Overview

The article outlines essential strategies for project managers to consider when renting excavator machines. It emphasizes the importance of:

- Clearly defining project requirements

- Understanding site conditions

- Meticulously reviewing rental terms

These strategies are bolstered by detailed guidance on:

- Equipment selection

- Maintenance planning

- Negotiation tactics

This ensures that managers can effectively manage rental costs while guaranteeing reliable machinery for their projects.

Key Highlights:

- Project managers must define specific project requirements to select the appropriate excavator type and size.

- Site conditions, including terrain and spatial constraints, are critical when choosing the right excavator.

- Weight and size of the excavator must align with project specifications for optimal performance and safety.

- Availability of attachments enhances the excavator's versatility and efficiency in performing various tasks.

- Prioritising fuel-efficient models can lead to significant cost savings during the rental period.

- Investigating brand reputation ensures reliability and quality of the machinery selected.

- Reviewing rental terms, including lease duration, payment terms, and maintenance responsibilities, is essential before finalising a rental.

- Negotiating rental rates and bundling leases can lead to cost savings and improved logistics.

- Monitoring usage and planning for downtime are crucial to managing rental costs effectively.

- Establishing a maintenance schedule and documenting maintenance activities enhance equipment reliability during the rental.

Introduction

Navigating the complexities of excavator machine rentals presents a significant challenge for project managers, particularly when stakes are high and timelines are tight. Understanding the critical factors influencing equipment selection, rental terms, and cost-effective strategies is essential for achieving favorable project outcomes.

With numerous variables at play, how can managers ensure they are making informed choices tailored to their specific needs while steering clear of common pitfalls?

This article explores essential strategies designed to empower project managers, enabling them to optimize their excavator rentals and ensure both efficiency and success in their projects.

