Key Highlights:

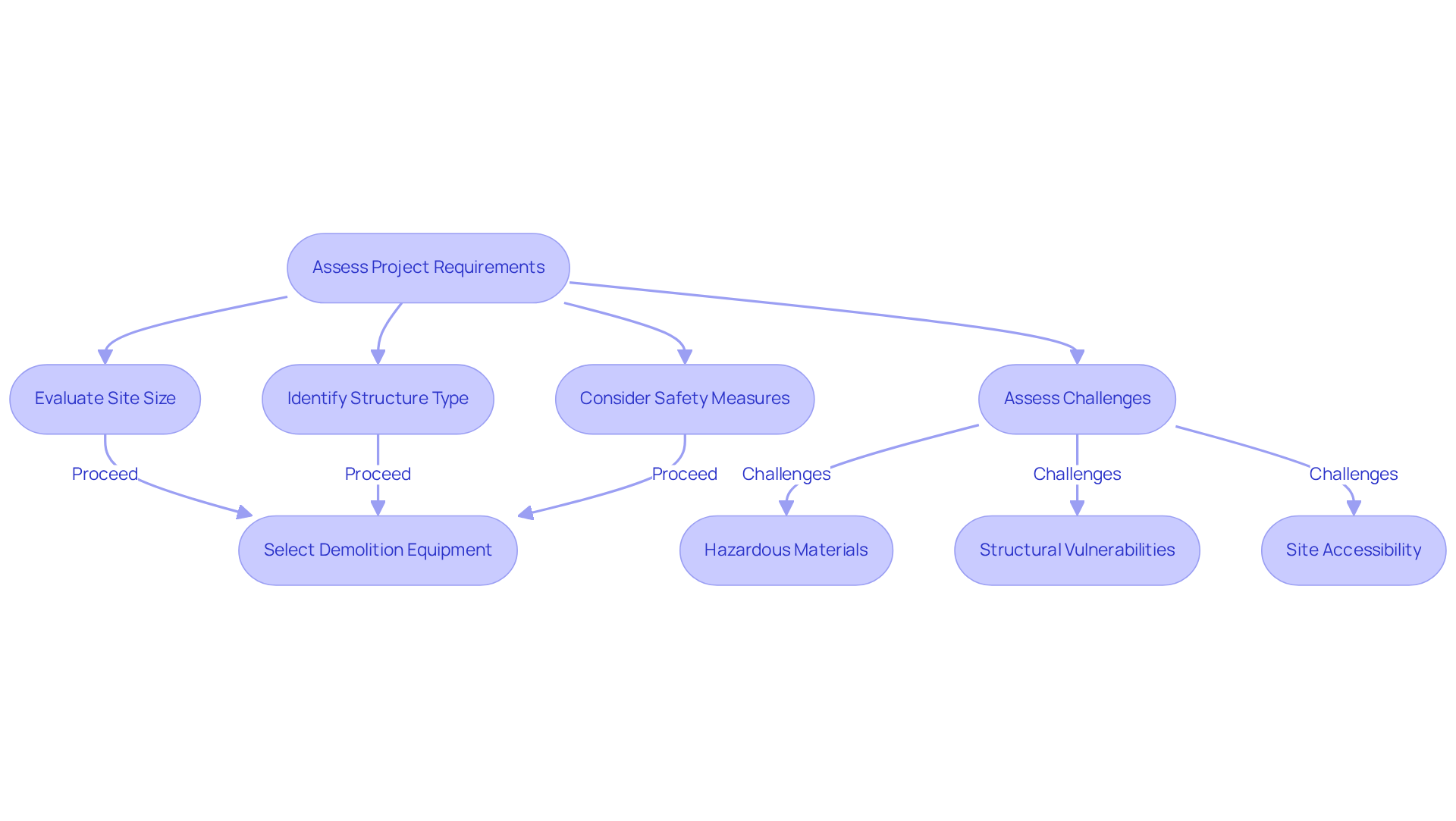

- Choosing demolition equipment requires a thorough evaluation of project needs, including site size and structure type.

- Multi-story buildings necessitate robust equipment like excavators and high-reach tools for safe dismantling.

- Site evaluations help identify risks such as hazardous materials and accessibility issues, aligning equipment choice with project timelines and budgets.

- Case studies demonstrate that tailored tool selection enhances safety and minimises delays in demolition projects.

