Overview

The article focuses on how to effectively select and use log splitters for rental purposes. It emphasizes critical factors such as log size, power source, and safety features, along with maintenance tips and common mistakes to avoid, ensuring that users can make informed decisions and operate the equipment safely and efficiently.

Introduction

Navigating the world of log splitter rentals can be a daunting task, especially for those new to the process or unfamiliar with the equipment. With a growing demand for log splitters in various industries, understanding the key factors that influence rental decisions is crucial.

From determining the right type and size of the splitter to ensuring safety and maintenance, each aspect plays a significant role in optimizing efficiency and effectiveness. By exploring the intricacies of log splitter rentals, users can avoid common pitfalls and make informed choices that enhance their wood-splitting experience, ensuring they have the right tools for the job while prioritizing safety and performance.

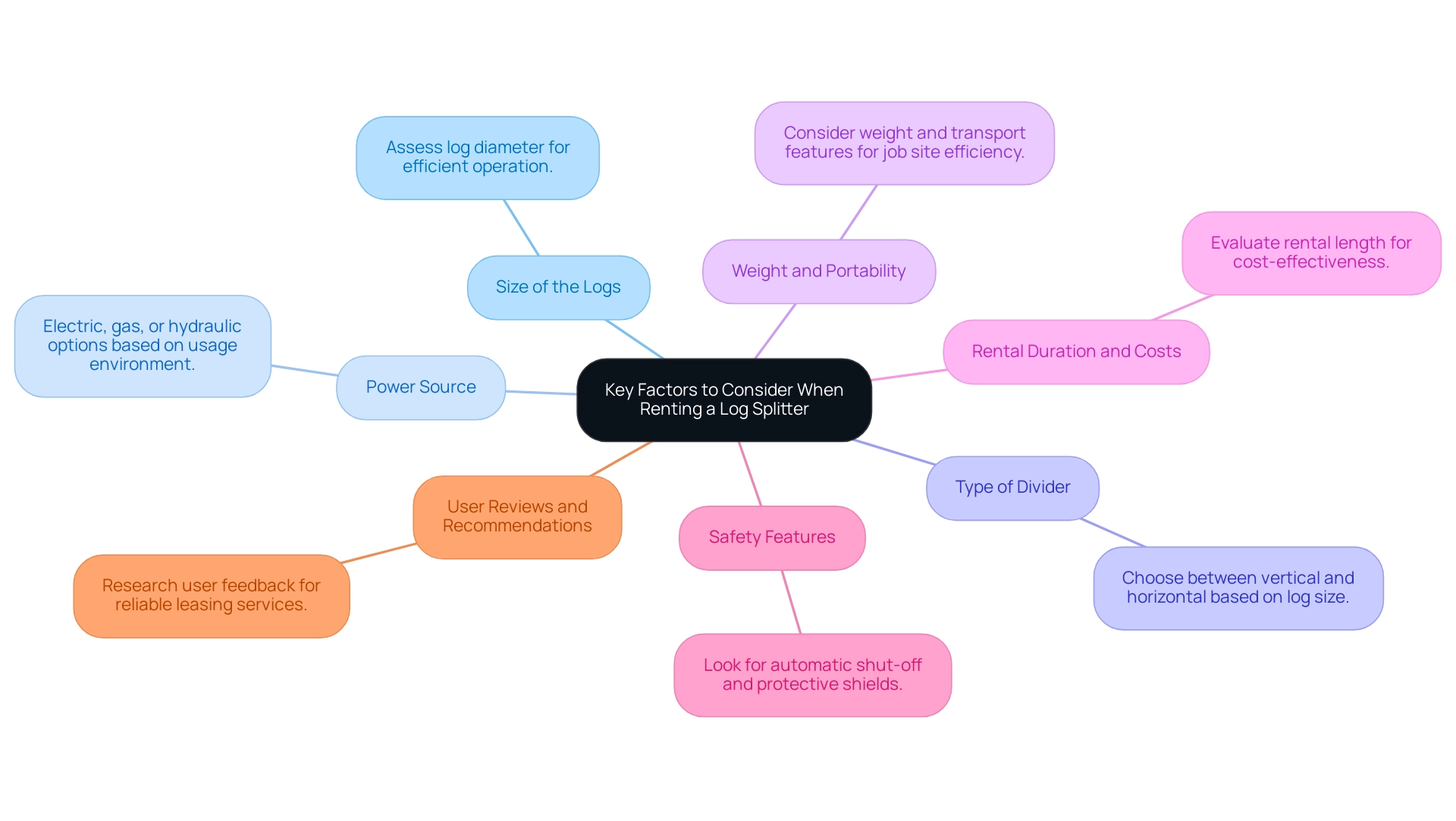

Key Factors to Consider When Renting a Log Splitter

When renting a log splitter, several critical factors must be taken into account to ensure you select the right equipment for your needs, especially in light of the growing demand for log splitters in the construction industry:

- Size of the Logs: Begin by assessing the diameter of the logs you will be splitting. Log cutting machines are designed to handle different log sizes, so selecting a model that corresponds to your log dimensions is essential for efficient operation.

