Key Highlights:

- Determine load capacity to ensure the forklift can handle the heaviest loads, typically ranging from 6,000 to 10,000 lbs for construction.

- Assess required lift height to select the appropriate lift truck mast for efficient material handling.

- Identify the work environment (indoor vs outdoor) to choose between electric forklifts for indoor use and diesel for rugged outdoor conditions.

- Estimate the duration of forklift use to decide between short-term rentals and long-term equipment acquisition strategies.

- Understand forklift specifications, including engine type, tyre composition, mast types, and safety features, for informed decision-making.

- Compare rental rates and included services to find the best value and avoid unexpected costs.

- Review lease terms carefully to understand obligations related to damage, liability, and maintenance.

- Research rental companies for reputation and reliability based on customer reviews and ratings.

- Follow a structured rental process, including account setup, documentation gathering, lease agreement review, and scheduling delivery and pickup.

- Implement safety and compliance measures, including operator training, daily inspections, PPE usage, and adherence to OSHA regulations.

Introduction

Navigating the complexities of project management requires a keen understanding of equipment needs, especially when it comes to renting heavy machinery like 8000 lb forklifts. This guide provides essential insights into the rental process, covering everything from identifying project requirements to comparing rental options and ensuring compliance with safety standards. With numerous factors to consider, project managers must select the right forklift rental service that aligns with their specific project goals and budget constraints.

Understanding the available services is crucial. Renting heavy machinery can significantly impact project efficiency and success. By choosing the right equipment, project managers can ensure that their operations run smoothly and safely. Furthermore, knowing the benefits of each tool and equipment type helps in making informed decisions that contribute to project success.

Reliability and quality are paramount when selecting a rental service. Statistics show that projects utilizing well-maintained equipment experience fewer delays and higher productivity. Testimonials from satisfied customers further emphasize the importance of choosing a reputable rental service. These insights not only build confidence but also highlight the value of investing in quality equipment for project success.

To ensure a seamless rental experience, it’s essential to act promptly. Engage with rental services that offer comprehensive support and guidance throughout the process. By doing so, project managers can secure the right equipment that meets their needs and enhances project outcomes.