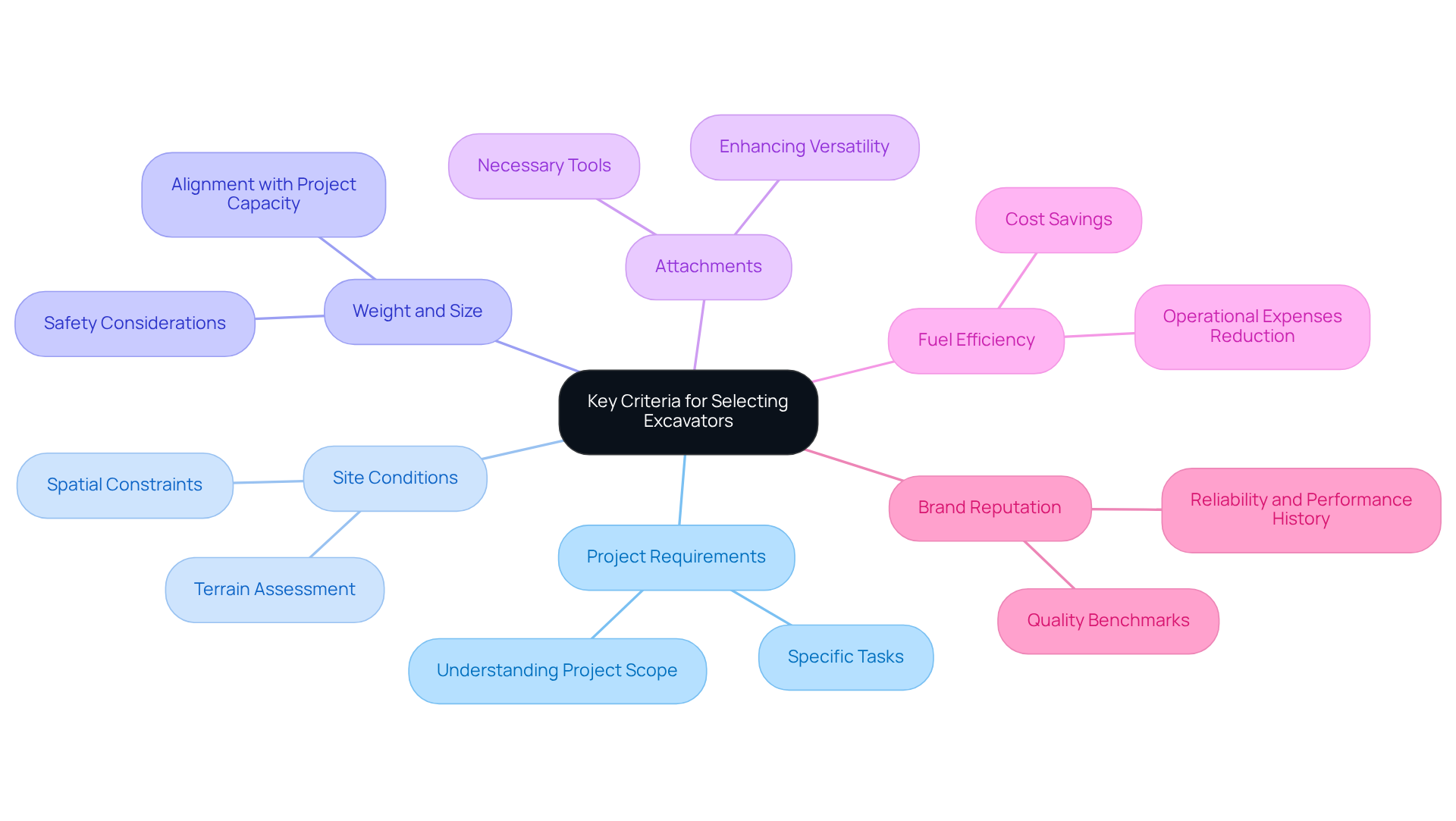

Identify Key Criteria for Selecting Excavators

When selecting an excavator, project managers must consider several key criteria to ensure optimal performance and project success.

-

Project Requirements: Clearly defining the specific tasks the machinery will perform—such as digging, lifting, or grading—is essential. A comprehensive understanding of the project scope is crucial for choosing the suitable type and size of digger. As Joy Gumz states, "Operations keep the lights on, strategy provides a light at the end of the tunnel, but management of initiatives is the train engine that moves the organization forward."

-

Site Conditions: Assessing the terrain and spatial constraints of the job site is vital. For example, a mini digger is ideal for tight areas, whereas larger models are appropriate for extensive excavation jobs. Effective planning, as highlighted by Winston Churchill, is essential for success in managing endeavors.

-

Weight and Size: Ensuring that the machinery aligns with the project's weight capacity and size requirements is critical. This alignment is crucial for optimal performance and safety during operations. According to Peter Drucker, "Management is doing things right; leadership is doing the right things," which applies to selecting the right equipment for the job.

-

Attachments: Evaluating the availability of necessary attachments, such as buckets, hammers, or grapples, can significantly enhance the excavator's versatility and efficiency in completing various tasks. Utilizing the appropriate tools can lead to consistent success in initiatives, as emphasized in numerous management resources.

Prioritizing models that demonstrate superior fuel efficiency can lead to substantial cost savings during the excavator machine rental period. Statistics indicate that fuel-efficient models can lower operational expenses considerably, making them a wise option for managers.

- Brand Reputation: Investigating the reliability and performance history of different brands is essential. Choosing a trustworthy brand guarantees that the machinery meets recognized quality benchmarks, aiding in the success of the endeavor. As Stephen Covey notes, "Technology and tools are useful and powerful when they are your servant and not your master," underscoring the importance of selecting the right equipment.

Integrating these criteria into the decision-making process can lead to more efficient equipment selection, ultimately improving results.

