Overview

This article outlines the essential steps for project managers to successfully rent a demolition excavator. Understanding the different types of excavators and key rental considerations is crucial.

- Project managers must evaluate their specific project needs. This evaluation serves as the foundation for selecting the right equipment.

- Thorough research of rental firms is necessary to identify reliable options that meet those needs.

- Adhering to safety protocols is imperative to ensure a safe working environment during demolition projects.

Collectively, these steps empower managers to select suitable equipment while maintaining safety standards.

Key Highlights:

- Demolition excavators come in various types tailored for specific tasks: Standard, High-Reach, Mini, Long-Reach, and Specialised excavators.

- Standard Excavators are versatile, suitable for digging, lifting, and demolition with various attachments.

- High-Reach Machinery is designed for demolishing tall structures with extended booms.

- Mini Excavators are ideal for smaller jobs in confined spaces, balancing manoeuvrability and power.

- Long-Reach Excavators are effective for tasks requiring extended reach in hard-to-access areas.

- Specialised Excavators have attachments like shears and hammers for heavy-duty dismantling operations.

- Key considerations for renting an excavator include project size, site conditions, material type, weight/reach requirements, and necessary attachments.

- Steps to rent an excavator include evaluating needs, researching firms, requesting quotes, reviewing agreements, examining machinery, and scheduling delivery.

- Best safety practises for operating demolition excavators include pre-operation inspections, using PPE, establishing a safe work zone, following manufacturer guidelines, effective communication, and being aware of surroundings.

Introduction

Understanding the intricacies of demolition excavator rentals is essential for project managers who aim to execute successful deconstruction projects. With a diverse range of excavator types available, each tailored for specific tasks, selecting the appropriate equipment can significantly improve both efficiency and safety on the job site.

However, navigating the rental process and ensuring compliance with safety protocols can present challenges that may lead managers to question their choices.

What key steps can be taken to ensure that the right machinery is not only selected but also operated safely and effectively?