- Power Source: Log cutters can be powered by electricity, gas, or hydraulics. Consider the environment in which you will be using the device. For instance, electric models are often quieter and suitable for residential areas, while gas-powered devices provide more power for larger jobs in remote locations.

- Type of Divider: Select between vertical and horizontal dividers according to the records you intend to divide. Vertical models are especially efficient for larger logs, facilitating easier handling, while horizontal devices are more appropriate for smaller, more manageable pieces.

- Weight and Portability: If you expect to need to transport the device, consider its weight and whether it includes features like wheels or handles that aid in movement. Portability can significantly impact your efficiency on the job site.

- [Rental Duration and Costs](https://blog.ezequipmentrental.com/10-key-factors-influencing-lawn-mower-rental-cost-for-projects): Assess how long you will require the device. Leasing expenses can vary depending on the length of the lease, and in numerous situations, choosing a more extended period can be more cost-effective. Understanding the market, which is projected to grow steadily, with the forestry and logging industry expected to reach a valuation of US$ 267.3 million in 2033, can help you make informed decisions about near me and associated costs.

- Safety Features: Prioritize safety by looking for splitters equipped with features such as automatic shut-off mechanisms and protective shields. These elements are crucial for preventing accidents and ensuring safe operation.

- User Reviews and Recommendations: Before concluding your lease for log splitter rentals near me, take the time to read user reviews and seek recommendations. This research can guide you to trustworthy leasing services that offer well-maintained equipment, thereby reducing the risk of operational issues.

As Husqvarna highlights, 'The company's emphasis on innovation and product development has allowed it to remain ahead of the competition,' which is a vital aspect as you assess leasing choices. By considering these factors, you can ensure that your log rental will meet your project’s demands efficiently and safely.

