Overview

Renting hole saws effectively necessitates that construction managers grasp the various types of saws available, the reputation of rental services, and optimal maintenance practices. Selecting the right rental service is crucial, as it hinges on factors such as equipment quality and customer support. Furthermore, understanding how proper maintenance can significantly enhance the performance and longevity of these tools is essential. This knowledge ultimately ensures project efficiency and cost-effectiveness, making the selection process paramount for successful outcomes.

Key Highlights:

- Hole saws are essential tools for creating precise round openings in materials like wood, metal, and plastic, crucial in construction for installations such as pipes and electrical fixtures.

- The demand for boring tools in construction is projected to increase from 2025 to 2031, driven by advancements in technology and innovative products like carbide-tipped saws.

- Key types of hole saws include bi-metal drills, carbide-tipped tools, high-speed steel drills, and adjustable saws, each suited for specific materials and applications.

- When renting hole saws, consider factors like the rental service's reputation, equipment quality, pricing, rental terms, and customer support to ensure a successful project.

- Best practices for maintaining rented hole saws include cleaning after use, following manufacturer's guidelines, lubricating during tough cuts, and inspecting tools before return to avoid additional charges.

- The hole saw rental market is expected to grow, with a compound annual growth rate from 2025 to 2033, highlighting the importance of staying informed about industry trends.

Introduction

In the dynamic realm of construction, precision is paramount; hole saws have emerged as essential tools for achieving accurate and efficient results. These specialized cutting instruments are meticulously designed to create clean, circular holes across a variety of materials—from wood to metal—making them indispensable for critical tasks such as installing pipes and electrical fixtures.

As the demand for these tools continues to rise, understanding the various types available and selecting the right rental service becomes crucial for construction professionals. Advancements in technology further enhance their effectiveness, ensuring that the right hole saw can significantly impact project outcomes, thereby safeguarding both quality and safety on the job site.

This article delves into the intricacies of hole saws, outlines considerations for renting them, and shares best practices for maintenance, equipping construction managers with the essential knowledge needed to navigate this vital aspect of their work.

