleet offering... are driving the momentum in our business.

This reflects the need for not just quality machinery but also well-trained operators to maximize performance. Additionally, consider the loader's features, such as the on-board fast charger and common adapters for power integration, which may be relevant to your selection process.

By following these steps, you can navigate the complexities of renting excavator equipment and ensure that your project runs smoothly and efficiently.

Understanding Excavator Specifications

When choosing a digging machine, it’s essential to familiarize yourself with the following key specifications:

- Operating Weight: The total weight of the excavator plays a pivotal role in its stability on various terrains. For instance, models like the PC290LCi-11 and PC290LC-11, which have an operating weight ranging from 70,702 to 72,091 pounds, demonstrate that heavier machines often provide enhanced stability, particularly in challenging conditions.

- Digging Depth: Comprehending the maximum digging depth is essential for endeavors requiring deep excavation. The aforementioned PC290LCi-11 boasts a maximum dig depth of 22 feet 5 inches, making it suitable for extensive underground work. Tim Forestell, co-founder and CCO of DOZR, emphasizes that understanding these specifications is crucial as requirements evolve, particularly concerning the depth needed for specific tasks. The reach capability indicates how far the machine can extend its arm, which is essential for accessing hard-to-reach areas. With models achieving a maximum reach of 35 feet 2 inches, ensuring that the machine's reach aligns with your project’s requirements can significantly impact operational efficiency.

- Bucket Capacity: The size of the bucket directly affects material handling efficiency. Excavators with bucket capacities ranging from 5.00 to 10.0 cubic yards can dramatically improve productivity by moving more material per load. However, it’s crucial to balance bucket size with overall machine weight to maintain optimal performance.

- Engine Power: Another critical specification to consider is engine power. For example, the JCB 245XR features an engine power of 173 horsepower, which contributes to its performance capabilities in various applications.

- Attachments: The versatility of a digger can be greatly enhanced through available attachments, such as hydraulic hammers or grapples. These tools can expand the machine's functionality, allowing it to tackle a broader range of tasks, thus increasing its value on site.

- Transportation and Storage: It’s also essential to consider transportation and storage requirements. As outlined in a relevant case study, transportation and storage needs vary by size; large machines may require special permits and equipment for transport, while mini models can be moved with standard trailers. Adequate preparation for transport and storage can lower expenses and logistical difficulties related to the use of machinery.

By comprehending these specifications, managers can make well-informed choices when renting excavators, ensuring they fulfill the particular requirements of their tasks.