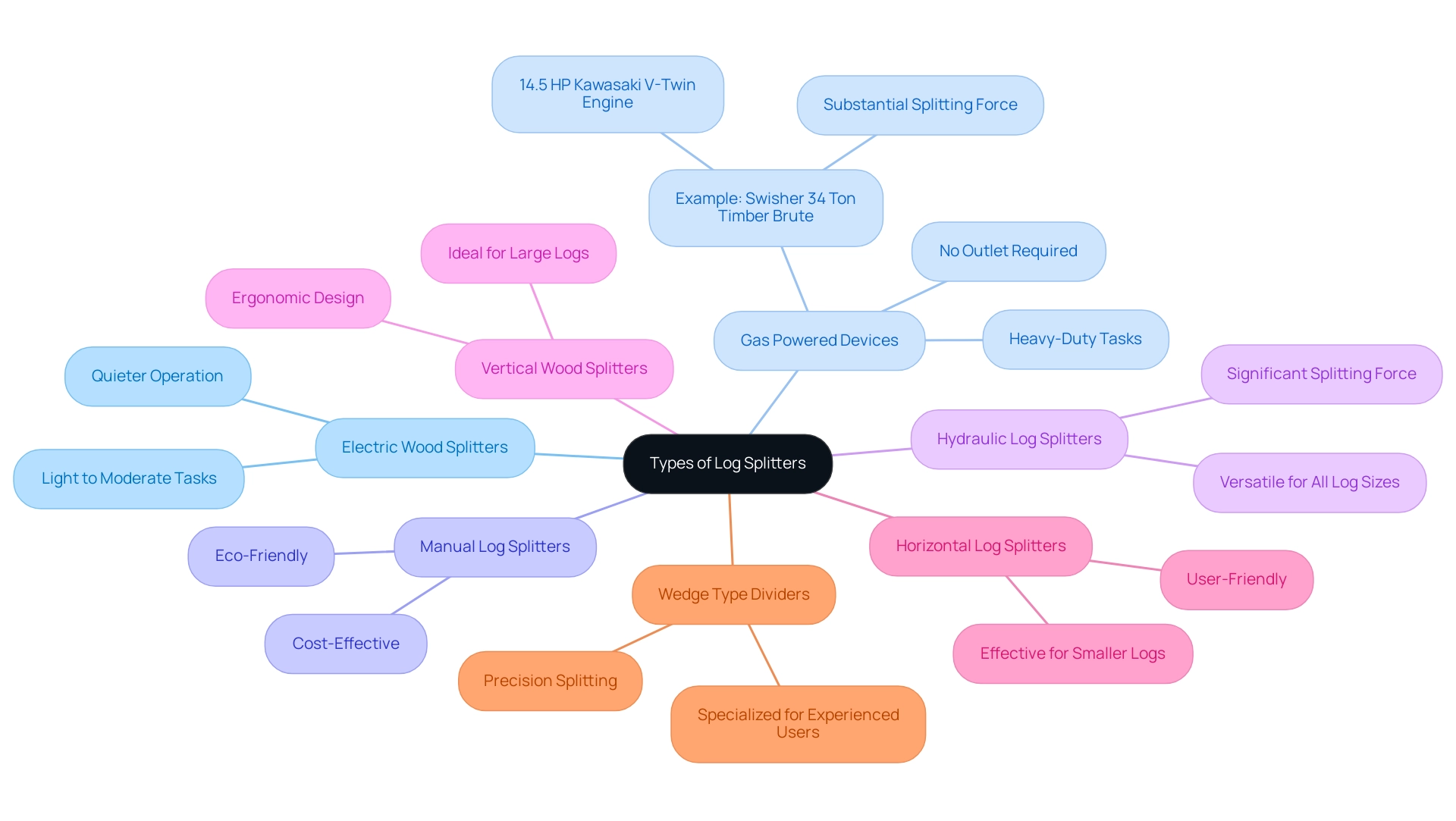

Understanding Different Types of Log Splitters and Their Usage

Log splitters are available in various types, each tailored to specific tasks and user needs:

- Electric Wood Splitters: These are well-suited for light to moderate wood splitting tasks, making them ideal for homeowners dealing with small to medium-sized timber. Their quieter operation is particularly advantageous in residential areas, allowing for use without disturbing neighbors.

- Gas Powered Devices: Famous for their strength, gas powered devices thrive in heavy-duty tasks and can handle bigger pieces of wood effortlessly. They are particularly advantageous for contractors and users working in remote locations where electrical outlets are unavailable. The Swisher 34 Ton Timber Brute, for instance, features a robust 14.5 horsepower Kawasaki V-Twin engine, providing substantial splitting force that is perfect for demanding wood splitting tasks. As mentioned by Grace Campbell from , "Here at DR Power Equipment, we dedicate a significant amount of time to designing, manufacturing, and discussing log devices, and we believe we have some valuable insight for you."

- Manual Log Splitters: These eco-friendly options require physical effort but are cost-effective, making them suitable for occasional users or those working with smaller pieces of wood. They promote a hands-on approach to splitting wood, often appealing to DIY enthusiasts.

- Hydraulic Log Splitters: With the ability to generate significant splitting force, hydraulic models can handle almost any log size. They are versatile enough for both professional contractors and residential users, providing a balance of power and efficiency.

- Vertical Wood Splitters: Designed for larger pieces of wood, vertical devices enable users to load heavy sections without the necessity to bend down. This ergonomic design is favored by serious woodworkers who require ease of use while managing substantial wood sizes.

- Horizontal Log Splitters: Commonly used for general splitting tasks, horizontal models are user-friendly and effective for smaller logs. They enable quick processing and are typically easier to operate.

- Wedge Type Dividers: Specialized for particular tasks, these devices utilize a wedge mechanism rather than conventional splitting methods. They are particularly suited for seasoned woodworkers seeking precision in their wood splitting endeavors.

Swisher provides both electric and gas log cutters, allowing customers to select the best option for their needs. Comprehending the distinct characteristics and uses of each kind of log splitter, including log splitter rentals near me, is essential for choosing the most suitable equipment for particular requirements, ensuring both efficiency and security during operation. Additionally, membership includes a year of Mother Earth News magazine, backed by 50+ years of trusted DIY guidance, which can further assist users in making informed choices.

