Key Highlights:

- Concrete mixers are categorised into batch types (e.g., drum, pan) for smaller projects and continuous types (e.g., twin-shaft) for larger projects.

- Batch blenders allow for precise control and customization, making them ideal for residential renovations.

- Continuous mixers are preferred for commercial applications due to their efficiency and ability to produce a steady flow of cement.

- Market trends indicate a growing preference for concrete mixers, driven by larger construction projects and technological advancements.

- Selecting the right concrete mixer depends on factors like project size, volume, and power source (electric or diesel).

- Efficient mixing techniques include proper loading ratios and blending times to ensure uniformity and quality.

- Routine maintenance is critical for extending the lifespan of concrete mixers and preventing costly repairs.

- Daily, weekly, and monthly maintenance tasks are essential for optimal performance and longevity of concrete mixers.

Introduction

Concrete mixers stand as the unsung heroes of the construction industry, playing a pivotal role in determining the quality and efficiency of concrete production. As project managers face mounting demands for speed and precision, understanding the nuances of different mixer types and their applications becomes essential.

With a plethora of options and techniques available, how can one ensure they are making the best choice for their specific needs? This article delves into best practices for selecting, operating, and maintaining concrete mixers, equipping project managers with the knowledge to elevate their projects to new heights.

Understand Concrete Mixer Types and Functions

Concrete mixers play a crucial role in construction, categorized primarily into batch types and continuous types, each tailored for specific applications and requirements. Batch blenders, such as drum and pan types, excel in smaller projects where precise control over the mix is essential. They allow for the customization of mixtures, making them ideal for residential and smaller-scale uses. For instance, drum blenders are frequently utilized in home renovations due to their ability to produce high-quality cement in manageable quantities.

On the other hand, concrete mixers are designed for larger projects that demand a steady flow of cement. Devices like twin-shaft models are preferred in commercial applications for their efficiency and superior mixing quality. They enable continuous production, which is vital for large-scale infrastructure projects such as highways and bridges, where a concrete mixer ensures the timely delivery of cement.

Market trends indicate a growing preference for concrete mixers, driven by the increasing scale of construction projects and the need for rapid material placement. Continuous blenders are expected to capture a significant share of the cement mixing market, with the concrete mixer reflecting a shift towards more efficient blending solutions. This trend is supported by advancements in technology, including automation and IoT integration, which enhance the operational capabilities of these machines. The market for concrete mixers is projected to grow at a rate of 5.7% from 2026 to 2033.

Real-world examples underscore the effectiveness of both types of concrete mixers. For instance, large-scale initiatives utilizing twin-shaft apparatuses have demonstrated improved blending efficiency and reduced waste, aligning with the industry's commitment to sustainability. Experts emphasize that selecting the right blending equipment, like a concrete mixer, whether batch or continuous, depends on various factors, including size, volume, and specific mixing requirements. Pouria Ghods notes, "Choosing the right cement blending device involves assessing multiple factors to ensure the equipment meets the project's needs effectively." Understanding these distinctions is crucial for managers aiming to optimize their material production processes.

