Key Highlights:

- Essential asphalt paving equipment includes asphalt pavers, rollers, milling machines, dump trucks, and compactors, each serving specific functions in paving projects.

- Quality and reliability of equipment can be ensured by researching reputable brands, inspecting machinery before purchase, and considering maintenance needs.

- Best practises for equipment usage include regular inspections, scheduled maintenance, proper cleaning, and comprehensive personnel training.

- Documentation of maintenance activities helps to identify performance patterns and informs future purchasing decisions.

- Training programmes should include hands-on experiences, ongoing education, mentorship, and feedback mechanisms to enhance operator competence and safety.

Introduction

Mastering asphalt paving equipment is crucial for project managers who aim to deliver high-quality results in their paving initiatives. Understanding the various types of machinery and implementing best practices for their use and maintenance can significantly enhance project efficiency and durability.

However, selecting the right tools and ensuring that operators are adequately trained to utilize them effectively presents a challenge. To navigate this complex landscape of equipment management and training, project managers must employ strategic approaches that ensure successful paving projects.

Identify Essential Asphalt Paving Equipment Types

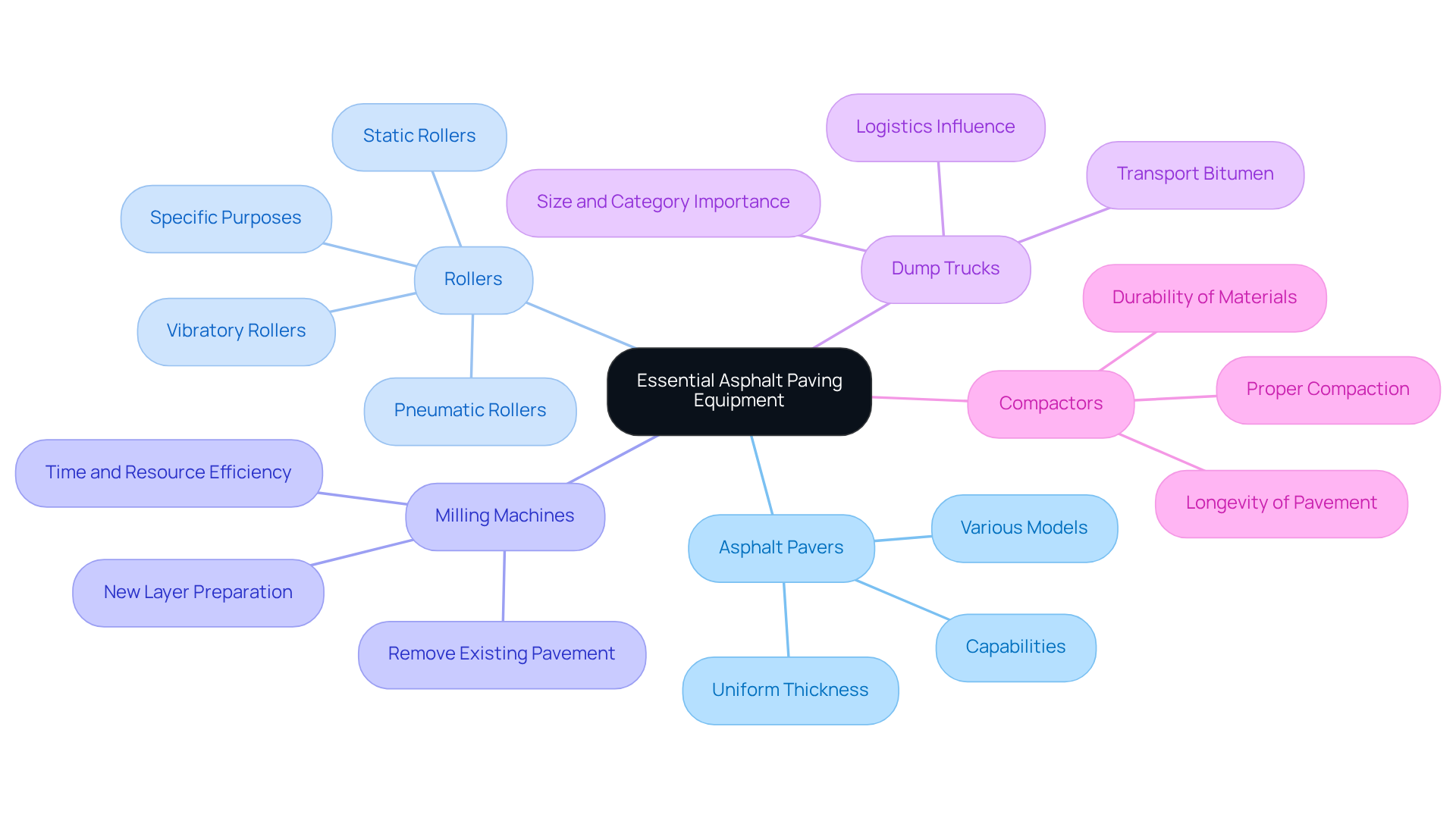

To effectively manage paving projects, recognizing the essential types of machinery is crucial. The primary equipment includes:

- Asphalt Pavers: These machines lay down asphalt at a uniform thickness, ensuring a smooth surface. Understanding the various models and their capabilities is vital for selecting the right paver for the job.

- Rollers: Used for compacting the pavement, rollers come in different types, including static, vibratory, and pneumatic. Each type serves a specific purpose and is suited for various conditions.

- Milling Machines: These machines remove existing pavement, allowing for a new layer of tarmac to be laid down. Knowing when to utilize a milling machine can save both time and resources.

- Dump Trucks: Essential for transporting bitumen from the facility to the work site, the appropriate size and category of dump truck can significantly influence logistics.

- Compactors: These are crucial for ensuring proper compaction of materials, which directly affects the longevity and durability of the pavement.

By understanding these essential tools, project managers can plan their projects more effectively and allocate resources with greater precision.