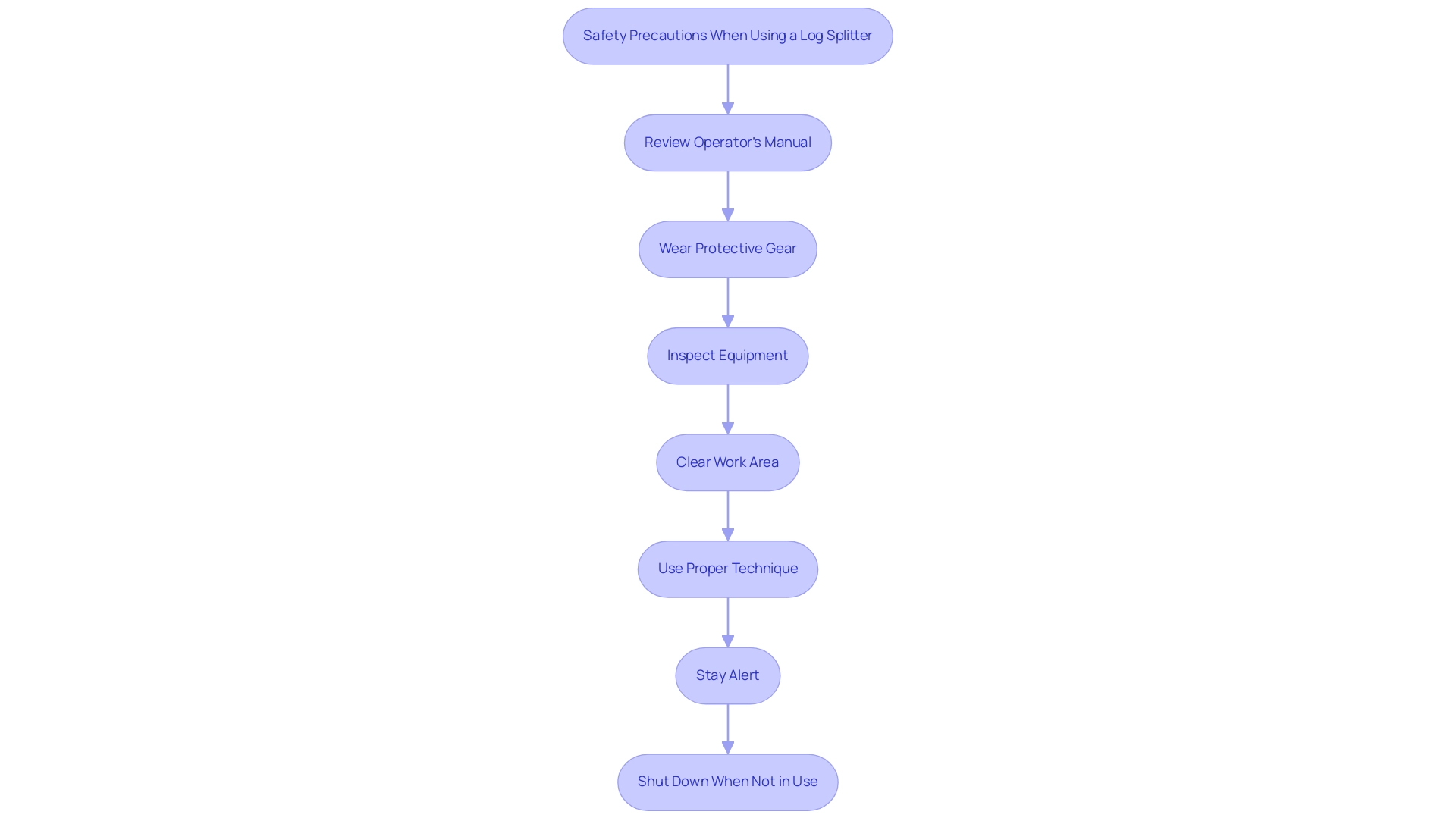

Safety Precautions When Using a Log Splitter

Ensuring safe log splitting operations necessitates a rigorous approach to various precautions:

- Begin by thoroughly reviewing the operator's manual provided by the rental company for log splitter rentals near me. Familiarity with the specific model’s features and operating instructions is essential for safe operation.

- Wear Protective Gear: Equip yourself with safety glasses, gloves, and steel-toed boots. These items are vital for shielding yourself from flying debris and the weight of heavy logs, minimizing the risk of injury.

- Inspect the Equipment: Conduct a comprehensive examination of the log device before use. Look for any signs of damage or malfunctioning parts. Ensure all guards and protective features are intact, as neglecting this step can lead to accidents. For instance, the recent Oregon Tool log cutting device recall was initiated due to a hazard where the hydraulic cylinder rod can separate from the piston, posing a risk of unexpected movement and potential injuries. This incident highlights the importance of using reliable equipment and adhering to safety protocols.