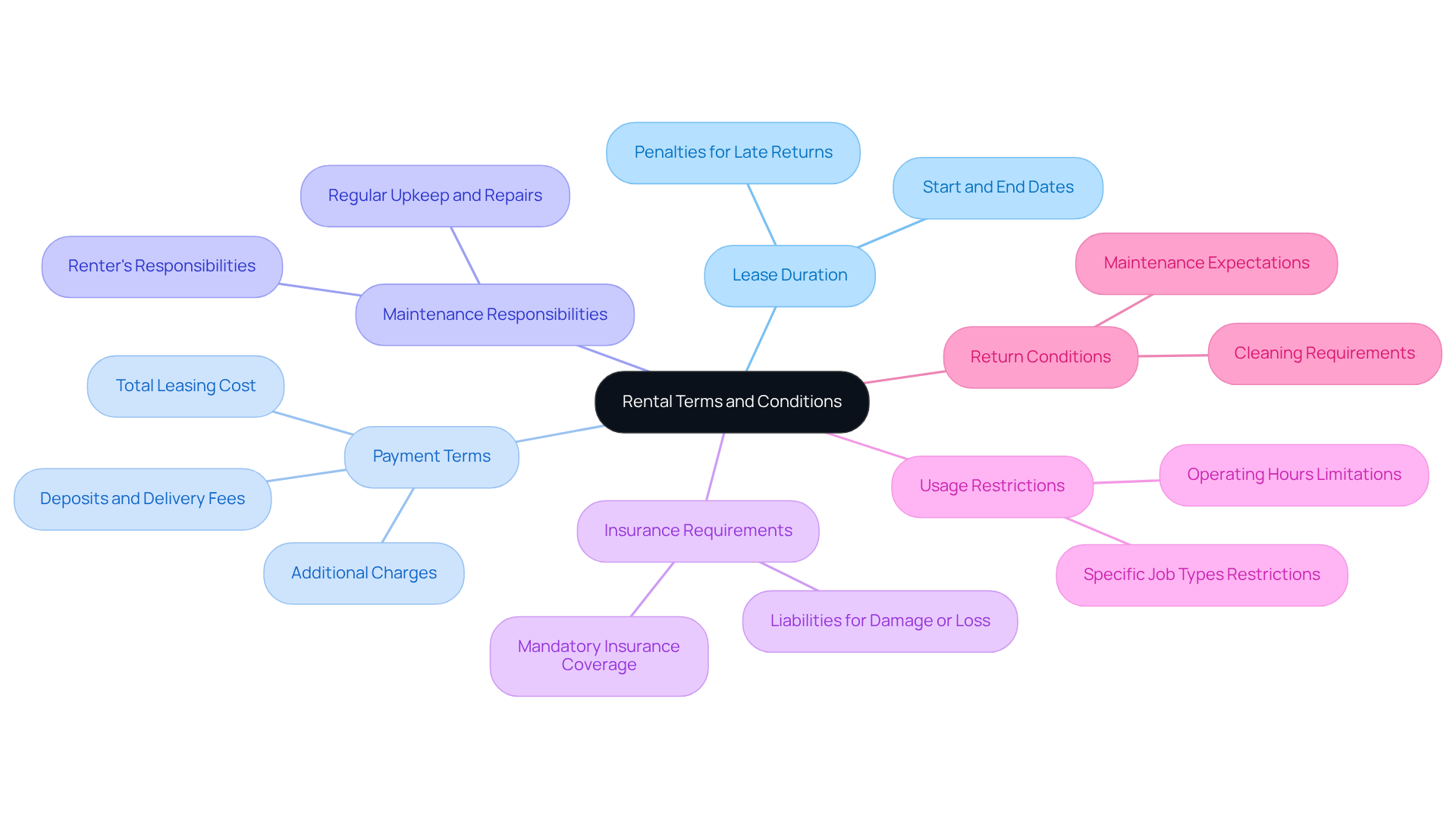

Understand Rental Terms and Conditions

Before finalizing an excavator rental, project managers must conduct a thorough review of the rental terms and conditions, paying close attention to several critical aspects:

-

Lease Duration: It is essential to understand the start and end dates of the lease period, along with any penalties that may apply for late returns. This knowledge will help avoid unexpected fees and ensure a smooth rental experience.

-

Payment Terms: Clarifying the total leasing cost is crucial. This includes any deposits, delivery fees, and additional charges that may arise from exceeding the agreed-upon period. Clear financial expectations prevent misunderstandings and facilitate budgeting.

-

Maintenance Responsibilities: Identifying who is accountable for regular upkeep and repairs during the leasing period is vital. Typically, the renter is responsible for basic maintenance, so understanding these obligations upfront can prevent complications later.

-

Insurance Requirements: It is important to check if the rental company mandates insurance coverage for the equipment. Understanding the implications of any damage or loss can safeguard against potential liabilities.

-

Usage Restrictions: Being aware of any limitations on how the equipment can be utilized is necessary. This includes restrictions on operating hours or specific job types, which can impact project timelines.

-

Return Conditions: Lastly, understanding the expectations for returning the equipment is crucial. This includes cleaning and maintenance requirements to avoid incurring additional fees. Clear guidelines will ensure that the return process is as seamless as the excavator machine rental experience itself.