Identify Your Project Requirements

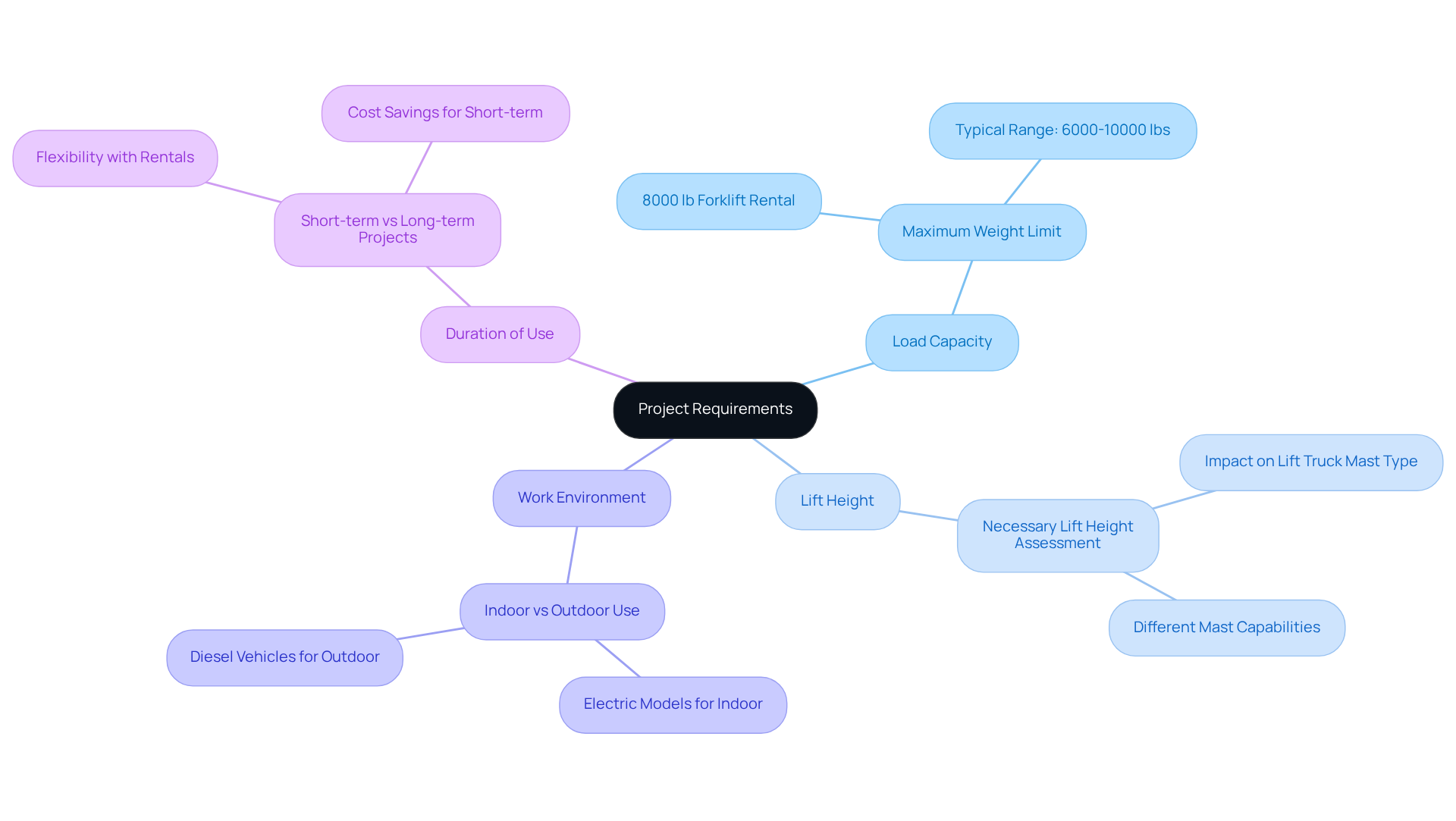

Evaluate the scope of your project effectively. Start by considering these key factors:

-

Load Capacity: Determine the maximum weight your forklift needs to lift. When using an 8000 lb forklift rental, ensure that your heaviest loads stay within this limit. In construction projects, average load capacities typically range from 6,000 to 10,000 lbs, depending on the materials involved. This understanding is crucial for selecting the right equipment.

-

Lift Height: Assess the necessary lift height for your materials. This requirement directly impacts the type of lift truck mast you need, as different masts offer varying lift capabilities. Choosing the right mast ensures that you can handle your materials efficiently and safely.

-

Work Environment: Identify whether your work will take place indoors or outdoors. This distinction is vital in selecting the appropriate lift truck; electric models are generally preferred for indoor use due to their lower emissions, while diesel vehicles excel in rugged outdoor terrains. Making the right choice here can enhance operational efficiency.

-

Duration of Use: Estimate how long you will require the forklift. For short-term projects, an 8000 lb forklift rental often offers flexibility and cost savings, while long-term initiatives may require a different strategy for equipment acquisition. Understanding your timeline helps in making informed decisions.

By clearly defining these requirements, you streamline the selection process, ensuring that the rented equipment aligns with your project goals. This structured approach not only boosts operational efficiency but also aids in managing costs effectively, allowing businesses to avoid unnecessary expenses associated with idle equipment during slower periods.

