Overview

Effective boom inspection is critical for ensuring safety and operational efficiency. Key steps include:

- Conducting routine evaluations to identify hazards

- Ensuring compliance with safety regulations

- Performing thorough checks of essential components like hydraulic and electrical systems

These measures not only enhance operator safety and extend equipment lifespan but also significantly improve operational efficiency. Consequently, this leads to reduced downtime and lower costs on job sites, making it imperative for businesses to prioritize these inspections.

Key Highlights:

- Routine boom lift inspections are essential for identifying hazards and ensuring operator safety, as falls are the leading cause of deaths involving aerial lifts.

- Compliance with safety regulations is necessary to avoid penalties and legal issues related to boom inspections.

- Regular inspections help detect wear and tear, allowing for timely maintenance that extends equipment lifespan and reduces operational costs.

- Well-maintained aerial platforms enhance operational efficiency, resulting in reduced downtime and increased productivity on job sites.

- Key components to inspect include functions and controls, platform assembly, elevator assembly, chassis, hydraulic system, electrical system, and outriggers/stabilisers.

- The inspection process involves pre-operation checks, visual inspections, functional tests, fluid level checks, battery checks, operational tests, and documentation of results.

- Utilising evaluation checklists, manufacturer manuals, and training resources enhances the inspection process and adherence to best practises.

- Operators should be aware of common issues like hydraulic leaks and electrical failures, and know when to seek professional assistance for repairs.

- Weather conditions should be monitored as they can impact safety and stability during boom lift operations.

Introduction

Ensuring the safety and efficiency of boom lifts transcends mere regulatory compliance; it embodies a critical responsibility that has the potential to prevent accidents and save lives. With alarming statistics indicating that falls are a leading cause of fatalities in aerial lift operations, grasping the intricacies of boom lift inspections becomes essential. This guide explores the vital steps and best practices for conducting thorough inspections, equipping operators to identify potential hazards and uphold compliance.

However, what challenges do operators encounter in executing these inspections effectively? Furthermore, how can they surmount these obstacles to cultivate a safer working environment?