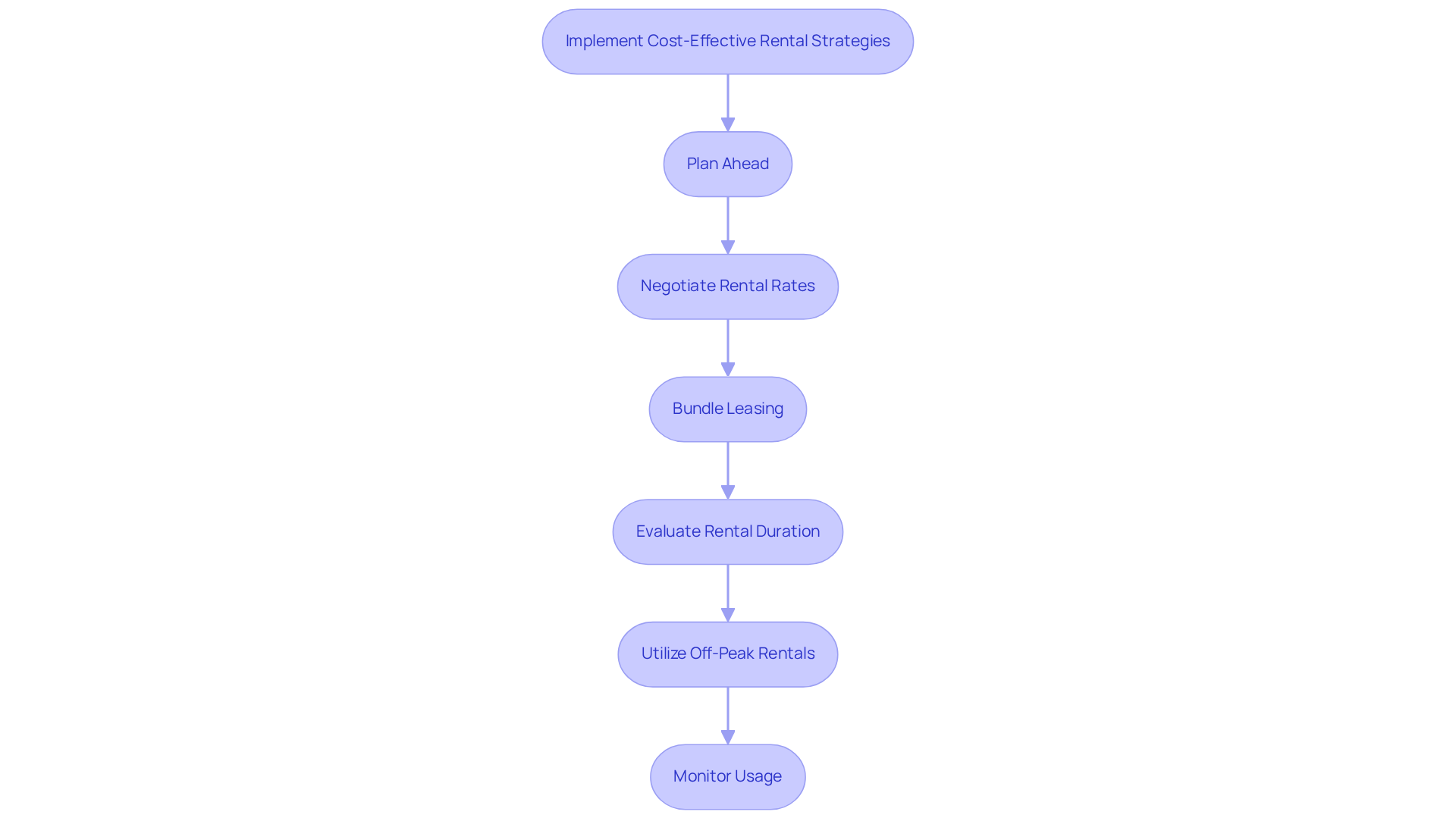

Implement Cost-Effective Rental Strategies

To implement cost-effective rental strategies, project managers should consider the following approaches:

-

Plan Ahead: Booking equipment in advance is crucial for securing better rates and ensuring availability, particularly during peak seasons when demand surges. Early planning can prevent expensive delays and help maintain schedules. As noted, last-minute bookings can lead to delays, affecting profits if tasks are postponed by even a single day.

-

Negotiate rental rates for excavator machine rental: Engaging in negotiations with suppliers can yield significant savings, especially for long-term excavator machine rentals. Project managers should not hesitate to discuss terms and seek discounts based on project duration and volume. Josh Nickell emphasizes the importance of planning and analytics in asset management, stating that effective forecasting is essential for success.