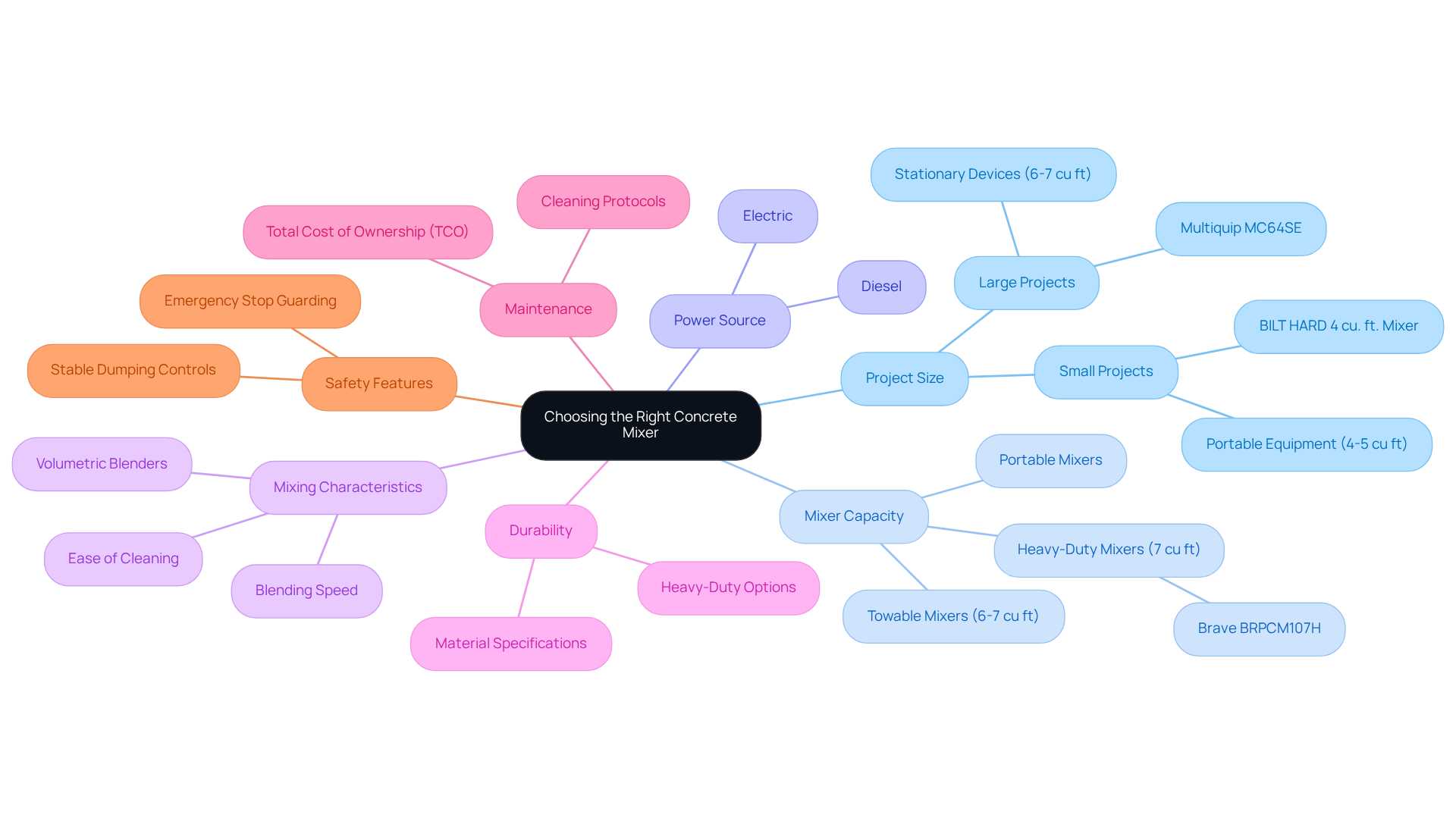

Choose the Right Concrete Mixer for Your Project

Selecting the appropriate concrete mixer for mixing cement is crucial for the success of your project. Factors like project size and concrete volume play a significant role in this decision. For smaller projects, portable equipment with a capacity of around 4 to 5 cu ft is often ideal. In contrast, larger projects may necessitate stationary devices with capacities of 6 to 7 cu ft or more. Take, for example, the Scheppach MIX125, a reliable mid-range concrete mixer with a capacity of 125 L, perfect for small to medium pours. On the other hand, the Multiquip MC64SE concrete mixer stands out as the best overall device for contractors, boasting a capacity of 6 cu. ft. and a powerful 1.5 HP Baldor motor. Additionally, consider the power source-whether electric or diesel-ensuring it aligns with site conditions and availability.

When it comes to mixing, characteristics like blending speed and ease of cleaning are essential. Volumetric blenders, for instance, offer the advantage of on-site blending, allowing for real-time adjustments to meet changing requirements. This flexibility can significantly boost productivity, especially in high-utilization projects where timely concrete management is critical.

Durability and maintenance needs of the blending equipment should also be top of mind for project managers. Heavy-duty options, such as the Brave BRPCM107H concrete mixer with a 7 cu ft capacity, are perfect for larger batches and can minimize the need for truck rentals. Understanding the total cost of ownership (TCO), which includes maintenance and potential downtime, is vital for making informed decisions. Furthermore, verifying site access for narrow streets and unmade roads is crucial to ensure practicality when using heavy towable equipment.

Safety features must not be overlooked; emergency stop guarding and stable dumping controls are essential for the safe operation of blending machines. Additionally, clarifying warranty terms and exclusions for critical components can help managers avoid potential issues down the line.