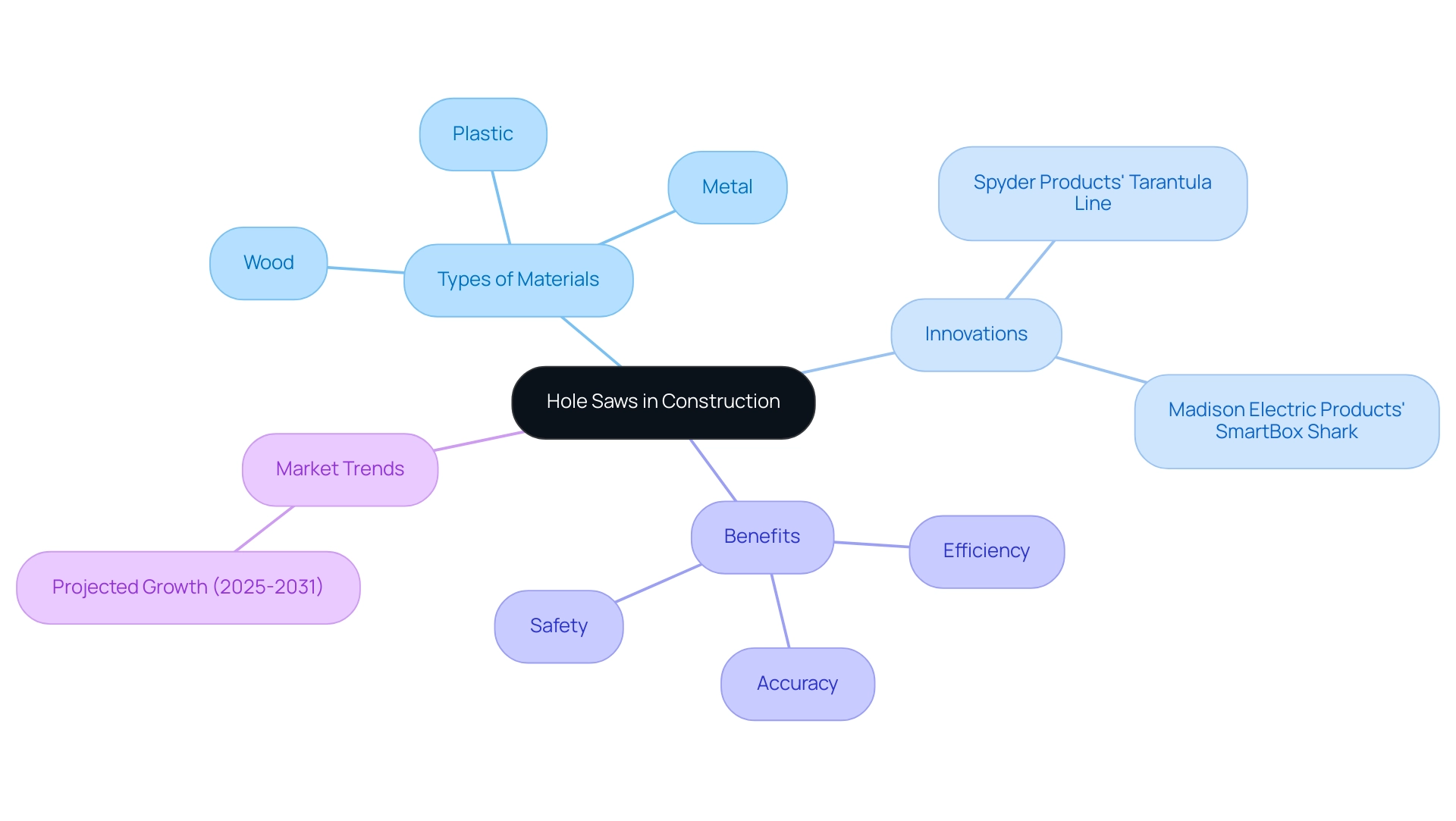

Understanding Hole Saws: Essential Tools for Construction

Circular cutting devices are specialized instruments designed to produce accurate round openings in various substances, including wood, metal, and plastic. These tools feature a cylindrical blade with sharp teeth along the edge, mounted on an arbor that fits into a standard drill. In the construction sector, [circular cutting tools](https://ezequipmentrental.com/about-us) are essential for installing pipes, electrical fixtures, and ventilation systems, where precision is crucial.

As of 2025, the use of boring tools in construction projects has seen a notable increase, underscoring their essential role in enhancing efficiency and accuracy. The projection timeframe for extends from 2025 to 2031, indicating a growing demand for these instruments. Recent innovations in saw technology, such as Spyder Products' Tarantula line of carbide-tipped saws and Madison Electric Products' SmartBox Shark fixture box—which integrates a saw for easier installation—have further improved their effectiveness.

These advancements cater to the evolving needs of both commercial and domestic users, ensuring that construction professionals have access to tools that facilitate cleaner and more accurate cuts. Choosing the suitable saw, particularly when renting a hole saw, necessitates a thorough understanding of the materials involved and the specific sizes of openings required for the project. Utilizing a rented hole saw not only guarantees clean, precise cuts but also enhances the overall quality of construction work. For instance, when placing pipes or electrical fittings, the accuracy provided by contemporary cutting tools minimizes the risk of damaging adjacent materials, thereby improving installation quality.

The advantages of using saws with circular blades, especially when renting hole saws, extend beyond mere functionality; they also promote safety and efficiency on the job site. By reducing the time spent on cutting and ensuring precise openings, construction teams can optimize their workflows and focus on other critical aspects of their tasks. Expert opinions emphasize the significance of these resources, with many professionals highlighting their reliability and effectiveness in achieving high-quality results.

As noted by a Senior Research Analyst at Cognitive Market Research, "I have a proven track record of conducting thorough analyses, distilling key insights, and presenting findings in a way that resonates with diverse stakeholders."