Evaluate Quality and Reliability of Equipment

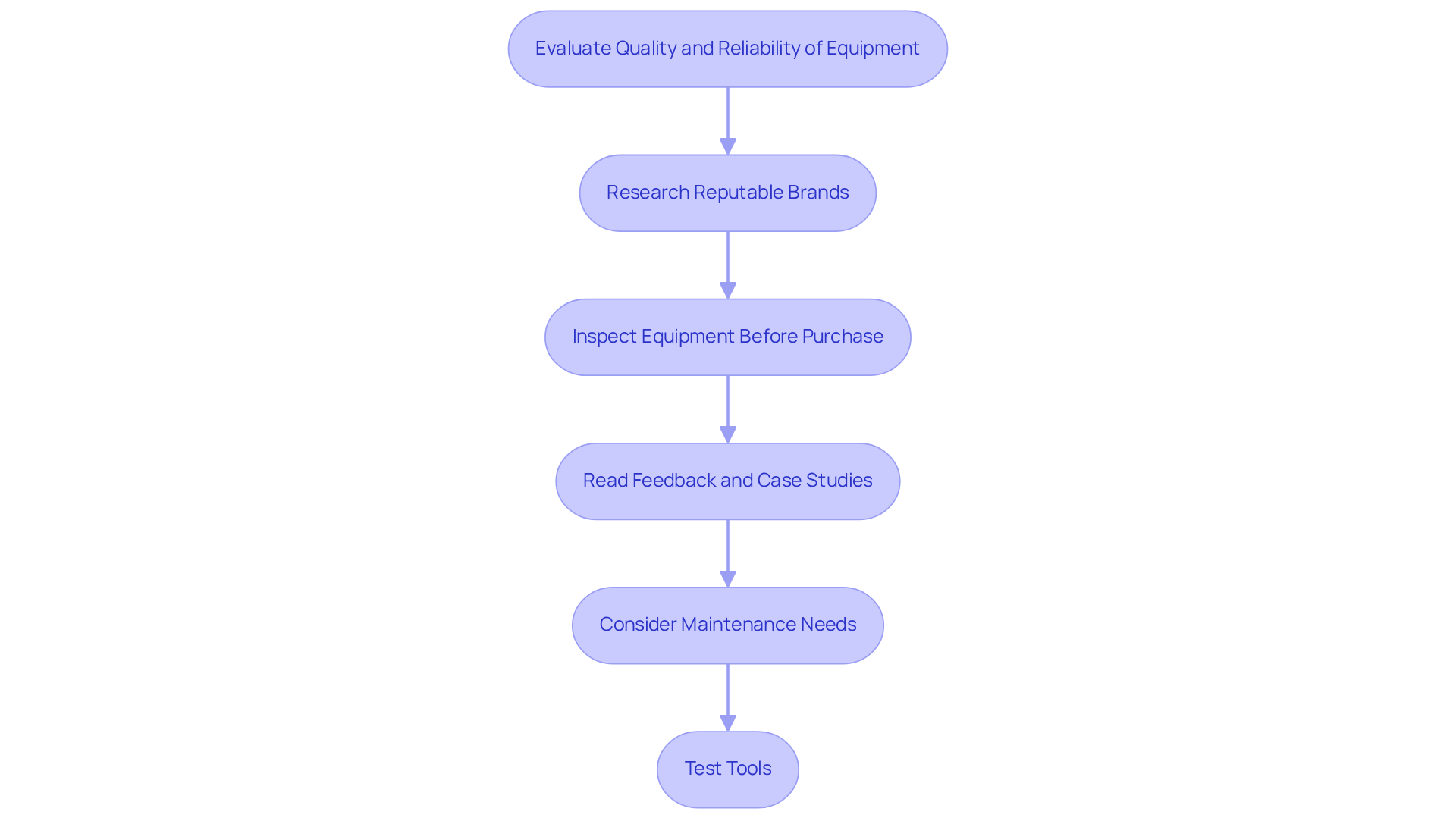

When selecting asphalt paving equipment, it's crucial to assess both quality and reliability. Here are some best practices to consider:

- Research Reputable Brands: Invest in equipment from manufacturers recognized for their durability and performance. Established brands typically offer better warranties and customer support, enhancing your investment.

- Inspect Asphalt Paving Equipment Before Purchase: Conduct thorough inspections to evaluate the wear and tear, functionality, and maintenance history of the asphalt paving equipment. This proactive approach can help prevent costly repairs and minimize downtime in the future.

- Read Feedback and Case Studies: Gather insights from other managers who have utilized the tools. Their experiences can provide valuable perspectives on the reliability of specific models, guiding your decision-making process.

- Consider Maintenance Needs: Equipment that requires frequent repairs can lead to delays in operations. Choose asphalt paving equipment that is easier to maintain and has readily available parts, ensuring smoother operations.

- Test Tools: If possible, evaluate the tools in real-world conditions to assess their performance before making a purchase decision.

By following these practices, managers can ensure they are investing in tools that enhance both efficiency and dependability.