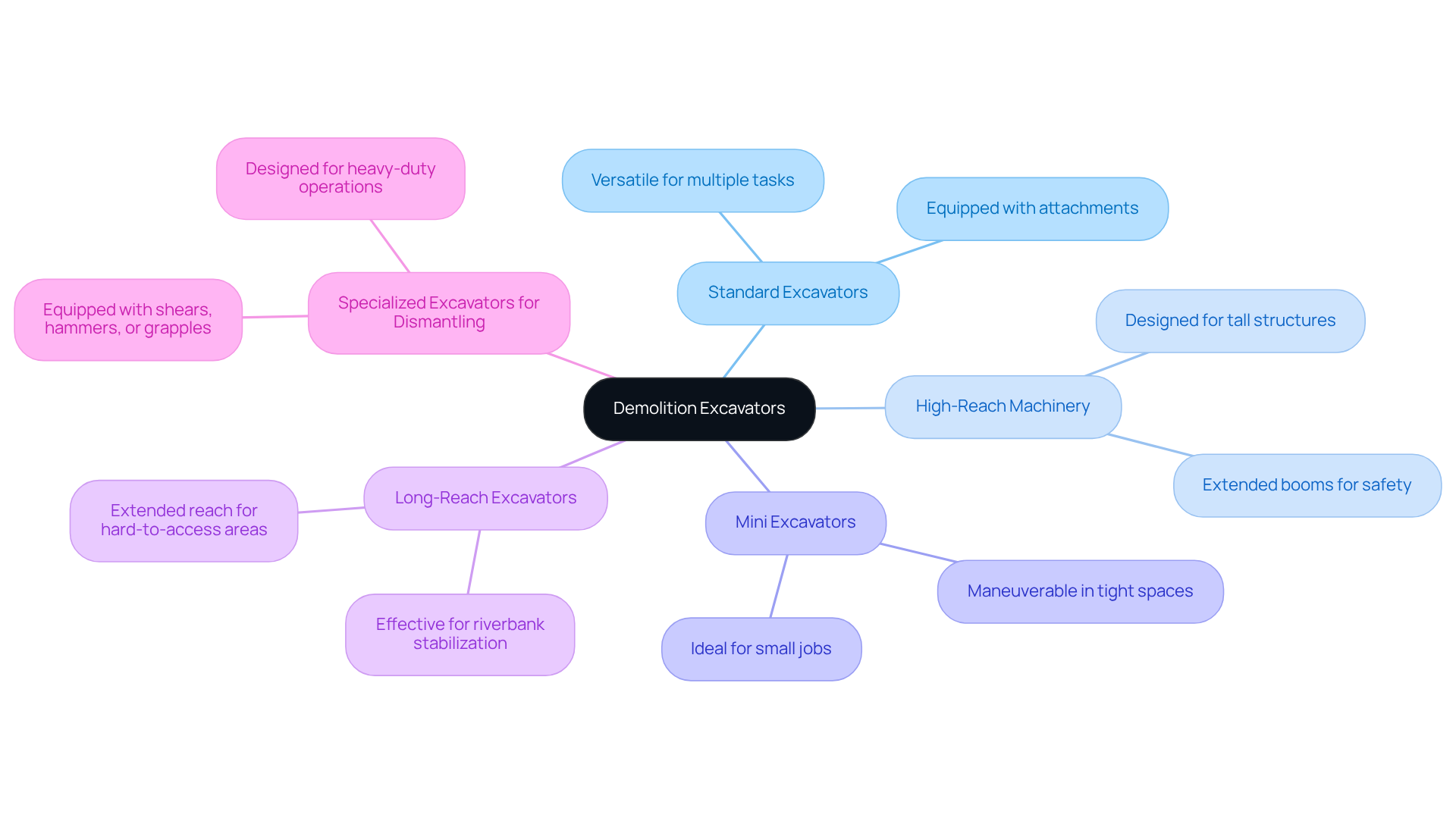

Understand Demolition Excavators: Types and Functions

Dismantling machines come in various types, each designed for specific tasks within the deconstruction process. Understanding these categories is essential for managers to select the right tools tailored to their unique dismantling needs.

-

Standard Excavators are versatile machines that excel in multiple tasks, including digging, lifting, and demolition. Equipped with a bucket, they can also accommodate various attachments, enhancing their functionality for different projects.

-

High-Reach Machinery is specifically designed for demolishing tall structures. With extended booms, these machines enable operators to safely reach higher elevations, making them indispensable for significant demolition tasks.

-

For smaller jobs or confined spaces, Mini Excavators are the ideal solution. Their maneuverability allows them to operate efficiently without compromising power, making them a favorite for tight spots.

-

Long-Reach Excavators are built for projects requiring extended reach. These machines are particularly effective for tasks such as riverbank stabilization or dismantling structures in hard-to-access areas, showcasing their adaptability and strength.

-

Finally, Specialized Excavators for Dismantling are equipped with specific attachments such as shears, hammers, or grapples, designed for heavy-duty dismantling operations. These machines provide the necessary power and precision for challenging tasks.

By comprehending the distinct types of dismantling machines available, managers can ensure they choose the most effective equipment for their deconstruction projects, ultimately leading to greater efficiency and success.