- Clear the Work Area: Maintain a tidy work environment by removing obstacles and ensuring bystanders are at a safe distance. A clear area fosters safe operation and helps prevent accidents.

- Use Proper Technique: When placing logs into the device, position yourself to the side and keep hands away from the splitting area. Adhere strictly to the operating controls as instructed, which is crucial for avoiding injuries.

- Stay Alert: It’s vital to remain focused while operating the log machine. Avoid distractions to ensure you are fully aware of your surroundings, as this can greatly reduce the likelihood of accidents.

- Shut Down When Not in Use: Always deactivate the log splitter when it is not in use or when making adjustments. This simple step can prevent accidental activations that may lead to injuries.

Recent statistics from the CPSC underscore the risks associated with improper log splitting, as they oversee products involved in an estimated 29 million injuries and 22,000 deaths annually. Moreover, previous evaluations of log-related fatalities, like those in Kentucky from 1994-1998, showed that logs rolling off trucks made up 15% of logging-related deaths, highlighting the need for strict precautionary measures. Experts like Osamu Nomura advocate for training, stating, "Therefore, we suggest that training should be provided to prevent traumatic injuries when these products are being sold."

This highlights the critical role of training in implementing the specific precautions outlined above. By adopting and utilizing the appropriate protective gear, you can significantly decrease the risk of accidents during log splitting operations.