In summary, the incorporation of advanced saw technology and a clear comprehension of their application in construction endeavors is crucial for any construction manager. By leveraging these tools effectively, teams can ensure that their projects meet the highest standards of quality and efficiency. Furthermore, the ongoing report on key industry developments, with a base year of 2024 and historical data from 2019 to 2023, provides valuable insights into market trends that construction managers should consider.

Types of Hole Saws Available for Rent

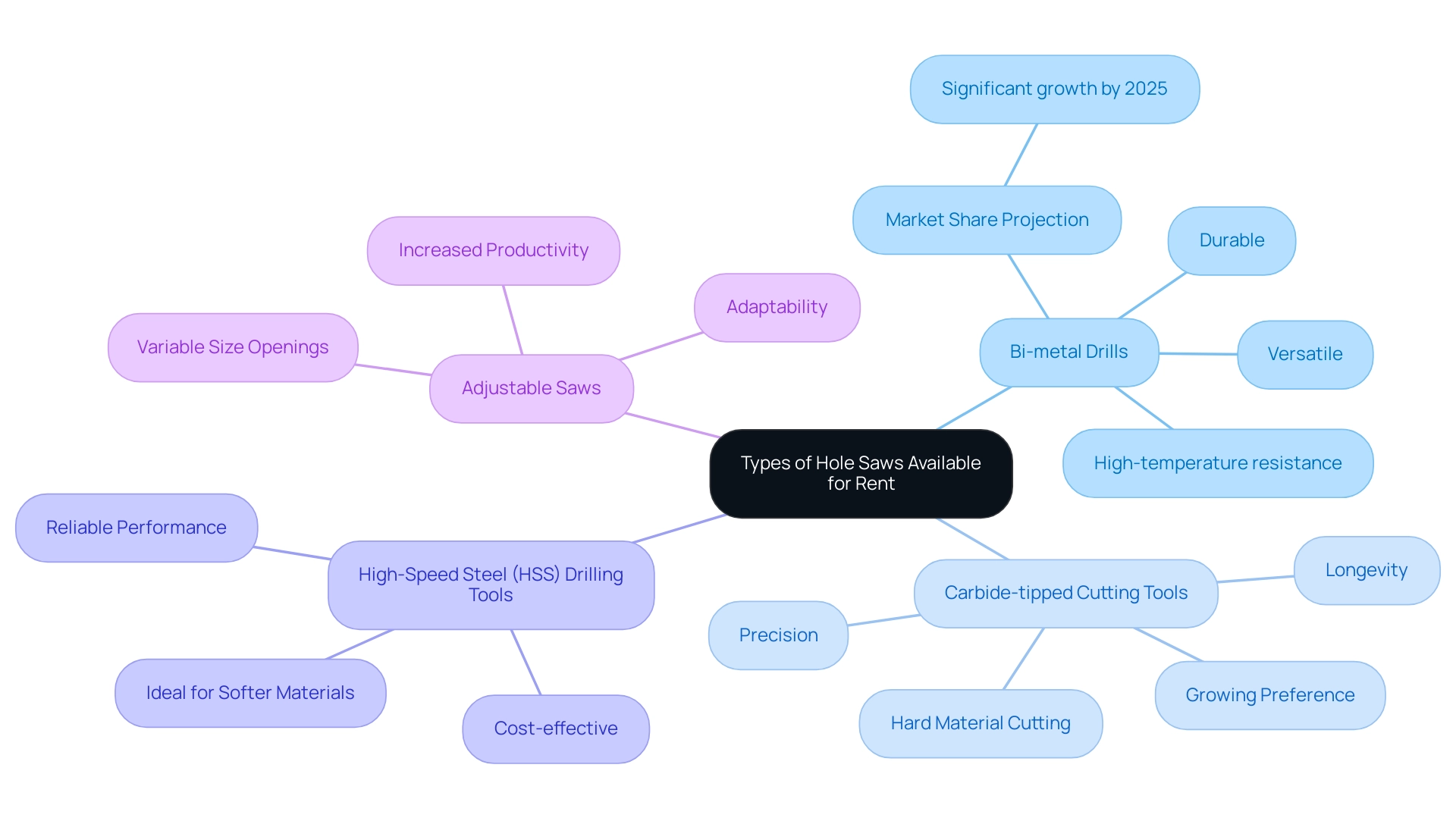

When leasing drilling tools, understanding the various types available is crucial, as each serves distinct functions in construction projects. Here’s a comprehensive comparison of the most common types:

- Bi-metal Drills: These versatile tools are designed to cut through both wood and metal with ease. Their robust construction allows them to withstand high temperatures, making them a durable choice for a wide array of applications. By 2025, bi-metal cutting tools are projected to capture a significant market share due to their exceptional versatility and performance.

- Carbide-tipped Cutting Tools: Excelling in cutting through hard materials like tile, masonry, and concrete, these tools feature carbide tips that offer remarkable longevity and precision. Their durability is becoming increasingly important in the construction sector, leading to a growing preference for carbide-tipped drilling tools among professionals.

- High-Speed Steel (HSS) Drilling Tools: Ideal for softer materials, HSS drilling tools present a cost-effective solution that ensures reliable performance for general use. They are particularly favored for projects where budget constraints exist, yet quality cannot be compromised.

- Adjustable Saws: These innovative tools allow for varying size openings, making them indispensable for projects that require different diameters. Their adaptability significantly enhances productivity on the job site, accommodating diverse cutting needs without necessitating multiple tools.

Understanding these types of cutting tools will empower you to select the most suitable option for your specific requirements. With the Hole Saw Industry anticipating (CAGR) from 2025 to 2033, staying informed about these instruments will prepare you to meet the evolving demands of construction projects. Moreover, industry reports indicate that while alternative cutting tools like jigsaws and reciprocating saws are gaining limited traction as substitutes, the demand for specialized instruments such as core drills remains strong.