By thoroughly assessing these factors, project managers can select a concrete mixer that not only fulfills their operational needs but also enhances the overall efficiency and success of their projects. Don't hesitate-make the informed choice today and elevate your project outcomes!

Implement Efficient Mixing Techniques

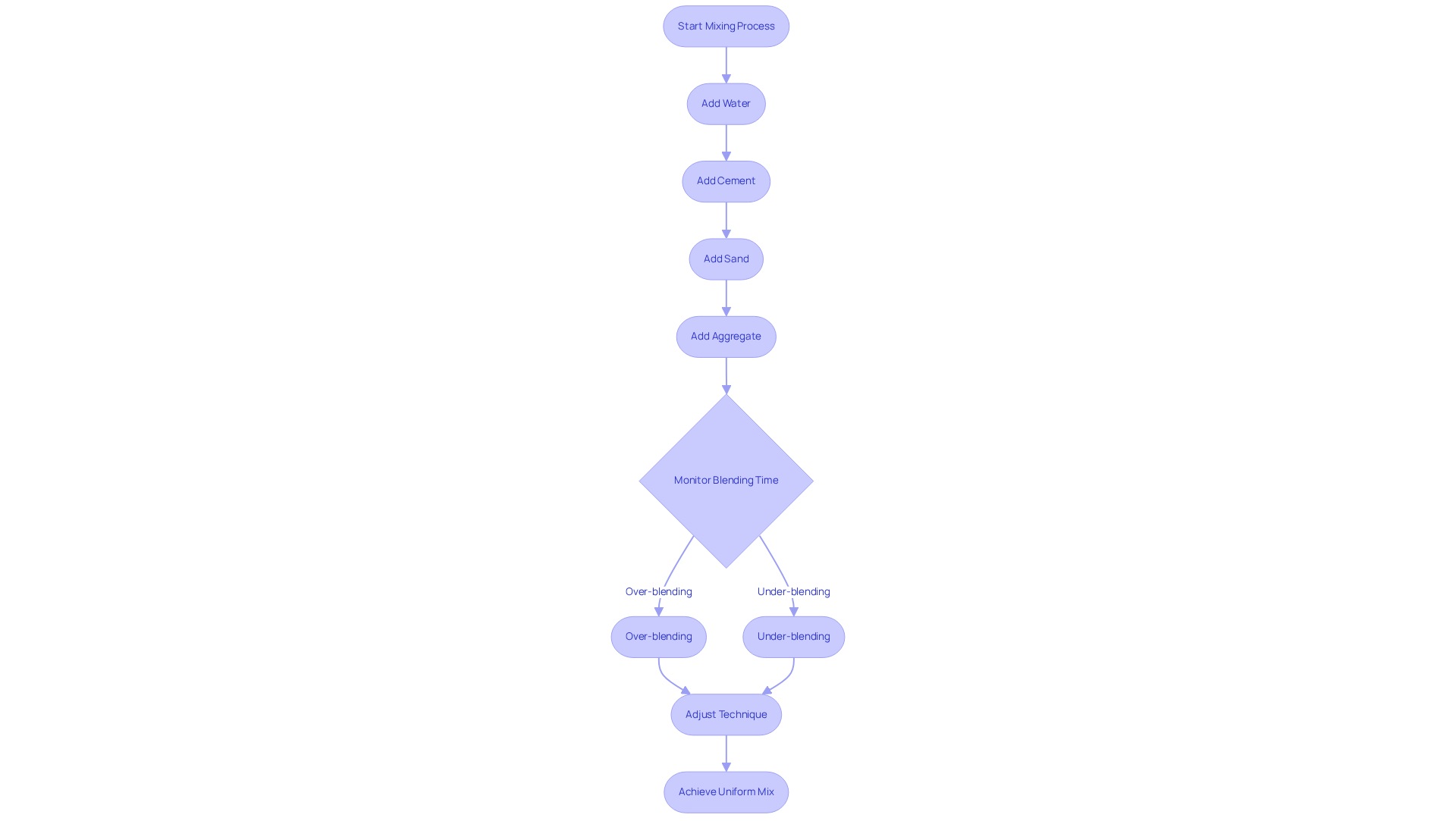

Achieving optimal concrete quality requires the use of a concrete mixer that implements efficient blending techniques, focusing on proper loading ratios and blending times. Start by adding water before the dry materials; this prevents clumping and ensures a uniform mix. The standard loading ratio is one part cement to two parts sand and three parts aggregate, which is crucial for achieving the desired strength and consistency. As Mursaleen Khan notes, "Concrete is a composite building material made from a mixture of:

- Cement (binding agent)

- Aggregates (sand, gravel, or crushed stone)

- Water

- Admixtures (optional additives)."