Understand Forklift Specifications and Features

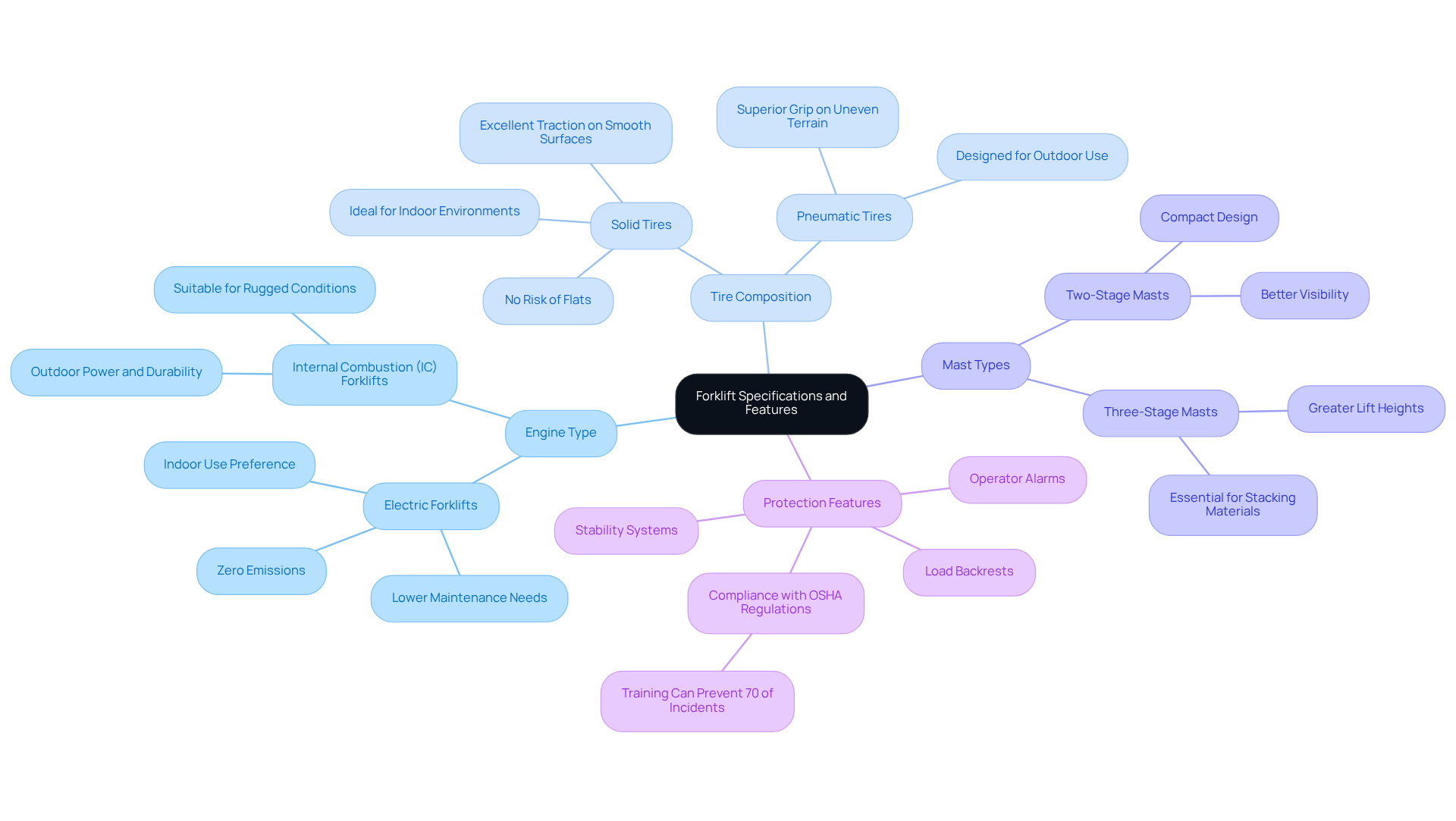

When selecting a forklift, understanding the following specifications is crucial for making an informed decision:

-

Engine Type: Choose between electric and internal combustion (IC) forklifts based on your operational environment and load requirements. Electric lift trucks, which represent 66% of the market, are preferred for indoor applications due to their zero emissions and reduced maintenance needs. In contrast, IC vehicles excel outdoors, where their power and durability shine, especially in rugged conditions.

-

Tire Composition: The choice of tires significantly impacts performance. Solid tires are ideal for indoor environments, providing excellent traction on smooth surfaces and eliminating the risk of flats. Conversely, pneumatic tires are designed for outdoor use, offering superior grip on uneven terrain, making them suitable for construction sites where conditions can vary.