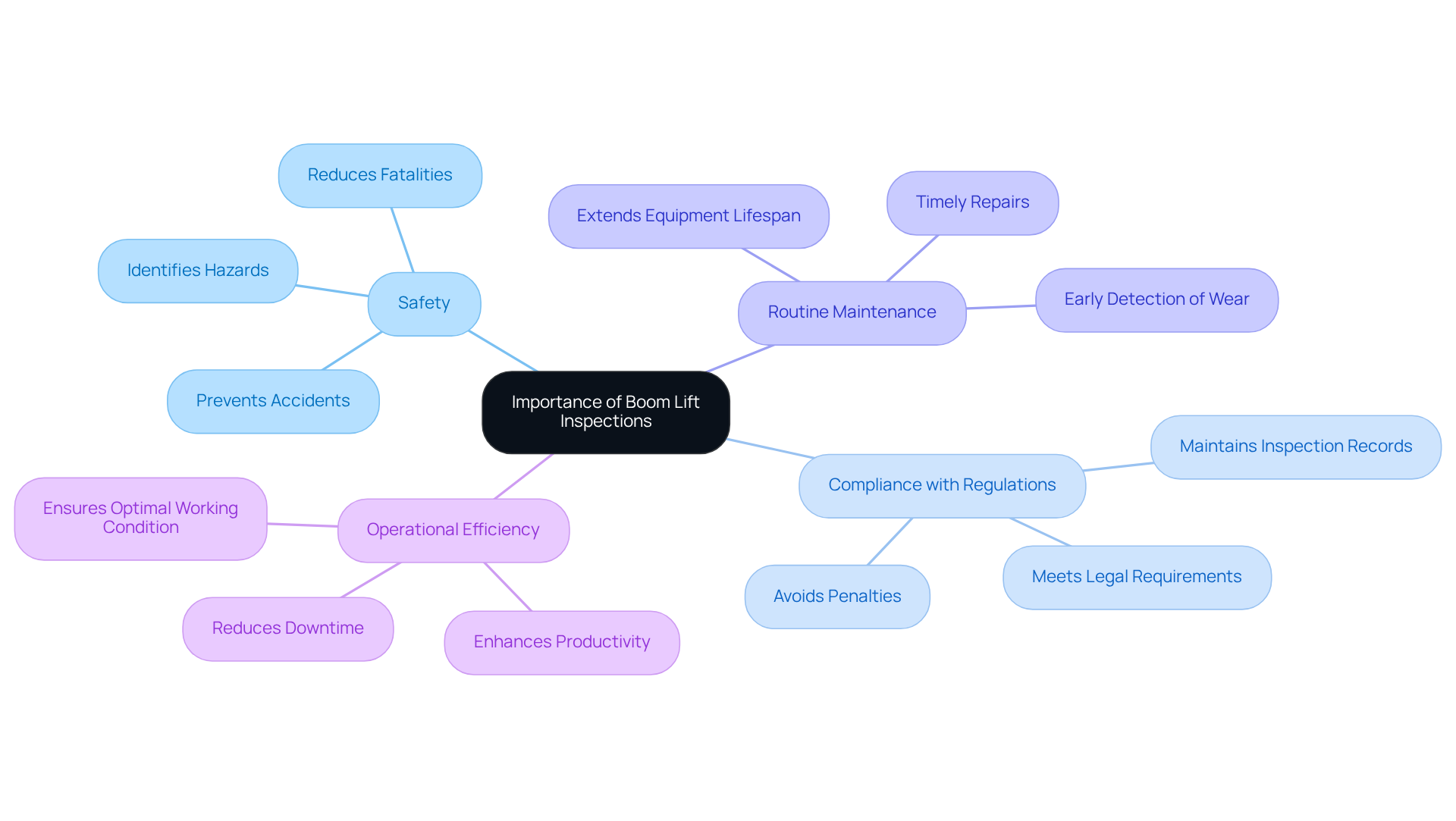

Understand the Importance of Boom Lift Inspections

Boom lift inspections are essential for several compelling reasons:

-

Safety is paramount. Routine evaluations, such as boom inspections, are crucial for identifying potential hazards, thereby protecting operators and nearby personnel. Neglecting boom inspection evaluations can lead to significant accidents, injuries, or fatalities; statistics reveal that falls are the leading cause of deaths involving aerial lifts.

-

Compliance with safety regulations is vital for ensuring proper boom inspection. Many regions require regular boom inspections, and non-compliance may lead to substantial penalties and legal consequences.

-

Routine boom inspections facilitate the early detection of wear and tear, allowing for timely maintenance and repairs. This proactive approach not only extends the equipment's lifespan but also reduces long-term operational costs by implementing thorough boom inspections.

-

Operational efficiency is another critical benefit. Well-maintained aerial platforms operate more effectively, resulting in reduced downtime and enhanced productivity on job sites. Regular boom inspections ensure that equipment is in optimal working condition, which is essential for maintaining workflow. Distinct features of aerial work platforms, including advanced stabilization systems and intuitive controls, enhance their operational efficiency and safety, enabling workers to complete tasks swiftly and securely.

Understanding these vital aspects empowers operators and managers to recognize the importance of conducting thorough boom inspections before utilizing aerial platforms, ultimately fostering a safer and more effective workplace.

