Overview

Renting electrical equipment is a strategic choice for construction managers, allowing access to necessary tools without the financial burden of purchase, especially for short-term projects. The article outlines a comprehensive step-by-step guide on the rental process, highlighting critical considerations such as evaluating machinery needs, understanding lease terms, and ensuring equipment reliability, all of which contribute to informed decision-making and successful project execution.

Key Highlights:

- Renting electrical equipment allows construction managers to access necessary tools without the financial burden of purchase, particularly beneficial for short-term projects.

- Key players in the standby power leasing industry include Aggreko, Al Faris, Atlas Copco, and Caterpillar, indicating a competitive market.

- The leasing process involves evaluating machinery needs, selecting tools, negotiating terms, and finalizing paperwork.

- The U.S. standby power leasing market is projected to reach USD 4 billion by 2034, highlighting the growing demand for rental services.

- Essential equipment categories available for rent include generators, forklifts, power tools, lighting equipment, and transformers.

- Critical factors for choosing rented equipment include project requirements, device specifications, condition and age, safety features, lease duration, and insurance considerations.

- Budgeting for rentals should include rental rates, delivery fees, insurance, and maintenance costs, with an emphasis on understanding market trends.

- Navigating rental agreements requires careful attention to terms, liability, maintenance responsibilities, and return policies to avoid conflicts.

- Best practices for ensuring equipment reliability during rentals include regular inspections, maintenance, effective communication with leasing companies, and emergency preparedness.

- Returning rented equipment should be done with care, including cleaning, inspecting for damage, timely returns, and thorough documentation to maintain good relationships with providers.

Introduction

In the world of construction, the choice between renting and purchasing electrical equipment can have significant implications for project success. As construction managers face the demands of tight deadlines and budget constraints, understanding the nuances of equipment rental becomes essential.

From navigating the competitive landscape of rental providers to making informed decisions about the right machinery for specific tasks, the intricacies of this process can greatly influence operational efficiency. With the U.S. standby power rental market projected to soar, the need for strategic insights into rental agreements, budgeting, and equipment reliability has never been more critical.

This article delves into the key considerations and best practices that construction managers must embrace to maximize the benefits of electrical equipment rentals, ensuring that projects not only meet but exceed expectations.

Understanding the Basics of Electrical Equipment Rental

Renting electrical equipment offers construction managers an efficient way to obtain necessary machinery and tools without the financial commitment of outright purchase. This approach is particularly advantageous for short-term projects, offering both flexibility and significant cost savings. Major participants in the standby power leasing industry, such as Aggreko, Al Faris, Atlas Copco, and Caterpillar, exemplify the competitive landscape that managers must navigate.

Familiarity with essential leasing terminology, including rates, terms, and conditions, is crucial for effective navigation of this landscape. The standard leasing procedure involves:

- Evaluating machinery requirements

- Choosing suitable tools

- Negotiating leasing conditions

- Finalizing essential paperwork

As the U.S. standby power leasing market is projected to reach USD 4 billion by 2034, understanding the benefits and potential drawbacks of choosing to rent electrical equipment versus purchasing becomes crucial.

By assessing factors such as equipment reliability, speed of deployment, and pricing, managers can make informed decisions that align with their objectives. Expert insights emphasize that successful leasing strategies can lead to enhanced operational efficiency and adaptability, ultimately driving better outcomes in construction project management. As Marlene Greenfield, Vice President of Hearst Magazines, aptly states,

'Statista has been my savior on several occasions. The site is easy to maneuver and the data is in a format that can go right into a report or presentation.'

This highlights the significance of trustworthy data in making informed leasing decisions. Furthermore, insights from case studies on regional dynamics and competitive landscapes in the power leasing market can further inform strategies, illustrating how different regions respond to the demands of apparatus leasing.

Types of Electrical Equipment Available for Rent in Construction

Construction managers have access to a varied selection of electrical tools that are essential for successfully executing projects. Key categories include:

-

Generators: These are vital for providing temporary power on job sites, especially in remote areas where access to electricity may be limited. The internal combustion engine sector of the machinery leasing market, which encompasses generators, remains the leader, possessing the largest revenue share and expected to expand at a CAGR of 4.1%.