-

Mast Types: Familiarize yourself with different mast configurations, such as two-stage and three-stage masts. Two-stage masts are generally more compact and provide better visibility, while three-stage masts allow for greater lift heights, essential for stacking materials in warehouses or construction sites.

-

Protection Features: Prioritize safety by seeking lifting vehicles equipped with essential features like load backrests, stability systems, and operator alarms. These enhancements not only improve operational safety but also ensure compliance with OSHA regulations, critical in reducing the risk of accidents-an area where proper training can prevent up to 70% of incidents.

By thoroughly understanding these specifications, you can select a lift truck that meets your project requirements while ensuring safe and efficient operation. For expert guidance and assistance, reach out to EZ Equipment Leasing for a seamless equipment leasing experience.

Compare Rental Options and Pricing

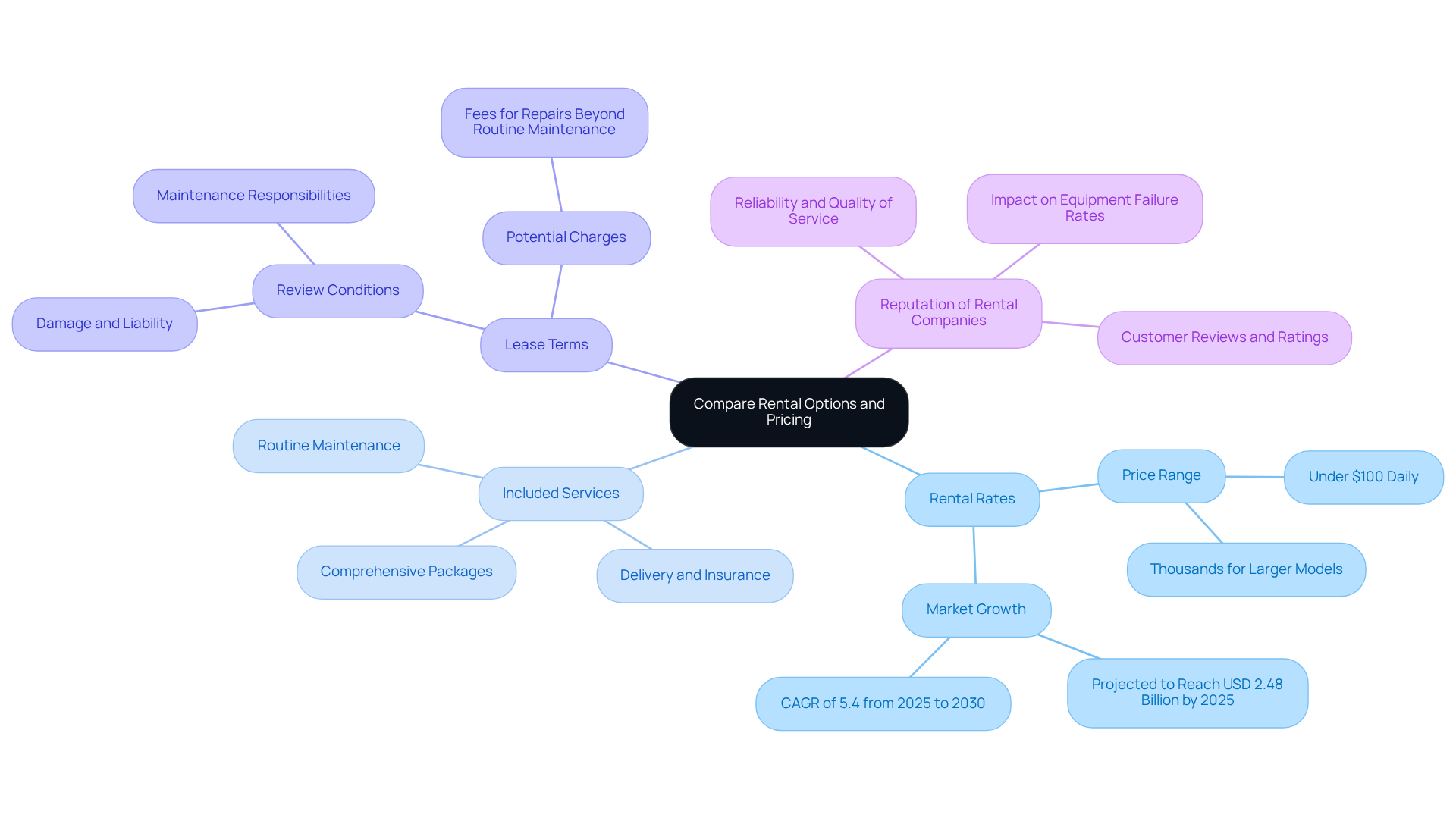

When it comes to selecting rental options for forklifts, several key factors demand your attention:

-

Rental Rates: It's crucial to gather quotes from various rental companies, as rates can vary significantly based on the type of forklift and the duration of the rental. For instance, leasing prices can range from under $100 daily to several thousand dollars for larger models. Assessing your budget against these options is essential. Notably, the North America Forklift Leasing Market is projected to reach USD 2.48 billion by 2025, highlighting the growing demand for flexible leasing solutions.

-

Included Services: Take the time to investigate what services are included in the leasing price. Many contracts cover routine maintenance, delivery, and sometimes insurance, which can lead to substantial savings. Understanding these inclusions allows you to identify comprehensive packages that deliver better overall value. As Larry Silber, CEO of Herc Rentals, points out, the focus on urban market growth is prompting companies to offer more competitive packages.

-

Lease Terms: It's vital to carefully review the lease agreement for conditions related to damage, liability, and maintenance responsibilities. Knowing your obligations and any potential charges for damages or excessive wear can significantly impact your budget. For example, some companies may impose fees for repairs beyond routine maintenance, so clarifying these details upfront is crucial.

-

Reputation of Rental Companies: Conduct thorough research on customer reviews and ratings to gauge the reliability and quality of service from different rental companies. A strong reputation often correlates with enhanced customer service and dependable equipment, which is critical for meeting deadlines. Case studies reveal that businesses with positive customer feedback typically experience lower equipment failure rates, ensuring smoother task execution.

By meticulously comparing these factors, you can make an informed decision that aligns with your budget and project requirements, ultimately selecting the best equipment leasing option for your needs.