- Key types of demolition machinery include excavators, bulldozers, and wrecking balls, each serving distinct functions.

- Advanced technologies like robotic systems are becoming essential in addressing labour shortages and improving safety in demolition.

- Implementing comprehensive safety protocols, including risk assessments and proper training, is crucial for worker protection.

- Regular maintenance practises, such as routine inspections and proactive repairs, are vital for optimal equipment performance.

Introduction

In the dynamic realm of construction, selecting the right demolition equipment is crucial for project success. Project managers are tasked with the vital responsibility of aligning machinery with the specific demands of each job, ensuring both safety and efficiency while navigating a landscape rife with potential hazards and technical challenges.

How can they effectively evaluate the diverse needs of a site, select appropriate tools, and implement best practices to enhance performance? This article explores essential strategies for mastering demolition equipment, providing insights that can lead to safer and more efficient dismantling processes.

Assess Project Requirements for Demolition Equipment

Choosing the appropriate demolition equipment begins with a thorough evaluation of project needs. This process involves assessing the average size of tear-down sites, which can vary significantly based on the type of structure being dismantled. For example, multi-story buildings typically require more robust demolition equipment, such as excavators or high-reach tools, to ensure efficient and safe dismantling. Understanding the type of structure is crucial, as it directly influences the selection of tools and techniques employed.

Moreover, managers must take into account specific challenges that may arise during the operation of demolition equipment. Factors such as the presence of hazardous materials, structural vulnerabilities, and site accessibility can affect the choice of demolition equipment and overall safety. A comprehensive site evaluation not only identifies these potential risks but also aligns the choice of demolition equipment with the project's timeline and budget constraints, which are vital for maintaining efficiency.

Successful case studies underscore the significance of this assessment process. For instance, in a recent dismantling project involving a large commercial facility, supervisors conducted detailed evaluations that led to the selection of specialized tools tailored to the site's unique challenges. This proactive approach resulted in enhanced safety measures and minimized delays, highlighting the importance of matching demolition equipment with task requirements.

Citations from experienced construction supervisors emphasize the value of site evaluations: "Understanding the nuances of a deconstruction site is essential for selecting the right tools. It's not merely about having the largest machine; it's about having the right machine for the job." By prioritizing comprehensive evaluations, supervisors can enhance safety and efficiency throughout the dismantling process.

Evaluate Types of Demolition Machinery for Your Needs

When evaluating dismantling machinery, project managers must align tool selections with the specific tasks at hand. Key types of demolition equipment include:

- Excavators

- Bulldozers

- Wrecking balls

Each designed for distinct functions. For instance, excavators are highly versatile, capable of being outfitted with various attachments for tasks such as breaking concrete or digging foundations. Bulldozers excel in clearing debris and leveling sites, making them essential for initial site preparation. For more complex dismantling tasks, specialized tools like hydraulic shears or concrete crushers may be necessary.

Understanding the strengths and limitations of each type of demolition equipment is crucial for project managers. A recent case study highlighted how a contractor employed remote-controlled destruction machines, significantly improving productivity by reducing crew sizes while ensuring safety. This approach streamlined operations and provided a competitive edge in the market.

Current trends indicate a growing reliance on advanced technology in deconstruction, such as robotic systems that enhance safety and efficiency. Industry insights reveal that the labor shortage in skilled trades is a pressing issue, exacerbated by an aging workforce and fewer young workers entering the field. Advanced robotic technology not only addresses these labor challenges but also attracts younger workers by offering modern, safe working conditions. By staying informed about these advancements, leaders can make educated choices that lead to successful outcomes.