-

Bundle Leasing: When multiple items are needed, combining leases with a single provider can lead to improved pricing. This strategy not only simplifies logistics but also enhances the potential for discounts, making it a smart choice for project managers.

-

Evaluate rental duration: Careful assessment of the timeline is essential to avoid over-renting the excavator machine rental. Leasing tools for a period longer than necessary can result in increased expenses, so aligning rental time with actual needs is vital for cost management.

-

Utilize off-peak rentals for excavator machine rental, as renting tools during off-peak times can lead to lower rates. Project managers should explore scheduling flexibility to capitalize on these cost-saving opportunities, ensuring that budgets remain intact.

-

Monitor Usage: Keeping track of resource usage ensures alignment with task requirements. This oversight allows for prompt modifications to lease agreements, avoiding unnecessary costs and enhancing resource distribution. Many planners underestimate the need for leasing equipment, which can lead to shortages, underscoring the importance of proactive management.

By applying these strategies, managers can efficiently control leasing expenses while ensuring that their initiatives stay on track and within budget.

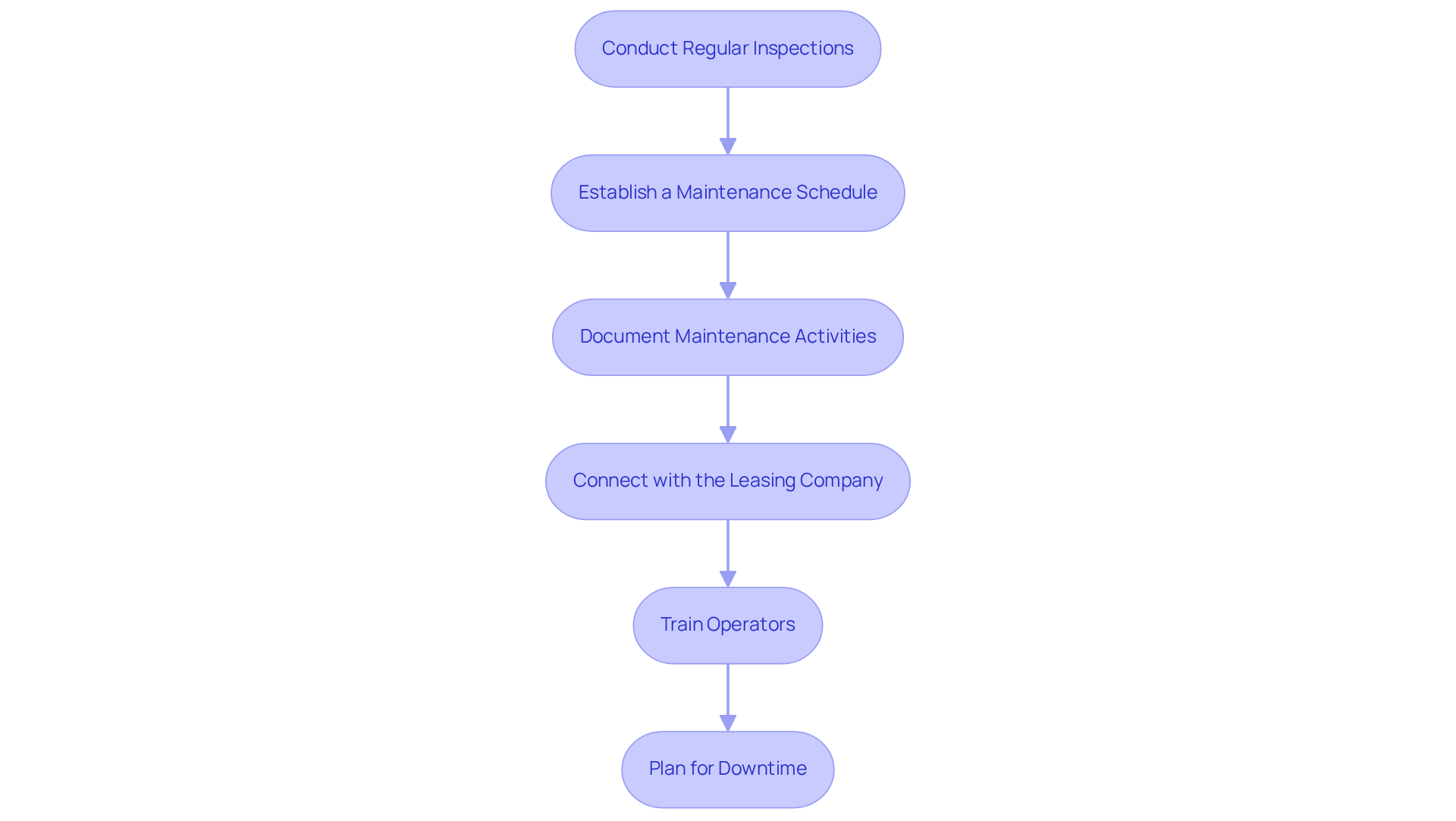

Ensure Maintenance and Support During Rental

To ensure optimal maintenance and support during the rental period, project managers must implement effective strategies.

Conducting regular inspections on rented excavators through an excavator machine rental service is crucial for identifying potential issues early. This involves overseeing fluid levels, tire pressure, and the overall condition of the machinery, which can prevent costly repairs and minimize downtime.

-

Establish a Maintenance Schedule: Collaborate with the leasing company to develop a maintenance plan tailored to the usage and operational requirements of the machinery. This proactive approach is essential for maintaining equipment efficiency and reliability.

-

Document Maintenance Activities: Keeping comprehensive records of all maintenance performed, including dates and types of services, fosters accountability and transparency. Such documentation is advantageous for future leases and audits, ensuring a clear maintenance history.

-

Connect with the Leasing Company: Maintaining open lines of communication with the leasing provider is vital for swiftly resolving any concerns or issues. A responsive leasing company can provide valuable assistance and guidance throughout the leasing period.

-

Train Operators: Ensure that all operators receive sufficient training in the correct use and maintenance of the tools. This training significantly reduces the risk of misuse and damage, ultimately extending the life of the rental tools.

-

Plan for Downtime: Develop contingency plans for potential equipment failures, including backup equipment or alternative solutions. This foresight is essential for reducing disruptions and ensuring smooth operations.

By adhering to these strategies, project managers can significantly enhance the reliability and performance of excavator machine rental, thereby ensuring successful project outcomes.