Implement Best Practices for Equipment Usage and Maintenance

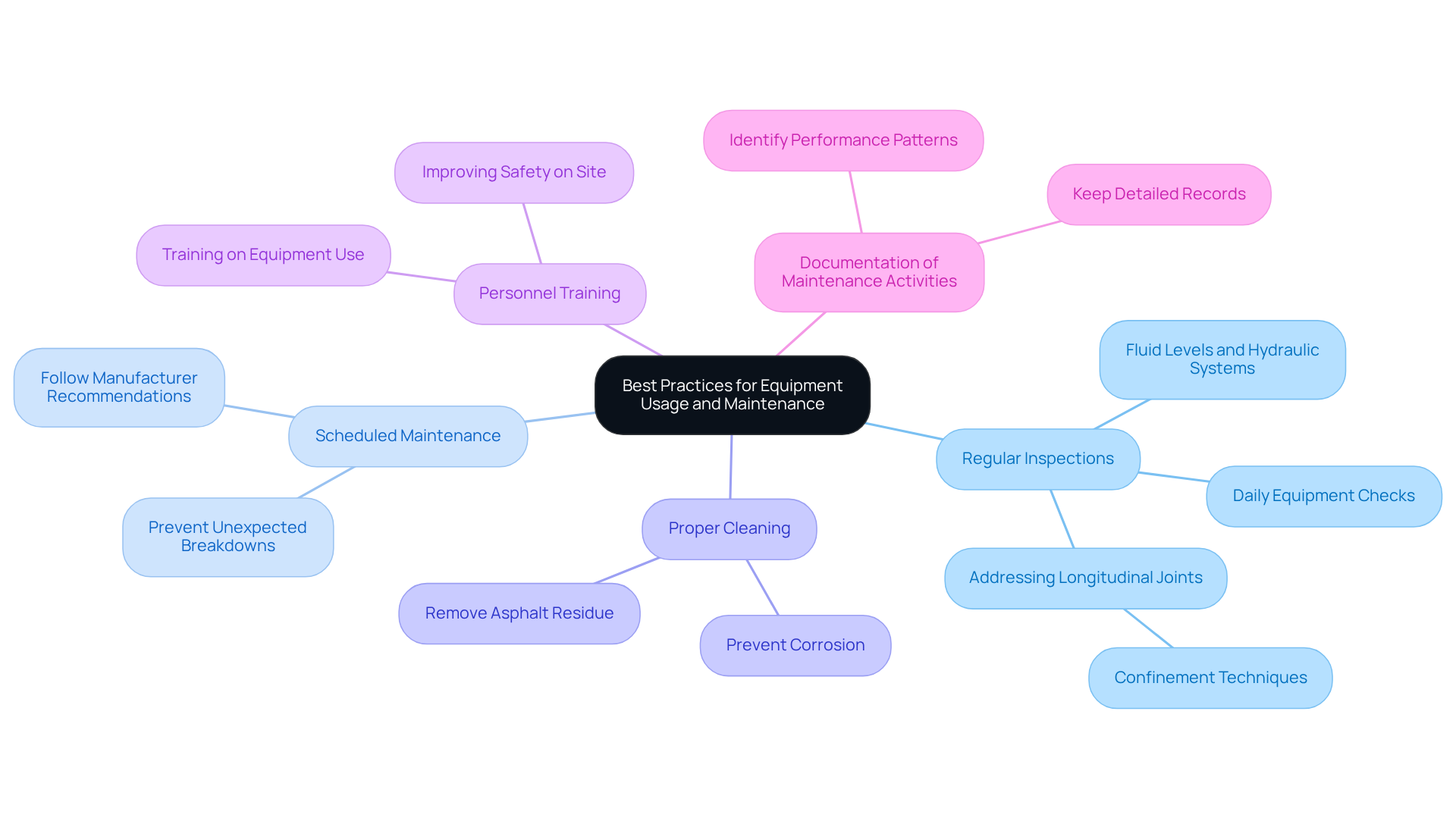

To maximize the performance and lifespan of asphalt paving equipment, project managers should adopt several best practices:

- Regular Inspections: Conduct daily inspections before equipment use. Check fluid levels, hydraulic systems, and wear components to identify potential issues early, thereby reducing the risk of costly downtime. As Benjamin Everett notes, addressing problems such as unsupported longitudinal joints can significantly enhance the longevity of pavement constructions, underscoring the importance of routine inspections.

- Scheduled maintenance for asphalt paving equipment should follow a maintenance schedule that aligns with manufacturer recommendations. Regular servicing not only prevents unexpected breakdowns but also extends the machinery's operational life, ensuring consistent performance on job sites.