Monitoring blending time is equally important. Over-blending can lead to air entrapment, while under-blending may result in uneven consistency. For extensive tasks, automated machines can enhance both blending speed and uniformity, guaranteeing a high-quality final product. Routine performance evaluations of the device and adjustments to techniques as needed will assist in upholding high standards of quality throughout the project.

According to industry standards, the typical mixing time for the material ranges from 3 to 5 minutes, which is essential for achieving a uniform mix. This careful attention to detail not only ensures reliability but also enhances the overall quality of your concrete work.

Maintain Your Concrete Mixer for Longevity

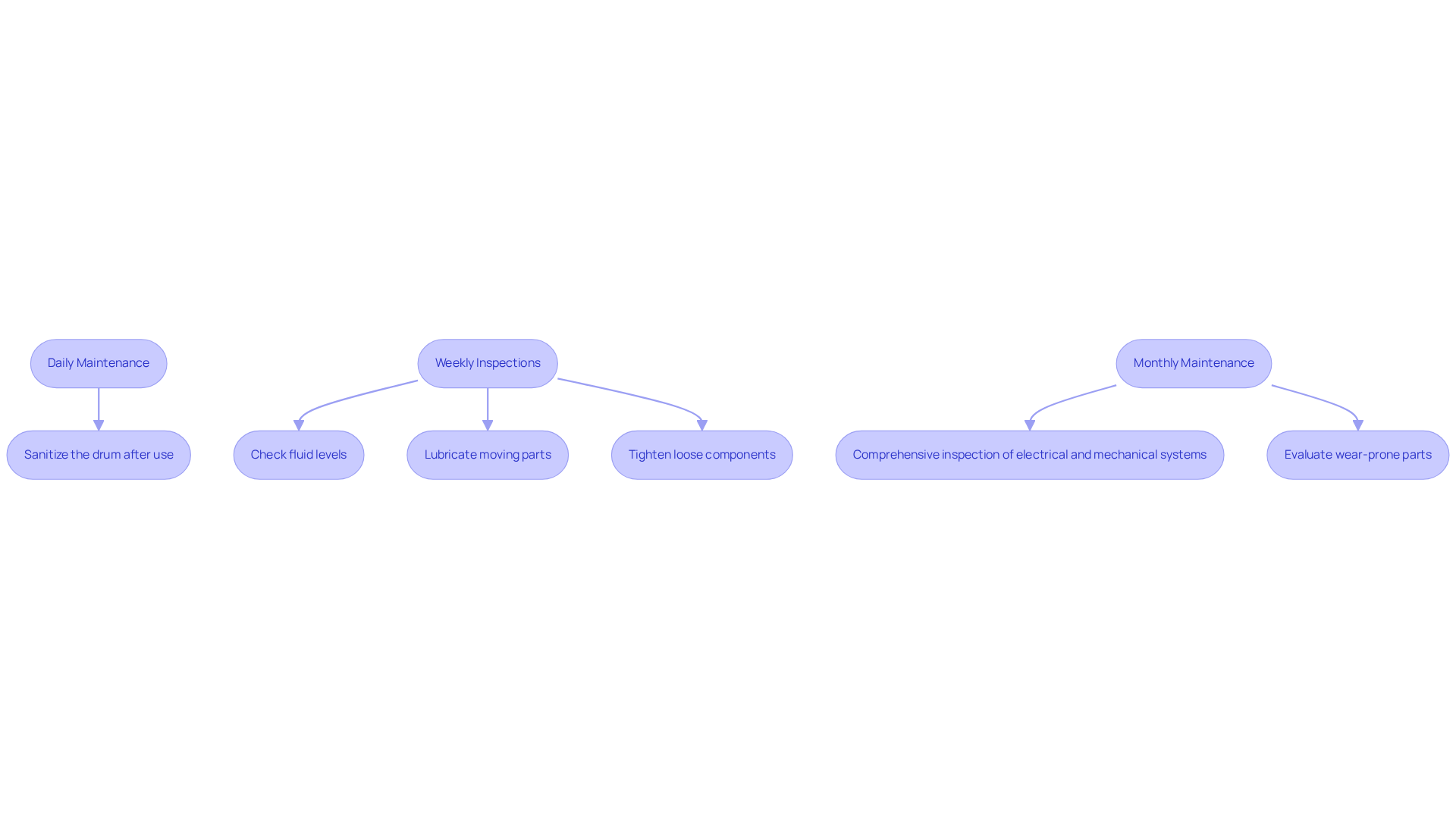

Maximize the lifespan of your concrete mixer by implementing a structured maintenance schedule that includes daily, weekly, and monthly tasks. Routine upkeep is essential; sanitize the drum immediately after use to prevent residue buildup, which can severely hinder functionality and lead to costly repairs. As the Simply Fleet Team states, "Preventive maintenance is essential for preventing expensive failures and prolonging the lifespan of your truck fleet."

Weekly inspections are crucial. Focus on checking fluid levels, lubricating moving parts, and tightening any loose components to ensure smooth operation. Monthly maintenance should encompass a comprehensive inspection of the machine’s electrical and mechanical systems, along with a thorough evaluation of wear-prone parts such as blades and belts. Replacing these parts as necessary can prevent unexpected breakdowns and keep your operations running smoothly.

Industry insights reveal that a well-maintained cement machine can last between 5 to 10 years, heavily influenced by diligent upkeep practices. By adhering to this comprehensive maintenance plan, project managers can extend the lifespan of their concrete mixers while improving their efficiency. This ultimately contributes to the success of their projects. Regular maintenance is not merely a routine; it is a strategic investment that pays dividends in reliability and performance.

Conclusion

Selecting the right concrete mixer and employing effective mixing techniques are crucial for the success of any construction project. Understanding the various types of concrete mixers - from batch to continuous models - empowers project managers to make informed decisions that align with their specific project requirements. By focusing on the unique needs of each project, such as size and volume, managers can optimize material production processes and significantly enhance overall project efficiency.