Navigate the Rental Process and Documentation

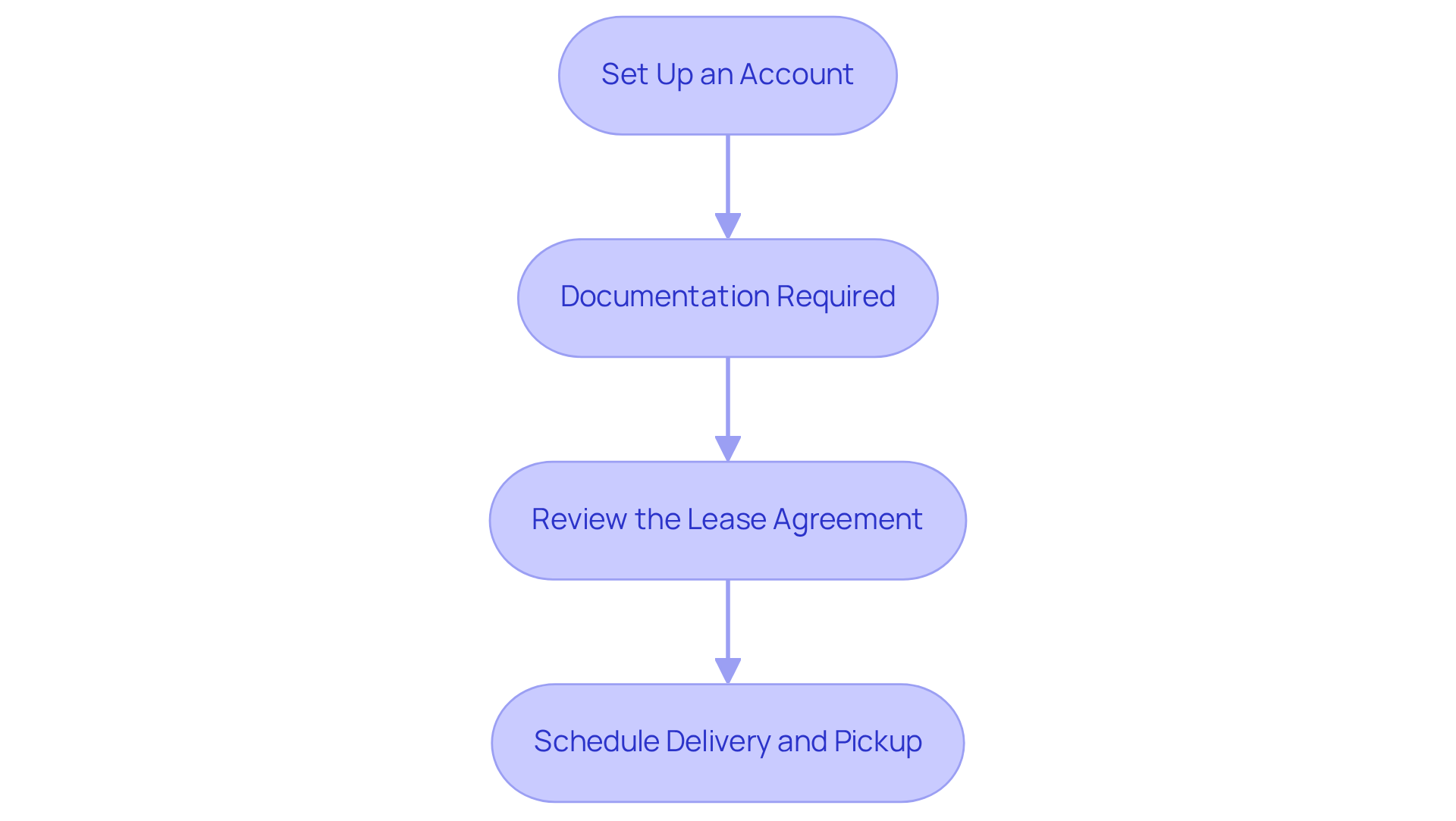

To navigate the forklift rental process effectively, follow these essential steps:

-

Set Up an Account: First-time renters must create an account with the rental company. This typically requires providing business information and credit details, which can take about 15 to 30 minutes to complete.

-

Documentation Required: Gather the necessary documents, which may include:

- Proof of insurance to cover potential damages or theft.

- A valid business license to verify your operational legitimacy.

- Operator certifications, if applicable, to ensure compliance with safety regulations.

-

Review the Lease Agreement: Thoroughly examine the lease agreement, focusing on terms related to duration, fees, and maintenance responsibilities. Understanding these details is crucial to prevent unforeseen expenses and ensure adherence to the leasing terms. As Daniel Hall emphasizes, "The conditions regarding liability for damages caused by accidents or improper usage must be clear in the lease agreement from the start."

-

Schedule Delivery and Pickup: Coordinate with the leasing company to arrange the delivery of the 8000 lb forklift rental to your job site and the pickup after the lease period concludes. Be aware that delivery and pickup charges may not be included in the leasing price, so clarify these costs upfront to avoid financial surprises.

By following these steps, you can promote a smooth leasing experience while ensuring compliance with all necessary regulations. The U.S. construction equipment rental market is projected to reach around USD 98.29 billion by 2034, underscoring the importance of understanding the rental process in a growing industry.