- Proper cleaning of the asphalt paving equipment after each use is crucial to remove asphalt residue and debris. This practice helps prevent corrosion and maintains the functionality of the machinery, which is crucial for ongoing operations.

- Invest in comprehensive personnel training for all staff on the proper use and maintenance of asphalt paving equipment. Well-trained personnel are less likely to misuse machinery, resulting in fewer repairs and improved safety on site. Hannah Garison's advocacy for training in the paving industry highlights the importance of equipping operators with the right skills.

- Document maintenance activities related to asphalt paving equipment by keeping detailed records of all maintenance and repairs. This documentation is invaluable for identifying patterns in equipment performance and can inform future purchasing decisions, ensuring that managers invest in the most reliable tools.

By implementing these best practices, managers can significantly enhance the reliability and efficiency of their paving operations, ultimately leading to successful outcomes.

Provide Training and Support for Equipment Operators

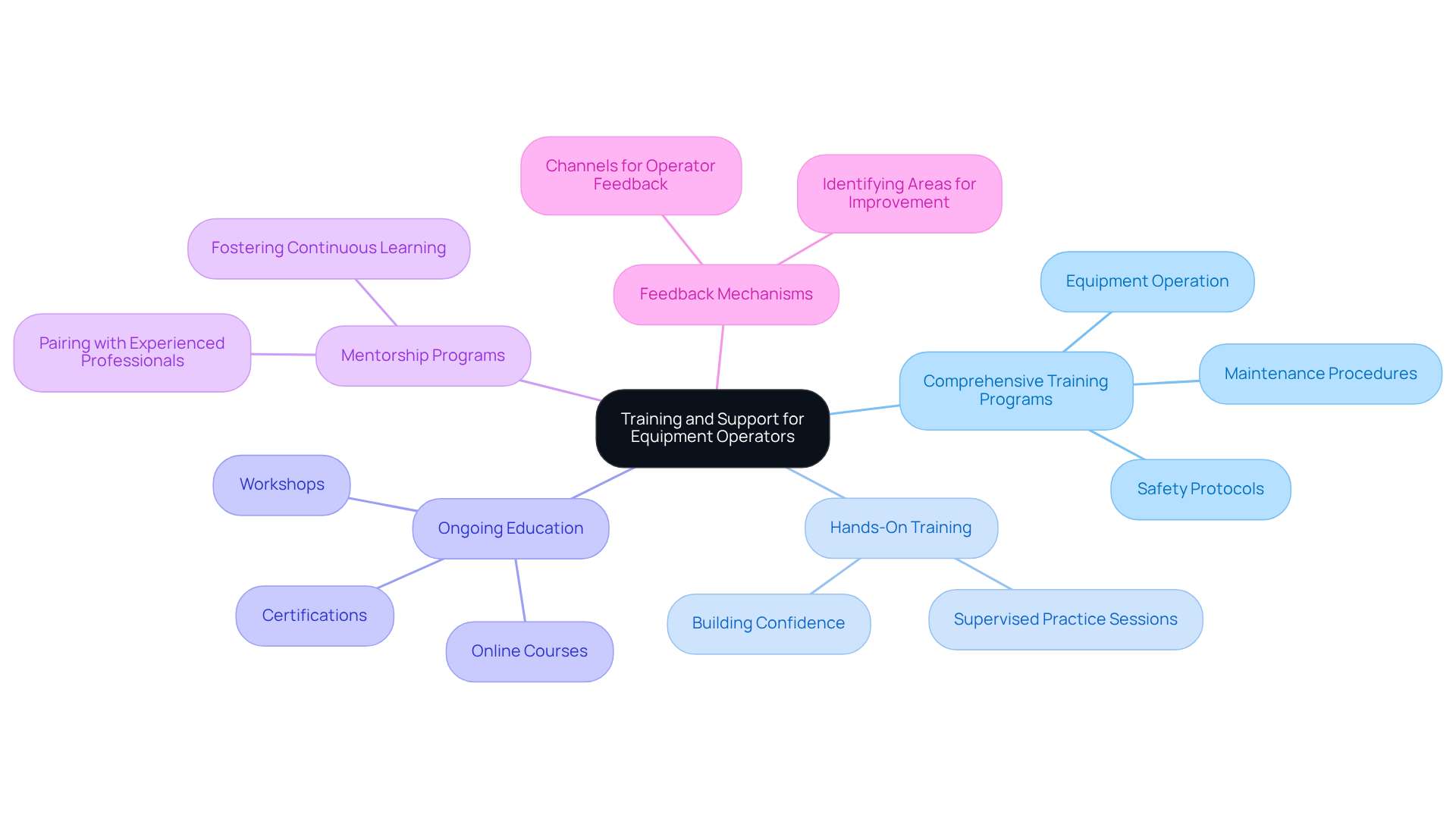

Efficient training and assistance for users of asphalt paving equipment are crucial for the success of asphalt paving initiatives. Here are some best practices:

- Comprehensive Training Programs: Develop training programs that encompass equipment operation, safety protocols, and maintenance procedures. This ensures that personnel are well-prepared for their roles.

- Hands-On Training: Incorporate practical training sessions where users can practice operating the equipment under supervision. This hands-on experience is invaluable for building confidence and competence.

- Ongoing Education: Provide continuous training opportunities to keep personnel informed about new technologies and best practices in the industry. This can include workshops, online courses, and certifications.

- Mentorship Programs: Pair less experienced individuals with seasoned professionals. Mentorship can offer valuable insights and foster a culture of continuous learning.

- Feedback Mechanisms: Establish channels for operators to provide feedback on machinery performance and training effectiveness. This helps identify areas for improvement and enhances overall results.

By prioritizing training and support, project managers can ensure that their teams are equipped to operate asphalt paving equipment safely and efficiently, ultimately leading to successful project completion.

Conclusion