Significantly, H&E Rentals recently announced a 7.2 percent rise in rental income in the second quarter, emphasizing the increasing demand for such machinery.

-

Forklifts: Playing a crucial role in improving building efficiency and safety, forklifts aid in the lifting of heavy materials and movement of tools on job sites. With features such as high load capacity, excellent maneuverability, and advanced safety mechanisms like automatic braking and load monitoring systems, forklifts streamline operations and significantly improve productivity.

-

Power Tools: Essential tools such as drills, saws, and sanders are often required for specific tasks, enhancing efficiency and precision in building work.

-

Lighting Equipment: Portable lighting solutions are crucial for night work or in areas with inadequate natural light, ensuring safety and productivity.

-

Transformers and Distribution Boards: These components are necessary for managing electrical supply on larger sites, enabling effective distribution of power to various tools and devices.

By understanding the specific requirements of a project, managers can make informed decisions about which tools to rent electrical equipment from these categories, ultimately leading to cost savings and enhanced operational effectiveness. Numerous building firms choose to rent electrical equipment to access newer technology, benefit from flexibility, and achieve substantial cost savings. As Kyle Clements, Founder & CEO of Quipli, observes, 'Partnering with independent rental companies can assist them in managing their operations more effectively and create a significant experience for their customers.'

This is particularly true for forklifts, as renting allows companies to utilize the latest models equipped with advanced safety features, ensuring both efficiency and safety on the job site. Additionally, the case study named 'Reasons for Renting Equipment' demonstrates that the majority of building firms emphasize the importance of renting electrical equipment for cost savings, access to newer technology, and flexibility, adapting their selections based on requirements.