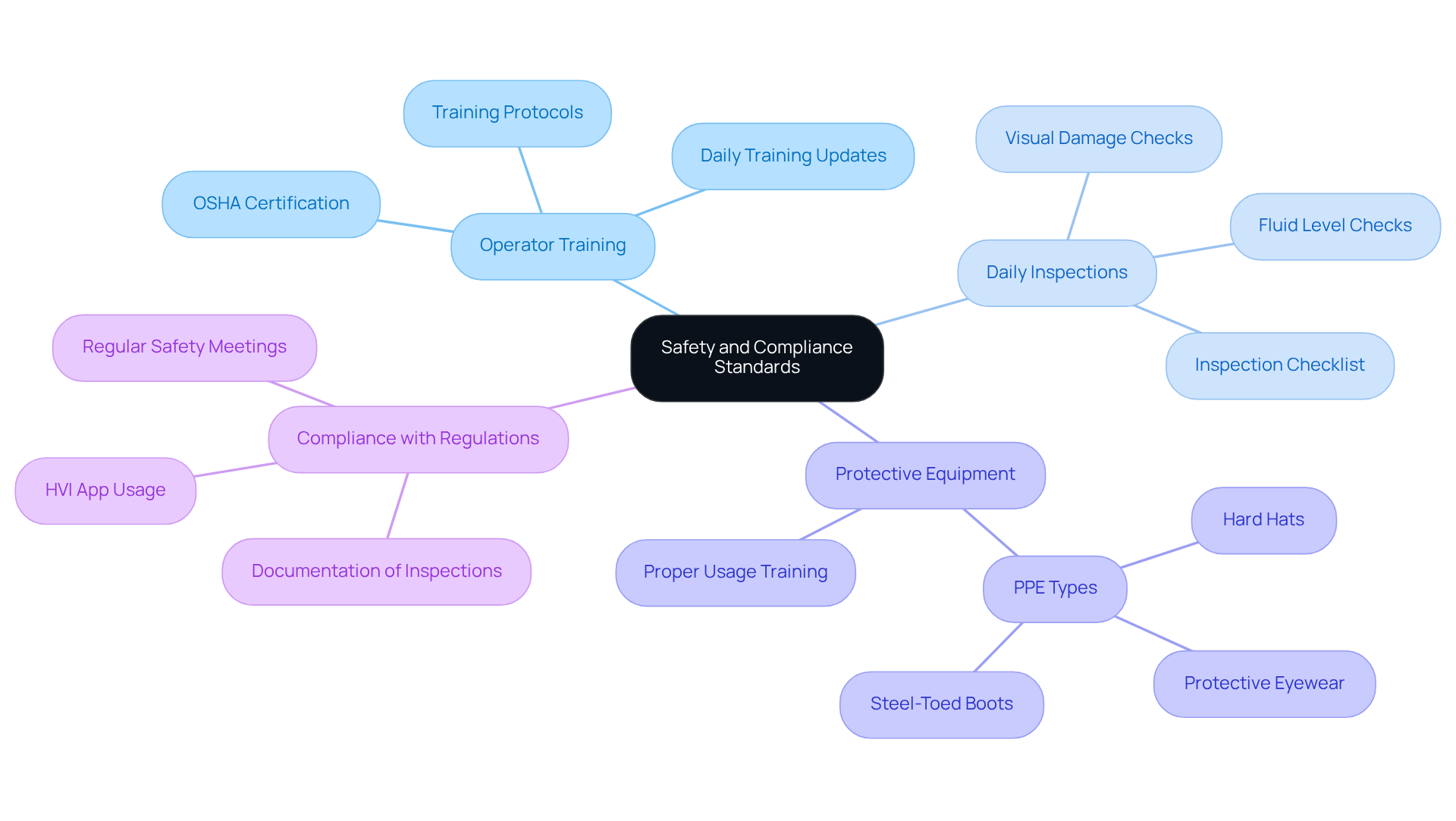

Ensure Safety and Compliance Standards

To ensure safety and compliance, it’s crucial to implement a comprehensive approach:

-

Operator Training: First and foremost, confirm that all forklift operators are properly trained and certified in accordance with OSHA standards. This training should encompass load limits, operational procedures, and essential protective protocols. Experts in the field emphasize the necessity of daily inspections, stating that 'daily inspections of the trucks should be required' to prevent accidents and maintain operational integrity.