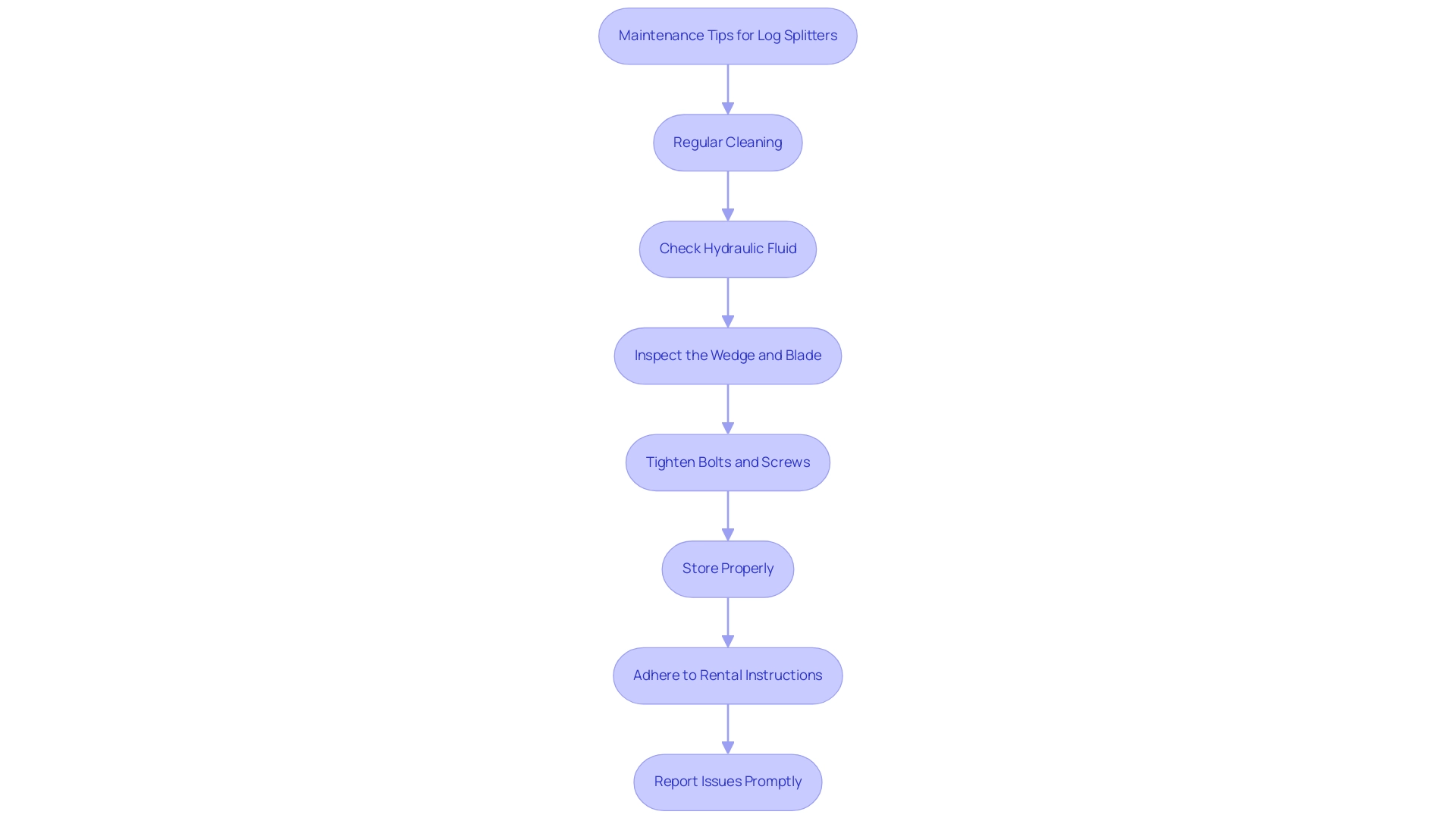

Maintenance Tips for Log Splitters

To ensure your log device remains in peak condition, adhere to these essential maintenance tips:

- Regular Cleaning: After each use, it’s crucial to clean the device thoroughly. Removing sawdust, dirt, and debris is vital, as accumulated materials can significantly hinder performance efficiency.

- Check Hydraulic Fluid: Keeping an eye on hydraulic fluid levels is essential. Ensure that the fluid is clean and at the correct level, replacing it promptly if it appears dirty or contaminated to avoid operational issues.

- Inspect the Wedge and Blade: Frequent checks of the wedge and blade are necessary to identify signs of wear. Sharpen or replace these components as needed, as maintaining sharpness directly impacts splitting efficiency.

- Tighten Bolts and Screws: Regular inspections of all bolts and screws are important to confirm their tightness. Loose components can lead to malfunctions, posing risks during operation.

- Store Properly: When the log splitter is not in use, store it in a dry, sheltered area. This practice protects the machine from the elements, helping to prolong its lifespan and maintain functionality.

- Always adhere to specific maintenance instructions for log splitter rentals near me provided by your leasing company. This compliance ensures you meet their policies and maintain the equipment properly.

- Report Issues Promptly: Should any issues arise during the usage of log splitter rentals near me, it’s imperative to report them to the rental company immediately. Timely reporting can avert additional damage and guarantees security during operations.

Alongside these suggestions, it's important to mention that is experiencing significant expansion, with a market size surpassing USD 1.12 billion in 2023. Avinash Singh noted that this increase is attributed to their affordability and the rising demand for eco-friendly products. Keeping your log processor well-maintained not only enhances its performance but also contributes to a sustainable approach to your projects.

Furthermore, initiatives like the EU Environment project in Moldova highlight the importance of sustainable practices in equipment maintenance, aligning with broader environmental goals.