Key Considerations for Choosing the Right Electrical Equipment

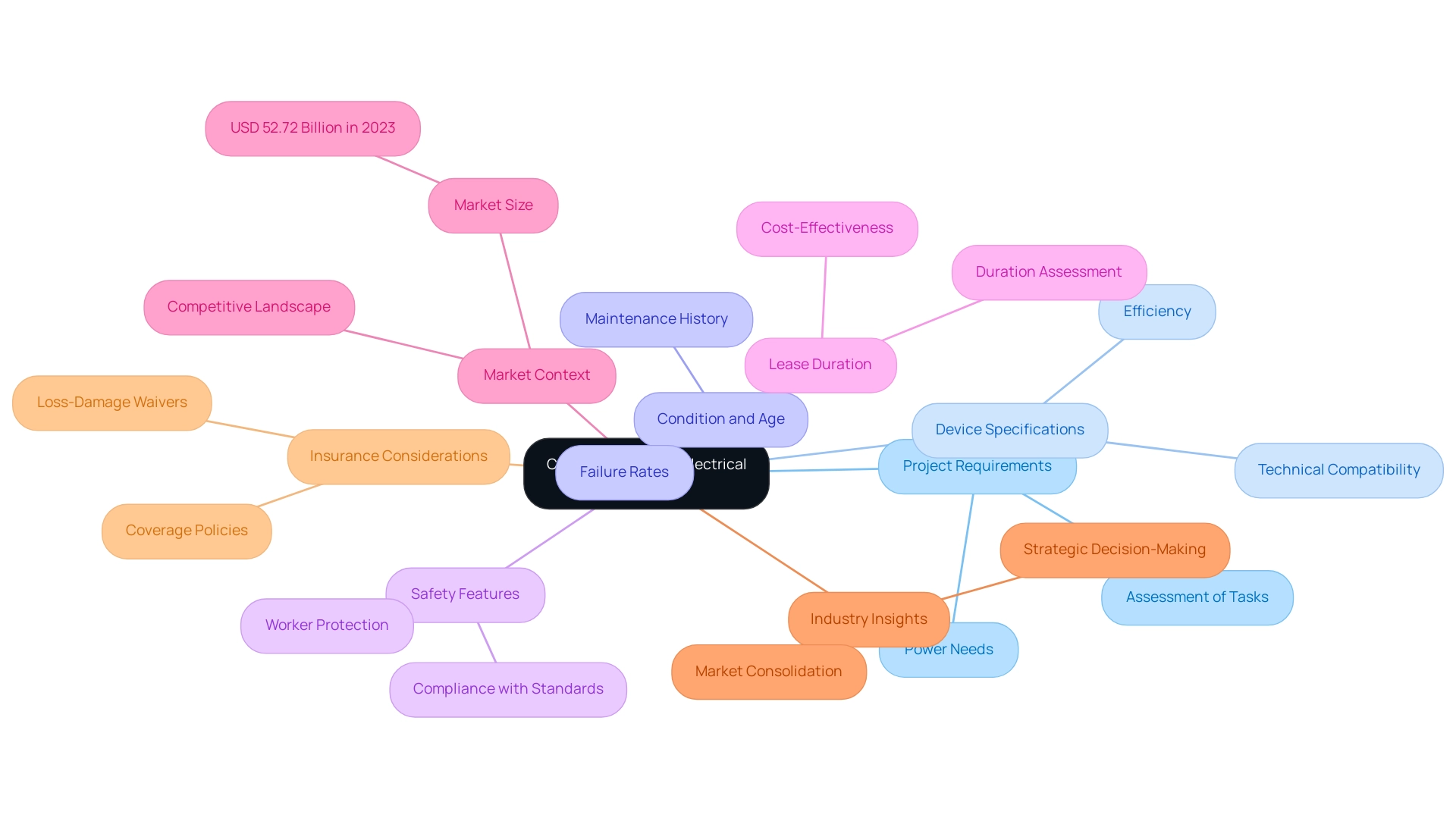

When choosing to rent electrical equipment, construction managers must assess several critical factors to ensure the success of their projects.

- Project Requirements: A thorough assessment of the specific tasks and power needs is essential. This will guide the selection of tools that can effectively meet those demands.

- Device Specifications: It is vital to confirm that the selected device aligns with the necessary technical specifications for the job at hand, ensuring compatibility and efficiency.

- Condition and Age: Prioritizing well-maintained and relatively new tools can significantly reduce the risk of breakdowns. Studies indicate that older machinery has higher failure rates, which can disrupt project timelines and inflate costs.

- Safety Features: Ensuring compliance with the latest safety standards is non-negotiable. Equipment must have adequate safety features to protect workers on-site, reflecting the industry's commitment to maintaining a safe working environment. As emphasized by industry specialists, safety should consistently be a top concern when we rent electrical equipment for machinery leasing choices.

- Lease Duration: Assessing how long the equipment will be needed can assist managers in selecting the most cost-effective options to rent electrical equipment, thereby reducing unnecessary costs.

- Market Context: The Asia Pacific Construction Equipment Leasing Market Size in 2023 is projected to be USD 52.72 billion, underscoring the importance of making informed borrowing decisions in a competitive landscape.

- Industry Insights: As noted by ERA, there is an appetite for further consolidation in the market, making strategic decision-making crucial for construction managers.

- Insurance Considerations: Understanding insurance coverage for leased equipment, as discussed in the case study, is critical. Managers should inquire about protection policies included in lease agreements to ensure comprehensive coverage and minimize financial risks.

Comprehending these essential elements will allow managers to make informed choices that improve efficiency and safety while adhering to best practices in the field.

Budgeting for Equipment Rentals: Costs and Financial Strategies

When planning to rent electrical equipment for building, it is crucial to have a careful strategy that considers different expenses affecting the total budget. Key considerations include:

- Rental Rates: Familiarize yourself with the daily, weekly, or monthly rental rates and how these align with your project’s financial plan. As the construction machinery rental market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2025, understanding these rates will be increasingly important.

- Delivery and Pickup Fees: Always consider the extra costs involved in transporting tools to and from the job site. The effect of these charges can differ greatly depending on distance and size, making it essential to factor them into your budget.

- Insurance: It’s vital to consider the costs of insuring rented items against potential damage or theft. This not only protects your investment but is also an important aspect of risk management.

- Maintenance Fees: Some rental agreements may include maintenance services; however, it’s important to clarify these terms upfront to avoid unexpected expenses later.

Along with these expenses, it's crucial to comprehend why many construction firms choose to lease machinery. Key reasons include significant cost savings, access to the latest technology, and increased flexibility in managing project timelines. Moreover, the integration of telematics is revolutionizing equipment management, enabling businesses to rent electrical equipment more effectively while providing valuable data that can help streamline operations and optimize budgeting decisions.