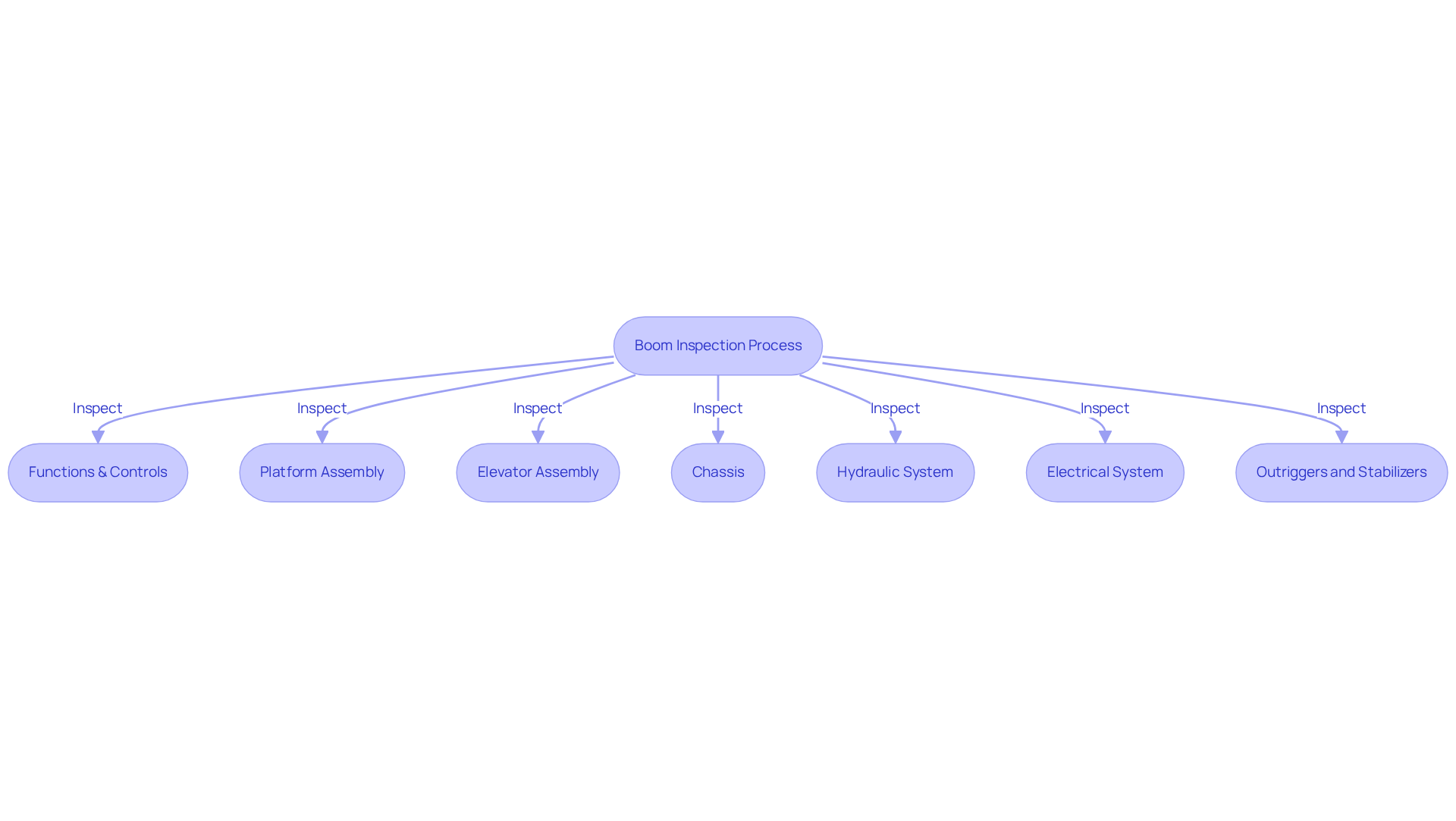

Identify Key Components for Inspection

During a boom inspection, it is essential to focus on key components that ensure safety and operational efficiency, ultimately enhancing construction project timelines.

-

Functions & Controls: Verify that all controls are fully operational, including emergency stop buttons, platform controls, and ground controls. This step is crucial; malfunctioning controls can lead to accidents and delays.