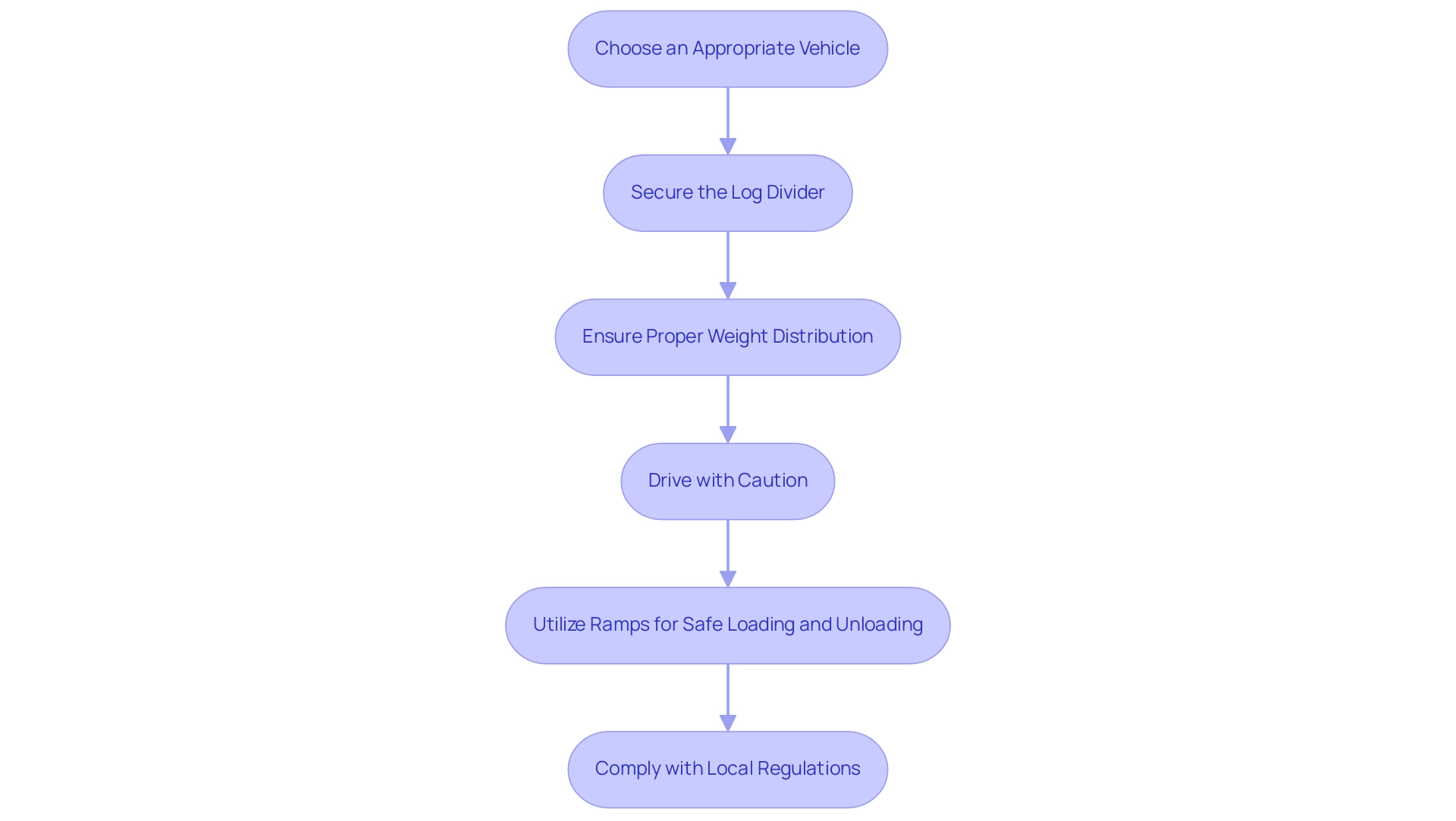

How to Transport a Log Splitter Safely

Transporting involves meticulous planning and execution to ensure safety and compliance. Here are key practices to consider:

-

Choose an Appropriate Vehicle: Opt for a vehicle that can manage the log cutter's weight.

Typically, a truck or a heavy-duty trailer is ideal for such tasks. Considering alternatives like pressurized and chilled liquid tanks can also be beneficial in specific conditions, showcasing the diverse options available for transporting heavy machinery.

-

Secure the Log Divider: Utilize durable straps or chains to firmly secure the divider, preventing any movement that could lead to tipping or shifting during transit.

Know Your Weight Limits: It's crucial to be aware of your vehicle's towing capacity to avoid overloading, which can lead to serious accidents or vehicle damage. With 34% of transportation equipment companies located in the South, understanding regional capabilities can also inform your choices.

-

Ensure Proper Weight Distribution: Load the device so that its weight is evenly distributed, keeping the center of gravity low for enhanced stability while on the road.

-

Drive with Caution: Maintain a steady speed, take turns gently, and avoid abrupt stops to keep the log device secure and prevent any mishaps. As emphasized by CPWR, these risks underscore the essential requirement for comprehensive protective systems across all industries to safeguard workers and avert accidents.

-

Utilize Ramps for Safe Loading and Unloading: If the splitter is particularly heavy, using portable dock ramps can facilitate safe loading and unloading, reducing the risk of strain or injury. Renting ramps in Dallas can be a cost-effective solution that improves security during transport, especially when combined with log splitter rentals near me. For more information, check out our latest post on how renting trailers in Dallas can save you time and money.

-

Comply with Local Regulations: It's essential to adhere to local laws regarding the transport of heavy machinery, ensuring that you are compliant while promoting safety on the road. Additionally, consider how log splitter rentals near me can save you time and money on your construction projects, boosting overall efficiency.

Common Mistakes to Avoid When Renting a Log Splitter

To ensure a seamless log borrowing experience, it's essential to steer clear of these common mistakes:

- Insufficient Research: Failing to thoroughly investigate the various types and features of log cutting devices can lead to the selection of unsuitable equipment. Understanding the capabilities of different models helps ensure that you select the right near me for your needs.

- Neglecting Rental Terms: Overlooking the terms outlined in rental agreements can result in unexpected charges or unfavorable conditions. Familiarizing yourself with these terms can help avoid financial surprises and ensure a smoother transaction.

- Underestimating Power Requirements: Choosing a log device that lacks sufficient power for the intended logs can cause frustration and inefficiency on the job. It’s crucial to assess your specific needs and choose equipment accordingly.