As highlighted by a US TPS Business Development Manager at Thermon, 'The response was good, and I got what I was looking for as far as the report.' This underscores the importance of understanding market dynamics when selecting the appropriate tools for your tasks.

How to Choose the Right Rental Service for Hole Saws

Selecting the appropriate rental service for core drills is crucial for ensuring efficiency and success in your projects. Here are several key considerations to assist construction managers in making informed decisions:

- Reputation: Investigate by examining customer reviews and testimonials. A strong reputation often signifies reliability and quality service, both of which are essential for adhering to project timelines. With approximately 59,650 private industry establishments in the rental sector, understanding the competitive landscape can help identify reputable providers like EZ Equipment Rental in Dallas.

- Equipment Quality: Focus on services that offer well-maintained and high-quality hole saw rentals. Inquire about their maintenance practices to confirm that the equipment is in optimal working condition, as this can significantly influence performance and safety on the job site. As John Jeanguenat, president of RentalMax, notes, "The rental business by its nature is a green industry," underscoring the environmental advantages of choosing rental services that prioritize sustainability, such as those provided by EZ Equipment Rental.

- Pricing: Conduct a comprehensive comparison of rental rates among various providers. Seek transparent pricing structures that clearly outline costs, avoiding hidden fees that could unexpectedly inflate your budget. EZ Equipment Rental offers competitive rates that can help you save on expenses while maximizing efficiency for your tasks.

- Rental Terms: Familiarize yourself with , including duration, deposit requirements, and potential late fees. Understanding these details can help prevent misunderstandings and ensure a seamless rental experience with EZ Equipment Rental.

- Customer Support: Opt for a rental service that excels in customer support. This includes assistance with instrument selection, usage guidance, and prompt responses to inquiries. A knowledgeable team at EZ Equipment Rental can enhance your rental experience and provide valuable insights tailored to your needs. Additionally, consider companies actively promoting sustainable practices and renewable fuels within the industry, as this commitment can positively reflect on their customer support and service quality.