To effectively manage costs, develop a comprehensive budget that encompasses all potential expenses. Participating in discussions for leasing conditions can also produce better rates, especially in a fluctuating market. As Josh Nickell, Vice President of Equipment Rental at the American Rental Association notes, high interest rates are not detrimental for leasing. Uncertainty is not detrimental for leases, indicating a resilient market that can be leveraged to your advantage.

By staying informed about trends in leasing rates and being aware of the cost factors associated with renting electrical equipment, you can create a robust financial strategy that supports your project goals.

Navigating Rental Agreements: What Construction Managers Need to Know

When entering a leasing agreement, project managers must meticulously evaluate several critical components to ensure a successful transaction:

- Terms and Conditions: It is vital to review all terms thoroughly, including the lease duration, payment schedules, and any potential penalties for late returns. Understanding these details can reduce unforeseen expenses.

- Liability and Insurance: Clarifying responsibility for damages or losses during the leasing period is crucial. As Bernd Meyer emphasizes, Understanding the terms and conditions of leasing agreements and insurance coverage is essential for a smooth and financially secure construction machinery lease experience. Managers should ensure they are safeguarded against liability matters that may occur.

- Maintenance Responsibilities: Determine what maintenance is included in the lease agreement and what is expected from the renter. Clear delineation of responsibilities can prevent misunderstandings and ensure that items remain in optimal condition.

- Return Policies: Familiarize yourself with the conditions regarding the return of items. Knowing these specifics can help avoid additional fees and streamline the process.

- Financial Considerations: It's important to note that interest rates for leasing options typically range between 7% and 16%. Comprehending these rates can offer important insight into the financial consequences of lease agreements.

By possessing a thorough grasp of these components, including the varieties of leases and their essential terms, managers can greatly decrease the chances of conflicts, resulting in a more seamless leasing experience and more effective management of tasks. For additional learning, the Resource Center provides guides, checklists, and videos that can help in navigating lease agreements.

Ensuring Equipment Reliability: Maintenance and Support During Rentals

To ensure machinery reliability during leases, project managers in the building sector should apply the following best practices:

- Regular Inspections: Routine checks of leased machinery, particularly forklifts, are essential for detecting potential issues before they worsen. Routine evaluations assist in sustaining operational effectiveness and minimizing the likelihood of machinery breakdowns, which is essential considering that data show a significant rate of machinery failures during leases. Indeed, North America was the largest area in the machinery leasing market in 2024, emphasizing the scale and significance of ensuring reliability.

- Regular Maintenance: Utilizing a leasing service like EZ Equipment Rental allows businesses to rent electrical equipment, such as forklifts, which undergo regular maintenance, significantly reducing the risk of breakdowns during critical operations. Their dedication to ensuring reliability of tools is essential for construction project managers who rely on consistent performance.

- Communication with Leasing Company: Establishing open lines of communication with the leasing provider is essential for addressing maintenance inquiries and securing support when needed. At EZ Equipment Rental, for instance, their commitment to exceptional customer service ensures that any issues are promptly addressed, minimizing downtime. This proactive strategy promotes a cooperative connection that can improve the dependability of leased tools. As David Bitton, co-founder at DoorLoop, emphasizes, effective communication is key to ensuring that both parties are aligned on maintenance expectations and responsibilities.

- Emergency Procedures: Ensure familiarity with the company's emergency procedures for managing equipment failures. Knowing how to respond effectively can minimize disruption and facilitate quick resolutions.

- Documentation: Keeping detailed records of maintenance performed and any issues encountered is critical. This documentation assists in clear communication with the provider and can streamline the resolution process.

By prioritizing these maintenance strategies, particularly utilizing the assistance provided by esteemed firms like EZ Equipment Rental, construction managers can significantly reduce downtime and improve the success of their projects, especially by choosing to rent electrical equipment, considering recent developments highlighting the significance of reliability in the leasing sector, including the increasing popularity of online construction machinery leasing solutions.