Conclusion

Selecting the right excavator machine rental is pivotal for project managers aiming to optimize performance and control costs. Understanding the key criteria for selecting excavators—including project requirements, site conditions, and brand reputation—enables managers to make informed decisions that align with their project goals. Furthermore, comprehending rental terms and conditions, implementing cost-effective strategies, and ensuring proper maintenance and support are essential components that contribute to a successful rental experience.

The importance of thorough planning and proactive management throughout the rental process cannot be overstated. From negotiating favorable rates to monitoring equipment usage and establishing maintenance schedules, each strategy plays a critical role in mitigating risks and enhancing operational efficiency. By integrating these best practices, project managers can avoid common pitfalls and maximize the value derived from their excavator rentals.

Ultimately, the strategies outlined serve as a comprehensive guide for project managers navigating the complexities of excavator rentals. Embracing these insights can lead to improved project outcomes, reduced costs, and a more efficient use of resources. Taking the time to implement these strategies will streamline operations and ensure that projects are completed on time and within budget, reinforcing the significance of effective excavator machine rental management.

Frequently Asked Questions

What are the key criteria for selecting an excavator?

The key criteria for selecting an excavator include project requirements, site conditions, weight and size, attachments, fuel efficiency, and brand reputation.

Why are project requirements important when choosing an excavator?

Clearly defining the specific tasks the excavator will perform, such as digging, lifting, or grading, is essential for selecting the suitable type and size of digger, ensuring optimal performance and project success.

How do site conditions affect the choice of excavator?

Assessing the terrain and spatial constraints of the job site is vital; for instance, a mini digger is ideal for tight areas, while larger models are better suited for extensive excavation jobs.

What role does weight and size play in selecting an excavator?

Ensuring that the machinery aligns with the project's weight capacity and size requirements is critical for optimal performance and safety during operations.

How can attachments enhance an excavator's performance?

Evaluating the availability of necessary attachments, such as buckets, hammers, or grapples, can significantly enhance the excavator's versatility and efficiency in completing various tasks.

Why is fuel efficiency an important consideration?

Prioritizing models that demonstrate superior fuel efficiency can lead to substantial cost savings during the rental period, lowering operational expenses considerably.

How does brand reputation influence the selection of an excavator?

Investigating the reliability and performance history of different brands is essential, as choosing a trustworthy brand ensures that the machinery meets recognized quality benchmarks, aiding in project success.