By carefully evaluating these factors, construction managers can confidently select a rental service like EZ Equipment Rental to rent hole saws, ensuring access to the right tools for successful outcomes. Explore our latest posts, such as 'Get Portable Dock Ramps on Rent for Smooth Holiday Logistics in Dallas' and 'How Renting Trailers in Dallas Can Save You Time and Money,' to discover how renting various types of equipment can enhance your efficiency and reduce costs.

Key Considerations When Renting Hole Saws

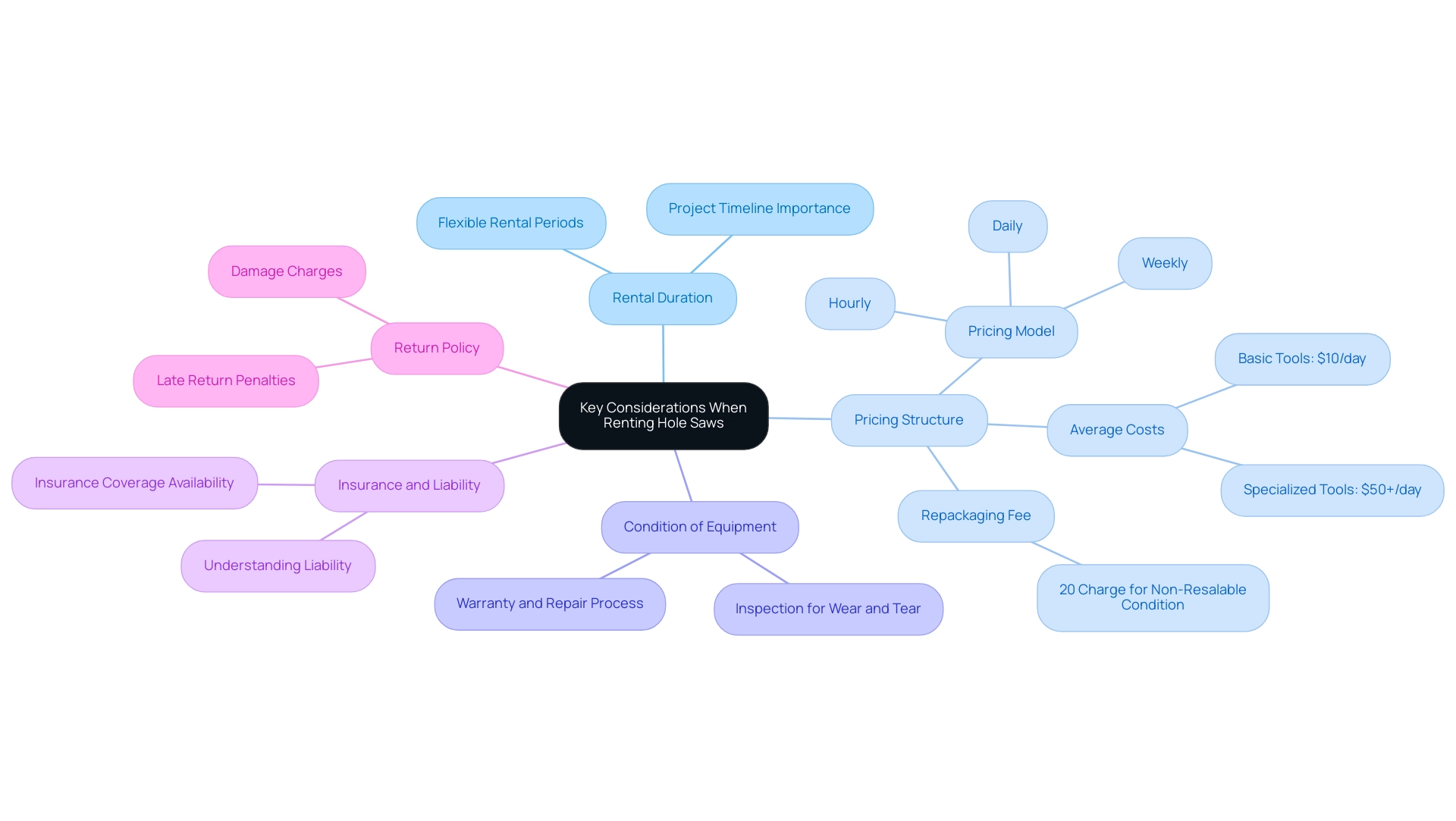

When , several important factors can significantly influence your undertaking’s efficiency and budget:

- Rental Duration: Evaluate the length of time for which you will require the drilling tools. EZ Equipment Rental offers flexible rental periods tailored to your project needs, which is crucial for effective project planning. Understanding your timeline is essential, as some rental companies may impose stricter timeframes.

- Pricing Structure: Familiarize yourself with the pricing model—whether it’s hourly, daily, or weekly. In 2025, the average expense for leasing drilling tools can fluctuate significantly depending on the kind and dimensions of the equipment. For example, basic drilling tools may begin at approximately $10 per day, whereas specialized versions might attain $50 or higher. Additionally, be aware that items returned not in resalable condition may incur a 20% repackaging charge, which can add unexpected costs to your budget. Comparing these costs across different rental services ensures you secure the best deal for renting a hole saw.

- Condition of Equipment: Before finalizing your rental, inspect the hole saws thoroughly. Look for any signs of wear and tear, ensuring that the equipment is clean and fully functional. This step is vital to avoid unexpected issues during your endeavor. If a device requires repair, EZ Equipment Rental has a specific warranty and repair process, ensuring that customers are informed about the warranty status of their devices and providing a clear path for obtaining repairs.

- Insurance and Liability: Verify whether the rental service provides insurance coverage for the equipment. Understanding your liability in the event of damage or loss is essential to protect your investment and manage risks effectively.