Implement Safety and Efficiency Practices in Equipment Use

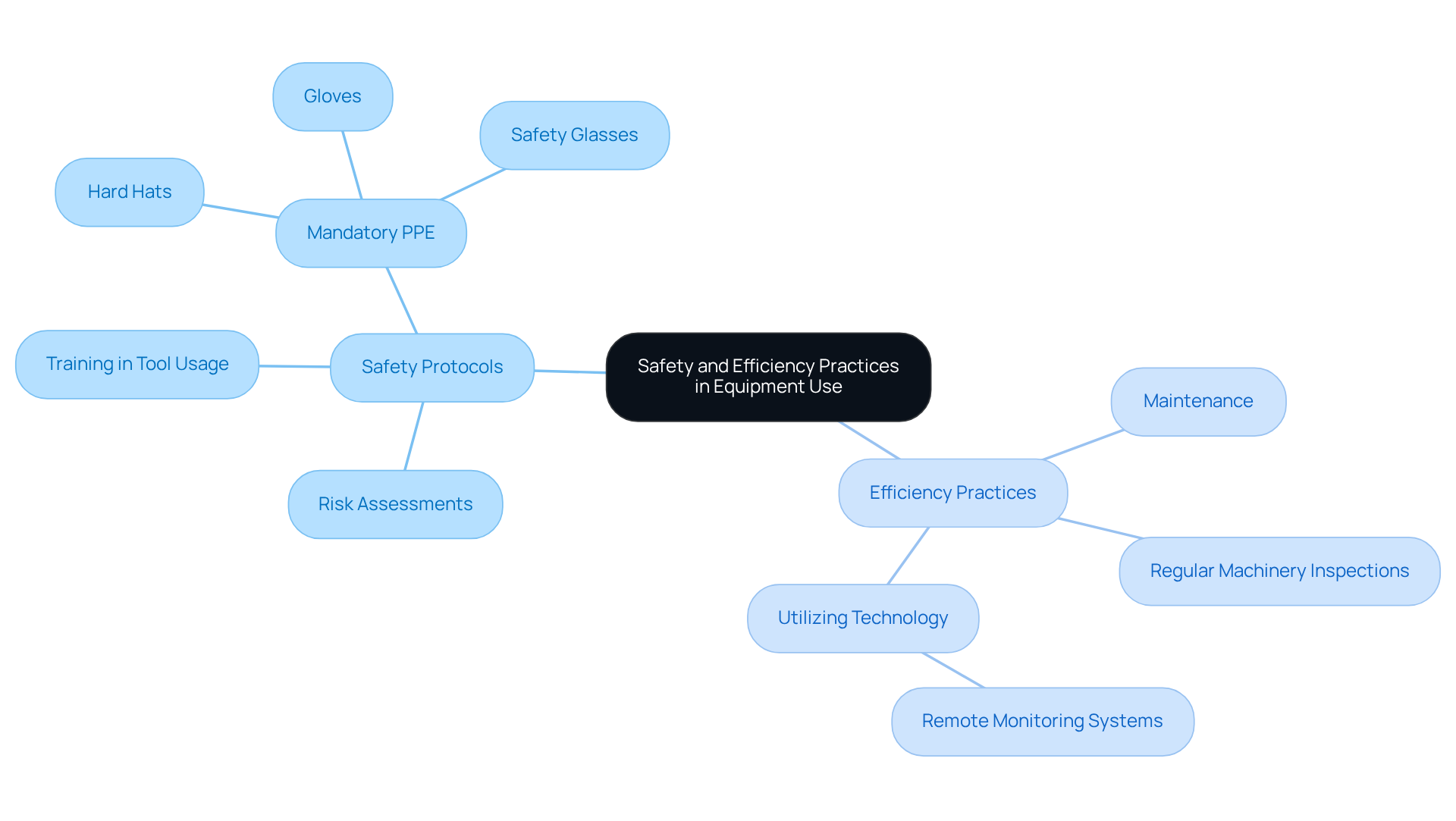

Safety is paramount in demolition projects. Project managers must implement comprehensive safety protocols, which include:

- Conducting thorough risk assessments

- Ensuring that all workers receive proper training in tool usage

Mandatory personal protective equipment (PPE), such as hard hats, gloves, and safety glasses, is essential on-site. Furthermore, adopting efficient practices - like regular machinery inspections and maintenance - can help prevent breakdowns and delays.

Utilizing technology, such as remote monitoring systems, enhances safety by allowing operators to control machinery from a safe distance. By fostering a culture of safety and efficiency, leaders can significantly reduce the likelihood of accidents and improve overall performance. This commitment to safety not only protects workers but also contributes to the project's success.