Best Practices for Returning Rented Electrical Equipment

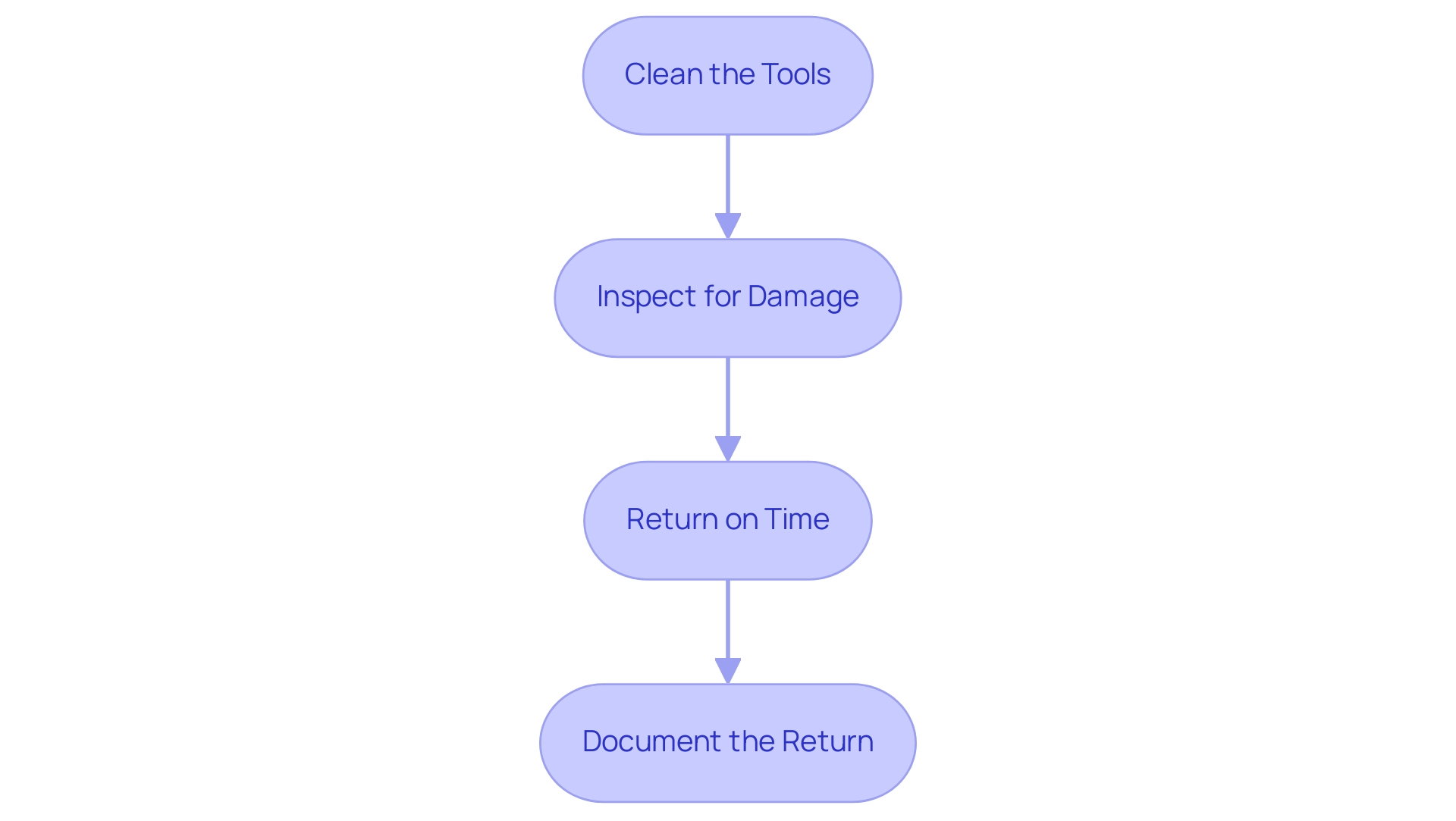

When returning borrowed electrical devices, following best practices is crucial for sustaining favorable relationships with providers and preventing unnecessary charges when you rent electrical equipment. Here are key steps to consider:

- Clean the Tools: Always return the tools in a clean and functional state. This not only helps avoid cleaning fees but also demonstrates respect for the company's assets. A lawnmower leasing business discovered that customers highly valued their free delivery service, which significantly increased their Net Promoter Score (NPS) and repeat business; similarly, presenting clean equipment can enhance your provider’s satisfaction and encourage repeat transactions.