- Return Policy: Familiarize yourself with the return policy, including any penalties for late returns or damage. For instance, items returned in a condition not appropriate for resale may incur a 20% repackaging fee, which can add unexpected costs to your budget.

By keeping these considerations in mind, you can make informed decisions that enhance your endeavor’s success while minimizing unforeseen expenses. Furthermore, examining case studies on rental duration effects can offer important insights into how prompt access to tools such as core drills can enhance project timelines. For more information or to reserve equipment, contact EZ Equipment Rental at (214) 951-7800.

Maintaining Rented Hole Saws: Best Practices for Construction Managers

To maximize the longevity and performance of rented hole saws, it is essential to adhere to the following best practices:

- Clean After Use: Thoroughly remove any debris or sawdust from the saw after each use. This simple step prevents clogging and ensures optimal cutting efficiency, which is crucial for maintaining the implement's performance.

- Use Proper Techniques: Always follow the manufacturer's guidelines regarding the use of saws, including recommended speeds and feed rates. Adhering to these specifications helps prevent overheating and extends the life of the tool.

- Lubricate: When cutting through tougher materials, apply cutting oil or lubricant to the saw. This reduces friction and heat buildup, which can otherwise lead to premature wear and tear.

- Examine Prior to Return: Carry out a detailed assessment of the cutting tools before giving them back. Look for any signs of damage or excessive wear, and report any issues to the rental service. This proactive approach can help avoid penalties and ensure a smooth rental experience.

- Store Properly: If temporary storage is necessary, keep the hole saws in a dry environment and avoid stacking them. Proper storage prevents damage and maintains the integrity of the equipment.

Implementing these maintenance practices not only ensures that rented equipment remains in excellent condition but also minimizes the risk of incurring additional charges. Construction managers who prioritize equipment care can significantly influence rental expenses, as effective maintenance can lead to reduced wear and tear, ultimately saving money in the long run. In fact, the yearly expense of crane preventive maintenance is $5,000, emphasizing the financial consequences of neglecting equipment upkeep.