Ensure Maintenance and Support for Optimal Equipment Performance

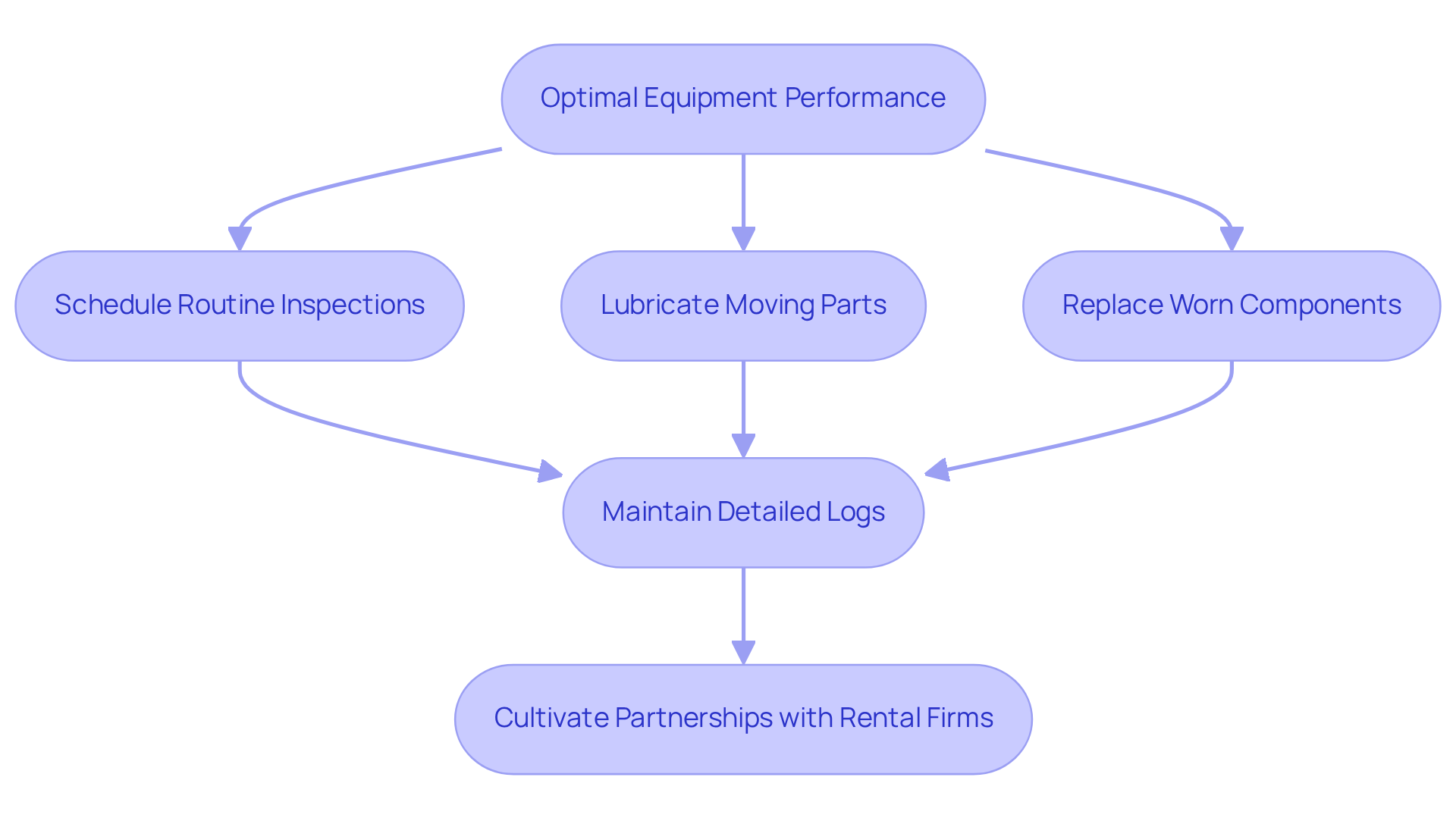

To achieve optimal performance from demolition equipment, project managers must prioritize regular maintenance and support. This includes:

- Scheduling routine inspections

- Lubricating moving parts

- Proactively replacing worn components to prevent equipment failure

Maintaining detailed logs of maintenance activities is essential for tracking the condition of each machine and identifying recurring issues. Additionally, cultivating a partnership with reliable rental firms, such as EZ Rental, ensures access to expert assistance and replacement machinery when needed. By investing in these maintenance strategies, particularly for equipment like boom lifts, project managers can significantly enhance the longevity and efficiency of their equipment throughout the demolition process.