Mastering asphalt paving involves a deep understanding of the necessary equipment and best practices for effective project management. By identifying key machinery types - such as asphalt pavers, rollers, and milling machines - project managers can make informed decisions that boost efficiency and enhance the quality of their paving projects.

Key insights emphasize the need to evaluate equipment quality and reliability, implement a rigorous maintenance schedule, and provide comprehensive training for operators. These practices not only reduce downtime and repair costs but also create a safer, more productive work environment. The focus on hands-on training and ongoing education underscores the importance of a skilled workforce that can adapt to the evolving demands of asphalt paving.

Ultimately, investing in the right equipment and prioritizing effective management practices are essential for achieving successful paving outcomes. As the industry evolves, staying updated on the latest techniques and equipment advancements will empower project managers to lead their teams confidently, ensuring the durability and quality of their work. By embracing these best practices, project efficiency will improve, contributing to long-term success in asphalt paving management.

Frequently Asked Questions

What is the purpose of asphalt pavers in paving projects?

Asphalt pavers lay down asphalt at a uniform thickness, ensuring a smooth surface for the pavement.

What are the different types of rollers used in asphalt paving?

The different types of rollers include static, vibratory, and pneumatic, each serving a specific purpose and suited for various conditions.

When should milling machines be utilized in paving projects?

Milling machines are used to remove existing pavement, allowing for a new layer of tarmac to be laid down. Knowing when to use them can save time and resources.

What role do dump trucks play in asphalt paving?

Dump trucks are essential for transporting bitumen from the facility to the work site, and the appropriate size and category can significantly influence logistics.

Why are compactors important in paving projects?

Compactors ensure proper compaction of materials, which directly affects the longevity and durability of the pavement.

How can understanding essential paving equipment types benefit project managers?

By understanding these essential tools, project managers can plan their projects more effectively and allocate resources with greater precision.

List of Sources

- Implement Best Practices for Equipment Usage and Maintenance

- Homepage (https://theasphaltpro.com)