-

Platform Assembly: Inspect the platform for any visible damage, ensuring that guardrails and gates are intact and functioning properly. A secure platform is vital for operator safety and contributes to efficient task execution.

-

Elevator Assembly: Examine the structure for indications of wear, cracks, or hydraulic leaks. All joints and pivot points should be lubricated and functioning smoothly to prevent mechanical failure during operation, which can impact project timelines.

-

Chassis: Assess the base for structural integrity, looking for signs of rust or damage that could compromise stability.

-

Hydraulic System: Check hoses and connections for leaks, ensuring that fluid levels are adequate. A well-maintained hydraulic system is essential for the platform's performance and efficiency in completing tasks.

-

Electrical System: Inspect battery connections and wiring, confirming that all lights and alarms are operational. Proper electrical functionality is critical for safe operation and contributes to the overall efficiency of the equipment.

-

Outriggers and Stabilizers: Ensure these components are functioning correctly and are free from damage. Properly deployed outriggers and stabilizers are necessary for maintaining balance during use, which is crucial for safe and efficient operations.

If any inconsistencies are discovered during the review, the aerial platform must be tagged out and not utilized until all problems are addressed. Furthermore, operators should record any inconsistencies discovered during evaluations to uphold safety and compliance. Technicians are also urged to download the AMI form for JLG aerial platforms to guarantee comprehensive record-keeping of evaluations.

By systematically performing boom inspections on these components, operators can significantly reduce the risk of accidents and ensure that the boom lift is safe and ready for use. Routine evaluations not only improve safety but also prolong the lifespan of the equipment, resulting in cost savings and prompt project completion, establishing it as a best practice for all operators.