-

Daily Inspections: Furthermore, establish a rigorous daily inspection routine for the lifting vehicle before use. This involves checking for visible damage, fluid leaks, and ensuring that all protective features are functioning correctly. A thorough daily inspection checklist for leased lift trucks should cover critical aspects such as the condition of the forks, operational controls, and security systems, including an assessment of overall condition, visible damage, and cleanliness.

-

Protective Equipment: In addition, ensure that operators are equipped with appropriate personal protective gear (PPE), including hard hats, protective eyewear, and steel-toed boots. This gear significantly reduces risks associated with lift truck operations.

-

Compliance with Regulations: It’s also vital to familiarize yourself with OSHA regulations governing lift operation. Ensure that your initiative adheres to these standards to avoid penalties. Statistics reveal that a substantial proportion of construction firms conduct daily forklift checks, underscoring the importance of maintaining compliance and security in the workplace. Utilizing tools like the HVI App can enhance compliance and documentation of inspections, ensuring that all records are accurately maintained.

By prioritizing safety and compliance, you foster a secure work environment that not only protects your team but also enhances project efficiency. Take action now to implement these essential practices!

Conclusion

Understanding how to effectively rent an 8000 lb forklift is crucial for project managers who want to optimize their operations. By following a structured approach that includes project requirements, equipment specifications, rental options, and safety compliance, project managers can confidently select the right forklift for their specific needs. This not only minimizes costs but also maximizes efficiency.

Key considerations include:

- Evaluating load capacity

- Lift height

- Work environment to determine the most suitable forklift type

Furthermore, understanding rental rates, included services, and lease terms is vital for making informed financial decisions. Navigating the rental process with proper documentation and ensuring adherence to safety standards - such as operator training and daily inspections - is equally important.

Ultimately, prioritizing these elements contributes to a successful rental experience and fosters a safer, more productive work environment. Emphasizing safety and compliance protects the workforce and enhances overall project performance. Taking decisive action now to implement these practices will lead to greater efficiency and success in future projects.

Frequently Asked Questions

What key factors should I consider when identifying my project requirements for a forklift?

Key factors include load capacity, lift height, work environment, and duration of use. Understanding these elements helps in selecting the appropriate equipment for your project.

How do I determine the load capacity needed for my forklift?

Assess the maximum weight your forklift needs to lift. For instance, when using an 8000 lb forklift rental, ensure that your heaviest loads do not exceed this limit, as typical construction project load capacities range from 6,000 to 10,000 lbs.

Why is lift height important in selecting a forklift?

The necessary lift height impacts the type of lift truck mast required, as different masts have varying lift capabilities. Choosing the right mast ensures efficient and safe handling of your materials.

How does the work environment affect forklift selection?

The work environment determines whether to use electric or diesel forklifts. Electric models are preferred for indoor use due to lower emissions, while diesel vehicles are better suited for rugged outdoor terrains.

What should I consider regarding the duration of use for a forklift?

Estimate how long you will need the forklift. For short-term projects, an 8000 lb forklift rental may provide flexibility and cost savings, whereas long-term projects might require a different equipment acquisition strategy.

What specifications are crucial to understand when selecting a forklift?

Important specifications include engine type (electric vs. internal combustion), tire composition (solid vs. pneumatic), mast types (two-stage vs. three-stage), and protection features (load backrests, stability systems, etc.).

What are the benefits of choosing electric forklifts?

Electric forklifts are preferred for indoor applications due to their zero emissions and reduced maintenance needs, making them suitable for environments where air quality is a concern.

What type of tires should I choose for my forklift?

Solid tires are ideal for indoor environments as they provide excellent traction on smooth surfaces, while pneumatic tires are better for outdoor use, offering superior grip on uneven terrain.

What are the differences between two-stage and three-stage masts?

Two-stage masts are more compact and provide better visibility, while three-stage masts allow for greater lift heights, which is essential for stacking materials in warehouses or construction sites.

Why are protection features important when selecting a forklift?

Protection features like load backrests, stability systems, and operator alarms enhance safety and ensure compliance with OSHA regulations, significantly reducing the risk of accidents. Proper training can prevent up to 70% of incidents.