- Disregarding Safety Protocols: Overlooking protective measures can lead to accidents, making it imperative to prioritize precautionary practices during both operation and transport of the equipment.

- Skipping Equipment Inspection: Not inspecting the log device before use may result in operating issues or safety hazards. Always check for any damage or wear to ensure safe and effective operation.

- Avoiding Requests for Assistance: If you're unsure about how to operate the log splitter, do not hesitate to seek help from log splitter rentals near me. Their guidance can help you avoid mishaps and enhance operational safety.

- Late Returns: Being unaware of the return policy can lead to additional fees. Plan ahead to ensure timely returns and avoid unnecessary costs.

Additionally, utilizing leasing software with advanced analytics can provide insights into asset performance, helping you make informed decisions and improve financial planning. New business owners often overlook costs associated with maintenance, repair, storage, transportation, depreciation, tax, and insurance, which can significantly impact the overall leasing experience. For example, companies that rent equipment from MacAllister for projects far from their main site can benefit from direct delivery, saving time and reducing logistical concerns.

As Emilia Pintos states,

Getting your data where it needs to go shouldn’t be a challenge. With the next phase of our Integration API, we’re cutting out the friction.

This mindset extends to managing your rental processes effectively, ensuring a hassle-free experience.

Conclusion

Understanding the intricacies of log splitter rentals is essential for both novice and experienced users. By carefully considering factors such as log size, power source, and safety features, one can select the most suitable equipment for specific wood-splitting tasks. Each type of splitter, whether electric, gas, or hydraulic, serves a unique purpose, and recognizing these differences is key to maximizing efficiency.

Safety should always be a priority when operating log splitters. Adhering to safety precautions, such as wearing protective gear and conducting thorough equipment inspections, significantly reduces the risk of accidents. Additionally, proper maintenance practices ensure that the splitter remains in optimal condition, enhancing both performance and longevity.

Transporting a log splitter requires careful planning to ensure safety and compliance with regulations. Utilizing appropriate vehicles, securing the equipment, and maintaining proper weight distribution are all critical steps in this process. Moreover, avoiding common mistakes—like neglecting rental terms or failing to research equipment—can lead to a more seamless and cost-effective rental experience.

In conclusion, the right preparation and knowledge can transform the log splitting process from a daunting task into an efficient and enjoyable experience. By prioritizing safety, understanding equipment types, and adhering to best practices, users can confidently tackle their wood-splitting projects, ultimately leading to successful outcomes.

Frequently Asked Questions

What factors should I consider when renting a log splitter?

When renting a log splitter, consider the size of the logs, power source (electric, gas, or hydraulic), type of divider (vertical or horizontal), weight and portability, rental duration and costs, safety features, and user reviews and recommendations.

How does the size of the logs affect the choice of log splitter?

The diameter of the logs you will be splitting is crucial, as log splitters are designed to handle different log sizes. Selecting a model that matches your log dimensions is essential for efficient operation.

What power sources are available for log splitters?

Log splitters can be powered by electricity, gas, or hydraulics. Electric models are quieter and suitable for residential areas, while gas-powered devices offer more power for larger jobs in remote locations.

What is the difference between vertical and horizontal log splitters?

Vertical log splitters are efficient for handling larger logs and facilitate easier handling, while horizontal log splitters are more appropriate for smaller, manageable pieces.

Why is weight and portability important when renting a log splitter?

If you need to transport the device, its weight and features like wheels or handles are important for ease of movement, which can significantly impact your efficiency on the job site.

How do rental duration and costs affect my decision?

Rental costs can vary based on the length of the lease, and often, choosing a longer rental period can be more cost-effective. Understanding market trends can help you make informed decisions about your rental.

What safety features should I look for in a log splitter?

Look for log splitters that include safety features such as automatic shut-off mechanisms and protective shields to prevent accidents and ensure safe operation.

How can user reviews and recommendations help in the rental process?

Reading user reviews and seeking recommendations can guide you to trustworthy rental services that offer well-maintained equipment, reducing the risk of operational issues.

What types of log splitters are available?

There are several types of log splitters available, including electric wood splitters, gas-powered devices, manual log splitters, hydraulic log splitters, vertical wood splitters, horizontal log splitters, and wedge type dividers, each suited for specific tasks and user needs.

What advantages do electric and gas log splitters offer?

Electric wood splitters are quieter and ideal for light to moderate tasks, while gas-powered devices are stronger and better for heavy-duty tasks, especially in remote locations without electrical access.