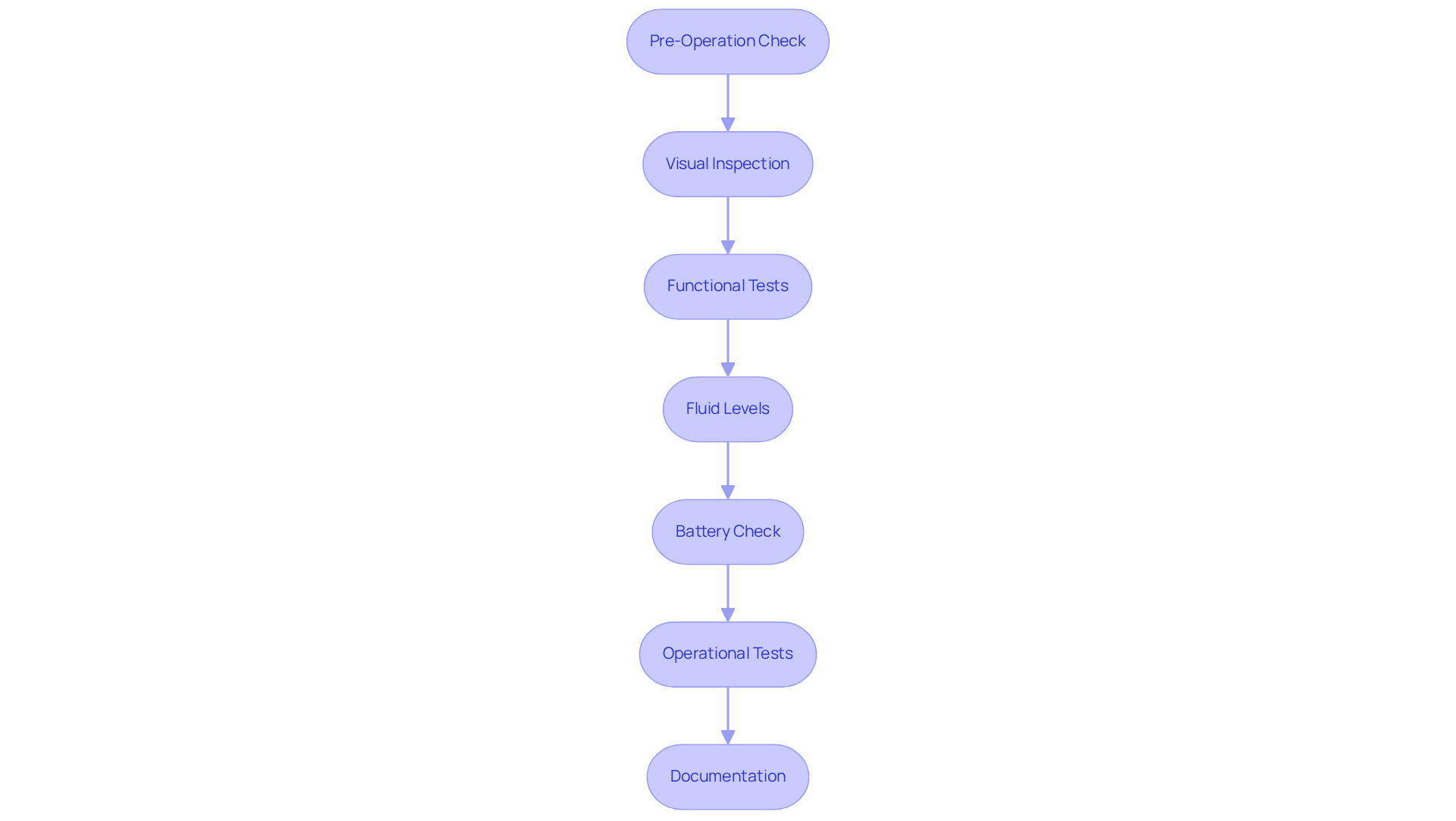

Execute the Inspection Process for Each Component

To execute the inspection process for each component effectively, follow these essential steps:

- Pre-Operation Check: Before commencing the inspection, ensure the elevating platform is parked on a stable surface and the engine is off. This initial step is critical for safety.

- Visual Inspection: Conduct a thorough visual check of the entire apparatus, looking for any signs of damage, leaks, or wear. Identifying potential issues early can prevent further complications.

- Functional Tests: Test all controls to ensure they respond correctly. This involves elevating and lowering the arm, extending and retracting it, and verifying the emergency stop function, which is vital for operational safety.

- Fluid Levels: Check hydraulic fluid, engine oil, and coolant levels. Top off any fluids as necessary to maintain optimal performance.

- Battery Check: Ensure the battery is charged and connections are secure. Inspect for corrosion or damage, as these factors can impact functionality.

- Operational Tests: If safe to do so, perform a test run of the boom lift to ensure all functions operate smoothly. This step confirms that the equipment is ready for use.

- Documentation: Record the evaluation results, noting any issues that require attention. This documentation is crucial for compliance and future reference, ensuring accountability.

By meticulously following these steps, operators can ensure a comprehensive review process that enhances both safety and equipment reliability.

Access Resources and Troubleshooting Tips

To enhance your inspection process, consider leveraging the following resources and troubleshooting tips:

-

Evaluation Checklists: Utilize pre-use and annual evaluation checklists to ensure comprehensive coverage of all components. These resources are readily available online or directly from equipment manufacturers, providing a solid foundation for your inspections.

-

Manufacturer Manuals: Always refer to the manufacturer's manual for specific guidelines on boom inspection and maintenance suggestions tailored to your apparatus model. This ensures that your inspections are aligned with best practices and manufacturer recommendations.

-

Training Resources: Enroll in training programs focused on aerial equipment security and inspection protocols. Certification courses are widely available and can significantly enhance operator knowledge, ensuring adherence to regulations and best practices.

-

Common Issues and Solutions:

- Hydraulic Leaks: If hydraulic fluid leaks are detected, inspect hoses and connections for damage. Replace any faulty components immediately to prevent operational hazards.