Real-life examples from industry professionals emphasize that consistent care and attention to detail can extend the life of rented hole saws, making them a reliable choice for any project. As noted by an expert, "Exploring advanced maintenance techniques can help you bridge the gap between ." Furthermore, utilizing software for rental management can streamline operations and enhance efficiency, ensuring that equipment is maintained properly and ready for use.

EZ Equipment Rental's commitment to quality and reliability underscores the importance of maintaining rented tools, aligning with their values and ensuring customer satisfaction.

Conclusion

Hole saws are indispensable in the construction industry, delivering precision and efficiency in crafting circular holes across a variety of materials. With technological advancements, their importance has surged, resulting in specialized types such as bi-metal, carbide-tipped, and adjustable hole saws. For construction professionals, comprehending these tools and the considerations for renting them is crucial to enhancing project quality and workflow.

Equally important is the selection of the right rental service. Factors such as reputation, equipment quality, pricing, and customer support can significantly influence project success. By conducting thorough research and evaluating various options, construction managers can secure reliable tools that cater to their specific needs.

Furthermore, maintaining rented hole saws through proper cleaning, lubrication, and inspection is essential for maximizing their lifespan and performance. Adhering to best practices not only preserves the integrity of the tools but also mitigates unexpected costs associated with damage or wear.

In summary, the effective use and maintenance of hole saws can lead to superior project outcomes, underscoring the significance of these tools in construction. By staying informed about their types, rental considerations, and maintenance practices, construction professionals can execute their projects with the highest quality and efficiency, ultimately fostering a safer and more productive work environment.

Frequently Asked Questions

What are circular cutting devices used for?

Circular cutting devices are specialized instruments designed to create accurate round openings in various materials, including wood, metal, and plastic, and are essential in the construction sector for tasks such as installing pipes, electrical fixtures, and ventilation systems.

How have boring tools impacted construction projects as of 2025?

The use of boring tools in construction projects has notably increased, highlighting their essential role in enhancing efficiency and accuracy.

What is the projected timeframe for the saw market?

The saw market is projected to grow from 2025 to 2031, indicating a rising demand for these instruments.

What innovations have recently improved saw technology?

Recent innovations include Spyder Products' Tarantula line of carbide-tipped saws and Madison Electric Products' SmartBox Shark fixture box, which integrates a saw for easier installation.

Why is it important to choose the right saw when renting a hole saw?

Choosing the suitable saw is crucial as it requires understanding the materials involved and the specific sizes of openings needed for the project, ensuring clean and precise cuts that enhance the overall quality of construction work.

What benefits do circular saws provide to construction teams?

Circular saws promote safety and efficiency by reducing cutting time and ensuring precise openings, allowing construction teams to optimize their workflows and focus on other critical tasks.

What types of drilling tools are commonly used in construction?

Common types of drilling tools include bi-metal drills, carbide-tipped cutting tools, high-speed steel (HSS) drilling tools, and adjustable saws, each serving distinct functions for various materials and project needs.

What are the advantages of bi-metal drills?

Bi-metal drills are versatile tools that can cut through both wood and metal, are durable, and are projected to capture a significant market share due to their exceptional performance.

What distinguishes carbide-tipped cutting tools?

Carbide-tipped cutting tools excel in cutting hard materials like tile, masonry, and concrete, offering remarkable longevity and precision, making them increasingly preferred in the construction sector.

How do high-speed steel (HSS) drilling tools serve construction projects?

HSS drilling tools are cost-effective solutions ideal for softer materials, ensuring reliable performance, particularly in budget-constrained projects without compromising quality.

What is the significance of adjustable saws in construction?

Adjustable saws allow for varying size openings, making them indispensable for projects that require different diameters, thereby enhancing productivity on the job site.

What is the anticipated growth rate for the Hole Saw Industry?

The Hole Saw Industry is expected to see a compound annual growth rate (CAGR) from 2025 to 2033, indicating a growing demand for these specialized cutting instruments.