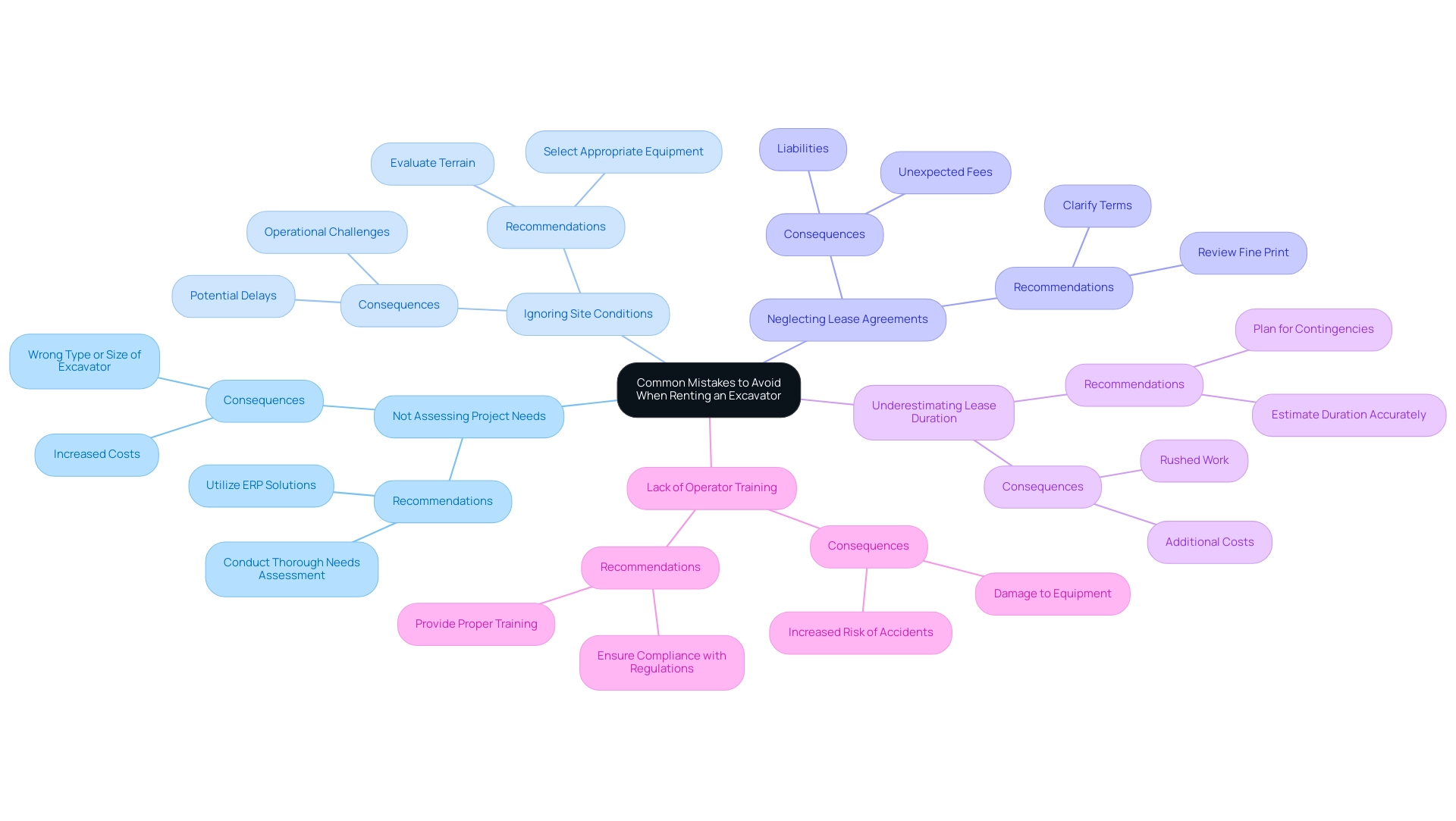

Common Mistakes to Avoid When Renting an Excavator

When leasing a digger, it's essential to steer clear of these frequent traps that can complicate your task and raise expenses:

- Not Assessing Project Needs: One of the most significant errors is failing to accurately assess the project requirements, which can lead to renting an excavator of the wrong type or size. Industry specialists highlight that a thorough needs assessment is essential for optimal selection of tools. As FIT Global states, ERP software providers offer industry-specific equipment management solutions that help manage potential challenges, ultimately leading to increased efficiency and profitability.

- Ignoring Site Conditions: Overlooking the specific conditions of the job site can result in selecting a machine ill-suited for the terrain, causing operational challenges and potential delays. Understanding the environment is key to ensuring operational efficiency.

- Neglecting Lease Agreements: Skipping the detailed review of lease agreements can expose you to unexpected fees or liabilities. Always scrutinize the fine print to avoid surprises that could impact your budget.

- Underestimating Lease Duration: Misjudging the length of time you will need the excavator can lead to rushed work or additional costs if you find yourself needing to extend the lease period. This can contribute to unplanned downtime, which costs manufacturers up to $50 billion per year. Planning for contingencies can save you both time and money.

- Lack of Operator Training: Allowing untrained personnel to operate heavy machinery significantly increases the risk of accidents and damage. Proper operator training is not just a regulatory requirement; it's a fundamental aspect of ensuring safety and efficiency on the job site. As mentioned by FIT Global, using ERP solutions can assist in addressing these operational challenges efficiently, resulting in improved productivity and profitability.

Moreover, companies frequently encounter logistical difficulties when handling projects situated far from their main location, which can complicate rentals. Renting equipment with delivery services allows crews to focus on their work without the hassle of transportation logistics.

Post-Rental Responsibilities

After using a digger, it is essential to fulfill several responsibilities to ensure a smooth return process and avoid unnecessary costs:

- Clean the Equipment: Thoroughly clean the excavator before returning it. This practice is essential to prevent extra cleaning charges, which can greatly increase your costs. A well-maintained appearance also reflects positively on your professionalism and aligns with the leasing industry's sustainability goals, as a clean machine reduces the need for excessive maintenance and waste.