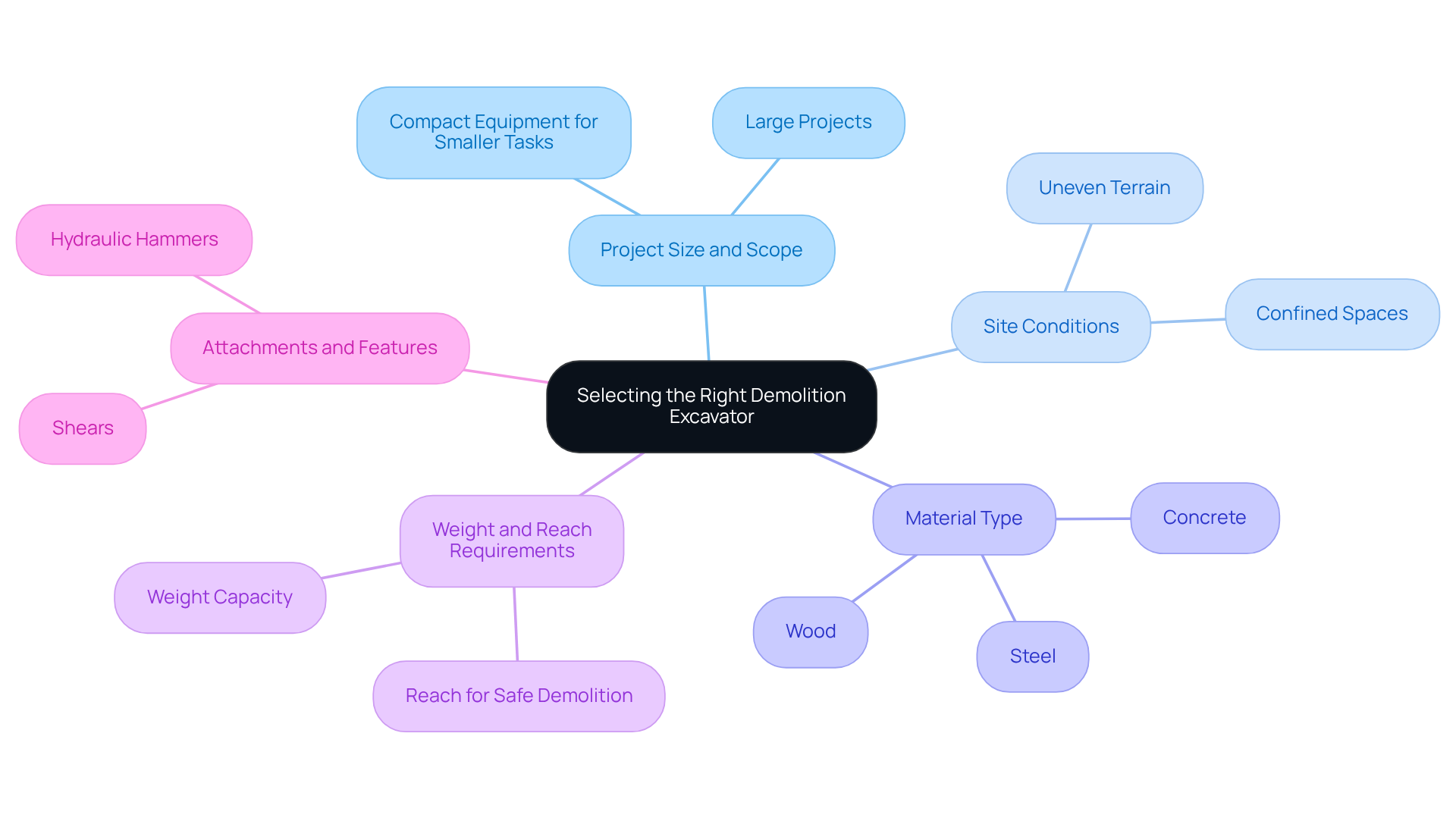

Select the Right Demolition Excavator: Key Considerations

When considering a demolition excavator rental, it is essential to take into account several key factors that will influence your decision.

-

Project Size and Scope: First, evaluate the extent of the dismantling task. Larger projects typically require more powerful machinery, while smaller tasks can be effectively managed with compact equipment. This assessment ensures that you choose the right machine for the job at hand.

-

Site Conditions: Next, consider the terrain and accessibility of the site. Uneven or confined spaces may necessitate smaller, more maneuverable machines. Understanding the site conditions will help in selecting equipment that can operate efficiently in the given environment.

-

Material Type: Additionally, different materials—such as concrete, steel, and wood—require distinct approaches. It is crucial to ensure that the machinery can handle the specific materials involved in the demolition process, as this will affect both safety and effectiveness.

-

Weight and Reach Requirements: Furthermore, determine the weight capacity needed for the machinery and the reach required to safely demolish structures without compromising stability. This consideration is vital to maintaining safety standards during operation.

-

Attachments and Features: Lastly, consider what attachments, such as hydraulic hammers or shears, may be required for the task. Ensure that the machine can accommodate these tools, as they can enhance the efficiency and effectiveness of the demolition process.

By thoroughly assessing these elements, managers can choose the most appropriate demolition excavator rental tailored to their specific requirements.