Conclusion

Selecting the right demolition equipment is crucial for effective project management, directly influencing both safety and efficiency. By carefully assessing project requirements and understanding the unique challenges of each demolition site, project managers can make informed decisions that align with their operational goals. This strategic approach not only enhances worker safety but also ensures that the dismantling process runs smoothly and stays within budget.

Key insights regarding the evaluation of demolition machinery, the implementation of safety practices, and the importance of regular maintenance have emerged throughout this discussion. By categorizing equipment based on their specific functionalities - such as excavators for versatility and bulldozers for site preparation - managers can optimize their tool selections. Furthermore, fostering a culture of safety through training and technology, along with diligent maintenance routines, significantly contributes to the overall success of demolition projects.

In conclusion, the importance of mastering demolition equipment cannot be overstated. By adopting best practices in assessing project needs, selecting appropriate machinery, and ensuring rigorous safety and maintenance protocols, project managers can navigate the complexities of demolition with confidence. The construction industry is evolving, and staying informed about advancements in technology and safety measures will not only enhance project outcomes but also attract a new generation of skilled workers to the field.

Frequently Asked Questions

What is the first step in choosing demolition equipment?

The first step is to conduct a thorough evaluation of project needs, including assessing the average size of tear-down sites and the type of structure being dismantled.

How does the type of structure influence the choice of demolition equipment?

Different types of structures require different demolition equipment; for example, multi-story buildings typically need more robust tools like excavators or high-reach tools for efficient and safe dismantling.

What specific challenges should be considered when selecting demolition equipment?

Challenges include the presence of hazardous materials, structural vulnerabilities, and site accessibility, all of which can affect the choice of equipment and overall safety.

Why is a comprehensive site evaluation important?

A comprehensive site evaluation identifies potential risks and aligns the choice of demolition equipment with the project's timeline and budget constraints, which are essential for maintaining efficiency.

Can you provide an example of the importance of assessing project requirements?

In a recent project involving a large commercial facility, detailed evaluations led to the selection of specialized tools that addressed the site’s unique challenges, resulting in enhanced safety measures and minimized delays.

What do experienced construction supervisors say about site evaluations?

Experienced supervisors emphasize that understanding the nuances of a deconstruction site is essential for selecting the right tools, stating, "It's not merely about having the largest machine; it's about having the right machine for the job."

List of Sources

- Assess Project Requirements for Demolition Equipment

- Construction & Demolition Waste Market Based On Type, Application, Region | MarketsandMarkets (https://marketsandmarkets.com/Market-Reports/construction-demolition-waste-market-225127553.html)

- Construction and Demolition Waste Management Market [2032] (https://fortunebusinessinsights.com/construction-and-demolition-waste-management-market-105550)

- Demolition & Wrecking in the US Industry Analysis, 2025 (https://ibisworld.com/united-states/industry/demolition-wrecking/207)

- Construction & Demolition Waste Management Market Report 2030 (https://grandviewresearch.com/industry-analysis/construction-demolition-waste-management-market-report)

- 24 Construction Waste Statistics | BigRentz (https://bigrentz.com/blog/construction-waste-statistics?srsltid=AfmBOoooUa5IfqR_uZGK8MvGZ5TmfBJ62HVVRHSZKamZNuWJxk2jSxGU)

- Evaluate Types of Demolition Machinery for Your Needs

- TOP 25 DEMOLITION QUOTES | A-Z Quotes (https://azquotes.com/quotes/topics/demolition.html)

- Early 19th-century Museum Building near Fincastle courthouse project faces potential demolition (https://cardinalnews.org/2025/06/30/early-19th-century-museum-building-near-fincastle-courthouse-project-faces-potential-demolition)

- Using Demolition Robots to Combat Labor Shortages - Brokk USA (https://brokk.com/us/news/brokk-articles/demolition-robots-combat-labor-shortages)

- Old PD Building Demolition Project | News | City of Corona (https://coronaca.gov/news/old-pd-building-demolition-project)

- Ensure Maintenance and Support for Optimal Equipment Performance

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- Construction Equipment Costs You Must Consider - Tenna (https://tenna.com/equipment-tracking-guide/construction-equipment-costs)

- 10 Compelling Statistics About Manufacturing Maintenance (https://worktrek.com/blog/manufacturing-maintenance-statistics)

- Key Facts and Statistics on Equipment Maintenance (https://gocodes.com/maintenance-management/equipment-maintenance-statistics)