- Inspect for Damage: Conduct a meticulous inspection of the excavator for any damage incurred during renting excavator usage. Document any findings and promptly report them to the leasing company to prevent disputes and ensure transparency. This proactive approach aligns with the leasing sector's commitment to sustainability, as noted by Jeanguenat, president of RentalMax, who emphasizes that the leasing business by its nature is a green industry. By addressing any issues promptly, you help maintain the equipment's utilization rate, which is essential for the profitability of leasing operations.

- Return on Time: Adhere to the scheduled return date to avoid incurring late fees. If you expect to require renting excavator for an extended time, contact the company as early as possible to negotiate an extension. This not only helps maintain a good relationship with the leasing service but also supports their operational efficiency, which is key in an industry expected to grow by 2.3% annually over the next five years.

- Complete Documentation: Ensure all required documentation is filled out accurately, including forms that detail the state of the items upon return. This step is critical as it protects both you and the leasing company from potential misunderstandings regarding the equipment’s state, thereby enhancing the overall utilization rate and ensuring a sustainable leasing process.

- Provide Feedback: If suitable, share your thoughts regarding your leasing experience. Constructive feedback can assist leasing companies enhance their services and contribute to a better experience for future customers. In a growing industry—expected to expand by 2.3% annually—your insights can play a role in shaping best practices and promoting sustainability.

By diligently following these steps, you not only protect your investment but also contribute to the sustainability narrative of the leasing sector. Understanding the importance of these responsibilities can enhance your project management effectiveness and ensure a successful renting excavator experience.

Conclusion

Navigating the process of renting an excavator requires careful planning and informed decision-making. By considering key factors such as project requirements, site conditions, and budget constraints, project managers can significantly enhance their chances of selecting the right equipment. Understanding the essential specifications of excavators, including operating weight, digging depth, and reach, plays a crucial role in ensuring that the chosen machinery meets the demands of the job.

Taking proactive steps in the rental process—such as:

- Researching rental companies

- Inspecting equipment

- Understanding rental agreements

can prevent common pitfalls that lead to inefficiencies and inflated costs. Moreover, prioritizing operator training and post-rental responsibilities not only ensures safety but also fosters a professional relationship with rental providers.

Ultimately, a structured approach to excavator rental not only streamlines the logistics of construction projects but also contributes to overall project success. By implementing these strategies, project managers can navigate the complexities of the rental market effectively, ensuring that they are well-equipped to meet the challenges of their projects head-on.

Frequently Asked Questions

What factors should be considered when planning to rent a digging machine?

Key factors include project requirements, site conditions, excavator size, rental duration, and budget constraints.

Why is it important to define project requirements before renting a machine?

Clearly defining project requirements helps determine the appropriate type of machinery needed, ensuring it aligns with the specific tasks, such as digging, grading, or demolition.

How do site conditions affect the choice of digging machine?

Site conditions, such as terrain type and access points, influence the size and type of machinery required, as they impact equipment maneuverability and performance.

What is the significance of choosing the right excavator size?

An appropriately sized excavator is essential for efficiency; an undersized machine may prolong the job, while an oversized one could damage the site.

How does rental duration impact the cost of leasing an excavator?

Leasing firms typically offer different pricing models based on the rental duration, so knowing how long you need the excavator can lead to cost reductions.

What should be included in a comprehensive budget for renting a digging machine?

The budget should cover the leasing cost as well as additional expenses like transportation, fuel, and any required attachments.

What steps should be taken to successfully rent an excavator?

Steps include researching leasing firms, contacting providers for availability and pricing, inspecting equipment, understanding leasing terms, scheduling delivery and pickup, and ensuring operator training and safety.

Why is it important to inspect equipment before renting?

Inspecting the machinery ensures it is in good condition and includes all necessary attachments, helping to prevent operational issues later on.

What should be reviewed in the leasing agreement?

The leasing agreement should be carefully examined for terms related to insurance, liability, and damage policies to prevent misunderstandings.

How can safety be ensured when operating rented machinery?

Ensuring that operators are adequately trained to use the machinery and are familiar with its controls and safety features is vital for preventing accidents and equipment damage.