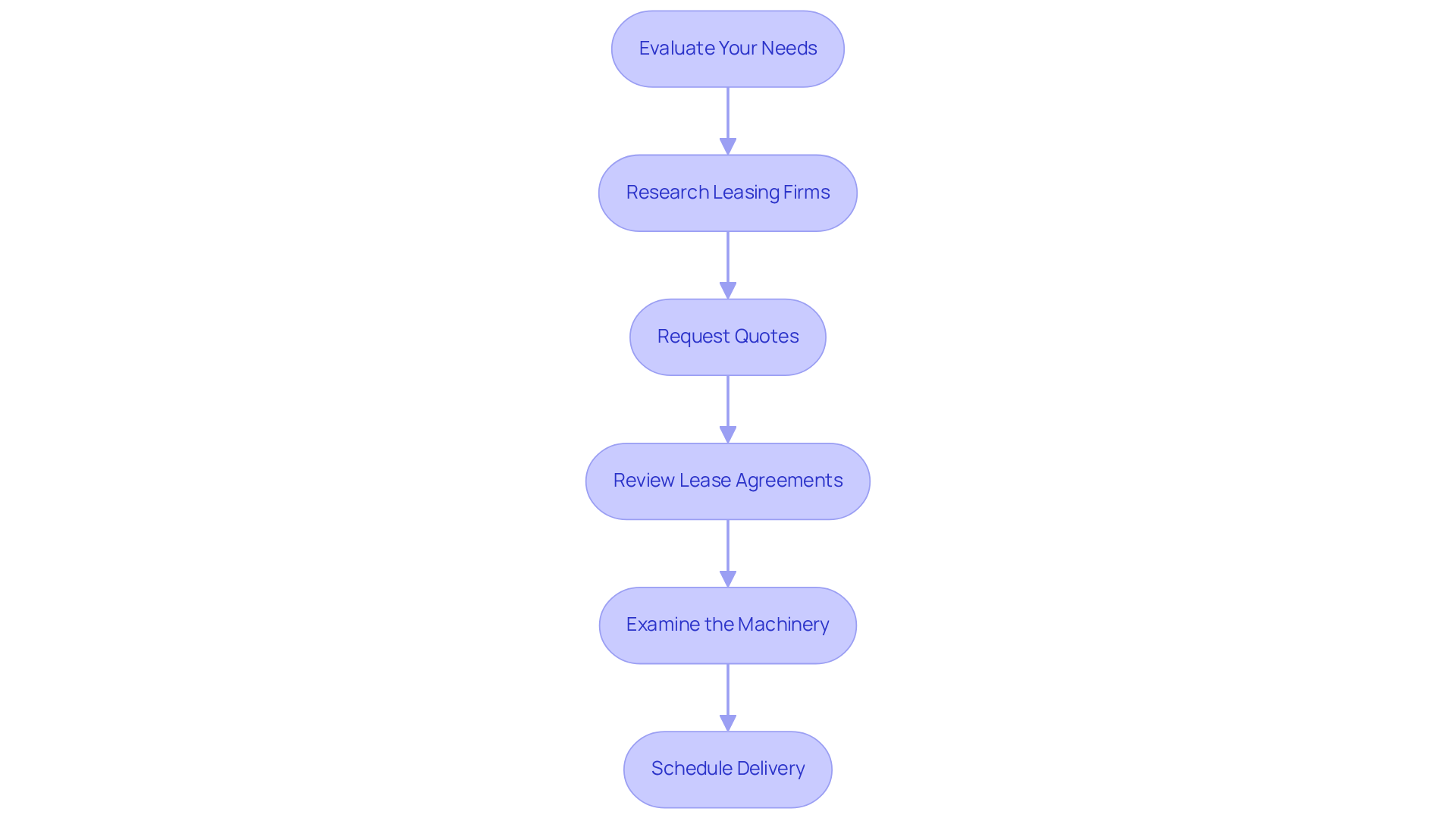

Navigate the Rental Process: Steps to Rent a Demolition Excavator

To successfully rent a demolition excavator, follow these essential steps:

- Evaluate Your Needs: Begin by clearly outlining the specifications of your project. Determine the type of machinery required, the duration of use, and any specific attachments necessary for optimal performance.

- Research Leasing Firms: Identify reputable leasing firms in Irving, TX, such as EZ Equipment Rental, which specializes in a diverse range of machinery, including mini excavators, boom lifts, and forklifts. Check customer reviews and compare pricing and availability across the DFW Metroplex to ensure you make an informed choice.

- Request Quotes: Reach out to multiple leasing firms to acquire detailed estimates. Be diligent in asking about any additional fees, such as delivery or insurance, to gain a comprehensive understanding of the total costs involved.