Key insights from this article underscore the importance of choosing appropriate equipment, implementing efficient mixing techniques, and adhering to a structured maintenance schedule. Factors like loading ratios, blending times, and routine upkeep are critical in achieving high-quality concrete. By emphasizing these aspects, project managers can improve their operations and ensure the longevity of their mixers, ultimately leading to superior project outcomes.

The significance of mastering concrete mixer use cannot be overstated. As construction projects evolve and scale, the demand for efficient and effective concrete mixing solutions continues to grow. Embracing best practices not only boosts productivity but also contributes to sustainability within the industry. Therefore, project managers are encouraged to actively apply these insights and strategies, ensuring they remain at the forefront of construction excellence. Take action now - optimize your concrete mixing processes and elevate your project outcomes!

Frequently Asked Questions

What are the main types of concrete mixers?

The main types of concrete mixers are batch types and continuous types. Batch mixers, such as drum and pan types, are suitable for smaller projects, while continuous mixers, like twin-shaft models, are designed for larger projects requiring a steady flow of cement.

What are batch concrete mixers best suited for?

Batch concrete mixers are best suited for smaller projects where precise control over the mix is essential. They allow for customization of mixtures, making them ideal for residential and smaller-scale uses, such as home renovations.

What advantages do continuous concrete mixers offer?

Continuous concrete mixers offer advantages such as efficiency and superior mixing quality, making them preferred for commercial applications. They enable continuous production, which is vital for large-scale infrastructure projects like highways and bridges.

What market trends are influencing the concrete mixer industry?

Market trends indicate a growing preference for concrete mixers due to the increasing scale of construction projects and the need for rapid material placement. Continuous mixers are expected to capture a significant share of the market, supported by advancements in technology, including automation and IoT integration.

What is the projected growth rate for the concrete mixer market?

The concrete mixer market is projected to grow at a rate of 5.7% from 2026 to 2033.

How do real-world examples demonstrate the effectiveness of concrete mixers?

Real-world examples show that large-scale initiatives utilizing twin-shaft apparatuses have improved blending efficiency and reduced waste, contributing to sustainability efforts in the industry.

What factors should be considered when selecting a concrete mixer?

Factors to consider when selecting a concrete mixer include the size of the project, the volume of cement needed, and specific mixing requirements. It is essential to choose equipment that effectively meets the project’s needs.