- Electrical Failures: Should controls become unresponsive, check wiring and battery connections. Ensure the battery is charged and that connections are clean and secure.

- Stability Issues: If the apparatus shows instability, verify that the outriggers are properly deployed and secured to maintain a stable working platform.

-

Protection Features Verification: Operators must confirm the functionality of protection features, including emergency stop controls and guardrails, to ensure safe operation. This is crucial for maintaining a safe working environment.

-

Weather Considerations: Always monitor weather forecasts, as adverse conditions can significantly impact elevation operations and stability. Staying informed can prevent potential accidents.

-

Professional Assistance: For issues that exceed your expertise, do not hesitate to contact a professional technician for repairs and maintenance. This step is vital for ensuring the longevity and safety of your equipment.

By utilizing these resources and suggestions, operators can effectively resolve issues and uphold the security and functionality during boom inspection of the machinery. This ultimately improves project efficiency and minimizes the risk of accidents. It is important to note that approximately 26 workers die annually due to aerial lift accidents, underscoring the critical need for adherence to safety protocols.

Conclusion

Thorough boom lift inspections are not merely a regulatory requirement; they are essential for ensuring safety, compliance, and operational efficiency in the workplace. By prioritizing these inspections, operators can significantly mitigate risks associated with aerial lifts, ultimately safeguarding both personnel and equipment. The necessity of conducting regular evaluations cannot be overstated, as they play a pivotal role in preventing accidents and enhancing the longevity of the machinery.

Key aspects of boom lift inspections include:

- A meticulous review of essential components such as functions and controls

- Platform assembly

- Hydraulic systems

- Electrical systems

Each of these elements contributes to the overall safety and performance of the equipment. By adhering to a systematic inspection process that encompasses:

- Pre-operation checks

- Visual assessments

- Functional tests

- Thorough documentation

Operators can ensure their equipment is safe and ready for use. Furthermore, utilizing available resources like checklists and manufacturer manuals can further enhance the inspection process.

Ultimately, the commitment to regular boom lift inspections fosters a culture of safety and efficiency on job sites. It is imperative for operators and managers to recognize their responsibility in maintaining equipment and adhering to safety protocols. By taking proactive measures and prioritizing inspections, the risk of accidents can be minimized, paving the way for a safer and more productive work environment. Embracing these best practices not only safeguards lives but also optimizes operational performance, reinforcing the critical nature of boom lift inspections in the construction and maintenance industries.

Frequently Asked Questions

Why are boom lift inspections important?

Boom lift inspections are important for safety, compliance with regulations, early detection of wear and tear, and operational efficiency. They help identify potential hazards, ensure adherence to safety laws, facilitate timely maintenance, and improve the effectiveness of aerial platforms.

How do boom lift inspections contribute to safety?

Routine evaluations, such as boom inspections, are crucial for identifying potential hazards, thereby protecting operators and nearby personnel. Neglecting these inspections can lead to significant accidents, injuries, or fatalities, with falls being the leading cause of deaths involving aerial lifts.

What are the consequences of not complying with boom lift inspection regulations?

Non-compliance with boom lift inspection regulations may lead to substantial penalties and legal consequences, as many regions require regular inspections to ensure safety.

How do routine inspections affect the lifespan of boom lifts?

Routine boom inspections facilitate the early detection of wear and tear, allowing for timely maintenance and repairs. This proactive approach extends the equipment's lifespan and reduces long-term operational costs.

What impact do well-maintained aerial platforms have on productivity?

Well-maintained aerial platforms operate more effectively, resulting in reduced downtime and enhanced productivity on job sites. Regular inspections ensure that equipment is in optimal working condition, which is essential for maintaining workflow.

What features of aerial work platforms enhance their operational efficiency and safety?

Distinct features of aerial work platforms, including advanced stabilization systems and intuitive controls, enhance their operational efficiency and safety, enabling workers to complete tasks swiftly and securely.