- Review Lease Agreements: Carefully read through the lease agreement, paying close attention to terms regarding maintenance, liability, and return conditions. This is particularly important as it pertains to the equipment you are borrowing, ensuring clarity and protection for your project.

- Examine the Machinery: Before finalizing the lease, thoroughly check the digger to ensure it meets your project needs and is in proper working order. EZ Equipment Rental prides itself on providing quality equipment rentals, including their demolition excavator rental, so take advantage of their expertise to ensure you have the right tools for the job.

- Schedule Delivery: Arrange for the timely delivery of the excavator to your job site. EZ Equipment Rental offers prompt delivery services throughout the DFW Metroplex, helping project managers stay on schedule and maintain workflow efficiency.

By following these steps, project managers can navigate the rental process with confidence and secure the appropriate equipment for their construction projects. For more information or to explore equipment options, contact EZ Equipment Rental today.

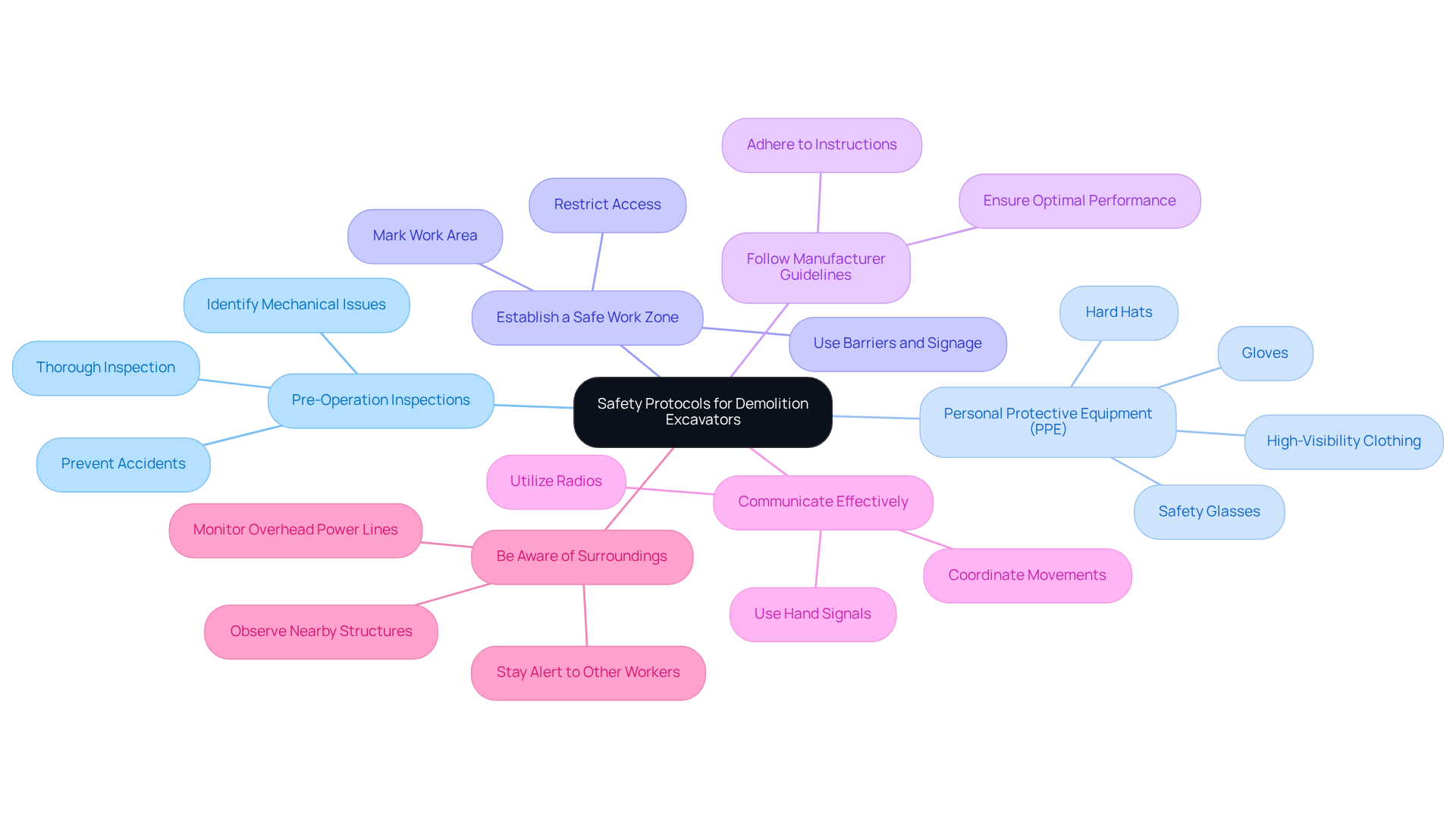

Implement Safety Protocols: Best Practices for Operating Demolition Excavators

To ensure the safe operation of demolition excavators, it is imperative to adhere to the following best practices:

-

Conduct Pre-Operation Inspections: Before utilizing the digging machine, perform a thorough inspection to identify any mechanical issues or safety hazards. This proactive measure is essential for preventing accidents.

-

Use Personal Protective Equipment (PPE): It is crucial that all operators and site personnel wear appropriate PPE, including hard hats, gloves, safety glasses, and high-visibility clothing. This not only enhances individual safety but also promotes a culture of safety on site.

-

Establish a Safe Work Zone: Clearly marking the work area and restricting access to unauthorized personnel is vital. Utilize barriers and signage to enhance safety, ensuring that everyone is aware of the designated zones.

-

Follow Manufacturer Guidelines: Always operate the excavator in accordance with the manufacturer's instructions and safety guidelines. This adherence is key to preventing accidents and ensuring optimal performance.

-

Communicate Effectively: Maintaining clear communication among team members is essential, particularly when operating heavy machinery. Utilize hand signals or radios to coordinate movements, thereby minimizing the risk of misunderstandings.

-

Be Aware of Surroundings: Operators must remain vigilant of their surroundings, including overhead power lines, nearby structures, and other workers. This awareness is critical for maintaining a safe working environment.

By implementing these safety protocols, project managers can significantly reduce the risk of accidents and foster a safer working environment during demolition projects that involve a demolition excavator rental.

Conclusion

Selecting the right demolition excavator is a crucial step for project managers aiming to ensure successful deconstruction outcomes. Understanding the various types of excavators and their specific functions empowers managers to make informed decisions that align with the unique requirements of each project. This knowledge enhances operational efficiency and contributes to the overall safety and effectiveness of the demolition process.

Key considerations, such as project size, site conditions, material types, and necessary attachments, significantly influence the rental decision-making process. By meticulously evaluating these factors, project managers can select equipment that meets their specific needs, ultimately leading to a smoother execution of demolition tasks. Furthermore, navigating the rental process with a clear understanding of the steps involved—from evaluating needs to scheduling delivery—ensures that the right machinery is secured without unnecessary delays.

In conclusion, the importance of proper planning and safety protocols cannot be overstated in the realm of demolition excavator rentals. Adhering to best practices for equipment operation and fostering a culture of safety on site allows project managers to mitigate risks significantly while maximizing productivity. Embracing these strategies leads to successful project outcomes and establishes a solid foundation for future endeavors in the construction industry.

Frequently Asked Questions

What are the main types of demolition excavators?

The main types of demolition excavators include Standard Excavators, High-Reach Machinery, Mini Excavators, Long-Reach Excavators, and Specialized Excavators for Dismantling.

What tasks can Standard Excavators perform?

Standard Excavators are versatile machines that excel in digging, lifting, and demolition tasks. They can also accommodate various attachments to enhance their functionality for different projects.

What is the purpose of High-Reach Machinery?

High-Reach Machinery is specifically designed for demolishing tall structures, featuring extended booms that allow operators to safely reach higher elevations during significant demolition tasks.

When should Mini Excavators be used?

Mini Excavators are ideal for smaller jobs or confined spaces due to their maneuverability, allowing them to operate efficiently without compromising power.

What are Long-Reach Excavators used for?

Long-Reach Excavators are built for projects requiring extended reach, making them effective for tasks such as riverbank stabilization or dismantling structures in hard-to-access areas.

What features do Specialized Excavators for Dismantling have?

Specialized Excavators for Dismantling are equipped with specific attachments like shears, hammers, or grapples, providing the necessary power and precision for heavy-duty dismantling operations.

Why is it important for managers to understand the types of demolition excavators?

Understanding the distinct types of dismantling machines helps managers select the most effective equipment for their deconstruction projects, leading to greater efficiency and success.