- Inspect for Damage: Prior to returning, thoroughly check for any damages. If you recognize any issues, promptly report them to the leasing company. This proactive communication can prevent disputes and foster goodwill, which is crucial in maintaining a positive relationship with your provider.

- Return on Time: It’s important to adhere to the agreed return schedule. Late returns can incur additional fees, which can quickly add up and impact project budgets. Maintaining a positive reputation with providers can result in improved terms on future agreements.

- Document the Return: Keep thorough records of the return process, including receipts, condition reports, and any correspondence with the company. Utilizing tracking software, like that provided by Record360, can streamline this documentation process, ensuring you have clear communication regarding item condition and reducing potential disputes. As mentioned in the case study on Record360’s tracking software, effective documentation can lead to lower inventory expenses and improved customer service.

By adhering to these practices, construction managers can enable a seamless return process, avoid unnecessary costs, and cultivate stronger relationships with their providers. Additionally, it's important to consider the maintenance cost per unit associated with returning equipment in poor condition when you rent electrical equipment, as this can significantly impact the overall profitability of rental services.

Conclusion

The decision to rent or purchase electrical equipment is a pivotal one for construction managers, influencing not only budgetary considerations but also project efficiency and success. This article has explored the critical aspects of electrical equipment rental, from understanding the basics and types of equipment available to key considerations for selection and budgeting strategies. By familiarizing themselves with the competitive landscape of rental providers and the nuances of rental agreements, construction managers can make informed choices that align with their project goals.

Effective equipment rental practices are not just about cost savings; they also involve ensuring reliability and safety on job sites. By prioritizing well-maintained equipment, conducting thorough inspections, and maintaining open communication with rental companies, managers can mitigate risks associated with equipment failures. Moreover, adhering to best practices when returning rented equipment fosters positive relationships with rental providers, paving the way for future collaborations.

As the electrical equipment rental market continues to grow, the insights shared in this article serve as a roadmap for construction managers aiming to enhance their operational efficiency. Embracing these strategies will not only lead to better project outcomes but also position managers to navigate the evolving landscape of the construction industry with confidence and agility. In a fast-paced environment, the right equipment rental decisions can make all the difference in achieving success.

Frequently Asked Questions

What are the advantages of renting electrical equipment for construction managers?

Renting electrical equipment allows construction managers to obtain necessary machinery and tools without the financial commitment of outright purchase, offering flexibility and significant cost savings, especially for short-term projects.

What are the key steps in the standard leasing procedure for electrical equipment?

The standard leasing procedure involves evaluating machinery requirements, choosing suitable tools, negotiating leasing conditions, and finalizing essential paperwork.

What is the projected growth of the U.S. standby power leasing market?

The U.S. standby power leasing market is projected to reach USD 4 billion by 2034.

What factors should construction managers assess when deciding between renting and purchasing electrical equipment?

Managers should assess equipment reliability, speed of deployment, and pricing to make informed decisions that align with their objectives.

What types of electrical tools are commonly available for rent in construction?

Key categories of electrical tools available for rent include generators, forklifts, power tools, lighting equipment, and transformers/distribution boards.

Why are generators important on job sites?

Generators provide temporary power, especially in remote areas where access to electricity may be limited.

How do forklifts enhance construction efficiency and safety?

Forklifts improve building efficiency and safety by aiding in the lifting of heavy materials and moving tools on job sites, featuring high load capacity, excellent maneuverability, and advanced safety mechanisms.

What role do power tools play in construction projects?

Power tools such as drills, saws, and sanders enhance efficiency and precision in building work.

How does renting electrical equipment contribute to cost savings for construction firms?

Renting allows firms to access newer technology, benefit from flexibility, and avoid the upfront costs associated with purchasing equipment, leading to substantial cost savings.

What insights do experts provide regarding the leasing of electrical equipment?

Experts emphasize that successful leasing strategies can enhance operational efficiency and adaptability, driving better outcomes in construction project management.